mitsubishi electric tft display free sample

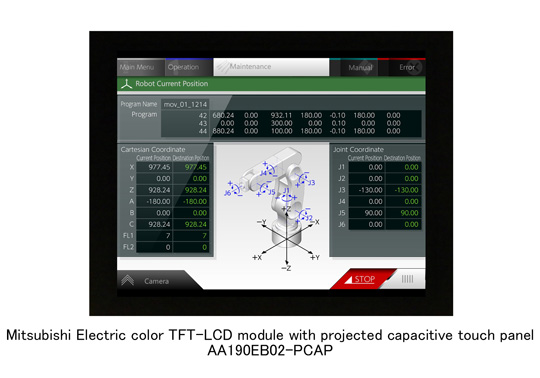

TOKYO, April 23, 2019-Mitsubishi Electric Corporation (TOKYO: 6503) announced today its coming launch of three new TFT-LCD modules for not only in automobiles but also industrial equipment such as ships and construction and agricultural machinery that require large screens combined with high performance and superior quality. Sales will begin July 16 through Mitsubishi Electric offices worldwide. The new models will be exhibited at Society for Information Display (SID) Display Week in the U.S. city of San Jose, California from May 14 to 16.

In addition to rear mounting, the models" wide 8:3 aspect ratio can accommodate display elements including instrument cluster, center panel and side-camera screen, ideal for space-limited car interiors

High-resolution screens of 1,920 (H) x 720 (V) are capable of displaying dense information with superb clarity (10.25-inch: 200ppi, 12.3-inch: 167ppi, and 15.0-inch: 137ppi)

ProductsEnergy and electric systems, electronic devices, industrial automation systems, home appliances, information and communication systems and space systems

Mitsubishi Electric Corporation(三菱電機株式会社, Mitsubishi Denki kabushikigaisha, also abbreviated as MELCO), established on 15 January 1921, is a Japanese multinational electronics and electrical equipment manufacturing company headquartered in Tokyo, Japan. It is one of the core companies of Mitsubishi. The products from MELCO include elevators and escalators, high-end home appliances, air conditioning, factory automation systems, train systems, electric motors, pumps, semiconductors, digital signage, and satellites.

MELCO was established as a spin-off from the Mitsubishi Group"s other core company Mitsubishi Heavy Industries, then Mitsubishi Shipbuilding, as the latter divested a marine electric motor factory in Kobe, Nagasaki. It has since diversified to become the major electronics company.

In 2015 the company acquired DeLclima, an Italian company that designs and produces HVAC and HPAC units, renamed Mitsubishi Electric Hydronics & IT Cooling Systems SpA in 2017.

MELCO is consistently innovative. In 2021, the World Intellectual Property Organization (WIPO)’s annual World Intellectual Property Indicators report ranked Mitsubishi Electric"s number of patent applications published under the PCT System as 3rd in the world, with 2,661 patent applications being published during 2020.air conditioners, overlap with the products from Mitsubishi Heavy Industries partly because the companies share the same root.

SOCIO-TECH: enhancing lifestyles through technology(技術がつくる高度なふれあい SOCIO-TECH, 1985–2001 in Japan. The "Blue MITSUBISHI" logo was introduced for use in Japan.)

Mitsubishi Electric signed a title sponsorship deal with the AFF Championship (renaming the competition as the AFF Mitsubishi Electric Cup) from the 2022 edition onwards.

United States –The TFT LCD Display ModulesMarket has witnessed continuous growth in the past few years and is projected to grow even further during the forecast period. In addition to the complete assessment of the market, the report presents Future trend, Current Growth Factors, attentive opinions, facts, historical data, and statistically supported and industry validated market data. This TFT LCD Display Modules Market report examines key business drivers such as market-wide economic factors such as policies, scope of revenue-generating market segments, and resource costs.

Panasonic Corporation, Schneider Electric, Siemens AG, LG Display, HannStar Display Corporation, AU Optronics Corp., Chi Mei Corporation, SAMSUNG Display, SHARP CORPORATION, Mitsubishi Electric Corporation, Displaytech, Innolux Corporation, Apollo Displays, Raystar

This independent report guarantees you will remain better informed than your competition. With over 150 tables and figures examining the TFT LCD Display Modules market, the report gives you a visual, one-stop breakdown of the leading products, submarkets, and market leader"s market revenue forecasts as well as analysis to 2029.

- Analytical Tools:The GlobalTFT LCD Display ModulesMarket report includes the accurately studied and assessed data of the key industry players and their scope in the market by means of a number of analytical tools. Analytical tools such as Porter’s five forces analysis, SWOT analysis, feasibility study, and investment return analysis have been used to analyze the growth of the key players operating in the market.

Meta Materials Inc. entered into a memorandum of understanding (“MOU”) in partnership with DuPont Teijin Films and Mitsubishi Electric Europe. Using META’s PLASMAfusion, the parties plan to scale a proprietary, high-volume, roll-to-roll manufacturing system for film-based, coated copper current collectors. The film-based products will reduce battery weight and cost, improve energy efficiency, extend vehicle range, and enhance safety against the risk of battery fires compared to standard Li-Ion batteries for electric vehicles and other use cases. The MOU is focused on developing battery materials, such as coated copper current collectors and solid-state battery electrodes, as a multi-year project in several stages: a pilot-scale roll-to-roll system, to be followed by an industrial-scale mass production line, and further development of the application to the production of solid-state batteries. META will contribute to the PLASMAfusion technology platform, system development, and independent testing of finished cells; DuPont Teijin Films will develop and supply the polyester substrates, and Mitsubishi Electric Europe will contribute automation technology, expertise, and interface to machine builders. (From a press release dated November 1, 2022)

Mitsubishi Electric and Bosch announced that they have agreed to terminate operations of their joint venture, Nippon Injector Corporation by the end of 2025 and subsequently dissolve the company and complete the liquidation. Due to the impact of the technological shift towards electrification in the automotive industry, it is estimated that the demand for fuel injectors for combustion engines will be declining in the future. In order to cope with this market development and to optimize manufacturing, it is intended to transfer production of gasoline fuel injectors step-by-step to Bosch"s manufacturing location in Hemaraj, Thailand (Robert Bosch Automotive Technologies) starting 2023, subject to approvals from the antitrust authorities within the relevant countries if applicable. Mitsubishi Electric intends to receive supplies from Bosch"s Hemaraj factory which is expected to be the main factory in Asia for port fuel injectors for gasoline engines in the future. (From a press release dated September 1, 2022)

Mitsubishi Electric Europe BV, a subsidiary of Mitsubishi Electric Corporation (Mitsubishi Electric)signed a memorandum of understanding with Belgium-based battery company Novali. Novali was set up to finance and deliver multiple ‘giga factories’ across Europe, with production scheduled to start in 2025. The partners aim at creating a network of local machine builders capable of delivering a complete cell manufacturing line at a gigawatt hour (GWh) scale. The focus will be on building best-in-class cells while avoiding wastage within the process. The target is to achieve CO2-neutral manufacturing of batteries.Novali plans to manufacture four generations of battery cells. Lithium iron phosphate (LiFePO) or (LFP) cells for low-cost market segments, nickel manganese cobalt (NMC) cells transitioning to high voltage cathodes and silicon anodes for mid-market segments, and Solid state or lithium metal batteries for the premium segment. It is working together with global investment funds and industrial partners to set up joint ventures with automotive companies to achieve this. (From a press release dated July 4, 2022)

On May 25, Mitsubishi Electric Corporation (Mitsubishi Electric) announced that investigations into its quality testing scandal by an investigative commission have revealed dishonest and inappropriate acts in its other divisions such as the Automotive Equipment Group and Factory Automation Systems Group. In the third interim report by the investigative commission, it has revealed 101 dishonest acts conducted at its 15 plants. In the Automotive Equipment Group, four dishonest acts were conducted, such as not executing some inverter manufacturing steps at the Himeji Works. At the Sanda Works, a total of 32 dishonest acts were conducted, such as not performing part of a regular sampling inspection of EGR valves and not performing some development tests relating to ICS. By the time of submitting the third interim report, the investigative commission has completed investigations on 1933 cases that account for about 80% of the total 2303 cases, in which the commission was notified of quality problems. A cumulative total of 148 dishonest and inappropriate acts at 16 plants have been revealed. (From an article in the Nikkan Jidosha Shimbun on May 27, 2022)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has released two AZ600 wire-laser metal 3D printer models that melt wires with a laser and sculpture 3D structures. Mitsubishi Electric expects the new models to be used for the manufacturing of parts for automobiles and ships. With the world’s first-ever original digital sculpture technology and a 5-axis spatial control method, the new wire-laser metal 3D printer models reduce processing time and material waste by about 80% compared with existing products. The new product is the world’s first digital sculpture technology that uses computer numerical control (CNC) to coordinate 5-axis spatial control, wire feeding, laser output and other processing conditions to realize complex 3D sculptures. The new models can be used for tungsten inert gas (TIG) welding, which was conventionally performed by skilled engineers manually. (From an article in the Nikkan Jidosha Shimbun on April 4, 2022)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has achieved the first-ever observation of a phenomenon in which the characteristics of motor magnets deteriorate under heat and stress. Conventionally, motors are designed by using estimated stress vales. Mitsubishi Electric’s newly developed technique will be utilized to enhance the efficiency of motors, clarify the mechanism of demagnetization, and develop high-performance magnets. (From an article in the Nikkan Jidosha Shimbun on March 2, 2022)

On February 17, Mitsubishi Electric Corporation (Mitsubishi Electronics) that it will establish a new "Business Area (BA)" under its umbrella in 2022. It aims to build and promote business strategies from a company-wide, medium- to long-term perspective, overlooking a wide range of business areas. Under the president, four BAs, "Infrastructure," "Industry Mobility," "Life," and "Business Platform," will be set up. A BA owner who will supervise each BA will be appointed. The Automotive Equipment Business Headquarters belongs to Industry Mobility BA. Along with the FA System Business Headquarters, the business environment is changing, such as Industry 4.0 and CASE (Connected, Autonomous, Shared, Electric). Amid this situation, the company aims to contribute to realizing a smart industrial society and mobility society by mutually utilizing and developing drive control technology and sensor technology. (From an article in the Nikkan Jidosha Shimbun on February 21, 2022)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced on February 1 that it will participate in an autonomous driving demonstration test that will be performed at Aichi Earth Expo Memorial Park (Nagakute City, Aichi Prefecture) from February 10 to 13. Mitsubishi Electric, which has developed a real-time on-demand operation control technology, will utilize it for an automatic operation control system that provides operational instructions to vehicles and distributes vehicle allocation information to stop terminals. Through the demonstration test, the company aims to accumulate expertise for practical use. The autonomous driving demonstration test will be jointly conducted with other companies, including NTT Docomo, Inc., Aisan Technology Co., Ltd., and Tier IV, Inc. The companies will provide vehicles, systems, and high-precision 3D maps to operate autonomous vehicles. Stop terminals will be placed at 6 boarding and deboarding stops in the park for on-demand operation services. Based on the boarding request information entered in the stop terminals, multiple autonomous vehicles receive automatic and flexible operational instructions in real time, such as the driving route, schedule, and the number of vehicles. (From an article in the Nikkan Jidosha Shimbun on February 2, 2022)

Mitsubishi Electric Corporation (Mitsubishi Electronics) will build a system that focuses on software development for its automotive related business. In the ADAS (advanced driver assistance system) business, which is positioned as a growth field, performance in the future is expected to be greatly decided by the software. In order to improve the technical level of software, which is one of the company’s strengths, the company will increase the number of people involved in the development of in-vehicle software. The company will also strengthen cooperation in the area of ADAS-related hardware development such as sensors. As the integration of in-vehicle ECUs (electronic control units) progresses and systems increase in complexity, the company will supply systems that respond to the development of software whilst expanding its business. (From an article in the Nikkan Jidosha Shimbun on January 19, 2022)

With the accelerating shift to electric vehicles (EVs), competition among parts suppliers for e-axle drive motor systems is expected to intensify. Nidec Corporation, which leads in the e-axle business, has started production in China for local automakers, and also plans to start production in Europe from around 2022-23. Meidensha Corporation, which manufactures motors and inverters for EVs, is currently developing e-axles to achieve commercialization from 2025. Mitsubishi Electric Corporation has also started discussing business with automakers to enter the market. The competition among suppliers of e-axle parts, which is one of few growing business fields, to increase their market shares will move into full swing. (From an article in the Nikkan Jidosha Shimbun on January 7, 2022)

Japan’s Ministry of Land, Infrastructure, Transport and Tourism announced that it will start joint research with private companies to expand the range of continued use of Level 3 autonomous driving (using autonomous vehicles that meet certain requirements in limited areas) on highways. A total of 28 companies and organizations will join the research, including automakers, electrical manufactures, and highway companies (e.g. Toyota Motor Corporation, Honda Motor Co., Ltd., Nissan Motor Co., Ltd., Hitachi, Ltd., Mitsubishi Electric Corporation, Fujitsu Limited, Zenrin Co., Ltd., and JRC Mobility Inc.). The Ministry will utilize the research to establish standards for the level of lane marking recognition by autonomous vehicles when it is difficult to detect the lane marking due to snow, heavy rain, or deteriorated road conditions, standards to create and maintain autonomous driving zone division lines, and improve its legal system. (From an article in the Nikkan Jidosha Shimbun on November 24, 2021)

Mitsubishi Electric Corporation (Mitsubishi Electric) will enter the market of e-axles that integrate motors, inverters, and reduction gears for electric vehicles (EV). As the EV market is expected to grow rapidly in China and Europe, Mitsubishi Electric will actively tap into a rise in demand for e-axles. The company intends to develop standard e-axles at low cost that can flexibly meet the needs of automakers in cooperation with a gear manufacturer in an effort to get orders. The company expects that its e-axle technology will be put into practical use in or after 2025. Mitsubishi Electric also announced plans to get orders for automotive parts in its SiC power semiconductor business. In anticipation of demand for SiC power semiconductors particularly for medium-sized EVs, the company will look into the possibility of boosting its production capacity for SiC power semiconductors. (From an article in the Nikkan Jidosha Shimbun on November 10, 2021)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it will integrate its 6 software design subsidiaries to establish a new company as the core of software designing for the Mitsubishi Electric group on April 1, 2022. The new company will accumulate software technology and expertise to improve productivity and quality. Mitsubishi Electric will also establish a recruitment system through the business consolidation to secure excellent technical human resources. Mitsubishi Space Software Co., Ltd. (Minato Ward, Tokyo) will survive the merger by integrating 5 other companies. The new company will have JPY 1 billion in capital and 4,700 employees. Mitsubishi Electric has not yet decided the name of the company. The business integration is part of Mitsubishi Electric’s medium-term management plan to strengthen its business foundation through the fiscal year that ends in March 2026 (FY 2025). (From an article in the Nikkan Jidosha Shimbun on October 26, 2021)

Five Japanese automobile manufacturers (Subaru Corporation, Toyota Motor Corporation, Nissan Motor Co., Ltd., Honda Motor Co., Ltd., and Mazda Motor Corporation) and five parts manufacturers (Aisin Corporation, Jatco Ltd, Denso Corporation, Panasonic Corporation, and Mitsubishi Electric Corporation) announced that they will be filing the role of executive member in the Japan Automotive Model-Based Engineering center (JAMBE) to promote Model-Based Development (MBD) across Japan’s automotive industry. JAMBE was founded to fulfill the purpose of creating the most-advanced development community in the mobility sector, able to carry out optimal and high-grade monozukuri (the art of manufacturing) efficiently and without rework. Executive member companies will lead the center’s activities to contribute to making Japan"s automotive industry more competitive internationally by enabling academia and businesses to share digital models across the board, linking academic research with development of parts, systems and vehicles. Therefore, allowing both sides to coordinate and make adjustments digitally from the initial stages of development. (From a press release dated September 24, 2021)

Mitsubishi Electric Automation Inc. and the Technological University of Aguascalientes (UTA) announced the joint creation of a laboratory to develop advanced equipment for production lines and help solve problems faced by the automotive industry. The rector of UTA, Guillermo Hernández Duque Delgadillo, said that the project to create the laboratory is part of an alliance which the university is aiming to create with several companies in order to enhance the capabilities and innovation of the automotive industry in the region through the use of advanced technology. (Mexico-Now article on August 23, 2021)

On April 15, Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it would build a new "development prototype building" at Power Device Manufacturing (Nishi Ward, Fukuoka City), which develops and manufactures power semiconductors. It will strengthen the development system for power semiconductors, for which demand is expanding. The investment amount is about JPY 4.5 billion. Operation is scheduled to start in September 2022. The new development and the trial building will accelerate the development of new technologies and products by consolidating the development laboratories, development product trial lines, performance testing rooms, and analysis and evaluation functions that were previously dispersed on the premises at the same place. (From an article in the Nikkan Jidosha Shimbun on April 17, 2021)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it will conduct field testing of on-demand operation control using autonomous vehicles at its Kobe Works site from March 22 to 29. The company will test a fully autonomous operation control system that provides operational instructions to vehicles and distributes vehicle allocation information to stop terminals. Mitsubishi Electric has been jointly pursuing research on autonomous vehicle operation control with Aisan Technology Co., Ltd. since 2020. The company will link its operation control system that is under development with the Autoware autonomous driving software developed by Tier IV, Inc. (Nagoya City, Aichi Prefecture) for the demonstration test. The operation control system will operate multiple autonomous vehicles, and change the schedule and route in real time in accordance with boarding request information sent from users. (From an article in the Nikkan Jidosha Shimbun on March 24, 2021)

u‑blox announced that it has acquired full ownership of Sapcorda Services GmbH, a joint venture formed by u‑blox, Bosch, Geo++, and Mitsubishi Electric. Sapcorda is the leading provider of advanced GNSS augmentation services serving the high precision GNSS mass market. The joint venture was formed by the four companies in 2017. Within the automotive sector, applications include automated driving and Advanced Driver Assistance System (ADAS), lane-accurate navigation, telematics, and vehicle-to-everything (V2X) communication. Sapcorda has developed its advanced SAPA (PPP-RTK) service based on open formats, and has specifically tailored it for industrial and automotive markets. The acquisition of Sapcorda expands u‑blox’s suite of location services complementing its existing data services, including its assistance data and communication service offerings. Full ownership of Sapcorda will also enable u‑blox to serve customers more efficiently, streamlining certain processes, including reducing implementation time to market and simplifying the integration process for customers.(From a press release on March 18, 2021)

Mitsubishi Electric Corporation (Mitsubishi Electric) and Stanley Electric Co. Ltd., (Stanley Electric) announced that they will conclude a business partnership agreement regarding their automotive lamp system business. As automotive lamps are required to have highly integrated systems for advanced driver-assistance systems (ADAS) and an autonomous driving society, both companies aim to enhance their competitiveness through collaboration. By combining Stanley Electric’s optical design technology and automotive lamp production technology with Mitsubishi Electric’s advanced control system technology, they intend to create lamp systems with high safety and functionality. Both companies will collaborate on their automotive lamp business, the joint development of next-generation lamp control systems and joint development related to production for automotive applications of DPM (Direct Projection Module), a Mitsubishi Electric proprietary optical technology. The agreement is scheduled to be signed in early January 2021. (From a press release dated December 25, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed a large-capacity EV smart charging system for large electric vehicles (EVs) such electric buses and trucks. With optimized charging plans and automatically controlled charging, the new charging system stabilizes electric power distribution systems and reduces charging costs. The company will officially start full-fledged technical verification testing from December, aiming to commercialize the system in 2022. The new smart charging system consists of devices such as EV chargers, an AC/DC converter, and a storage battery converter. Mitsubishi Electric has improved power conversion efficiency by adopting a silicon carbide (SiC) semiconductor for the power conversion elements of the AC/DC converter and the EV charger that converts DC voltage. The newly developed EV charger can charge four large EVs. (From an article in the Nikkan Jidosha Shimbun on November 11, 2020)

Mitsubishi Electric announced that it has found a part of its car audio products manufactured at Sanda Works, Sanda city, Hyogo Prefecture, Japan and at Mitsubishi Electric Thai Auto-Parts Co., Ltd, Rayong Province, Thailand, has been shipped to the EU market with specifications which does not comply with the European Radio Equipment Directive (RED). Although these products may cause noise when receiving AM radio in Europe, Mitsubishi Electric has confirmed that there is no effect on the safety of these products. The products in question are only sold to certain car manufacturers, not consumers, and Mitsubishi Electric has already reported the situation to the customers who purchased the affected products. This nonconformity was discovered on October 20, 2020 through an in-house inspection prompted by the revision of technical standards for the RED which will come into effect in December 2020. Mitsubishi Electric stopped new shipments of these products immediately after the discovery of this situation. Mitsubishi Electric takes this matter that it has shipped non-conforming products seriously, and the company will investigate the cause and announce prevent recurrence measures. (From a press release on November 6, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) will strengthen in-house collaboration for product development. The company’s research centers for elemental technology as well as its design and production departments will actively communicate with customers for the commercialization of products. Since the speed of the introduction of new products is key especially for the automotive market, Mitsubishi Electric will establish a system for early commercialization of products that flexibly satisfies the applications and costs its customers desire. The company expects that its research centers will find potential needs by directly talking to its customers. Mitsubishi Electric has four research centers in Japan, including an information technology R&D center for the research and development of technology such as automotive sensing and human-machine interface (HMI) control technologies. The main field of research is elemental technology that realizes significant performance improvement and cost reduction. (From an article in the Nikkan Jidosha Shimbun on September 1, 2020)

Mitsubishi Electric Corporation announced that it has developed an intuitive route guidance system for car navigation that enables human-machine interaction through natural language. With the new Scene-Aware Interaction technology, the system automatically prioritizes different categories of information acquired through different automotive sensors and understands surrounding conditions. The system then communicates information to the driver through context-based natural language to provide natural and intuitive human-machine interaction. In addition to route guidance, the system senses pedestrians and bicycles and provides the driver with assistance such as sounding an alert. The new technology was developed based on Mitsubishi Electric’s Maisart compact AI technology. The new technology recognizes contextual objects and events based on multimodal sensing information, such as images and video captured with cameras, audio information recorded with microphones, and localization information measured with LiDAR. By selecting information of high importance, the system is able to accurately understand a situation. (From an article in the Nikkan Jidosha Shimbun on August 5, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced the launch of its N-series 1200V SiC MOSFET and will start sample shipment of six product types in July 2020. By utilizing this newly developed SiC MOSFET, which adopts junction field effect transistor (JFET) doping technology, power consumption can be reduced by approximately 85% compared to conventional Si-IGBTs. It also reduces mirror capacitance which results in improving self-turn-on tolerance by 14 times compared with competitors’ products. The company introduced six models for various applications including three that are qualified to Automotive Electronics Council’s AEC-Q101 standards; the N-series SiC-MOSFET can be used in solar power generation systems as well as in EV on-board chargers. (From a press release dated June 16, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric)announced that it will end the production of TFT-LCD modules manufactured by Melco Display Technology Inc. (MDTI), a wholly owned subsidiary of Mitsubishi Electric, around June 2022. MDTI conducts development, manufacturing, and sales of small and medium-sized TFT-LCD modules for industrial and automotive use. With the expectation of severe global price competition, Mitsubishi Electric made the decision to end production because of the difficulty to maintain product competitiveness. Mitsubishi Electric will shift MDTI’s operating resources from the LCD business to business growth drivers such as power devices and will aim for further growth and development. (From a press release dated June 15, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it will acquire buildings and land from Sharp Fukuyama Semiconductor Co., Ltd., a wholly owned subsidiary of Sharp Corporation. The acquired properties will serve as a new plant where Mitsubishi Electric’s Power Device Works will process wafers for the manufacture of power semiconductors. With electrification progressing worldwide, the demand for power semiconductors, which are needed to efficiently control electric power, is rising rapidly. To meet this growing demand, Mitsubishi Electric will expand production capacity and its power device business through establishing the new plant. The new plant will have a total floor space of 46,500 square meters and conduct wafer processing for power semiconductors from November 2021. The company will invest approximately JPY 20 billion in total. (From a press release dated June 11, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed an AI that coordinates with humans to enable machines to perform natural movements as though they were being operated by humans. The AI uses reverse reinforcement learning, the maker"s artificial intelligence (AI) technology "Maisart,” to efficiently imitate human learning with a small amount of data for operation. It will be applied to Automatic Guided Vehicles (AGV) and robots at logistics sites where humans and machines coexist and will undergo demonstrations and practical use development. The company also plans to apply the technology to autonomous vehicles in the future. The newly developed technology collects operational data of coordinate actions performed by humans, such as "giving way” on roads. It realizes natural actions as though humans are operating it using imitation learning by inverse reinforcement learning on a simulator. The imitation learning based on the image around AGV and the operational driving data of humans was realized by using the inverse reinforcement learning of Maisart. As a result, less than one-tenth of the operational driving data is required for learning compared to the conventional method of imitating and learning the experts" optimal operation. (From an article in the Nikkan Jidosha Shimbun on June 8, 2020)

The University of Tokyo, Oki Electric Industry., and Mitsubishi Electric announced that they have succeeded in the communication control technology test to efficiently provide IoT (Internet of Things) services. The test demonstrated that it is possible to flexibly build optimal virtual networks for various IoT services with different communication requirements, such as autonomous driving and digital cinema services. The success made it possible to launch a service for businesses. The makers developed "PON resource management / allocation control technology" that manages and controls the communication resources of the most popular optical access system "PON" and succeeded in the virtualization control test of optical access networks. (From an article in the Nikkan Jidosha Shimbun on April 24, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it will jointly develop a new dust-proof coating material with Nagase ChemteX Corporation (Nagase ChemteX) and Nagase & Co., Ltd (Nagase). Mitsubishi Electric’s Smart air coating technology that prevents adhesion of dust by using an air film will be utilized. Mitsubishi Electric will provide basic technologies, Nagase ChemteX will develop and manufacture products, and Nagase will conduct marketing and sales. The project aims to provide materials for a variety of products such as automotive interior and exterior components, housing materials, furniture and interiors. (From a press release dated April 21, 2020)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it had developed a component integration technology to integrate components, such as power semiconductor devices, capacitors, current sensors and other embedded components in the same substrate. The technology realizes the world"s most power-dense power converter of 136kW/L (eight times higher than conventional models) and is expected to contribute to the downsizing of power electronics equipment. It suppresses electric voltage fluctuations and realizes high-speed switching by a low inductance structure that shortens the current path length by incorporating components, such as power semiconductor elements and capacitors in the substrate. (From an article in the Nikkan Jidosha Shimbun on April 6, 2020)

Mitsubishi Electric Corporation announced that it has developed a compact LiDAR solution incorporating a micro-electromechanical system (MEMS). It achieves an extra-wide horizontal scanning angle to accurately detect the shapes and distances of objects ahead in autonomous driving systems. The new LiDAR solution irradiates objects by laser and uses a dual-axis (horizontal and vertical) MEMS mirror to scan for the reflected light, generating three dimensional images of vehicles and pedestrians. The MEMS mirror can be produced in large quantities on a silicon substrate using semiconductor-processing technology, making it suitable for mass production. In addition, it uses fewer parts compared to mirrors driven mechanically with motors, which will contribute to the durability of the LiDAR solution. (From a press release dated March 12, 2020)

Mitsubishi Electric Corporation announced that it has developed new miniaturization and energy-efficient technologies for electric vehicle (EV) power conditioners, which will facilitate domestic use of the electricity stored in EV battery. By utilizing high-speed switching and improved circuitry, it achieved a size reduction of almost 50%. The new technology is capable of highly efficient control of two DC/DC converters with an output of 3kW. When power output is low, the system uses only one of the converters and partially stops the switching of the active converter"s power semiconductor devices. As a result, the power loss of power semiconductor devices at outputs of 1 kW or less can be reduced by approximately 30%. (From a press release dated January 29, 2020)

Mitsubishi Electric Corporation announced that its exhibit in Las Vegas at CES 2020 will focus on technologies and products that highlight Mobility as a Service (MaaS). At its exhibit, Mitsubishi Electric will display a video showcasing “the next step in mobility,” which will show transportation applications in a MaaS society utilizing a variety of technologies. Mitsubishi Electric will also display the Emirai S concept vehicle, various products for electrified vehicles and demonstrate a mobile mapping system that can create 3D mpas. (From a press release on December 17, 2019)

Mitsubishi Electric Automotive de Mexico announced that it would invest approximately USD 40 million to expand its plant at El Marques, Queretaro, Mexico. The expansion would enable the plant to add 350 additional employees. Mitsubishi Electric Automotive de Mexico aims to create a new production center for the manufacturing of systems including electric power steering units, central information displays and LED control units. (From multiple news sources on November 13, 2019)

Mitsubishi Electric Corporation announced that it has released the new AQLOC-Light high-precision positioning terminal, which receives high-precision positioning augmentation information such as centimeter-level positioning augmentation service (CLAS) signals from the Quasi-Zenith Satellite system. The new receiver has fewer components compared to its predecessor and features a 70% reduction in power consumption. This allows it to dispense with a heat discharge structure. As a result, the new AQLOC-Light is made about 80% smaller and lighter. This compact and lightweight design allows it to be mounted on drones and other small moving bodies as well as passenger cars. The new receiver offers autonomous positioning using a gyro sensor incorporated in it and vehicle speed pulse signals sent from the moving body to interpolate positioning information. This enables positioning even in mountainous regions, tunnels, and underpasses where satellite signals cannot be received. The AQLOC-Light is capable of receiving network-style positioning augmentation information in addition to CLAS signals. Accordingly, the company is aiming to expand the use of the new receiver in a wide range of fields. (From an article in the Nikkan Jidosha Shimbun on November 8, 2019)

On October 21, Mitsubishi Electric Corporation announced that it has developed new autonomous driving technologies applicable to various public road situations such as driving in local areas without high-definition maps and autonomous parking both indoors and outdoors. Mitsubishi Electric will incorporate the technologies into its xAUTO autonomous driving demonstration car and exhibit it at the 46th Tokyo Motor Show 2019. The technologies incorporated in the xAUTO enable autonomous driving without high-definition maps using vehicle trajectory data in which past driven routes are recorded accurately and with high precision as well as autonomous parking both outdoors and indoors by accurate positioning and optimizing of routes. Mitsubishi Electric also developed a sensor-fusion technology that integrates information from various sensors such as millimeter-wave radars and cameras in consideration of data-processing time variations. This technology enables the xAUTO to detect the situation surrounding the vehicle fast and accurately. (From an article in the Nikkan Jidosha Shimbun on October 23, 2019)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced on October 7 that its automotive device sales and production subsidiary, Mitsubishi Electric Automotive India Pvt. Ltd (MEAI, Haryana, India) will construct a new plan in Gujarat. The new plant will produce automotive parts such as motor control units for electric power steering systems, in order to respond to growing demand for products that comply with environmental regulations. The total capital investment will be about JPY 1.7 billion, and the new plant will start operations in October 2021. It will have a total floor area of about 20,000 square meters, and production items will include electric power steering motor control units, giant magnet-resistance (GMR) rotational sensors, and exhaust gas recirculation valves. (From an article in the Nikkan Jidosha Shimbun on October 8, 2019)

Mitsubishi Electric Corporation announced that it will showcase EMIRAI S which incorporates its latest sensing and HMI (human machine interface) technologies and a new mobility concept oriented toward MaaS society at the Tokyo Motor Show. EMIRAI S is a concept of vehicle cabin with biological sensing technologies which support safe and secure transportation and HMI technologies which realize easy communication inside or outside the vehicle. In addition, the company will exhibit “xAUTO”, a demonstration vehicle of autonomous driving, as well as compact and high power motor inverters for hybrid vehicles (HVs) and electric vehicles (EVs). (From a press release on October 1, 2019)

Mitsubishi Electric Corporation announced on August 5 that it has completed construction of a new test facility at its main Himeji Works (Himeji City, Hyogo Prefecture) for an automotive device business. The new test facility will be seven stories high and have a total floor area of about 8,200 square meters. The investment was about JPY 2.2 billion. Mitsubishi Electric aims to focus on the development of products by utilizing its original technologies for power electronics, automotive control, and motor coils, in order to expand its automotive device business. (From an article in the Nikkan Jidosha Shimbun on August 7, 2019)

Mitsubishi Electric Corporation announced that it will launch Wide-HD TFT-LCD Modules for automobile as well as industrial equipment. It will introduce 10.25-inch, 12.3-inch, and 15.0-inch models for corresponding to growing demand of automotive displays that are required to have various functions as instrument clusters and center panels in recent years. (From a press release on April 23, 2019)

Mitsubishi Electric Corporation and Schaeffler Technologies AG & Co. KG announced a global strategic partnership as part of the e-F@ctory Alliance network. This concept supports companies with measures within the framework of the digital transformation, such as the integration of machine and plant data into MES (manufacturing execution systems) and ERP (enterprise resource planning systems). Schaeffler contributes concepts that combine mechatronic products, condition monitoring systems, and digital services to form application-specific 4.0 solution packages. These provide the basis for the creation of customized products and services whose main focus is always on the effectiveness of the overall system. Mitsubishi Electric Corporation offers a vast range of factory automation and processing technologies, including programmable logical controllers (PLC), inverters, robots, servo-drives and HMI, helping to bring higher productivity and quality to the factory floor. (From a press release on April 5, 2019)

Mitsubishi Electric Corporation announced that it would start construction of a new plant on the premises of its subsidiary Mitsubishi Electric Automotive Czech s.r.o (MEAC) in Slany, Czech Republic. The new factory will enable MEAC to increase its mass production of motor and inverter systems for electric vehicles, such as the company"s integrated starter-generator (ISG) systems for 48V hybrid vehicles. The plant will have a Single story and total floor space of 9,880 square meters. It will see investment of JPY 1,200 million. It will start operation by April 2020. (From a press release on March 6, 2019)

Mitsubishi Electric Corporation announced on February 13 that it has developed a super-compact power unit for hybrid and plug-in hybrid vehicles, which is the world’s smallest power unit measuring 2.7 liters in volume and offers the best electric power density of 150 kilovolt-amperes per liter (kVA/L). The company has also developed a high-power-density motor that offers the world-leading power density of 23 kilowatts per liter (kW/L). The company will continue development for mass production and commercialization of the motor from the fiscal year that ends in March 2021 (FY 2020), and the power unit from FY 2024. The new power unit and motor can increase installation flexibility, expand automotive interior space, help reduce fuel consumption, and can also be used for electric vehicles. (From an article in the Nikkan Jidosha Shimbun on February 14, 2019)

Mitsubishi Electric Corporation announced that it has developed sensing technology for highly accurate detection of vehicle perimeters even in dense fog or heavy rain. Time series data, such as velocity, width, orientation and distance, was detected with various sensors and then compared to information and values estimated based on each sensor"s features. Using real-time calculations, the reliability of each sensor"s information which is affected by weather, was predicted. The system then selected and integrated information determined to be highly reliable. Using this technology, autonomous-driving and driving-assistant systems were demonstrated to perform normally in dense fog or heavy rain. An AEB (autonomous emergency braking) system was tested in heavy rain (rainfall 80mm/h) while the vehicle traveled a maximum 40km/h. The AEB system was confirmed to have worked normally due to the successful detection of objects, which initiated emergency braking. (From a press release on February 13, 2019)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed a new sensor-security technology that detects attacks on sensor fusion algorithms that acquire measurement data from multiple automatic control sensors. Optimal automatic control is achieved based on these data, but up until now there was no established sensor-security technology to prevent malicious attacks using ultrasound and electromagnetic waves. Mitsubishi Electric expects the new technology to be used for autonomous driving devices, such as electronic control units, and drones. In automotive fields where autonomous driving technology is advancing, sensor security as well as cyber security will be important to ensure optimal automatic control. The company will verify conceivable patterns of attacks on automatic control sensors, and aims to establish a new business from the fiscal year that ends in March 2021. (From an article in the Nikkan Jidosha Shimbun on February 9, 2019)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced on January 22 that it has developed a human machine interface (HMI) technology that supports safe driving and comfort by utilizing artificial intelligence and driver monitoring systems (DMSs). The new HMI technology assesses the direction drivers are facing, and calls attention to vehicles and pedestrians that can be overlooked. Mitsubishi Electric has also developed a technology that detects the driver’s voice and indicates driving routes through natural two-way conversations. The company aims to commercialize the HMI technology from 2021. (From an article in the Nikkan Jidosha Shimbun on January 23, 2019)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced on January 22 that it has developed an automotive multi-layered defense technology. The new technology is an insurance against cyber-attacks that are likely to increase with the popularization of connected vehicles. It detects unauthorized software installed on automotive information devices unintentionally or through the Internet, and serves to protect the devices. Mitsubishi Electric is hoping to win orders from car navigation system makers and automakers from 2019. (From an article in the Nikkan Jidosha Shimbun on January 23, 2019)

Mitsubishi Electric Corporation announced that it will exhibit cutting-edge automotive technologies and products, including its EMIRAI4 driving-assistance concept car at the CES 2019 show in Las Vegas, Nevada. The newest version of the EMIRAI4 smart-mobility concept car features next-generation driving-assistance technologies, advanced human-machine interface (HMI) technologies and other Mitsubishi Electric technologies for vehicle electrification, autonomous driving and network connection. During CES 2019, Mitsubishi Electric will present two new technologies in the EMIRAI4 with its realistic texture expression technology, called Real Texture and ground-illuminating indicator technology. The Real Texture LED dashboard display realistically expresses the appearance of metallic-like surfaces by adjusting gloss and shadow according to the person"s viewing angle. Ground-illuminating indicators for turning and door-opening project animated illuminations on road surfaces around the vehicle. (From a press release on December 20, 2018)

Mitsubishi Electric Corporation announced today it has established mass-production technology for a new curved (concave) color TFT-LCD module that combines environmental ruggedness to withstand extreme temperatures and an attractive design, making it ideal for use in automobiles and leisure boats. The module offers a curvature radius from 700mm to less than 1,000mm and optical performance equivalent to that of flat screens. It has excellent visibility, even in bright environments, thanks to super-wide viewing angles, both horizontally and vertically, high brightness, high contrast ratio and high-resolution display capably handles rich information. New mass-production technology ensures fast, high quality production with one-stop solution covering everything from TFT panel production to bonding of curved cover glass. (From a press release on November 26, 2018)

Mitsubishi Electricannounced that it has developed a technology for efficiently managing photovoltaic (PV) and other power-generation systems and also the charging/discharging of electric vehicles (EVs) parked on company campuses. By optimizing the schedules for not only charging EVs but also discharging their power back into the company, as well as optimizing the operation of PV and other power-generation systems according to the fluctuating unit price of electricity sold on the grid, the new system enables companies to reduce their electric-power costs. In November 2018, Mitsubishi Electric and its affiliate Mitsubishi Electric (China) will conduct a joint-demonstration test of the new technology at the factory of Mitsubishi Electric Automotive (China) in Changshu in China, where the use of EVs is expected to advance rapidly. (From a press release on October 25, 2018)

Mitsubishi Electricannounced that it has developed a unique dot forming technology that realizes high-precision shaping by combining laser, computer numerical control (CNC) and computer aided manufacturing CAM technologies in 3D printers. The technology produces high-quality three-dimensional (3D) parts with few voids at high speed, employing a laser wire directed-energy deposition (DED) method. The company believes that its new technology will raise productivity in a wide range of applications, such as the "near-net" (near-final) shaping of aircraft and automobile parts. Mitsubishi Electric expects to launch a commercial version within the fiscal year ending in March 2021. (From a press release on October 23, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has constructed a new plant at its Koriyama Factory, a communication networks plant in Fukushima Prefecture, with an investment of JPY 2.6 billion to boost its production capacity for communications devices, video monitoring systems, and other products. Demand for fiber-optic and wireless communications devices and video monitoring systems is expected to grow because of an increase in communications traffic along with the advancement of IoT, big data, and artificial intelligence technologies. Accordingly, the company set up the new plant to bolster its supply network. The new facility is two stories high and has a total floor area of 7,600 square meters. Mitsubishi Electric expects that its production capacity will double from the current level with the establishment of the new plant. (From an article in the Nikkan Jidosha Shimbun on October 18, 2018)

Mitsubishi Electric announced that it will release a compact version of its mobile mapping system (MMS) on December 25. MMS are highly precise measuring systems comprising car-mounted GPS antennas, laser scanners and cameras to gather 3D positioning data on road surfaces and roadside features, generally used as base data to create high-definition 3D maps for autonomous driving and infrastructure inspections. The compact, lightweight and transportable new MMS-G, which is especially suited to mounting on automobiles, railways, carts or ships, is expected to be used for diverse applications in markets including Europe, North America, Asia and Oceania, where high growth is forecast. The new MMS-G will be showcased at the Mitsubishi Electric stand during INTERGEO in Frankfurt, Germany from October 16 to 18, 2018. (From a press release on October 9, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) will increase its sales of motors and inverters for electrified vehicles more than 10 times by fiscal year 2020 (ending in March 2021) from the FY 2017 level. The company announced that to achieving this target, it will construct a new laboratory at its Himeji Works, a major production base of its automotive device operations. The new laboratory will specialize in the development and evaluation of motors and inverters for electrified vehicles. Demand for electrified vehicle devices is expected to grow in the future. Mitsubishi Electric will strengthen its development capacity in this field. It constructed a new eighth factory at its Himeji Works Hirohata Plant this spring to boost production capacity for hybrid and electrified vehicle inverters and motor generators. Mitsubishi Electric is positioning its automotive device operations as a growth engine in its strategies for the period through FY 2020. The company is strengthening research and development functions and production capacity at its Himeji Works, a major plant in its automotive device operations, in rapid succession. (From an article in the Nikkan Jidosha Shimbun on August 7, 2018)

Mitsubishi Electric Corporation announced that it has developed a compact, high-performance automotive LED headlight optical module, and will join the growing LED headlight market. The company has adopted a unique projection system that doesn"t use many components. The new LED headlight optical module can increase vehicle design flexibility and reduce power consumption. It offers high-performance light distribution like spot beams aimed at pedestrians, and supports safe nighttime driving. The company aims to commercialize the LED headlight optical module from 2021. (From an article in the Nikkan Jidosha Shimbun on June 8, 2018)

Mitsubishi Electric Corporation held a management strategy presentation meeting for fiscal year 2018 (ending in March 2019) at its headquarters in Tokyo, and President Takeshi Sugiyama indicated the company"s plans to position its automotive device operations as a growth engine for achieving consolidated sales of JPY 5 trillion and a target of 8% in operating income in 2020. Accordingly, the company will expand its business for devices compatible with electrified vehicles. Demand for automotive power semiconductors is expected to grow and Mitsubishi Electric will respond to that by boosting production capacity at its semiconductor plant in Koshi City, Kumamoto Prefecture by the end of this year. Sugiyama also indicated the company"s intention by saying, "Depending on the future growth in demand, we will have to make massive capital investments. We will further increase investment in equipment related to electric vehicles (EVs) from 2020 onward." However, he added, "We will closely watch demand developments to carefully proceed with investment and not lose business opportunities," because of uncertainties about when and how significant EV demand will truly begin. In order to expand production of electrified vehicle-compatible devices, the company will begin operations at a new building that has been constructed at its Himeji Works Hirohata Plant and boost its production capacity for motor generators and inverters for electrified vehicles. Meanwhile, Sugiyama indicated the company"s plans to encourage cooperation with other companies in and outside Japan and thereby expand its autonomous driving-related business. Last year, Mitsubishi Electric entered into a partnership with HERE, a major European map maker, and Sapcorda Services, a Germany-based provider of high precision GNSS positioning services. (From an article in the Nikkan Jidosha Shimbun on June 4, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has completed construction of a new eighth plant building at its Himeji Works Hirohata Plant. The new plant was constructed to boost the production of motor generators, as well as hybrid and electric vehicle inverters. The company will successively start operations, and aims to expand its automotive device business. It invested about JPY 7 billion. (From an article in the Nikkan Jidosha Shimbun on May 30, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) held a research and development presentation and announced a new design technology that reduces the power consumption and size of motors and inverters for crankshaft-mounted integrated starter-generator (ISG) systems. The company utilized magnetic and cooling designs for motors, and silicon carbide drive and electromagnetic compatibility designs for inverters. ISG systems support energy recovery during idling stop and vehicle deceleration, and provide assist torque during vehicle acceleration. Mitsubishi Electric developed an ISG system connected to crankshafts for hybrid and electrified vehicles. The new system is mounted between an engine and a transmission, and saves total energy consumption. (From an article in the Nikkan Jidosha Shimbun on March 13, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed smart-control artificial intelligence (AI) technology. AI and multiple sensors detect changes in objects in real time. This enables automation of tasks that are conventionally difficult for industrial robots, such as inserting cable connectors. The technology will initially be mounted on the company"s own equipment systems. The automatic generation of optimal control algorithms through deep reinforcement-learning frees designers from having to redesign complex control algorithms. At a briefing held at Mitsubishi Electric"s Information Technology R&D Center in Kamakura City, Kanagawa, there was a demonstration of an industrial robot inserting connectors with its arms equipped with a camera and a force sensor at the tip of the arm. Mitsubishi Electric expects the technology will have commercial application for a variety of personal computers and automatic guided vehicles (AGVs). (From an article in the Nikkan Jidosha Shimbun on February 14, 2018)

Mitsubishi Electric announced it has developed a compact hardware artificial intelligence (AI) technology that can be implemented on small-scale field programmable gate arrays (FPGAs) that users and designers can configure to develop tailored applications. Mitsubishi Electric leveraged its Maisart-brand AI technology to achieve a solution that uses a highly efficient calculation order and optimized circuit architecture for improved real-time processing and reduced costs, which is expected to expand the scope of AI deployment in home appliances, elevators, high-precision maps and more. (From a press release on February 14, 2018)

Mitsubishi Electricannounced that it has developed a realistic "texture expression" technology, named Real Texture, that makes vehicle displays and digital signage appear to be realistic metallic-like surfaces for added viewing appeal. It adjusts gloss and shading in real-time according to the person"s viewing angle. Real Texture consists of 2D flat display (parallax stereographic display not required) and camera to track viewer"s facial position. It is expected to be commercialized for vehicle instrument panels and signage displays in the near future. (From a press release on February 14, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed new automotive ground-illuminating technology that prevents accidents. The company developed a system that projects large animated illuminations on roads and a system that is linked with external sensors and signals the opening of doors and reverse movement of vehicles. It also created a development tool that evaluates how the illumination patterns are seen. The new illuminations are easy to see even in bad weather conditions like snow, and the flowing lighting is easy to understand vehicle actions for children and other pedestrians who don"t know traffic rules. Mitsubishi Electric will continue research and development for commercialization from fiscal year 2020 (ends in March 2021). (From an article in the Nikkan Jidosha Shimbun on February 9, 2018)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed a new automotive electric mirror technology that detects objects up to 100 meters behind vehicles. The company developed an automotive built-in system that recognizes objects in real time by utilizing its original visual cognition model and artificial intelligence technologies. Drivers will receive advanced warning of vehicles approaching fast from behind, which helps prevent lane change accidents. Mitsubishi Electric will further improve detection accuracy for night and bad weather conditions by combining millimeter-wave and LiDAR sensors. The visual cognition model uses the company"s original algorithm that is based on the fact that people"s attention is attracted to noticeable areas. Mitsubishi Electric improved the maximum detection distance from 30 meters to 100 meters, and the average detection accuracy from 14% to 81%. (From an article in the Nikkan Jidosha Shimbun on January 18, 2018)

Mitsubishi Electricannounced that it will exhibit cutting-edge technologies and products, including its EMIRAI4 driving-assistance concept car for safer and more convenient transportation in the smart mobility era under the concept of "Make the move to mobility," at CES 2018 in January 2018 in Las Vegas. (From a press release on December 26, 2017)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has developed a crankshaft-mounted integrated starter-generator (ISG) system for 48V hybrid vehicles (HVs). The crankshaft direct-driven ISG system is the auto industry"s first to be put into mass production. The new system will be mounted in Daimler AG"s Mercedes-Benz vehicles. The new ISG system has a crankshaft-mounted motor. Compared to belt-driven starter-generators, the crankshaft-mounted motor produces higher output power and generates more electricity, which contributes to better fuel efficiency. Mitsubishi Electric"s original coil winding technology realizes a high-density configuration for thick coils required in a 48V high-current motor. The new system combines both the high-power motor and thin-profile to adapt flexibly to various vehicle layouts. (From an article in the Nikkan Jidosha Shimbun on November 17, 2017)

Mitsubishi Electric Corporation (Mitsubishi Electric) announced that it has launched field tests of the world"s first autonomous driving technology using a centimeter-level augmentation service (CLAS) broadcast from the Quasi-Zenith Satellite System (QZSS). CLAS is a positioning-augmentation service for high-precision positioning that is distributed free of charge in Japan from the QZSS, which operates under the auspices of the Cabinet Office.

Mitsubishi Electric has launched driving tests on highways to verify the potential for autonomous driving via infrastructure utilizing CLAS signals and high-precision 3D maps combined with the company"s sensing technologies such as millimeter-wave radars and cameras. It aims to thereby make autonomous driving technology commercially viable. (From an article in the Nikkan Jidosha Shimbun on November 7, 2017)

On October 17, Mitsubishi Electric Corporation (Mitsubishi Electric) conducted a test ride for the media of its xAUTO vehicle featuring autonomous driving technologies at its Ako proving ground in Ako City, Hyogo Prefecture. The xAUTO is an experim

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey