lcd panel recycling manufacturer

LCD displays that contain mercury pose a significant threat to the environment, as well as the companies disposing of them, historically public opinion hasn’t been very kind to companies who discard waste stream management and irresponsibly dispose of their waste. Sadly, the threats associated with LCDs don’t end with the environment, those handling old, cracked or damaged LCD displays must be properly trained and protected by safety equipment or risk serious serious bodily harm. This is why it’s important to leave recycling LCD displays to capable and responsible recyclers like Cleanlites. Our trained personnel and state of the art recycling facilities are designed to safely recycle harmful wasted associated with LCD displays, along with many other waste streams. To speak with one of Cleanlites’ recycling experts about managing your waste streams,and team member will get back with you ASAP.

Liquid Crystal Displays (LCDs) have replaced Cathode Ray Tubes (CRTs) as the main display devices in recent years. To satisfy the increasing demands, billions of LCDs are manufactured annually. As more LCDs are produced and used, the amount of LCD waste is increasing at an alarming rate. Current treatment technologies can disassemble LCD into multiple components and recycle them according to their materials. However, there is no suitable model for treating LCD panels. Research has repeatedly shown the harmfulness of liquid crystal, indium and other heavy metals which LCD panels contain. As a result an increasing number of countries have classified LCD panels as hazardous waste. Because of this, future processing of LCD panel waste will require on-site burial, burning, or physical disposal, not only increasing processing costs, but also causing environmental damage. This is a huge problem. That is why this recycling technology for waste LCD panels is a kind of revolutionary breakthrough.

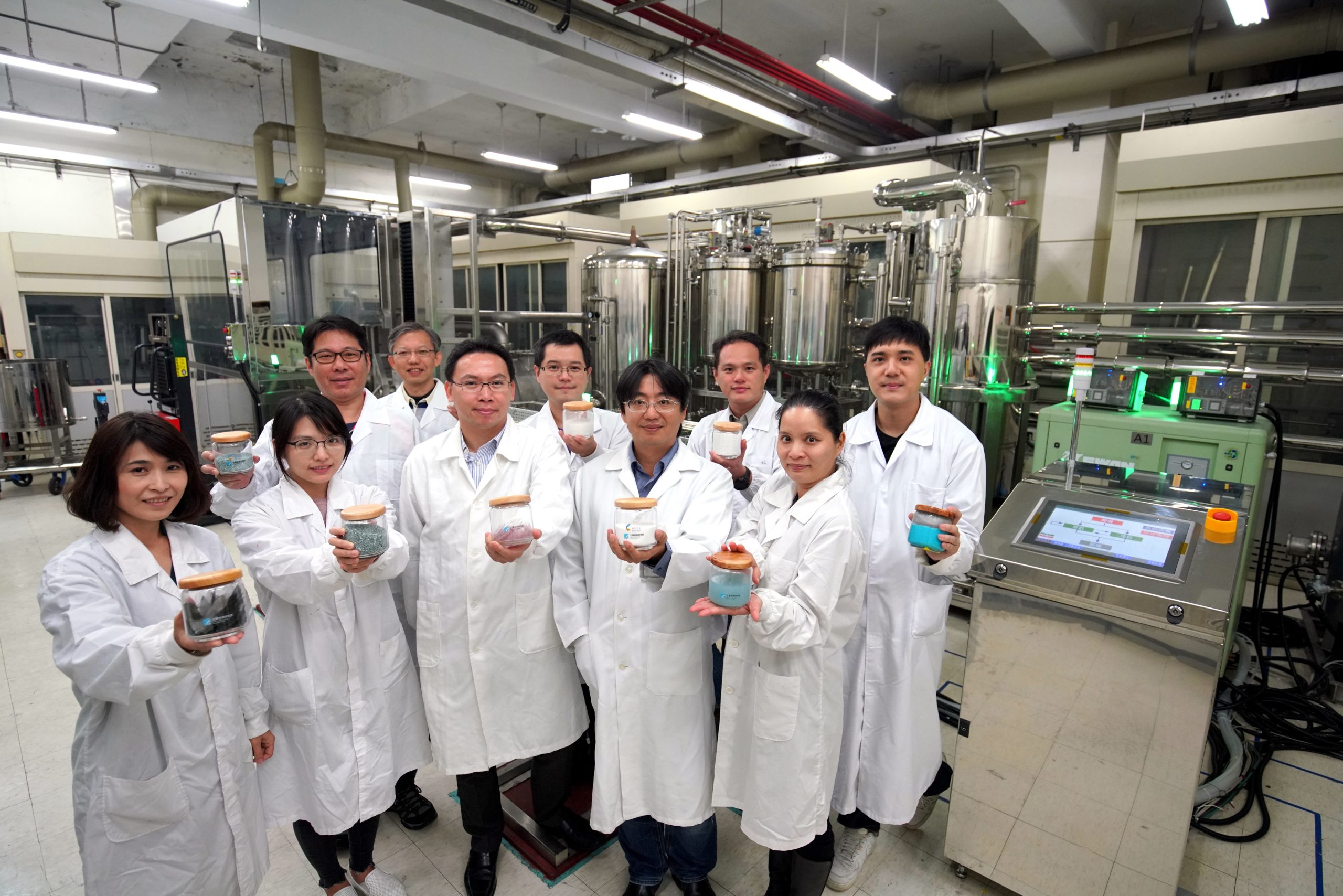

The pilot plant handles 3T of waste LCD panels daily, with a liquid crystal recycling rate of 100%, indium recovery rate of more than90% and glass recycling rate of 100%

Liquid crystal is the main component of LCD. It is a chemical with a high unit cost, high stability and low biodegradability. While the harmfulness of liquid crystal is uncertain, its structure contains a large volume of benzene rings, fluorine, chlorine, and bromine, which, if buried, may seep into subterranean water systems and impact ecosystems. Physical processing entails breaking down LCD panels and adding them to cement or concrete, which does not remove liquid crystals and heavy metals from the panels, so they may still enter and harm the environment following rain or washing. Based on environmental and economic considerations, the liquid crystal in the LCD panel should be reused.

To prevent the pollution caused by waste LCD panel disposal, and to control processing costs, ITRI thoroughly analysed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material, first separating liquid crystal, indium, and glass, and then developing purification technology for each material which enables the reuse of these materials. Liquid crystal can be reused in new LCDs or liquid crystal smart windows. Indium can be refined as the raw material of sputtering targets. Glass can become a humidity-controlling green building material or heavy-metal adsorption material.

ITRI’s pilot plant can treat 3 tons of waste LCD panel per day of operation, producing 3 kilograms of liquid crystal, 750 grams of indium, and about 2,550 kilograms of glass, which can be reused as humidity-controlling green building material or heavy-metal adsorption material. ITRI’s team uses the pilot plant for technical verification of on-line scrap LCD panels and end-of-life LCD panels. ITRI can build the LCD panel processing center for LCD manufacturers and e-waste recycling companies.

Try using lcd panel recycling machine found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd panel recycling machine to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd panel recycling machine are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd panel recycling machine at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd panel recycling machine on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

Where can you recycle your old crt or lcd monitor? Crt monitor recycling and lcd monitor recycling is easy. By allowing STS Electronic Recycling, Inc., to recycle your old crt monitor or lcd monitor you are helping safeguard against electronic waste polution. A single crt monitor can contain up to six pounds of lead. Lcd monitors contain harmful contaminants such as mercury. Recycle your old or broken lcd and crt monitors.

Hard drive and hard drive data destruction are essential when recycling obsolete/unwanted computers and electronic equipment. STS Electronic Recycling, Inc., guarantees hard drive data destruction in compliance with NIST hard drive data destruction recomendations. Protecting personal/business data can save you money and safeguard against improper data destruction and potential data theft. STS Electronic Recycling offers hard drive destruction tracking and an official certificate of data destruction for clients choosing to recycle their unwanted computers and electronics. Hard drive data destruction processes exceed Department of Defense requirements.

Proper electronics recycling can be achieved with STS Electronic Recycling, Inc. It is important to use a reputable electronics recycler for disposal of out of date/obsolete computer and electronic equipment. Making the environement a priority in electronics recycling is important to STS Electronic Recycling. By practicing a no landfill policy for computers and electronics recycled at the STS Electronic Recycling, Inc., 50,000 sq. ft. facility, we insure a complete compliant recycling process.

Compliant computer, laptop and pc recycling goes further than turning over your obsolete/unwanted electronic equipment to a recycling company. At STS Electronic Recycling, Inc., we aim to create the most environmentally friendly solution for each piece of electronic equipment recieved. Recycling or disposing of your old electronic equipment and computers with STS Electronic Recycling assures the best solution for end of life electronics. Contact us at 903 589 3705 for information on recycling/disposing of your electronics.

Crushers, shredders and bespoke recycling plants - that"s the world of ERDWICH. We are a highly-specialised engineering and manufacturing company working in recycling and shredder technology. Our core competencies are shredding machinery, turnkey ...

Crushers, shredders and bespoke recycling plants - that"s the world of ERDWICH. We are a highly-specialised engineering and manufacturing company working in recycling and shredder technology. Our core competencies are shredding machinery, turnkey ...

Votechnik has spent several years developing the Trumaster product series and now bring these innovative technologies to the recycling industry. Having evolved from ALR Innovations, Votechnik and is now launching the Trumaster-ALR. Trumaster-ALRTM ...

Votechnik has developed a state of the art recycling technology which through a fully automated process removes the hazardous waste materials from LCD flat screen panels and monitors. The process has been developed ...

Votechnik has spent several years developing the Trumaster product series and now bring these innovative technologies to the recycling industry. Having evolved from ALR Innovations, Votechnik and is now launching the Trumaster-ALR. Trumaster-ALRTM ...

The Stena Metall Group is involved in metal recycling, paper recycling, electronics recycling, hazardous waste recycling and chemicals recycling. Stena Metall Groupd is a leader in recycling and environmental services in the Nordic region and a ...

With innovative customer solutions and our research and development, we are driving electronics recycling forward. One of the unique recycling methods we have designed in recent years is for LCD ...

The Stena Metall Group is involved in metal recycling, paper recycling, electronics recycling, hazardous waste recycling and chemicals recycling. Stena Metall Groupd is a leader in recycling and environmental services in the Nordic region and a ...

CCL was established in 2000 to meet the increasing demand to securely dispose of recycle and reuse computer and IT equipment. We specialise in various aspects of the recycling and secure environmental disposal of old and unwanted electronic ...

CCL was established in 2000 to meet the increasing demand to securely dispose of recycle and reuse computer and IT equipment. We specialise in various aspects of the recycling and secure environmental disposal of old and unwanted electronic ...

URT Umwelt- und Recyclingtechnik GmbH was founded in 1995 by the owners and managing directors Peter Heßler and Thomas Gundersdorf. The business field of URT includes the engineering, sales and service of recycling plants for electrical and ...

URT Umwelt- und Recyclingtechnik GmbH was founded in 1995 by the owners and managing directors Peter Heßler and Thomas Gundersdorf. The business field of URT includes the engineering, sales and service of recycling plants for electrical and ...

STS Electronic Recycling, Inc., "The Power of Electronics Recycling." At STS Electronic Recycling, we are leading the way to a green, safe future. By offering a full service computer and electronic equipment recycling service, we are leading the ...

STS Electronic Recycling, Inc., "The Power of Electronics Recycling." At STS Electronic Recycling, we are leading the way to a green, safe future. By offering a full service computer and electronic equipment recycling service, we are leading the ...

Saperatec is an innovative technology solutions provider for high-value recycling. The company has developed and markets a patented technology to split up waste composite materials into valuable secondary raw materials. saperatec thereby bridges the ...

Saperatec is an innovative technology solutions provider for high-value recycling. The company has developed and markets a patented technology to split up waste composite materials into valuable secondary raw materials. saperatec thereby bridges the ...

Founded in 2011, Chengdu Taichang Technology Co.,Ltd ( Originally called Chengdu Jinxingtai Machiney Co.,Ltd )is a professional manufacturer of WEEE (Waste Electrical and Electronic Equipment)recycling equipment, including TV (both CRT and LED) , ...

Founded in 2011, Chengdu Taichang Technology Co.,Ltd ( Originally called Chengdu Jinxingtai Machiney Co.,Ltd )is a professional manufacturer of WEEE (Waste Electrical and Electronic Equipment)recycling equipment, including TV (both CRT and LED) , ...

Environmental Computer Recycling are an IT & Computer Recycling / WEEE Recycling & Disposal company who are based in Birmingham in the UK. Our integrity lies in making sure that your old computer equipment and other IT electrical equipment is not ...

Environmental Computer Recycling are an IT & Computer Recycling / WEEE Recycling & Disposal company who are based in Birmingham in the UK. Our integrity lies in making sure that your old computer equipment and other IT electrical equipment is not ...

Evciler has been in refining of precious metals found in specific types of waste. With this well-built experience, Evciler is a licensed electronic waste (e-waste) recycling company for over a decade; dedicated to responsibly eliminate and dispose ...

Evciler has been in refining of precious metals found in specific types of waste. With this well-built experience, Evciler is a licensed electronic waste (e-waste) recycling company for over a decade; dedicated to responsibly eliminate and dispose ...

Ad Rem is a company that is specialized in the research, design, engineering and construction of machinery for the recycling-, mineral- and food-processing industry. These machines rely on a wide range of different technologies. Ad Rem has strong ...

LCD screens are a typical example of electronics which have not been designed with recycling in mind. Most LCD screens which are now end of life use mercury lamps as a backlight for the screen. ...

Ad Rem is a company that is specialized in the research, design, engineering and construction of machinery for the recycling-, mineral- and food-processing industry. These machines rely on a wide range of different technologies. Ad Rem has strong ...

Our recycling plant and production activities have acquired the ISO 14000 recycling certification and advanced recycling technology and process. We desire to protect our precious Earth and preserve an affluent environment for the next generations.

We have specialized processes and facilities for recycling scrapped electronic/electric products (LCD/CRT TVs, monitors, refrigerators, cell phones, washing machines, air conditioners, microwave ovens, OA equipment, and other small home appliances)

•Recycling process: After the dismantling process of electronic/electric scrapped products, our factory is recycling plastics (resin), metals, copper, aluminum, gold, silver, and other rare earth metals.

It might come off as a surprise but about 98% of an LCD/monitor can be recycled to extract useful material including plastic, copper, and other metals. The plastic removed from an LCD monitor is used for manufacturing new products while the circuit boards are smelted to extract metals. The wiring in the monitor can also be stripped to extract copper and rubber. All these materials can be recycled instead of getting wasted and polluting the environment. Moreover, some LCDs and monitors can be refurbished to be used again by extending their lifecycle. Only an expert in electronic recycling can do this through a meticulous process. Trust our team at Hummingbird International to do this for you, be it commercial waste disposal or residential ewaste disposal.

Dr Lisa O’Donoghue is resourceful, level-headed and driven, especially when it comes to electronics recycling. Her company Votechnik, a spin-off inspired by her work as a materials scientist at Ireland’s University of Limerick, celebrated its tenth anniversary this June. The business created a patented solution to a modern-day problem: how to deal with discarded liquid crystal displays (LCDs). We’re catching up with her to discuss how far she’s come.

‘In Ireland, the e-scrap recycling sector is in general pretty good, being heavily regulated. There are good collection rates for waste electronics in terms of kg per capita, which are then filtered to a handful of specialist electronics recyclers in the country which process everything to a very high standard. The EU is leading the way with good examples such as the European Raw Materials Alliance, the European Batteries Alliance, the Circular Plastics Alliance and the WEEELABEX guidelines. The last allows industry players to self-implement a requirement for high standards and not solely depend on national legislation.’

‘Getting alignment across the value chain from the producers, manufacturers, transportation sector, consumers, compliance schemes, recyclers and regulators. Each participant has a different objective. The typical route towards growth for any business is to simply do more and that means either selling more or recycling more. The hard fact is that both ends of this value chain depend on customers consuming! The real question is how do you, in the words of the European Green Deal, “uncouple economic growth from resource use”.’

‘An estimated 200 million TVs and 120 million computer monitors are sold globally in a year. Double monitor viewing screens and home office set-ups are the norm now due to the pandemic, further boosting sales. The concerning aspect regarding LCDs is the hazardous materials they can contain, particularly the mercury-containing fluorescent tubes and liquid crystals. And that’s where Votechnik comes in; we have focused our efforts on creating automated plants to depollute flatscreens.’

‘It all started with the prototype in 2011. ALR1000 was rudimentary with open access blades to cut off the liquid crystal panel and a chain system to smash up the CCFL tubes for removal. For the second generation machine, the entire process was encapsulated within the machine with specialised air filtration for the mercury. It allowed sequential processing of different size LCDs. The ALR3000 (photo left) took another massive leap forward where we decided to use robotics to lift the LCD as lightly as a feather. The latest version, the ALR4000 (photo bottom), has levelled up again with enhanced functionality now processing 60+ LCD, LED and PC monitors per hour. Thanks to our collaborations with KUKA robotics and Siemens, I believe this machine represents the future of LCD recycling.’

‘The volumes of LCDs arriving at recycling facilities have increased significantly over the last ten years. While many recyclers were able to keep up with manual disassembly for a period, it has become a lot more difficult. The only exception is countries where manual labour is cheap.

‘We need producers and the media to develop and drive a desire for different products that are compatible with the circular economy. We are seeing flatscreen design move away from LCD displays and towards LED displays. These have the same structure using liquid crystal but the backlighting is now a light emitting diode. These are much easier to recycle. Better yet, some brands have asked us to help them assess the compatibility of their products and displays with our automated recycling process.’

‘Every time I stand in front of one of our new LCD recycling machines, welcoming it into the world, there is a moment of awe. Our latest ALR4000 machine, which stands five metres tall and 12 metres wide and has futuristic white armour, Is not just a cutting-edge piece of engineering, it’s a piece of art. The most recent development that means a lot to me personally is taking up a position on the European Commission’s Operational Expert Group for Raw Materials. It gives me the opportunity to take a stand, share my expertise and help make a difference so we may have a better future.’

Industrial Technology Research Institute (ITRI) recieved a 2017 R&D 100 Award as well as a Merit in the Special Recognition: Green Tech category for the LCD Waste Recycling System. They were presented both awards at The R&D 100 Awards Gala held in Orlando, Florida on Nov. 17, 2017. See the full list of 2017 R&D 100 Award Winners here.

With more and more electronics in the home and the car featuring liquid-crystal display (LCD) screens, reducing the environmental impact once the devices are no longer used is crucial moving forward.

Research has repeatedly shown the harmfulness of the liquid crystal, indium and other heavy metals which LCD panels contain, but currently there is no suitable model for recycling these panels

Researchers from the Industrial Technology Research Institute (ITRI) are working to change that, developing a new LCD Waste Recycling System that is cost-effective, does not produce any waste and will allow manufacturers to save and reuse some of the valuable heavy metals used to create LCD panels. ITRI received a 2017 R&D 100 Award for the technology at the R&D 100 Awards Gala held in Orlando, Florida on Nov. 17, 2017. At the same event, ITRI also received a Merit in the Special Recognition: Green Tech category for its LCD Waste Recycling System.

“LCD panels, which are only a few millimeters thick, contain over ten kinds of materials, making their disposal and recycling especially difficult,” Chien-Wei said. “We thoroughly analyzed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material, first separating liquid crystal, indium, and glass, and then developing purification technology for each material which enables the reuse of these materials.”

The method begins with a panel-smashing system that shatters the LCD panel, exposing the liquid crystal. The separated LCD panel then enters the continuous liquid crystal extraction system and an agent that can be used on multiple cycles extracts the liquid crystal. The liquid crystal is exposed on the surface of the glass substrate, enabling the system to shorten the processing time by integrating the extraction and purification functions.

The impurity is removed by a salt adsorption method. After the liquid crystal has been removed, the panel fragments enter the indium extraction system and an agent is used repeatedly as a scrub to enable the removal of the indium from the panel fragment.

Extracting liquid crystal from waste LCD panel achieves a nearly 100 percent liquid crystal recovery rate and a 90 percent recovery rate of indium. The process could reduce the production of new liquid crystal, lessening the environmental impact.

“Treating waste LCD panels with this system can transform the panels’ material [liquid crystals, indium, and glass] into valuable, reusable products, not only increasing profits but effectively reducing the production of waste material,” Chien-Wei said.

“The liquid crystals with halogen-substituted aromatics are designed and synthesized for LCD,” Chein-Wei said. “Their production process and their final disposal both cause severe health and environmental impacts. However, people cannot get this information.

“Waste LCD panels are generally disposed of in landfills or by incineration in most countries, due to lack of proper environmental regulation. Without strict environmental regulation, it is difficult to promote new disposal method.”

Current treatment technologies disassemble LCD devices into multiple components and recycle them according to their materials. However, there is no model for treating LCD panels.

To physically process the panels, the panels must be broken down and then added to cement or concrete, which does not remove liquid crystals, indium, tin and molybdenum from the panels. Therefore, the liquid crystals and heavy metals could still enter the environment following rain or washing.

This has led to an increasing number of countries, including Hong Kong and China, to label LCD panels as hazardous waste. This requires future processing of LCD panel waste to be buried on-site, burnt or physically disposed, which increases both the processing costs and the environmental damage.

To test the new technology, ITRI has built a pilot plant that can treat three tons of LCD panel waste per day, producing three kilograms of liquid crystal, 750 grams of indium, and about 2550 kilograms of glass, which can be reused as green construction material or heavy-metal adsorption material.

Contact electronic recycling companies with your list in hand. You’ll want to find a company that is set up to handle everything, including LCD monitor or LCD TV recycling and pick-up from multiple locations, if required.

Be prepared to wrap and palletize your inventory based on the electronics recycling company’s specifications. Some companies will provide this service.

Expect a variety of bids on the value of your equipment. Some companies are recycling for parts or metals. Responsible recycling practices advocate recycling for resale. Companies that are recycling for resale will typically pay more for your LCD monitor-LCD TV recycling than will a company that wants to tear it apart and toss the rest.

Choose your electronics recycling company based on the services and the convenience, but remember that your equipment has value, so get the most for the equipment possible by working with a reputable company with a long history of responsible recycling.

Boggio B, Wheelock C (2009) Executive summary: Electronics recycling and E-waste issues recycling and responsible disposal of consumer electronics, computer equipment, mobile phones, and other E-waste. Pike Research LLC, Boulder

Felix J, Letcher W, Tunell H, Ranerup K, Retegan T, Lundholm G (2010) Recycling and re-use of LCD components and materials. SID Symp Dig Techn Pap 41(1):1469–1472

Kim Y-J, Qureshi TI (2006) Recycling of calcium fluoride sludge as additive in the solidification-stabilization of fly ash. J Environ Eng Sci 5(5):377–381

Lei C-N, Whang L-M, Chen P-C (2010) Biological treatment of thin-film transistor liquid crystal display (TFT-LCD) wastewater using aerobic and anoxic/oxic sequencing batch reactors. Chemosphere 81:57–64

Lin K-L, Chang W-K, Chang T-C, Lee C-W, Lin C-H (2009) Recycling thin film transistor liquid crystal display (TFT-LCD) waste glass produced as glass-ceramics. J Cleaner Prod 17:1499–1503

Liu WT, Li KC (2010) Application of reutilisation technology to waste from liquid crystal display (LCD) industry. J Environ Sci Health Part A 45:579–586

Lo S-F (2010) Global warming action of Taiwan’s semiconductor/TFT-LCD industries: how does voluntary agreement work in the IT industry? Technol Soc 32(3):249–254

Martin R, Simon-Hettich B, Becker W (2004) New EU Legislation (WEEE) compliant recovery processes for LCDs. IDW 04 Proceedings of the 11th IDW: 583–586. http://www.lcdtvassociation.org/images/Proceeding_New_EU_Legislation_WEEE_Compliant_Recovery_Processes_for_LCDs-Merck_September_2008n.pdf. Accessed 10 Nov 2015

Matharu AS, Wu Y (2008) Liquid crystal displays: from devices to recycling. In: Hester RE, Harrison RM (eds) Electronic waste management, issues in environmental science and technology. RSC Publishing, Cambridge

Nakamichi M, Kokai Jpn. Tokkyo Koho JP 2005 227,508 (Cl. GO2F1/13), 25 Aug 2005, Appl. 2004/35,597, 12 Feb 2004. Decomposition method and apparatus for liquid crystals in recycling of liquid crystal panels. CAN: 143: 219606g

Parthasarathy P, Bulbule KA, Anantha Murthy KS (2008) E-waste recycling – best option for resource recovery and sustainable environment. Res J Chem Environ 12(1):93–98

Schluep M, Hagelueken C, Kuehr R, Magalini F, Maurer C, Meskers C, Mueller E, Wang F (2009) Sustainable innovation and technology transfer industrial sector studies: recycling from E-waste to resources. United Nations Environment Programme and United Nations University, Nairobi

Wang HY (2011) The effect of the proportion of thin film transistor-liquid crystal display (TFT-LCD) optical waste glass as a partial substitute for cement in cement mortar. Construct Build Mater 25:791–797

You S-H, Tsai Y-T (2010) Using intermittent ozonation to remove fouling of ultrafiltration membrane in effluent recovery during TFT-LCD Manufacturing. J Taiwan Inst Chem Eng 41:98–104

Environmental problem turns one of the most important issue in the world. Recently, more and more people concerned about environment and their health. Especially, waste management and resources recycling issues are important problems equal to global warming, disruption of ecosystem and other problems. The markets of electric appliances and electronics devices are highly developing, therefore wastes from those items are supposed to be rapidly increasing. Rapid rise of industrial production leads to growing demand of resources, so securing of resources is very important for manufacturer in the future. So there are strong needs to recover and recycling of resources from used products and waste from materials. Thanks for its advantages such as “flat screen”, “lightweight”, and “low power consumption”, LCD panels are utilized in many final products such as LCD TV, mobile phone etc. And the production of final products with LCD are growing rapidly, too. Therefore, in the recycling technology of LCD panels, we should focus on how we collect the materials from LCD panel effectively. Especially, indium is very important. Because indium is a one of rare metal, and essential materials for transparent electrode of LCD panel. To avoid the shortages of indium for LCD production in near future, securing indium resources is important for LCD panel manufacturers. We are developing technologies that work to recover indium resources from LCD panels.

In particular, the simple and energy-saving ion exchange method is proving to be effective approach. We have constructed demonstration equipment that can process 240kg of waste LCD panels per day. We have achieved a recovery rate of 94%, using glasses discarded from LCD panel manufacturing plant.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey