lcd panel symptoms factory

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

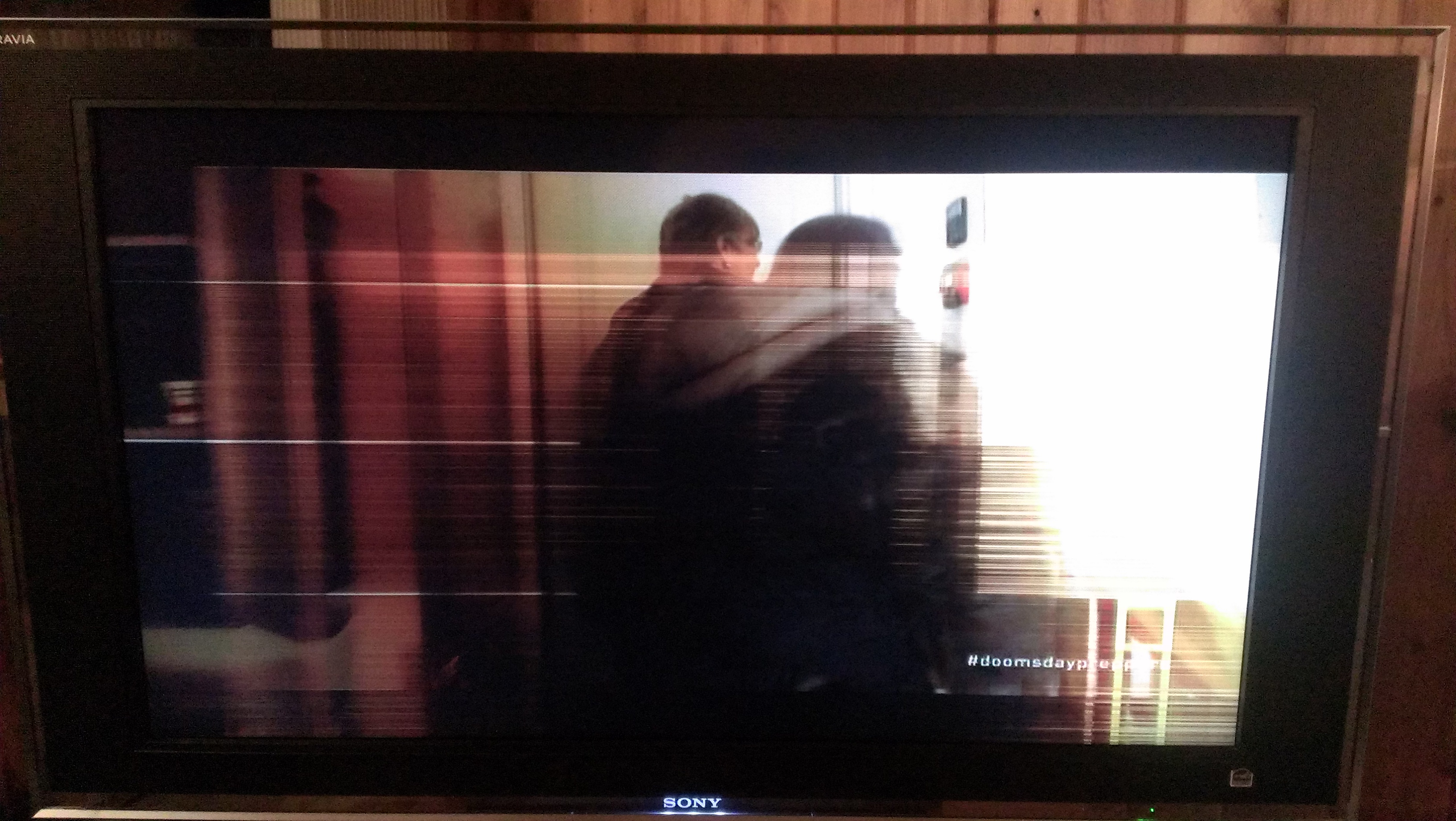

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

2. If any of the symptoms on the left remain after Factory Reset, then the graphic card or integrated graphic feature needs to be checked. Reset the settings for the Display to Optimal Resolution. For instructions on how to do this, consult the Online Owner"s Manual

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

LCD display screens on tablets are made of two thin layers of glass with dark liquid crystal material in between. The glass is covered on the outside by a layer of plastic. Customers often feel there cannot be a broken LCD display because they cannot feel the break. However, cracks in the glass usually cannot be felt because the plastic covering rarely breaks or fractures.

It is important to understand that lines on the LCD can also be caused by video driver issues or a problem with the media you are using. Video driver issues can normally be resolved by downloading and installing a new video driver. However, if the damage is due to a broken LCD, you should understand the following policies.

First, I would like to mention that both an LED TV and a LCD TV are actually LCD TVs except that first one has LED stripes and the latter one has CCFL Backlights- (Florescent Tubes).

This Blog is just Symptoms and Repair of different Models in Alphabetical order. These are real case history Symptoms and Repairs. For more information about different symptoms, sound, picture display, etc. and general repair tips, please visit my other blogs.

Repair- Suspect a stuck VOLUME down(-) button. A normal button will give you that tactile feel, compare it with the other buttons. If it feels similar to the other buttons then it could be the switch behind that button. The switch used in most front panel buttons are called ‘tact’ switch, obviously named because of that tactile feedback

Repair–Suspect T-Con Board–Sometimes, just resitting, unplugging and re-plugging the flexible ribbon wire from the T-Con board to the LCD panel, will fix it-If not replace T-Con Board-

Symptom- the unit powers on with a steady red light on the front panel. However, I could not turn the unit on using either the remote or mechanical buttons. The red standby light never flashes and remains steady.

Emerson LF501EM5F TV Symptom- Bought it less than 2 years ago and now won’t turn on. The Led light is solid red once I plug it back in. I took the rear panel off and can hear a small humming sound in the marked location. Repair- Replace Main Board

Funai LC320SSX LCD TV- Symptom- ” It does not turn on at all. It use to turn and turn off then it just stop turning off” Repair- Bad capacitor on Power Board

Replace- Replaced the power board with a new one and replaced the main board as well and also replaced the t- con board–No ChangeRepair–1 burnt Led on LED Strip inside panel–

Hisense 50K23DG LED-LCD HDTV - 50K23DG Symptom- red light comes on, flashes 6 times Replace- Replaced the power board with a new one and replaced the main board as well and also replaced the t- con boardNo Change Repair1 burnt Led on LED Strip inside panel

Insignia NS-L42Q120-1-A LCD TVSymptom–The TV plays awesome beautiful pic, but powers down , I can turn it back on and it plays great! Then powers down– Repair–Firmware Update

Insignia NS 50D550NA15 TV Symptom- While watching the tv I could hear a sizzling sound a flickering light in the top right corner and then the picture faded to black . I have changed the power supply board and with the new board installed there is power and audio. I can see a picture doing a flashlight test but I do not see any backlights. Repair- Replaced Power Board, have sound no picture. Can see movement, with flashlight-Apparently, shorted Mosfet on Power Board, burnt LED strip inside panel.

Symptom–While I was fixing a ribbon cable on LCD screen TCON board popped. Replaced with new one but now my screen has sound but image is extremely bright. With image but no colors.

Repair–Replaced T-Con Board–No change. Found shorted VA1-(Variable Resistor) Since it is on the Control Board, which is Micro Soldered to the Panel and cannot be replaced, it`s considered as panel failure-

Activate the TV’s menu — let’s see if that flickers too. We want to see if the menu flickers, because it might be only the TV’s picture that flickers. If the menu flickers, then we know we’re dealing with the panel or the TCON. If only the picture flickers and the menu is steady, then we know we’re dealing with the Main board.

LG LED TV-50LN5310 Symptom–Turns on quick white flash (Backlights) then sound, no picture- Repair-Burnt Line inside panel on negative side–Re-soldered negative line on connector

Now, You only have 2 boards- Power Board and Main Board. What I need you to do, is disconnect the LVDS Cable, the cable that runs from, Main Board to T-Con at top of Panel–See picture below- Disconnect at red box, plug in TV. Does it come on–

Panasonic 42 THAS610D LED TV Symptom- backlights are looking fine, no picture- Repair- Checked SMD Fuse is good. Replaced T-Con, no difference When removing 1 FPC Cable(Cable at top of T-Con, we get 1/2 picture. Was considered panel Failure’

Philips LCD TVSmoke like shadow on one side of the screen It is most likely a LCD panel problem. It is costly and impractical to have it replaced. You can only discern the smoke like shadow on low light scenes

RCA 42″ Flat Screen TVSymptom–I have only half the screen is working . After it warms up the you can see the whole thing. Repair-This problem is either the T-Con Board or Panel Failure–

Symptom-When the TV is plugged in the Red Light is on-No Blinking-Then when I turn the set on with either the front panel Button or the remote control the light then goes off and nothing happens, No sound or picture

Repair-3 shorted LEDs inside panel–In stead of replacing strips, put a jumper resistor and soldered in–Use 5K Resistors is best–Remember his LEDs where in Sequence and not Parallel–

Samsung-LCD TV Multiple Color Vertical Lines- This type of TV problem, we must call out the OSD Menu to confirm–If the OSD Menu is showing normally on the screen, but the-background is full of color vertical lines then this symptom is caused by the Main Board or LVDS Cable–

The only thing you have to do is disconnect the cable between the power board and main board. Then, power on your TV. If you see the back light in the back of panel the problem is the main board if not, the power supply is the problem.

Sony LCD TVHas dim picture–1 of the CCFL(cold cathode fluorescent lamp/light) could have burnt or the circuit(inverter) that powers it might have failed. A technician will usually swap the connectors between the suspected dead lamp with the other good ones. The backlight consist of more than 2 CCFLs. When swapped and the dark area is at the same location then you have a bad lamp, otherwise suspect the inverter.

Sony 52″ LCD TVSymptom-Turns off by its self after a few minutes- Try to check first TIMER Settings on the TV set. Disable features such as auto-off and sleep timer. If everything seems to be ok, check air vent holes for possible obstruction and clean, maybe a sign of overheating.

Repair-Activate the TV’s menu — let’s see if that flickers too. We want to see if the menu flickers, because it might be only the TV’s picture that flickers. If the menu flickers, then we know we’re dealing with the panel or the T-CON Board. If only the picture flickers and the menu is steady, then we know we’re dealing with the Main board.

Symptom– Turns on, then says “Digital Television” then turns off.( Short flash of Light...and a short Display ) This type of failure is almost always caused by Inverter circuit failure, in the majority of LCD TV’s. Check the pico fuses or smd fuses and HV Transformers in the main inverter circuit, but with these models, I know that one of the HV Transformers, often develops a open a secondary winding. It is usually the HV Transformer, at location T1100

Symptom–Nothing happens if I press buttons from the remote control or even on the TV panel. If I unplug it for an extended period of time it seems to “boot up” right away and everything is fine.

If you ever notice multi-coloured or single-coloured vertical lines on your laptop screen, it may be a result of a hardware failure or due to damage to the screen. To try fixing it yourself, first unplug your laptop, hold the power button for 30 seconds and restart the laptop. If you continue to see coloured lines, the issue is probably with the LCD screen, which will need to be replaced from the brand’s service center. To be sure about the LCD screen problem, try connecting your laptop to another monitor and see if the issue persists. If it does, the issue is certainly in the LCD panel.

Firstly, check if your laptop’s brightness level is set to maximum. If the display is still dim, try restarting the device. This could just be a system error that can be resolved by restarting the device. Also, check if the AC adapter cord is loose and firmly connect it to the outlet and laptop. If the issue still persists, it is mostly due to a failure of the LCD. Behind the LCD, there is an inverter board and backlight bulb which control the picture.

The inverter board converts the low voltage your laptop uses, into higher voltage required by the long bulb that lights up the LCD screen. If the inverter board or bulb fail, you will experience the problem of a dimmed display. Even if one of these two components fail, the screen will need to be replaced, unless the service center can help by just replacing the bulb. We wouldn’t recommend you try resolving it yourself, as this is more complex and you could end up damaging the circuit board and the backlight lamp. So, it’s best to leave this job to an expert.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

Some TV displays, such as LCD screens, use a backlight to illuminate the picture. If the backlight burns out or stops working, it will result in a blank TV screen.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey