tft lcd ips vs gorilla glass supplier

IPS-LCDs are costlier than normal TFT LCD and hence are found only on higher end smartphones. A higher resolution (640 x 960 pixels) version of IPS LCD is used in Apple iPhone 4 and is called Retina Display because of its brilliant picture quality.

It is a special alkali-aluminosilicate glass shield with exceptional damage resistance that helps protect mobile displays from scratches, drops, and bumps of everyday use. Many companies like Motorola, Samsung and Nokia are now using Gorilla Glass to make their mobile displays more durable and reliable. It is always better to go for a smartphone with Gorilla Glass for that added protection and peace of mind.

LCDs use a simple grid to supply the charge to a particular pixel on the display. Creating the grid is quite a process! It starts with two glass layers called substrates.

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

As you can see in the table above, with chemical strengthening we can make glass even 6 or 8 times mechanically stronger than the regular one. This is a very long process; it can take several hours, and we need hot temperature, 400 or more degrees. Thermally tempered glass is a separate way of strengthening glass. We use hot temperature and very fast cooling to make the glass stronger. We need a higher temperature, 700 degrees in this process, but it is much faster, it takes just several minutes, and we achieve strong glass, 4 to 5 times stronger than regular float glass. Thermally tempered glass is not as strong as chemically strengthened glass. It is cheaper, but we cannot use it for thin glass. The thinnest glass that we can thermally temper is 3-4 millimeter. If the glass is thinner, with hot temperature it starts floating and the surface will not be flat again. So, if we have a thick glass, it would be cheaper to use the thermally tempered solution. That is why it is more popular. For thinner glass we use chemical strengthening, because we cannot use the thermally tempered solution.

Now we will talk about the other difference between these two methods of strengthening glass. On the left side of the picture above, you can see chemically strengthened glass broken, and on the right side there is thermally tempered glass broken. Chemically strengthened glass breaks like regular glass because we do not change the internal part of the glass. We only make the surface stronger, but inside the glass is the same as regular float glass, and it breaks just like it. Thermally tempered glass changes the internal structure of the glass and it breaks into very small pieces. In many cases it is better because it is safer for humans, that is why we normally use thermally tempered glass in cars or in places where broken glass may injure people.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now we know how glass is made, how it is being strengthened, how it breaks and what types of glass, Float and Optiwhite, we have. To continue, we will talk about surface treatments other than strengthening. The other treatments that we use are anti-glare, anti-fingerprint, anti-reflective and anti-bacterial. About anti-reflective treatment we have talked in another video about

On the picture above there are examples of glass. One of them is a little bit blurry, it is anti-glare and the other one is clear – it is anti-reflective. In the past, anti-glare glass was more popular and used in some commercial devices, but later manufacturers have found that devices with anti-glare are being sold less frequently than the glare ones. It is because as humans we think that there is something wrong with a little bit blurry image even if the reflections are lower. When we are in a shop and looking at phones, we do not see the image clearly and we think that there is something wrong and we do not want this device. That is why we do not see any more anti-glare glass in consumer products. Everything is glare in consumer products, it could be anti-reflective or could be only regular without any surface treatment. But in the professional market that we are working on, like medical devices, military devices, we have many projects where we use anti-glare and anti-reflective treatments, both solutions to reduce reflections and increase contrast.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

This scale is about surface hardness – how hard is it to scratch the surface. As you know, even glass with hardness 9 can be scratched, everybody has some scratches on their phone because this hard layer is very thin – 10 micrometers only. If we put enough force and break this barrier, then we have soft glass with hardness 6 or even lower, that is why we have the scratches.

A couple more words about Gorilla glass. Now there is the sixth generation of Gorilla Glass on the market. The goal for Corning company and Gorilla Glass is to make the glass as strong and as light as possible, because most of the cases are handheld devices, where we want the glass to be light, that is why we want to make it very thin. We have also other companies that are making equivalents of Gorilla Glass, like Dragontrail from AGC or Xensation from Shott. They are not so popular but in many mobile phones or tablets on the market you can find these types of glass.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

When we do the Screen Printing, we need a screen for each color, so to minimize cost, we try to reduce the number of colors to 2–4, like the background and the colored logo. Each color is a different process, we need to wait until the previous painting dries and then we need to put another screen and print another color. More colors mean a longer process and of course a higher cost. Of course, we can change the shape of the glass, we can make rounded corners or custom design of the glass, but it is expensive because first it is just the rectangular piece, then you need to go to the CNC machine to make the proper shape of the glass.

Now we will talk about mechanical impact protection. It is different than the surface hardness we talked about before. On the picture above, we have the test and scale to measure the mechanical strength of glass, that means how much energy we can put on the glass before it breaks. It is measured in IK rate. IK rate is a scale where we have different levels and different energy that will boost. For example, if we want to test IK 9, we need to take 5-kilogram mass from 200-millimeter height. The mass is kept above the tested glass using an electromagnet, then we just drop it, and we see if it breaks or not. If not, of course the test is passed.

If the glass has not passed the test, we can try to change the glass type from thermally tempered to chemically strengthened or go to a thicker glass.

The last point in this article is laminated glass. We laminate glass because of a few reasons. First, what is laminated glass. Laminated glass is like putting the film inside two glass sheets. This process is expensive, we need pressure, we need temperature, we need time, and we need an exceptionally clean environment, because when we laminate together two sheets of glass, we need to be sure that no particles get inside. This kind of process needs to be done in a Clean Room, so it is expensive, but as you see on the picture above, even if the glass is broken, it still holds up because of the laminated film inside.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

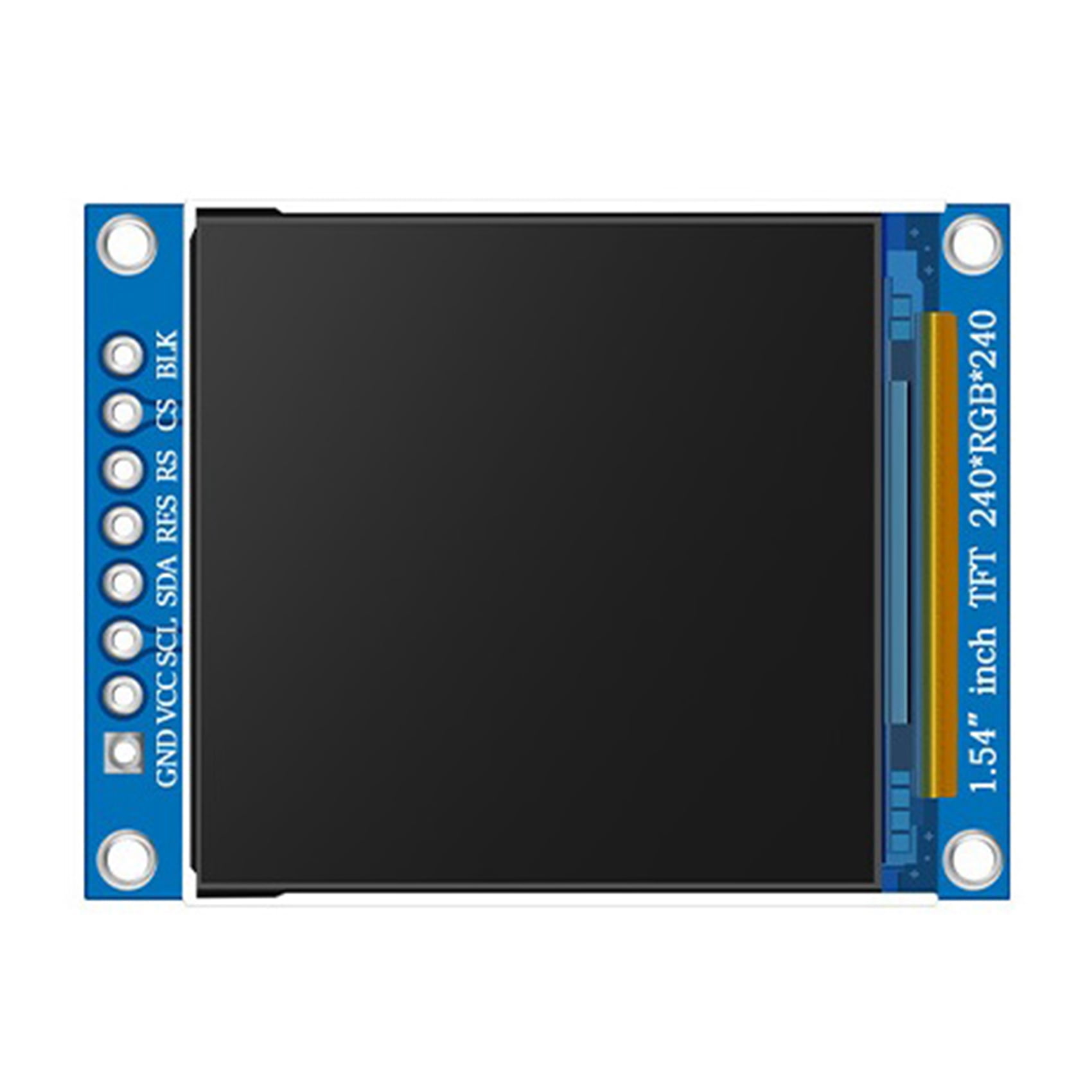

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

With the newest addition to the displays like LCD and LED, we have some significant modifications to them. These displays are most often used in smartphones. A smartphone usually has a Touch screen interface and thus people are more into the display quality. Manufacturers are trying to provide customers with displays that could be better, brighter, and vivid. There are three most popular displays that we often see with most of the phones. These are IPS LCD, AMOLED and Super AMOLED which are the modification to the traditional LCD and LED.

The IPS LCD(In-Plane Switching Liquid Crystal Display) is a modified version of the old LCD and was developed to overcome the limitations of it. If you remember using a phone with a plain old LCD, we didn’t get much of a viewing angle. Colors used to fade away while looking at it from another direction and the image quality was blurry due to poor color reproduction.

When these crystals are subjected to an electric field by two sets of electrodes they tend to obtain a 90 degree twisted structure. The IPS works on the same strategy but the alignment of the electrodes is a little different. In the IPS display, they are located on the same plane. Electrodes in the IPS LCD generate an electric field that is parallel to the lower glass plate. It then uses a polarised light that passes through these liquid crystal molecules with additional horizontal and vertical filters on either side.

The AMOLED(Active Matrix Organic Light Emitting Diode) has an active matrix of Organic LEDs. These consist of the electroluminescent layer which is made up of organic compounds. Whenever electricity is passed through the Thin Film Transistor (TFT) which houses the organic compound, it generates light. The transistor also acts as a series of switches that control the illumination by controlling the current flow.

The IPS needs a good backlight to produce a proper polarised light. Which in turn gives us a brighter white and good visibility in sunlight. It also gives good screen clarity too. The power consumption of the IPS LCD is almost 15% greater than the AMOLED.

On the other hand, the IPS LCD has great color reproduction. The whites are far better than that of the AMOLED, which look a little yellowish. It also adds natural color to the other segments. The electric field changes the nature of the liquid crystal’s behavior to produce good viewing angles. Thus most of the time photographers usually prefer to use an IPS LCD display in a camera.

The cost related to the development of the AMOLED is very high. The fabricating substances needed to build up the display are very costly. Another factor is the complexity to assemble them together makes it much more expensive than building an LCD. Thus we mostly see AMOLED displays in high-end devices like Samsung.

The IPS LCD also has a higher cost in development than that of the TFT LCD, but it is not as expensive as that of AMOLED. IPS LCDs are also used by some of the renowned phone manufacturers like Apple (in their earlier iPhone 8, 7, and so on), and HTC.

Since the AMOLED uses organic compounds for electroluminescent. Like all, these organic compounds tend to fade after a long-span use. The Red and Green pixel have a longer life span than that of the blue. These Red, Blue, Green are the base pixel that gives us the multi viewable color. Thus fading of one of the fundamentals pixels can lead to a significant color change. There is another term known as Burn-in, where the pixels permanently lose their ability to return to the relaxed state. Well, this phenomenon also happens in IPS LCD but it’s not permanent.

This works the same as the Super AMOLED, reducing the gap between the touch-sensitive screen and the physical display. This specific display is used by HTC in its flagship phones. The resulting combination has a similar effect to super AMOLED like increased visibility in sunlight and low power consumption. There are also Super LCD 2 and 3 which differ in terms of brightness. Super LCD 3 is much brighter than its predecessors.

People often confuse Gorilla glass with the categories of displays. You cannot differentiate Gorilla Glass and AMOLED or IPS LCD. The Gorilla glass is a chemically strengthened glass that is used over your display like AMOLED or IPS LCD to prevent them from scratches. The Gorilla Glass is developed by Corning and now in its sixth generation.

Hi all, I"ve done some research on tft vs IPS screens and it seems tft screens are the worst type around. With that said, all the videos and articles I found were from 5ish years ago. Are tft screens still garbage? If so, why in the world would Motorola put it in their flagship?

Hi all, I"ve done some research on tft vs IPS screens and it seems tft screens are the worst type around. With that said, all the videos and articles I found were from 5ish years ago. Are tft screens still garbage? If so, why in the world would Motorola put it in their flagship?

I have noticed that distributors for small and medium TFT, they consider TFT still a top quality product, it"s enough to see product list of any online distributor like

Before we dive in, it"s helpful to understand the layout of a smartphone screen. The oversimplified version is that displays are composed of several layers of material, starting backing material and including a lighting element (like the backlight for LCD screens), which is then topped with a TFT (thin-film transistor) layer, which uses voltage-sipping transistors to keep the display"s pixels shining until you refresh or change the image.

There"s also the touch-sensitive panel; various films and filters that might reduce glare, for instance; and the cover glass, which is often bonded to the touch layer like Gorilla Glass. And there are also sensitive digitizer screens found on Samsung Note family..... ..... enough

The LCD screens are the most common technology used on mobile phones and they range from the budget smartphones like the HTC desire C to high-end tablets, like the Google Nexus 7. Two types of LCDs are primarily found in mobile phones: TFT and IPS technology.

TFT-LCD stands for thin-film transistor - liquid crystal display and use the thin-film transistor technology to improve image quality. They are often just referred to as LCD, since TFT-based LCD screens are the only type used in practice. Each pixel on a TFT-LCD has its own transistor on the glass itself, which offers more control over the images and colors that it renders.

While TFT-LCDs can deliver sharp images, they also tend to offer relatively poor viewing angles. TFT are found on more low-end smartphones or feature phones, and on basic cell phones.

IPS stands for in-plane switching. It involves arranging and switching the molecules of the liquid crystal (LC) layer between the glass substrates. This is done in a plane parallel to these glass plates. It features two transistors for each pixel, where TFT use just one. Requires a more powerful back-light (up to 15% comparing to TFT screens) but resolves the TFT"s weaknesses related to relatively high response time (lower is better), strong viewing angle dependence and low-quality color reproduction.

IPS are more expensive in production and typically are found on high-end mobile phones and portable devices. Apple"s iPhone, iPad, HTC One X and Nokia 920 are a good example of high quality IPS-LCDs screens.

The liquid crystals do no emit light themselves, so LCDs require a backlight. That means that LCD requires more power, and could potentially be more taxing on your phone’s battery.

The LCDs however produce some of the most realistic colors you can find on a screen, but might not offer as wide of a contrast ratio (darker darks and brighter brights) as AMOLED or OLED.

Due to this simple construction, AMOLED offers many advantages over LCD displays as it is thinner, brighter, more power efficient and provides wider viewing angles. They also provide much better contrast and response times.

Mostly those advantages are down to the fact that AMOLED technology doesn"t require a back-light. The black colour stays truly black without producing an energy (unlike on many LCDs where the black is rather grey and its being artificially made), which also leads to expanding battery life as long as the background of your phone is close to black.

However AMOLED screens have proved costly and difficult to produce in the same numbers as LCD, a fact that forced HTC company to replace AMOLED screen in their HTC Desire for Super-LCD halfway through its manufacturing life. A decision that led HTC to stick with LCD screens onward. Often those screens were also criticized to have lower visibility in the direct light than their LCDs counterparts and having over-saturated colours, until Samsung introduced the next generation of Super AMOLED technology, which solved the above issues.

LCD screens start with an always-on backlight; this technology requires light to create black, white, and colors. High-end LCDs produce the most accurate colors, though their manufacturers sometimes intentionally calibrate LCDs to produce weaker red, blue, and purple shades in order to reduce the device"s power consumption.

AMOLEDs also age more rapidly than LCD"s. Using an organic polymers, means that the red and blue colors deteriorate faster than green. Samsung used Super AMOLED plus screens in their Galaxy S II phones, but reverted back to Super AMOLED screens for the Galaxy S III citing screen life as the reason for the switch.

Both display technologies offer advantages and disadvantages. AMOLED screens have higher contrasts and deeper, true blacks, but LCD’s tend to offer more accurate colors. While AMOLED displays are brighter when viewed off-center, LCD panels can be viewed more easily under direct sunlight.

AMOLED displays tend to be more power efficient overall however, LCD panels are more power efficient when it comes to displaying web pages. AMOLED screens have better viewing angles, but LCD panels tend to be sharper on lower resolution panels thanks to the use of the RGB structure instead of PenTile/RGBG.

One of the problems with existing LCD displays used on smartphones is that they can’t keep up. While the internal hardware and operating system are fast enough to deliver a full 60 frames-per-second (FPS), the screens themselves lag behind, leading to pixelated video and ghost images appearing as your screen moves.

PureMotion HD+ uses an IPS type LCD display that is also given a higher voltage difference when changing states to produce a clean transition from frame to frame, even when operating at top speeds. This allows the display to deliver a steady 60FPS without any blurring. Nokia claims it lights up twice as fast on 920 than on any competing LCDs smartphones.

Ever take your phone outside and squint to read the screen? Phones with high reflectance can be a real setback, but some manufacturers are good at getting on top of it. ClearBlack is Nokia"s name for an anti-glare filters applied to the screen above the touch layer (but below the glass) on its high-end phones. It works on both AMOLED and LCD screens.

The color saturation is beyond the reach of any LCD out there, which make even the dullest image appear remarkably vibrant. Still, if you are not a fan of the oversaturated look of AMOLEDs, Samsung gives you the option to tune down the saturation to more natural levels and enjoy the best of both worlds. There"s a dedicated Adobe RGB setting that gets this done.

Triluminos is a technology that enables LCD TFT displays to show a wider range of colors, therefore the images are richer and more vivid. It’s all down to intelligent backlight technology, a Triluminos display reproduces more tones and textures than standard LED backlighting. Sony says that it boasts a color gamut that is 50 percent larger than that of a conventional LCD panel.

Conventional LCD displays use a white backlight that passes through red, blue, and green filters to form the color that the user perceives. The problem with this approach is that filters are not very selective – in other words, it’s hard to form very specific colors, and the end result might be a washed out colors (LCD needs very careful calibration to work perfectly). With Triluminos, the white backlight is replaced by a blue LED, which emits a blue light that causes a film of quantum dots to produce pure green and pure red. The different wavelength light is combined to form the color on the screen. This way the display can show more pure, unadulterated colors.

Sony has been using the X-Reality and X-Reality Pro image processors on its high-end TVs for a while now, though it’s not clear if X-Reality for mobile is the same thing.

According to Sony,Triluminos and X-Realityshould allow the Sony screens to compete with the Super AMOLED displays on Samsung flagships, which are recognized for their rich colors. But that’s the theory. In practice Xperia"s Z1 screen is a huge improvement in image quality since the Xperia Z and the images are truly coming to live (also the viewing angles has been greatly improved) but still cannot compete fully not only with super AMOLED screens, but also with the top IPS LCD panels.

Saying that this technology is superior to conventional LCD"s, and most likely will become dominant in the next couple of years. The very first example of implementing it into LCD IPS screen is a new Amazon Kindle Fire HDX 8.9, that surpasses every panel on the market related to intensity and accuracy of the colours produced. Here are some of the key findings from DisplayMate"s regarding Nexus 7 vs Fire HDX vs new iPad Mini display shootout

When Apple rolled out the iPhone 5, they announced that it had a full sRGB gamut, and would be a substantial improvement over the 4 and 4S displays. They also had done away with layers of technology below the screen to bring the display as close to the glass as possible, something they said would bring increased brightness and sharpness to the user"s eye. In practice however, compering the quality and brightness, Iphone 4S has still upper hand.

Retina Display - Apple"s proprietary name for its LCD screen, which serves up a 1,136x640 pixel resolution in mobile phones.1080p - The highest common high-definition screen resolution, measuring 1,920 pixels by 1,080 pixels. Also called "full HD."

720p -The lower high-definition designation, 1,280 by 720 pixels.Super LCD - Manufactured by Samsung, but used mostly by HTC, Super LCD is a display technology which removes the air gap between the outer glass and the display elements. This reduces the glare, and also consumes less power and has better outdoor visibility than regular LCD screens.

IPS - A type of LCD screen technology known for producing clearer image quality and wider viewing angles, among other traits. It"s used in many smartphones.

AMOLED Display and Gorilla Glass Has Been Popular Out of Marketing by the Companies. What Are AMOLED Display and Gorilla Glass of Smartphones? In very short – AMOLED Display is a display technology like OLED, TFT-LCD are display technologies. Basic is any type of LED display is one multi color RGB LED controlled by a programmable micro-controller, multiple RGB LED controlled via multiplexing. Up to RGB LED display is what we can do with Arduino to built DIY color display unit. After that, the individual units become too small SMD components. As they many a times AMOLED Display and Gorilla Glass co-exist in advertisements for the display units of modern Android smartphones, we thought to discuss them together in one article divided in two sub-headers.

Corning Inc is an 167 years old company who manufactures patented glass related things like yellow colored headlamp lenses of automobile. Today after 100 years, that yellow colored headlight seems ordinary. Corning is a glass expert company themselves with huge resources :

Gorilla Glass is a branded toughened or tempered glass. Tempered glass glasses upon fracture stress does not splinter into jagged shards plate glasses but cause the glass to crumble into small granular chunks. These glasses are most susceptible to breakage due if extra stress applied to the edge of the glass. But shattering can also occur in the event of a hard impact in the middle of the glass.

Gorilla Glass is simply a branded scratch resistant touchscreen glass. Corning is manufacturing similar tempered glass since 1960s, which are used for both industrial and commercial fields. In 2005, 2008 they introduced newer type of tempered glass. Gorilla Glass is an alkali-aluminosilicate thin glass designed to function as protective cover glass for smartphone display (in our current context). That Gorilla is made by a proprietary process named Corning’s fusion draw. Gorilla Glass does not interfere with Capacitive Touch Screen. Gorilla Glass has versions and Gorilla Glass 5 is towards latest version. Corning has full lists unless smartphone manufacturer not allowed to publish :

2.5D glass is kind of generic version of toughened glass for smartphones which can have edges like Gorilla Glass. There are 3D Curved Surface Tempered Glass for J7 Max with videos on YouTube. That will give you an idea of “curved edges”.

Samsung, LG are working on plastic screens which can be folded and are lighter than Corning’s products. Gorilla Glass is exactly like Corning’s yellow colored headlamp lenses of automobile. It is important now, sells well; may be outdated in future.

If we expand the term AMOLED, we get Active-Matrix Organic Light-Emitting Diode. AMOLED display technology is now used in many smartphones and televisions especially in the Samsung products. By the use of this technology, the capacitive touchscreen layer is directly integrated into display. Traditionally the touchscreen layer is overlaid on the top of the display. As such, the AMOLED screen gets an advantage over ordinary capacitive touchscreen because it is possible to manufacture a thinner design. The AMOLED screen uses less power and reflects less light and therefore it gives a very good performance when you use your smartphone outdoors and in more light. In addition to smartphones, the technology has been very useful in manufacturing low-power, low cost devices especially devices with large screens. AMOLED screens have better contrast ratios than the LCD screens. LCD displays are better in direct sunlight when compared to the ordinary AMOLED display. But Samsung"s Super AMOLED display technology has overcome this defect by reducing the size of gaps between the layers of the screen. As such Super AMOLED is the term used by Samsung for AMOLED display whereby the layer that detects the touch is integrated directly into the screen in stead of overlaying it on the top of the screen.

The U.S. glassmaker Corning has manufactured an alkali-aluminosilicate sheet glass and has registered the patent under the name of Gorilla. This glass is commonly known as Gorilla glass. It is used as a cover glass for most of the electronic gadgets. The maximum use of this technology is in devices like mobile phones, portable media players and laptop computer displays and even on some television screens. The glass is very thin, light and damage resistant. By 2010, the Gorilla glass came to used in about 20 per cent of the mobile hand sets manufactured in the world. Gorilla Glass 2 which is second generation glass from Corning was introduced in the market in 2012. Corning announced on October 24, 2012 that one billion mobile devices used its product called Gorilla Glass. It is rumoured that the third generation protective glass Gorilla Glass 3 will be used in the devices from 2013 onwards. The best feature of Gorilla Glass 3 is that it is three times more scratch resistance that Gorilla Glass 2. So we now know that Gorilla Glass is the protection for the display screen. Corning has also launched some other glass protections like Lotus Glass and Willow Glass."Teaching is my passion & sharing of knowledge is my motto"

Cutting edge display technology has been a central feature of flagship smartphones in recent years. The LG V30 arrived late last year with yet another innovation in screen tech: new panel type called P-OLED. With Samsung still marketing its Super AMOLED and Infinity Display technology, and some other manufacturers moving away from the tried and tested IPS LCD, there’s never been more choice for display panel tech in the smartphone market.

P-OLED isn’t exactly the new kid on the block, but the technology is just starting to appear in a number of flagship handsets. We’ve already seen how LG Display’s P-OLED stacks up against Samsung’s AMOLED,but what about the common IPS LCD display technology? That’s what we aim to find out in this P-OLED vs IPS LCD breakdown.

The common LCD stands for Liquid Crystal Display, while IPS stands for “in-plane switching”. The latter controlls the crystal elements in the display’s RGB sub-pixel layout. IPS replaced twisted nematic field effect (TN) as the technology of choice for LCD in the 90s, and is what you’ll find in all LCD-based smartphone panels.

The technology features a polarized backlight passing through the liquid crystals, in front of red, green, and blue color filters for each sub-pixel. With IPS, a current is used to create an electric field parallel to the plate, which twists the polarized crystal and further shifts the polarity of the light. A second polarizer then filters out the light based on its polarity. The more light passes through the second polarizer, the brighter the associated RGB sub-pixel will be.

Each sub-pixel is connected up to a thin-film transistor active matrix, which drives the panel’s brightness and color without consuming as much current as an outdated passive matrix display. Using different TFT materials and production techniques can alter the driving properties of the display and alter the transistor sizes, which affects properties such as brightness, viewing angles, and color gamut. Hence why you’ll find a variety of different naming schemes for IPS LCD display, including Super IPS, Super LCD5, and others.

The makeup of the backlight can vary between LCD panels too, as the white light has to be created from another group of colors. The light source can be made up of LEDs or an electroluminescent panel (ELP), among others, each of which can offer a slightly different white tint and varying degrees of even light across their surface.

OLED technology has been the major rival to LCD in the smartphone market for what seems like forever. Samsung’s AMOLED technology has powered generations of the top selling Android flagship. Plastic-OLED (or P-OLED) is simply the latest iteration of this technology, primarily designed to enable new and interesting form factors.

Compared with the numerous layers of an LCD display, P-OLED is considerably less complicated looking. The key component is a Light Emitting Diode (LED). So rather than relying on a universal backlight, each sub-pixel is capable of producing its own red, green, or blue light, or being shut-off completely. The O part in OLED stands for organic, which is the compound type that lights up when current is applied.

To drive this current, the TFT matrix is used in a very similar way to LCD. Although this time the current is used to produce the light rather than twist the polarizing crystals. As this is an active matrix TFT, Samsung chose to call its OLED panels AMOLED. P-OLED shouldn’t be confused with the outdated PMOLED technology, which stands for passive matrix and isn’t used in any modern pieces of high-end display tech.

So where does the plastic element come in? Well it’s simply the material used as the back substrate on which the TFT and OLED components are placed. Historically, this has been made from glass but using a plastic substrate makes the display more malleable and flexible. It’s important to note however, that switching over to a plastic substrate requires new materials for the TFT plane that can withstand the manufacturing temperatures, while still providing sufficient electron mobility and current for the LEDs.

The two display technologies have their own pros and cons in terms of viewing quality, but plastic OLED has a trick up its sleeve that LCD can’t yet match — flexibility.

LG recently stated that its move to P-OLED in the V30 smartphone wasn’t based on increased image quality. Instead, the company acknowledged that thin bezels and curved designs are in high demand from consumers. The only currently viable way to achieve these designs is by using a flexible plastic substrate in an OLED display, which makes the panel lighter, thinner, and more pliable than using a traditional glass substrate.

Although the very top of a smartphone display will likely feature a protective glass layer, such as Gorilla Glass, the underlying plastic substrate layer does offer some additional shock absorption. This means that it’s less likely that the TFT layer will break on dropping, helping to preserve functionality even if the top layer cracks.

It’s worth stating that flexible LCD alternatives are in development. Japan Display showcased its low-cost flexible LCD technology in early 2017 and other companies are working on Organic LCD and similar ideas. However, the trick is still to match flexible OLED for pixel density and resolution, color gamut, and production yield. So it’s likely to be a while before we see competing flexible LCD products.

Unfortunately, there’s no definitive superior technology between IPS LCD and P-OLED. There are too many variables beyond the basic display type that determine the quality of the viewing experience. These include sub-pixel layouts and manufacturing materials.

No two IPS LCD manufacturers are necessarily alike, and even P-OLED will undoubtedly go through generational revisions over the next few years and continue to improve performance. Furthermore, new advances in LCD technology, including Quantum Dot, WRGB, and others, keep reinvigorating the already well-refined technology.

LCD (Liquid Crystal Display) displays consist of a matrix of Liquid Crystals. Liquid Crystals do not emit light themselves and are reliant on some form of back-light to illuminate the whole display. As a result LCD displays can be very visible in direct sunlight.

IPS-LCDs provide a superior viewing angle and better color reproduction than non IPS-LCDs due to the layout of the LCD"s themselves. This has become a common display type for mid-range to high-end phones.

OLED & AMOLED utilizes "organic" LEDs which emits light and in the majority of cases does away with the need for the back-light of an LCD display resulting in a potentially thinner panel.

They consume less power as opposed to LCDs which always have the back-light on. When a pixel is "black" on a OLED/AMOLED display the pixel is truly off.

Anti-Glare coatings and glass etching processes use a material’s diffusive properties to disperse reflected light across the screen surface, making it appear fuzzy or blurred, eliminating any sharp reflections or hot spots. Learn more.

Backlight. The source of light for the LCD panel in a display, today a grid of light-emitting diodes, or LEDs. Edge-lit LEDs form a line around the rim of the screen with a diffusion panel to spread the light evenly. In a direct full LED array the LEDs are arranged behind the screen at equally spaced intervals. In a mini or micro LED backlight, a larger number of smaller LEDs (less than .2 mm) provide the illumination, improving contrast by showing little or no light behind black pixels. Learn more.

Bezel. The frame, or edge, around the LCD panel in a display. Zero bezel panels, with no frame around the front edges, are favored in monitor-based video walls because there is little or no gap between the displays forming an image. They are also preferred for many medical devices, as they offer fewer places for pathogens to collect.

Brightness. Typically measured in candelas per square meter (cd/m2) or nits. Displays in laptops and mobile devices usually produce between 200 and 500 nits, with many televisions higher and outdoor TVs often at 1,000 nits or higher.

Cover glassis a protective layer of glass installed over an LCD panel to protect it from damage and to hold display enhancements, such as a touch sensor, in place. The glass used may be plain or tempered soda lime glass or a chemically-hardened glass such as Gorilla Glass or Dragontrail Glass. Learn more.

Display Interfaces internally connect the liquid crystal display module which consists of a TFT Cell, Driver IC/Source PCB and a backlight unit. Common interfaces used today are Low Voltage Differential Signaling or LVDS, Embedded Display Port or eDP, Mobile Industry Processor Interface - Display Serial Interface (MIPI-DSI), RGB, V-by-One, I2C, Serial Peripheral Interface or SPI and MCU. Learn more.

EMI, or Electromagnetic Interference, is a disturbance generated by a nearby electromagnetic source that can affect the electrical circuits within an LCD display. RFI, or Radio Frequency Interference, is closely related. Either or both can be generated by electrical devices including motors, microwave ovens, transformers, CRT monitors, and power supplies, and wireless devices including phones and network transmitters.

Optical Bonding. The process of bonding a touch screen and/or cover glass to an LCD panel, while at the same time filling the gap between them with an optically transparent material that eliminates internal reflections, thus improving durability, brightness and contrast. OCR, or wet bonding, uses optically clear resin to fill in the gap between the elements, creating the strongest bond and the most readable image, because it does the best job of eliminating internal reflections. OCA, or dry bonding, uses optically clear adhesive to create good durability and readability. Air Gap is the least expensive and least effective, using double-sided tape to bond the elements.Learn more.

Pixel. The “picture element” or dot formed by a single liquid diode, or LCD. The overall image seen on an LCD display is formed by millions of pixels, blended together by the human eye into a single picture.

Polarizer. A layer of crystalline material placed between the backlight and the LCD element within a display to direct the alignment of the light waves passing through the LCDs.

In an LCD module, a rear polarizer, placed between the backlight and the LCD panel, forces all of the light passing through the LCD element to be aligned in one direction. Since the ambient light outside the panel will be aligned in different random directions, a front polarizer, placed on the outside of the panel, eliminates virtually all of the transmission of light into the panel. Thus the two polarizers work together to keep ambient light from washing out the image created by the display.

Refresh Rate.A measure of how often a display updates its picture each second. Most LCD displays refresh at 60 cycles per second, or 60 Hz, but some special purpose displays, notably those used for gaming, resulting in smoother on-screen motion.

TFT LCD.Thin-film-transistor liquid-crystal display, the technology used in most displays today. There are three types commonly used. The oldest, twisted nematic (TN) displays offer extremely fast response times but originally had limited color reproduction and viewing angles. Over time, however, TN has been improved to display 8-bits per channel RGB (16.7 million colors) and relatively wide viewing angles. In-plane switching (IPS) offers deeper color depth and wider viewing but somewhat lower response times. Newer technologies, including VA (vertical alignment) panels offer various tradeoffs between color, response, viewing angles and cost.

Touch Interface.A technology to translate touches to the display to the computer or processor. Three are most commonly used: PCAP or Projected Capacitive Touch, which uses a conductive grid to recognizes changes in an electromagnetic field caused by the touch of a finger or stylus; Surface Capacitive Touch, which uses a glass overlay with a conductive layer to recognize the touch; Resistive Touch, in which the touch presses two electrically resistive layers together; and IR, which uses an array of invisible infrared LED light sources and detectors around the edges of the screen to recognize the touch of the finger or stylus. Learn more.

Supply your customers with the best wholesale gorilla glass touch screen tablet from Alibaba.com, one of the world"s largest B2B marketplaces. Our options include touch screen monitors for pc, portable touch screen monitors and more so they can start tapping and pinching their screens right away.

When choosing the best touch screen monitor for their needs, customers will look at a variety of factors. Firstly, there are large touch screens available but the maximum that is comfortable for use with hands is a 32 inch touchscreen monitor. Any bigger than that and customers will not be able to reach the four corners. These gorilla glass touch screen tablet are best used for visual artists to draw on and video editors.

You can also look at portable monitor touchscreens which run from the laptops battery and are small gorilla glass touch screen tablet. They can also be used for projects involving single board computers. Additionally, we also have a lot of options for smart tv touch screens which are great to incorporate into home entertainment systems and allow users to surf the net, send messages on more right from their living room.

Over time, the purpose of using mobile phones or Smartphones has changed. Comparatively, it has now become a basic necessity of every individual. Smartphone has dramatically transformed the lives of individuals. It has now become a mini-computer that everyone carries in their pocket. Instead, you can have multiple things at your fingertips in a few seconds. While there are plenty of things to look for, AMOLED vs OLED is also a part of it.

This article will introduce you to AMOLED vs OLED display technologies. Then, we will discuss the properties of both display technologies, followed by the difference between AMOLED vs OLED.

AMOLED stands for Active Matrix Organic Light Emitting Diode. This type of display is generally for large platforms. It contains TFT, which further consists of a storage capacitor. It also works on the same principle as OLED displays.

AMOLED offers no restriction on the size of the display. The power consumption of AMOLED is much less than other display technologies. The AMOLED provides incredible performance. It is thinner, lighter, and more flexible than any other display technology like LED, or LCD technology.

The AMOLED display is widely used in mobiles, laptops, and televisions as it offers excellent performance. Therefore, SAMSUNG has introduced AMOLED displays in almost every product. For example, Full HD Super AMOLED in Samsung Galaxy S4 and Samsung Galaxy Note 3, Super AMOLED in Samsung Galaxy S3, HD Super AMOLED in Samsung Galaxy Note, and HD Super AMOLED Plus in Samsung Galaxy S3. Apart from this, it is also used in AMOLED vs OLED creating the following:

OLED comprises thin layers of the organic component, which emits light when the current passes through it. In this technology, each pixel transmits its own light. On the other side, AMOLED consists of an additional layer of thin-film transistors (TFTs). In AMOLED, the storage capacitors are used to maintain the pixel states.

While the technology is different among various manufacturers, Samsung’s edge AMOLED displays use plastic substrates with poly-Si TFT technology similar to how LG uses it in their POLED technology. This technology is what makes the possibility to build curved displays using an active-matrix OLED panel.

OLED display much deeper blacks as compared to the AMOLED displays. You cannot see the screen in AMOLED display under direct sunlight. The AMOLED display quality is much better than the OLEDs as it contains an additional layer of TFTs and follows backplane technologies.

These organic compounds are present between the protective layers of glass or plastic. Comparatively, AMOLED comprises an active matrix of OLED pixels along with an additional layer of TFTs. This extra layer is responsible for controlling the current flow in each pixel.

OLED displays are comparatively much thinner compared to the LCDs. Hence, it provides more efficient and bright presentations. In addition, OLED offers support for large display sizes compared to the traditional LCDs. AMOLEDs remove the limitation of display sizes. one can fit it into any display size.

The Xiaomi Mi 11 Lite runs on Snapdragon 732G chipset bundled with Adreno 618 GPU and up to 8GB RAM. The display front comes with a 6.55-inch AMOLED display with HDR 10+ support and 402 PPI.

OPPO has recently launched the Oppo Reno 6 Pro with MediaTek’s Density 1200 chipset coupled with Mali-G77 MC9 GPU and up to 12GB of RAM. In addition, it comes with a 6.55-inch curved AMOLED FHD+ display with support for HDR 10+ and an Oleophobic coating.

Major smartphone manufacturers attempt to provide their consumers with the most delicate devices possible that incorporate the most up-to-date technologies. In AMOLED vs OLED, AMOLED is a type of OLED and a more prominent example of both OLED and POLED, so there’s no debate about which is superior.

Key Difference: AMOLED is a type of screen used in consumer electronics, such as smartphones, tablets, and laptops. Gorilla Glass is a type of protection that is used on the screen.

There are many different types of screens available, such as TFT LCD, IPS-LCD, Resistive Touchscreen LCD, OLED, AMOLED, Super AMOLED, etc. Each of these types has something that helps them stand apart from the others.

AMOLED stands for Active-Matrix Organic Light-Emitting Diode or "Active Matrix OLED" for short. It is a hybrid display technology that combines the active matrix backplane from a traditional TFT display with an OLED display. The advantage of this is that it has a faster pixel switching response time than the traditional OLED displays.

As compared to other screens on the market, AMOLED has a faster pixel switching response than traditional OLED displays, consumes less power and has better contrast ratios than LCDs. However, AMOLED displays may be difficult to view in direct sunlight as they have reduced brightness. Also organic materials used in AMOLED displays are very prone to degradation, which may result is fading of one color over the others.

As anyone with a cracked screen knows, displays are very easy to damage. Hence, it is essential that the companies that charge so much for their product provide some form of protection on their screens. This is where Gorilla Glass comes in.

Gorilla Glass is an alkali-aluminosilicate sheet toughened glass. It is scratch resistant as well as impact resistant, which means that it will protect the display of the device against the accidental scratches made with keys in the pocket or accidentally dropping the phone.

Gorilla Glass was developed and is manufactured by Corning Inc. It was developed from a chemically strengthened glass called "Chemcor" that Corning developed in the 1960’s. Today, Gorilla Glass is used primarily for portable electronic devices, including mobile phones, portable media players, portable computer displays, and some television screens.

The main difference between Gorilla Glass and AMOLED is the fact that AMOLED is a type of display used in electronics, whereas Gorilla Glass is a type of toughened glass that acts as a screen protection, usually laid on top of the display such as AMOLED.

Another critical advantage of OLED tech is high contrast ratios. Technically, OLED displays offer "infinite contrast," or 1,000,000:1 contrast ratios. This is because OLED displays reproduce black by turning off pixels entirely, and contrast is measured by comparing the brightest part of the screen to the darkest part. Improved contrast makes on-screen content more vivid and makes bright highlights look more impressive. This also means that OLED screens can reach higher brightness than the best IPS LCD screens.

OLED displays can display more colors with greater color accuracy than their LCD peers. This is great for photographers and videographers using their phones to preview, edit, and create content.

OLED displays have near-instantaneous pixel response times. Older LCD screens often have lower response times because to change from one color to another, they must physically change the orientation of a liquid crystal, which takes time. An OLED display turns a subpixel on or off with an electrical charge, giving them a faster pixel response time.

The omission of a separate backlight and the use of fewer components means OLED displays can be thinner than LCDs, making them more versatile in their applications. This means they are more fragile and prone to damage in high-impact or high-stress situations. Engineers combat this by using technologies like Gorilla Glass and robust metal frames. Mitigation strategies like these raise the cost of OLED screens.

OLED displays can also be transparent, depending on the materials used. Transparent displays are helpful for in-display fingerprint readers and under-display cameras, which allow manufacturers to design smartphones with fewer and smaller bezels, notches, and display cutouts. When notches and cutouts are necessary, OLED displays have more even brightness around those cutouts and notches compared with LCDs, where the backlight has to make it around the cutout, and things get a little messy.

Of particular import to smartphones, OLED displays often consume less power, especially when displaying dark images or UI elements, thanks to the pixel-level regulation of brightness. However, at max brightness, an OLED screen usually uses more power than an equivalent LCD.

Early OLED screens placed all the organic materials on a glass substrate. However, glass is rigid, so a flexible plastic substrate is needed to create foldable display screens, leading to the creation of POLED screens.

POLED (polymer organic light-emitting diode) offers advantages in terms of durability and versatility. The replacement ofglass substrates with plastic ones makes them more shock-resistant. Another unique advantage is in the implementation. Designers can reduce bezel size by folding the electronics underneath an edge of the display instead of having it be on the same plane. POLED displays are also significantly thinner than OLED displays with glass substrates.

Thin-film transistor (TFT) arrays used in modern active-matrix OLED displays control the charging of the display"s storage capacitors. These TFTs control current flow, resulting in more energy-efficient OLED panels than PMOLED displays. This allows a larger display size without compromising resolution, lifetime, or power consumption.

QLED is found in TVs and large computer monitors because that"s where it sees the most benefit. OLED displays in phones are small enough, bright enough, and cheap enough that QLED wouldn"t be able to compete or offer any practical benefit to the end user.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey