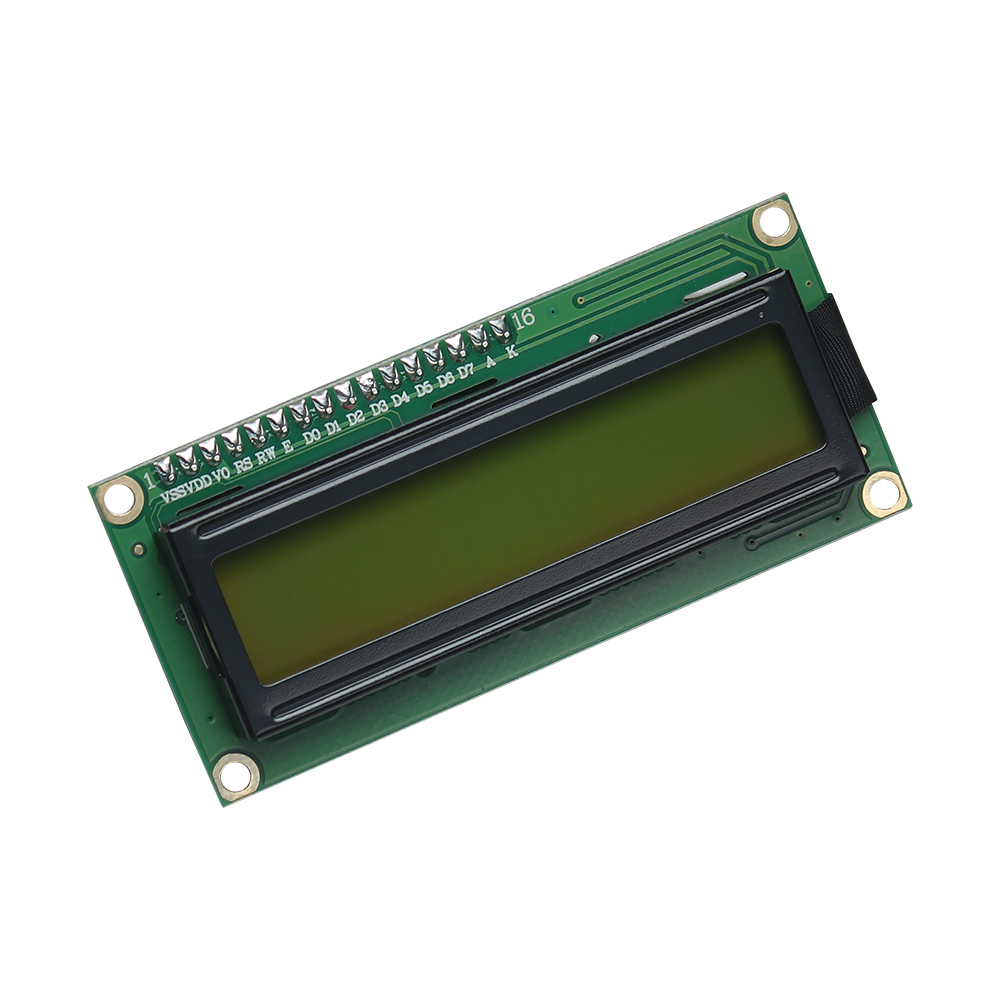

parallax lcd display made in china

The Parallax Serial LCDs (liquid crystal displays) can be easily connected to and controlled by a microcontroller using a simple serial protocol sent from a single I/O pin. The LCD displays provide basic text wrapping so that your text looks correct on the display. Full control over all of their advanced LCD features allows you to move the cursor anywhere on the display with a single instruction and turn the display on and off in any configuration. They support visible ASCII characters Dec 32-127). In addition, you may define up to eight of your own custom characters to display anywhere on the LCD. An onboard piezospeaker provides audible output, with full control over tone note, scale and duration using ASCII characters Dec 208–232.

The LCDs currently for sale are updated to Revision F. Basic functionality remains the same, but power requirements and the layout of the backpack have changed. Please see the documentation for information on your model.

This device can be connected to a PC serial port using a MAX232 line driver. The circuit isn’t supported by Parallax, but it’s possible to make this connection with a few extra parts.

The Parallax Serial LCDs (liquid crystal displays) can be easily connected to and controlled by a microcontroller using a simple serial protocol sent from a single I/O pin. The LCD displays provide basic text wrapping so that your text looks correct on the display. Full control over all of their advanced LCD features allows you to move the cursor anywhere on the display with a single instruction and turn the display on and off in any configuration. They support visible ASCII characters Dec 32-127). In addition, you may define up to eight of your own custom characters to display anywhere on the LCD. An onboard piezospeaker provides audible output, with full control over tone note, scale and duration using ASCII characters Dec 208–232.

The LCDs currently for sale are updated to Revision F. Basic functionality remains the same, but power requirements and the layout of the backpack have changed. Please see the documentation for information on your model.

This device can be connected to a PC serial port using a MAX232 line driver. The circuit isn’t supported by Parallax, but it’s possible to make this connection with a few extra parts.

Wearing special glasses to watch 3D video is inconvenient for many people and especially those who wear glasses for the correction of eyesight. Moreover, wearing glasses is not natural for applications such as role-playing games, virtual reality, and mobile displays. Therefore, high-quality ‘autostereoscopic’ displays (i.e., that do not require glasses) are desirable. An autostereoscopic display projects different images of the same object onto the left and right eyes through independent spatial channels. Conventional autostereoscopic displays include ‘lenticular’ and ‘parallax barrier’ (PB) displays. Lenticular 3D displays use a cylindrical lenticular lens to direct diffuse light from an individual pixel so it can only be seen in a limited angle in front of the display. This then allows different images to be directed to the viewer"s left or right eye. Existing PB display designs use a barrier in front of a screen such as an LCD display. Slits in the barrier separate left and right images displayed interlaced on the screen, and send them into left and right eyes of the viewer, respectively (see Figure 1). However, the inherent structure of conventional autostereoscopic displays, such as PB or lenticular 3D displays, requires the viewer to remain in a position such that each eye is in the appropriate viewing zone; if they do not, ‘crosstalk’ between adjacent viewing zones mean that each eye will see both left and right images simultaneously (see the example of the inset pair of eyes in Figure 1).

To overcome this, researchers have previously proposed a ‘dynamic’ (moving) PB with segmented slits,1 or a dual-stacked LCD display.2 A dynamic PB with segmented slits divides a conventional parallax barrier slit into several segments, where electrical switches control the tiny moving parallax barrier (see Figure 2). However, light leaks between slit segments and degrades the image. A dual-stacked LCD display is constructed by stacking multiple layers of liquid crystal, and its displayed images are changed according to the viewer"s position. It is necessary to improve the low brightness, low effective resolution, and barrier line visibility with this design.

Figure 1. Viewing zones for a conventional single-layer parallax barrier. When viewers have their left eyes in a red zone and their right eyes wholly in a blue zone, they will see a good 3D image. If, however, their eyes are in the position of the inset pair of eyes, each eye will simultaneously see the left and right images.

Recently, we demonstrated a novel advanced autostereoscopic 3D display, which we have named the dual-layer parallax barrier (DLPB). It can shift the position of the viewing zones without heavily increasing the viewing distance by combining a dual PB, dual pairs of indium tin oxide (ITO), and a liquid crystal (LC). In addition to providing dynamic viewing zones, the DLPB"s independent ITO pairs sandwich a common LC, which reduces its thickness. Moreover, when connected to a head tracking system, it provides a smooth transition of 3D depth feeling as the viewer changes position (Figure 2).

Figure 2. White light pattern images operated by the first and the second parallax barrier (PB) layers (a) the first PB layer (b) the second PB layer. ITO: Indium tin oxide. TN-LC: Twisted nematic liquid crystal.

We used the commercially available thin-film transistor liquid crystal display (TFT-LCD) LMS480KF01 made by Samsung. It is 4.8" across, and has a pixel pitch of 0.12975mm and a resolution of 800×480. The block width and the slit width of each PB layer are 0.17262mm and 0.08632mm, respectively. The distances between each PB layer and TFT-LCD are 0.863mm and 0.007mm. Finally, the offset displacement between the two PB layers is 0.06474mm. Compared to conventional PB displays, the increase in thickness of the DLPB display from adding two ITO layers and two insulator layers is only 0.007mm, which is reasonable for commercialization.

The DLPB method is able to change the position of the aperture in a twisted nematic LC (TN-LC) display by controlling the polarization of light. Our method applies a voltage to one of the pairs of ITO. This sets up a local electric field in the TN-LC and, as a result, twists the polarization of vertically polarized light from a TFT-LCD panel so that it is horizontally polarized and can pass through a horizontal polarizer (see Figure 2). This determines which path is taken by light from the display and shifts the light emerging from the DLPB such that the positions of the viewing zones are moved when the second (rather than the first) PB is switched on (see Figure 3).

Figure 5.Block diagram of the prototype of the dual-layer parallax barrier (DLPB) system. The viewing zone numbers refer to four cases for the interlacing order and the choice of PB: #1 is PB1 and left image first; #2 is PB2 and left image first; #3 is PB1 and right layer first; and #4 is PB2 and right layer first, for a seven-position setup.

We have also designed a DLPB system prototype that includes a video camera and a laptop-based head-tracker. The video camera captures images that are analyzed by the laptop to calculate the viewer"s position, and then it optimizes the viewing zones for that location in real time. This is done by selecting the order in which to interlace the images shown on the display (left first or right first) and which PB to turn on. In addition to optimizing the viewing zones, it is possible to select the images so that the angle of view matches that of the viewer (see Figure 4). Our prototype has a total of seven viewing positions, 44 images viewed from separate angles with 800×480 resolution, and a horizontal field of view of 29.394° (see Figure 5). The threshold values of the boundaries between viewing zones (according to the different beam forming states) are −14.697°, −10.611°, −6.413°, −2.146°, 2.146°, 6.413°, 10.611°, and 14.697°, respectively.

In summary, we have developed a novel autostereoscopic display system that provides dynamic viewing zones with a reasonable display thickness to provide seamless stereoscopic views without abrupt change of 3D depth feeling at any eye position. This system can be applied to mobile devices, such as portable multimedia players, smartphones, and cellular phones. We have also extended it to multi-view 3D video services that provide different view images to match the viewer"s position as he or she moves. These services include role-playing games, simulation games, and virtual reality.

Our proposed DLPB method, however, is limited by having only two beam-forming states. The more beam-forming states there are, the more viewing zones we can control, and the greater the degree of freedom the display provides. Currently, the need to track the position of the viewer means that our DLPB system operates for only a single viewer. In our future work, we plan to implement an ‘advanced dual layer parallax barrier’ method that uses a virtual PB layer to increase the number of beam-forming states without any structural changes to the current DLPB structure. We hope to extend it to a multi-viewer environment in the near future.

1. S. Yi, H. Chae, S. Lee, Moving parallax barrier design for eye-tracking auto-stereoscopic displays, Proc. 3DTV Conf.: the True Vision—Capture, Transm. Display 3D Video, pp. 165-168, 2008. doi:10.1109/3DTV.2008.4547834

2. T. Peterka, R. L. Kooima, D. J. Sandin, A. Johnson, J. Leigh, T. A. DeFanti, Advances in the dynallax solid-state dynamic parallax barrier auto-stereoscopic visualization display system, IEEE Trans. Visualiz. Comput. Graph. 14, no. 3, pp. 487-499, 2008. doi:10.1109/TVCG.2007.70627

Below, an embodiment of the invention are described as follows according to Fig. 1~Fig. 6.In the following description, as multi-display device of the present invention, be that example describes with the liquid crystal indicator.

At first, the general configuration with the liquid crystal indicator 1 of present embodiment is shown in Fig. 2.As shown in Figure 2, liquid crystal indicator 1 roughly comprises display panel 10, disparity barrier 20 and backlight 30.

Backlight 30 comprise light source 31 and reflecting part 32, and the light that shines from light source 31 is reflected by reflecting part 32, thus, light are shone to display panel 10.As light source 31, can use for example LED (light emitting diode; Light emitting diode), cold-cathode tube (CCFT; ColdCathode Fluorescent Tube) or cold cathode type fluorescent lamp (CCFL; Cold CathodeFluorescent Lump).

Display panel 10 is at the TFT of relatively configuration (Thin Film Transistor: substrate 11 and CF (Color Filter: colored filter) liquid crystal layer 13 that clamping is made of nematic liquid crystal between the substrate 12 and the display panels of the active array type that forms thin film transistor (TFT)).

On TFT substrate 11, a plurality of scan signal lines that are provided with a plurality of data signal lines and intersect with each data signal line respectively, each combination at these data signal lines and scan signal line is provided with pixel.Above-mentioned each pixel, as shown in Figure 2, along the bearing of trend of data signal line (not shown), to the left image shows that (image to the left side of display device shows) pixel column L of usefulness shows that with image to the right the pixel column R of (image to the right side of display device shows) usefulness alternately disposes.In addition, in liquid crystal indicator 1, the thickness of TFT substrate 11 is 700 μ m.

Disparity barrier 20 is made of barrier glass 21 and barrier light shield layer 22.As barrier glass 21, the clear glass of used thickness 0.7mm.In addition, barrier light shield layer 22 forms by on barrier glass 21 metal level or resin bed being carried out patterning.Display surface side (side opposite with backlight 30) at barrier glass 21 is provided with Polarizer 23.

In addition, each row of barrier light shield layer 22 are provided with in the mode corresponding with each pixel column of display panel 10.That is to say that each row of barrier light shield layer 22 are arranged to: the part of the light that will penetrate from each pixel column of display panel 10 covers, and makes not observe from the display direction direction in addition of each pixel column.

Therefore, for example as shown in Figure 3, liquid crystal indicator 1 is being used as under the situation of on-vehicle display, with regard to the pixel column R that the driver"s seat side is used, can observe from the driver"s seat side, but not observe from the co-pilot seat side, and, with regard to the pixel column L that the co-pilot seat side is used, can observe from the co-pilot seat side, but not observe from the driver"s seat side.Thus, in liquid crystal indicator 1, can show different images with the co-pilot seat side in the driver"s seat side.

Disparity barrier 20 and display panel 10 are bonding by the bonding coat certain interval of 41 maintenances.Bonding coat 41 forms on whole of the opposite face of disparity barrier 20 and display panel 10.That is to say that disparity barrier 20 is bonding by whole with display panel 10.As bonding coat 41, use the bonding agent (for example ultraviolet curable resin) of light-cured type.In addition, in liquid crystal indicator 1, the thickness of bonding coat 41 (interval of barrier glass 21 and CF substrate 12) is 40 μ m.In addition, bonding coat 41 preferably uses the flexible material that also has to a certain degree after curing.

In addition, in order suitably to show each image in right side and the left side been separated in liquid crystal indicator 1, need accurately carry out the location (aligning) of disparity barrier 20 and display panel 10.Therefore, telltale mark is set on both preferably, uses that this telltale mark positions etc., to carry out accurate localization.

When making the multi-display device of present embodiment, photo-mask process is used in the formation of the formation of the pixel of display panel and the light shield layer of disparity barrier.In order to carry out this photo-mask process, the mask that needs pattern exposure to use.

In the multi-display device of present embodiment, even in whole image in order to make for observer"s visuality, in other words, in order to obtain the viewing angle characteristic shown in Figure 10 (b), be set at the barrier spacing of disparity barrier slightly littler than the pel spacing of display panel.In addition, in this case, on the mask that in photo-mask process, uses, also carry out mask design in the little mode of the above-mentioned pel spacing of above-mentioned barrier gap ratio.In addition, the barrier spacing on the mask is meant the spacing of the slit that forms on mask.

For example, be 99.99 if display panel is made the barrier spacing that the pel spacing of the mask of usefulness is 100, disparity barrier is made the mask of usefulness, then the disparity barrier aforementioned mask of making usefulness requires 0.01 precision.Relative therewith, be 0.5 if utilize present liquid crystal to describe the precision of describing that technology can reach with mask, even then in the mask design stage barrier spacing is set at 99.99, the barrier spacing of the actual mask that produces is 100 or 99.5.

Thus, in the multi-display device that the disparity barrier that will produce according to the method for present embodiment and display panel combination form, can make in the ratio (being applied to the example of Fig. 1, is 99.99: 100) of the expectation mode different according to the average barrier spacing of disparity barrier with the pel spacing that shows barrier.

Therefore, in the multi-display device of present embodiment, shown in Figure 10 (b), can make the visual angle of controlling by disparity barrier in each display position difference, thereby the display light that optimum visibility is provided is assembled on the direction of imaginary observation place.That is, can make the visuality for the observer even in whole image.

In addition, multi-display device of the present invention is not limited to the liquid crystal indicator of above-mentioned explanation, as with the display panel of disparity barrier combination, except display panels, also can use PDP panel or organic EL panel.

In addition, multi-display device of the present invention, be the video generation device of the matrix type by will generating display image and the multi-display device that above-mentioned disparity barrier is fitted and formed, the average headway of above-mentioned disparity barrier is set to the size different with the pel spacing of above-mentioned video generation device.

Thus, in the disparity barrier that in multi-display device, uses, can there be the mask of the limit to describe the disparity barrier that the technology manufacturing can improve the visuality of whole image by service precision.

In light field display methods, it is empirically known that 3D images with a favourable motion parallax can be obtained by setting angle interval of light rays to less than 1°

To realise the diffusing screen with the narrow diffusion angle of approximately 1.0° and top-hat diffusion characteristics, we developed a special 3D screen whose surface is finely fabricated in micro-lens shapes. The configuration of the screen is shown in Fig. 2a. The lens structure, with a fine lens size smaller than the pixel size of the multi-view images projected onto the screen (under 500 μm), was fabricated in a two-dimensional array shape. The shape of one lens was hexagonal so that the diffusion angles were almost uniform in all directions and non-lens part was not formed. Further, the lens size was set to be 170 μm, such that the resolution of the displayed images is not reduced while restricting the generation of diffracted light rays with large diffraction angles. When a parallel light ray is incident on the 3D screen, widening of the light occurs according to the numerical aperture of the lens. Control of the light widening angle must be adjusted and optimised according to the angle interval between light rays in the display optical system. In the fabrication of the 3D screen, first, we manufacture a metal mould of hexagonal lens shape by an etching process; the metal mould is filled with a UV-curable resin and the lenses are formed by curing. Next, the formed resin of the lens array is filled with UV-curable resin made of another material with a different refractive index and is cured (Fig. 2b). The widening angle θ of the screen is given as follows:

where n1 and n2 are the refractive indices of the lens and filling materials, respectively; r is the lens diameter; and R is the curvature radius of the lens. Finally, the widening angle of the light is controlled to the optimal value according to the display system by selecting curable resin materials for the lenses and their fillings to adjust the difference in refractive index Δn. In our prototype system, we set the refractive indices of the lenses n1 and their fillings n2 to 1.60 and 1.50, respectively, the screen size to 488 mm × 274 mm, and lens size to 170 μm (Fig. 2b). Figure 2c shows the measurement results of the diffusion characteristics when white parallel light was incident on the screen. Diffusion characteristics close to a top-hat shape with a narrow diffusion angle and a full width at half maximum (FWHM) of approximately 1.0° were realised. The 3D screen widens light rays not by the diffraction effects but because of the refraction of the lenses. Therefore, the chromatic dispersion is low compared with holographic optical elements, and speckle noise is not observed.

Figure 3a shows the top view of the display optical system. In this method, image information consisting of a large number of pixels is necessary to reproduce many light rays and to reconstruct an ideal optical image. This is because each pixel of multi-view image corresponds to one light ray. Therefore, in the development of the prototype system, we reproduced numerous light rays by implementing multiple ultra-high definition (UHD) projectors. As shown in Fig. 3a, multiple projectors are placed in parallel, and each projector directly projects multi-view images consisting of 25 viewpoints (5 horizontal and 5 vertical). All multi-view images are projected without gaps by placing the projectors close to each other. Each multi-view image is enlarged and projected onto the 3D screen by the imaging lens and condenser lens. In Fig. 3a, the projection angle interval φ of the multi-view images is given by the following equation:

Prototype display system. (a), Configuration of the prototype display system. Multi-view images are incident on the imaging lens as parallel light and projected onto the 3D screen in a superposed manner at different angles while being enlarged. (b), Photograph of the prototype display system. By projecting multi-view images consisting of 350 viewpoints with 14 4K projectors, an optical 3D image is reconstructed by over 100,000,000 light rays. Photo credits: Masanori Kano and Hayato Watanabe.

where fb is the focal length of condenser lens 2 and fb is set to fb ≤ fa. The longer the focal length fb, the longer the distance L. When fa is equivalent to fb, parallel light rays are reproduced, which are geometric-optically the same as light rays reproduced with an ordinary integral imaging method. From an arbitrary point on the 3D screen, light rays were emitted in both horizontal and vertical directions at narrow angle intervals, represented by Eq. (2). Consequently, high-density light rays were emitted from the entire screen, and they formed an optical 3D image in front of and behind the 3D screen, unlike the conventional display methods based on multi-view projection

Figure 3b show the prototype system. We adopted a configuration in which light rays are returned by mirrors placed at two positions. Dedicated compact projectors with full 4K resolution were developed as display devices, and 14 such projectors were placed in parallel. One projector displayed multi-view images consisting of 25 viewpoints, 5 horizontal and 5 vertical, with a resolution of 768 × 432 pixels. By using 14 projectors to project multi-view images consisting of a total of 350 viewpoints onto the 3D screen at angle intervals of less than 0.93°, high-density light fields were reconstructed with over 100,000,000 light rays. The horizontal viewing angle was enlarged by projecting 40 multi-view images in the horizontal direction.

To verify the spatial resolution characteristics of the 3D images perceived by the viewer, we displayed a wedge chart and captured the display screen directly using a digital camera placed at a position of 1500 mm, which is the distance from the 3D screen to the widest effective viewing area L of the prototype system (Fig. 4a). The display position of the wedge chart was five steps, from 200 mm in the rear direction to 200 mm in the front direction with reference to the position of the 3D screen. The modulation factor of the wedge chart was reduced according to the increase in the spatial frequency of the pattern, and folding distortion occurred when 2.10 lines/mm, which is the upper limit of resolution, was exceeded. The cause of the modulation factor degradation is thought to be the aberration of lenses constituting the display optical system and the limit of condensing performance of the Fresnel lens used as condenser lens 1. In contrast, the spatial resolution characteristics of the captured 3D image did not significantly depend on the depth position of the 3D image. This result shows that the viewers can perceive 3D images with wide depth ranges. In Aktina Vision, multi-view images are condensed at the widest effective viewing area as shown in Fig. 4a. When observing the display screen from this area, the spatial resolution of 3D images perceived by the viewer is the same as that of multi-view images

Displayed 3D images. (a), Displayed 3D images of a resolution chart. A resolution limit of 2.10 lines/mm, where folding distortion occurred, could be displayed. Even in the depth range of ±200 mm, resolution characteristics did not decrease significantly. This result show that viewers can observe 3D images with wide depth ranges. (b), 3D image of CG observed from different viewpoints. Motion parallax was confirmed by the change in the positional relation between the heart and blood vessels. The viewing angle is 35.1° in the horizontal direction and 4.7° in the vertical direction, and simultaneous viewing by multiple viewers is possible. (c), Projected images of reproduced light rays on the diffuser film. When the diffuser film was set at 30 mm and 100 mm in front of the 3D screen, the pink mascot character and blue rabbit, respectively, were projected clearly. This result shows that an optical image of objects can be reconstructed with Aktina Vision. Photo credits: Hayato Watanabe.

Next, Fig. 4b illustrates a 3D image observed from different viewpoints when displaying 3D images of computer graphics (CGs). The occurrence of motion parallax in both the horizontal and vertical directions according to the observation position was confirmed by the change in the positional relation, such as between the heart and blood vessels. The side of the heart could be viewed while moving. Additionally, the front and rear positional relations could be recognised by the viewer in any posture because binocular parallax was also obtained when viewers leaned their heads. The viewing angle was 35.1° in the horizontal direction and 4.7° in the vertical direction, and simultaneous viewing by multiple viewers was possible. A video of the displayed 3D image is provided in the Supplementary Information.

Finally, as shown in Fig. 4c, we displayed a 3D image of real objects and confirmed the image-formation position by setting the diffuser film. When the diffuser film was set 30 mm in front of the 3D screen, the face of the pink mascot character was clearly projected onto the diffuser film. Next, when the diffuser film was moved to 100 mm in front of the 3D screen, the blue rabbit was clearly projected. In this manner, with the proposed method, the formation of the optical images of objects in the depth direction was confirmed. Owing to this feature, 3D images without distortion could be observed independent of the viewing distance and viewer’s posture. A video related to this experimental result is provided in the Supplementary Information.

The autostereoscopic display is a promising way towards three-dimensional-display technology since it allows humans to perceive stereoscopic images with naked eyes. However, it faces great challenges from low resolution, narrow viewing angle, ghost images, eye strain, and fatigue. Nowadays, the prevalent liquid crystal display (LCD), the organic light-emitting diode (OLED), and the emerging micro light-emitting diode (Micro-LED) offer more powerful tools to tackle these challenges. First, we comprehensively review various implementations of autostereoscopic displays. Second, based on LCD, OLED, and Micro-LED, their pros and cons for the implementation of autostereoscopic displays are compared. Lastly, several novel implementations of autostereoscopic displays with Micro-LED are proposed: a Micro-LED light-stripe backlight with an LCD, a high-resolution Micro-LED display with a micro-lens array or a high-speed scanning barrier/deflector, and a transparent floating display. This work could be a guidance for Micro-LED applications on autostereoscopic displays.

Human eyes are capable of perceiving three-dimensional (3D) scenes and sensing the depth of objects, but the present two-dimensional (2D) displays are unable to show the depth perception, so people are pursuing more advanced 3D displays to make images closer to the reality. In physiology, depth cues include many agents; here, we focus on the physiological cues used in 3D displays: accommodation, convergence, binocular parallax, and motion parallax [1,2].

Accommodation refers to the adjustment of focal length of eyes on the watched object; convergence refers to the rotation of eyeballs to converge on the perceived point; binocular parallax, or binocular disparity, refers to the slightly different perceived images from left and right eyes, and the brain merges the two images into a stereoscopic image. It is the most important depth cue utilized in 3D displays. The last, motion parallax, refers to the relative location change of objects when moving our viewing position.

In these cues, binocular parallax gives rise to a strong depth sensation. Based on binocular parallax, many types of 3D displays were invented. In general, they can be classified into stereoscopic and autostereoscopic displays, respectively. Stereoscopic displays require audience wearing specialized glasses to perceive 3D images, but autostereoscopic displays permit watching 3D images with naked eyes. The very first autostereoscopic display was invented by Charles Wheatstone in 1830s using two tilted mirrors with 90 between them. Here, we focus on autostereoscopic displays because it is much closer to our natural visual experience. Moreover, in this article, the term “3D displays” is limited to “autostereoscopic displays”.

Autostereoscopic displays of interest to the market, and there are several commercial products which employ them, such as Nintendo 3DS, HTC EVO 3D, Sony Spatial Reality Display, and Google Starline. It shows that many corporations are striving to promote autostereoscopic displays to consumers. However, they still face challenges such as image blur, low resolution, narrow viewing angular range, limited viewing distance, eye strain, and fatigue [3,4].

For autostereoscopic displays, the “light field” is a pivotal concept that must be mentioned. The term “light field” was coined by Andrey Gershun [5] in 1936. It illustrates the light intensity at a given position (x, y, z) and direction (θ, ϕ), and it is a 5D plenoptic function [6]. Furthermore, in 1996, Marc Levoy and Pat Hanrahan [7] proposed that the 5D function can be reduced to a 4D function as L(x, y, θ, ϕ) since the light ray remains unchanged along its propagation in free space. It implies that we can use a display that emits 2D spatial and 2D directional light rays to reproduce the light field including the depth information as shown in Figure 1a. Therefore, it fundamentally guarantees that 3D displays are feasible in principle, rather than a science fiction. However, the 4D function still carries too much information than the present technology can handle; to further reduce the information quantity, the vertical parallax depending on ϕ is dropped, since human perceives depth mainly based on horizontal binocular parallax of θ. Thus, the 4D function is reduced to a 3D function of (x, y, θ) as shown in Figure 1b. In general, 2D panels encode only the 2D spatial light intensity information but lack the light-ray directional information. However, it is possible to modify a 2D panel into a light-field display with light-directional-control elements, such as a parallax barrier [8,9], lenticular lens [10,11], and micro-lens array [12,13], etc.

(a) A 4D light-field function L(x, y, θ, ϕ) fully presents the information of a 3D scene with a horizontal and vertical parallax. (b) To reduce the huge amount of information of a 4D light field, the ϕ-direction information is dropped and simplified into a 3D function L(x, y, θ), and only the binocular and horizontal parallax is preserved.

Since the binocular parallax gives rise to a strong depth cue, people start to think how to make two eyes catch different perspective images. A parallax barrier or a lenticular sheet can achieve this. These methods usually redistribute the pixels evenly into two eyes, and this is called spatial multiplex. It is compatible with the modern liquid crystal display (LCD) or organic light emitting diode (OLED) display, but the drawback is that it reduces the resolution and luminance of the display. Commonly, spatial-multiplex displays are designed as two-view or multiple-view displays and multiple images share all the pixels evenly, so the spatial resolution of a single view is only 1/N, where N is the number of views. The problem can be resolved by the time-multiplex method, which is introduced in Section 4.

In 1896, Auguste Berthier [14] proposed a “parallax barrier” to create an auto-stereogram. Its mechanism is described in Figure 2, showing that the parallax barrier is (a) in front of the display panel or (b) behind the display panel. The parallax barrier is an interlace of transparent and opaque stripes. For the left eye, only the pixels labeled as L are perceived, and the pixels labeled as R are blocked. In the same way, only pixels labeled as R are perceived by the right eye. Thus, the left and right eyes watch different images, and it generates binocular parallax. In Figure 2b, the parallax barrier is inserted between the display panel and the backlight to make the barrier invisible, so people would not be aware of the existence of black strips. The details of the optical design can be found in Huang’s article [15].

The method can be modified into multiple views by changing the pitch of the barrier. Figure 3 demonstrates a four-view design, the pitch of the parallax barrier is slightly smaller than four times of the subpixel pitch to converge the light into a single view, and the width of the transparent region determines the brightness. Wider transparent region increases the brightness, but induces more crosstalk. A common width is one quarter of the pitch to avoid significant crosstalk. A multiview design offers a motion parallax on top of a binocular parallax, so it allows multiple people to move around and to watch 3D images. However, the brightness and horizontal resolution becomes only 1/N, where N is the view number. The low brightness remains a problem of the parallax barrier; in Section 3.2, a lenticular method is introduced to reconcile the brightness problem.

For practical use, this type of 3D display is usually designed as a 2D/3D switchable display. In real life, we have a bunch of 2D content such as texts, 2D images and videos, and watching 2D content with a parallax barrier makes the images fragmented, so switching back to the conventional 2D display is more suitable. The Nintendo 3DS [16] is a popular commercial product with a switchable parallax barrier. It used the configuration of Figure 2b and replaced the parallax barrier with a switchable liquid crystal (LC) shutter array, and it produced a two-view 3D image with 400 × 240 pixels for each eye. Sharp Inc. [17] also developed a 2D/3D switchable display with a switchable binary liquid crystal panel in front of a LCD; it is similar to the Nintendo 3DS but with a configuration shown in Figure 2a. Meanwhile, Samsung Inc. [18] and LG Inc. [19] have published a similar work with a switching LCD barrier inserted between the LCD and its backlight. Sanyo Inc. [20] used polymer-dispersed liquid crystal (PDLC) as a transparent/diffuse switchable film. With an applied electric field, the transparent mode makes the parallax barrier effective as a 3D mode; on the contrary, the diffuse mode disturbs the direction of light and makes the barrier ineffective as a 2D mode. It is worth mentioning that the Industrial Technology Research Institute (ITRI) [21] developed a localized 2D/3D switchable display and won the R&D100 award in 2010. It stacked two same-resolution LCDs and a micro-retarder film to form a localized parallax barrier, so the 2D content and 3D content were shown at the same time.

The parallax-barrier method faces the degradation of brightness. To overcome the problem, Hess [22] invented a lenticular-lens method in 1915, which is described in Figure 4. The lenticular sheet is a one-dimensional cylindrical micro-lens array which replaces the role of the parallax barrier and collimates the diffused light from pixels into a specific direction, being received by a specific eye in the end. Hence, two eyes receive different images and merge them into an image with depth. Since the lenticular sheet is a transparent film, none of light is blocked; hence, it maintains the level of brightness. This is a remarkable advantage over a parallax barrier. On the other hand, a multiview setup can be implemented with the pitch of the lenticular array slightly less than N times of the width of a subpixel. However, it still suffers from the 1/N reduction in resolution.

The lenticular-lens method used to produce a 3D image (top view) is plotted. It is similar to the parallax barrier; however, a lenticular sheet guides left-eye pixels to the left eye, and right-eye pixels to the right eye without blocking light.

Nowadays, many companies have developed lenticular 2D/3D switchable displays. Philips Inc. [23] developed LC switchable lenticular lenses that consist of a hollow lenticular shell filled LC in the hollow part. It is the 3D mode if the electric field is off, and 2D mode if the electric field is on. Given the mismatch of refractive index of LC and the material of lenticular shell, it behaves as a lens; on the contrary, with an electric field, the refractive index of LC would be the same as the lenticular shell, and the lens effect would vanish. Ocuity Inc. [24] developed another type of lenticular 2D/3D switchable display. The switchable lenticular lenses are comprised of a birefringent surface relief and a second layer made of isotropic material. It is polarization-sensitive, so a polarization rotator used to switch the polarization of light activates the function of lenticular lens in 3D mode. LG Inc. [25] adopted electric-field driven LC lenses as the switchable lenticular lenses. By controlling the distribution of the electric field, the LC has various rotation angles over the LC cell and forms a refractive index profile, equivalent to a convex lens. Without applying an electric field, it is nothing but a uniform-refractive-index plate, and behaves as a 2D mode. Chang et al. developed another configuration of rotatable 2D/3D display using an LC lens array with a gradient electric field to watch 3D content in landscape/portrait mode [26]. Lastly, ITRI demonstrated a lenticular sheet and a polymer dispersed liquid crystal (PDLC) inserted between an LCD panel and its collimated backlight. When PDLC is in clear mode, the lenticular sheet directs the light into viewing zones as the 3D mode; when the PDLC is in diffusing mode, the collimated backlight is diffused and behaves as the 2D mode [27].

Besides the multiview displays, a “super-multiview display” means a very high dense of view number that allows at least two views impinging into a single eye. Two or more views represent two or more rays entering the pupil of eyes such that eyes can focus on the intersection of two or more rays [28]. Researchers have demonstrated 64-, 72-, 128-, and 256-view systems with a micro-lens array [29,30,31,32,33,34]. The National Institute of Information and Communications Technology (NICT) [35] developed a super-multiview display with 57 units of projectors, and a viewing angle of 13. ITRI [36] also demonstrated a multiple projector systems involving 60 views and a 32-inch lenticular screen. Takaki et al. [37] proposed a tabletop 360 system with high-speed projectors and a rotating transmissive screen. However, super-multiview suffers a huge loss of resolution, so introducing a head-tracking system is an effective manner to keep the resolution from dropping too much. Sony Inc. [38] has developed a 15.6″ 4 K light-field display with lenticules and a head-tracking system to avoid the pseudoscopic image and to reduce the resolution loss, but it is designed for a single user only.

The main shortcoming of the spatial multiplex is the severe drop in resolution, especially for multiview displays. To overcome the problem, “time multiplex” was proposed to solve it. The idea is multiplying the refresh rate by the number of views and reusing each pixel multiple times to compensate for the loss of resolution. This method projects each view time-sequentially. As an example of a two-view display, the refresh rate needs to be 60 Hz × 2 = 120 Hz to ensure that both eyes perceive images without flickers. Nonetheless, achieving an even higher refresh rate is not easy for common LCDs and the directional device, and it is also one of the major barriers to pursuing multiviews in time multiplex.

In general, the spatial multiplex can be generalized to time multiplex. For a parallax barrier, we can just shift the position of open slits by one half pitch, so all the pixels are perceived by two eyes, illustrated in Figure 5. In this case, the barrier and frame rate are scanning with doubled 120 Hz, so human eyes would not feel flickers.

The parallax barrier slits are shifted by one half pitch within 1/120 s, so both eyes can perceive red and blue pixels, and then the resolution is retained. (a) As t = 0 s, the parallax barrier is at the original place. (b) As t = 1/120 s, the parallax barrier shifts one half pitch.

This type of scanning parallax barrier can be realized with an electro-controllable LC shutter array. So far, most time-multiplex displays are two-view displays owing to the slow scanning rate of LC. Samsung Inc. [39,40] has developed a fast-scanning parallax barrier with an optical compensated bend (OCB) display mode to achieve a 5 ms response time, and an active-matrix OLED (AMOLED) display was adopted because of its high refresh rate. Overall, a 2.2-inch, full resolution 240 × 320, two-view time-multiplex display was demonstrated. PolarScreens Inc. [41] demonstrated a 120Hz 3D LCD panel, a vertical patterned active shutter panel and a head tracking system to achieve a full resolution autostereoscopic display.

In Figure 8, the scanning prism is configured with an isotropic prism with refractive index n and a LC-filled prism whose refractive index is determined by the orientation of LC. Without applying an electric field, the LC direction is parallel to the polarization of light, and it behaves as refractive index of ne; by applying an electric field, the LC direction is perpendicular to the polarization of light, and it behaves as a refractive index of no. If ne>n>no, then the light is bent to left without applying an electric field and bent to right with applying an electric field. Thus, the direction of light is controlled by the applying electric field. By scanning the light direction, time-multiplex multiview display was realized.

Integral imaging (InIm) was invented by the Nobel laureate in physics, Gabriel Lippmann in 1908, and he coined this technique as “integral photography” [46]. Figure 9 shows the idea behind InIm: A voxel [2] is formed by intersecting rays being emitted from the 2D display and being directed to the position of voxel by the 2D micro-lens array. In other words, the multiple perspectives of a voxel are recorded by the 2D micro-lens array and reconstructed by the reversed way, and it presents a full parallax. If the ray density is high enough to allow at least two rays into a single eye, then it shows the accommodation effect [47] that resolves the accommodation-convergence conflict [6]. Hence, it mitigates the fatigue problem. The range of pupil diameter is 4–6 mm [48], indicating the ray separation is 2–3 mm when arriving at the eyes, so hundreds of rays in horizontal and vertical directions are required to cover a head movement in hundreds of millimeters, and the overall ray number could be tens of thousands; thus, the native display resolution must be tens of thousands-fold the perceived resolution, so an extremely-high-resolution display is required.

The principle behind integral imaging: The light field is reconstructed by the rays from the 2D display, which are directed to the voxel’s position by the micro-lens 2D array and intersect with a voxel.

A large-screen InIm of 87 inch and a 360 light-field display with a holographic functional film was demonstrated [49,50]. In addition, a floating 96 × 96 view-point system was demonstrated at a 45 viewing angle [51]. Another interesting application of InIm is tabletop displays. A 360 interactive tabletop display comprised of an 8K LCD, lens array, optical diffuser film, and a hand-tracking device has been demonstrated [52].

Holography was invented by the Nobel laureate, Dennis Gabor [53] in 1947. It records all the information of the light field, consisting of its amplitude and phase. In a reversed manner, the light field is reconstructed as a 3D image. Since holography does not mimic 3D with 2D images, it builds the authentic 3D wavefront instead; hence, holography is regarded as the ultimate 3D display. The formation of holography, in Figure 10, is that the object beam interferes with the reference beam coherently and the interference fringe is recorded on a photo film. Since the fringe carries the phase and amplitude information of the object beam, we can reconstruct the wavefront of object beam in reversal by illuminating the hologram with the original reference beam, so eyes perceive not only the amplitude but also the phase that produces the sensation of depth.

Electronic holography is an ideal solution for autostereoscopic display; however, it faces some large challenges. First, an ultrahigh resolution spatial light modulator (SLM) is required. The fringe width could be one half the wavelength, so it can go down to 200 nm based on 400 nm blue light; then, a 127,000-ppi SLM with 200-nm pixel size is needed to display such a narrow fringe. So far, the commercial SLM can achieve only 7000 ppi [54], so it needs a huge jump in pixel density. Second, to compute, restore, and display such a high resolution image, a huge computing power, transfer rate, and memory are required [55].

The Media Lab at Massachusetts Institute of Technology (MIT) developed an electronic holographic display, Mark III [56]. It utilized a lithium niobate guided-wave acousto-optic device as an SLM that provides 200 MHz bandwidth to create the fringe pattern, which can display a 24 viewing angle, an 80 mm × 60 mm × 80 mm viewing volume with a 532 nm laser source. University of Arizona developed a updatable holographic display with a photorefractive polymer as an SLM, which exhibits a viewing angle of 45, 4 inches; the downside is that it takes two seconds to refresh a frame [57,58]. ITRI proposed another configuration of a head-mounted holographic display that reduces the required pixel density to the level of presentation of the SLM [59,60]. For this head-mounted configuration, the holography display only needs to generate a small viewing angle around 4 to cover a single eye; thus, the fringe width is around a few microns, which can be displayed in the present SLM.

Nowadays, LCD and OLED dominate the display market, and the micro-light emitting diode (Micro-LED) is the next emerging display technology. All of them can be used to implement 3D displays based on different scenarios. LCD requires a backlight to light the display on, so it has an extra flexibility to implement the light-directional-control elements within the backlight, such as the parallax barrier in Figure 1b, directional backlight [61,62], or a light-bar method introduced in Section 8. However, LCD has a slow response time around few ms [63,64], so it is hard to achieve a high refresh rate. On the contrary, OLED and Micro-LED both achieve fast response times of the order of µs and ns, respectively [65]. Hence, they are beneficial to time-multiplex. Another drawback of LCD is that it is less power efficient than OLED and Micro-LED; using a parallax-barrier setup would further deteriorate the power efficiency.

As shown in Figure 11, LCD usually has an encapsulation glass around 0.5 mm thick, which leads to small viewing zone pitch comparing to the larger viewing zone pitch of OLED/Micro-LED whose encapsulation layer is less than 1 µm [66]. Under the same number of views, small viewing zone pitch shrinks the viewing angle, which is harmful to auditing experience. Hence, OLED/Micro-LED have the advantage of enlarging the viewing angle than LCD with the same number of views.

(a) The viewing zone pitch is small in a thick-encapsulation-layer system, such as LCD, that has a thick front glass around 0.5 mm. (b) The thin-encapsulation-layer system, e.g., OLED/Micro-LED has an ultra-thin film less than 1 µm, which shows a large viewing zone pitch.

On the other hand, OLED usually has a pentile-pixel arrangement (Figure 12), which is more sophisticated than LCD’s RGB arrangement, and it requires a special pattern design for the parallax barrier. Lee and Kim have shown how to design the parallax barriers in their work [67,68]. In our group, we also developed a slanted-barrier autostereoscopic display with OLED, whose slanted angle is arctan(1/4), owning a 12-view, 166-ppi, viewing angle up to 50, because we removed the cover glass and took the advantage of the thin encapsulation of OLED. The left, middle, and right perspectives are shown in Figure 13, and it shows the horizontal parallax that the relative positions of petals and trunk change over views.

The pentile-pixel-arrangement image captured from an OLED display, showing a more sophisticated pattern than the RGB pattern of LCD, such that it is trickier to design the parallax barrier or lenticular pattern.

We have implemented an autostereoscopic display with an OLED smartphone. Comparing the (a) left, (b) middle, and (c) right views, the relative positions of petals and trunk (in the red circle) are different, and it shows a horizontal parallax.

Micro-LED is further superior to LCD/OLED with even lower power consumption and higher brightness [65]. The most impressive superiority is the ultra-high resolution as 8500-ppi [69] that can even support a super-multiview or InIm setup. OLED has achieved 10,000-ppi [70] as well, but its brightness is far lower than Micro-LED by at least one order. The overall comparison is summarized in Table 1.

TypePros for 3D DisplayCons for 3D DisplayLCD1. LCD is more flexible regarding installation of the light-directional-control element cooperating with the backlight or in front of the color filter.1. Slow response time (∼ms), unsuitable for time multiplex.

4. High brightness (∼10,000 nits) and low power consumption (6∼7 cd/W) compensates for light loss of the parallax barrier.1. No backlight, the light-directional-control element must be mounted in front of the panel, less flexible setup.

Micro-LED is an emerging technology that potentially drives the realization of 3D displays. Micro-LED provides the pixel size down to few microns, equivalent to tens of thousands of ppi [71]. Micro-LED satisfies the ultra-high-resolution requirement for InIm, and it is able to push the development of InIm greatly forward. Second, Micro-LED provides response time of nanoseconds such that it can be used as a time-multiplex display, so every time-multiplex method in Section 4 can be applied with Micro-LED. Third, Micro-LED offers a partial-coherent light source because of its small-area luminance, and it is capable of replacing the laser as the point light source to reduce the speckle effect for the electronic holographic display [72].

On the other hand, considering Micro-LED as a function of the backlight, the configuration in Figure 14 illustrates how the rays propagate through each pixel and converge to the viewing zone; here is an example for a four-view display, and the pitch of line stripes is slightly larger than four times the pixels. In this manner, the narrower the light stripe is, the less crosstalk is induced. Taking the advantage of small dimension of Micro-LED, the crosstalk can be effectively suppressed. ITRI [73,74] has developed a light-stripe backlight with inverted trapezoids, but its light efficiency is moderate. Now, it is possible to assemble Micro-LEDs as the light-stripe backlight and promote their light efficiency significantly.

This light-stripe method can be generalized to time-multiplex display with multiple sets of light-stripe arrays. In Figure 15, four light-stripe sets are introduced, and they are manipulated with the lighting on and off in the order of yellow, purple, grey, and black cyclically. Each light-stripe set projects a quarter of the pixels to a single eye, and four sets of light stripes allow all the pixels to be perceived by a single eye. Hence, it achieves a full resolution with time-multiplex lighting on-and-off. For the four-view example, it turns 240 Hz lighting on and off. Based on the fast response of Micro-LED, it is easy to turn high-frequency lighting on and off. ITRI [45,61] has demonstrated another variant with light stripes and a lenticular sheet to collimate the backlight into a single direction; turning on different light-stripe sets directs the collimated backlight into different directions, and full-resolution images are delivered into various directions.

In addition, Micro-LED can be transferred onto a transparent glass substrate, and it becomes a transparent display that owns a floating 3D effect [75]. Japan virtual idol Hatsune Miku already demonstrated a projection image onto a transparent curved screen to mimic a holographic image [76]. Furthermore, Micro-LED has much higher luminance, up to tens of thousands of nits, than LCD, OLED, so it can be used outdoors where the ambient light is high.

Lastly, Micro-LED has a fast response time down to nano-seconends [65], it is especially suitable for time-multiplex 3D displays. Speeding up the frame rate up to 960 Hz and with the same-speed scanning barrier or a deflector such as the LC deflector shown in Figure 8, it generates a sixteen-fold multiview without any loss of resolution. Moreover, Micro-LED is more power-saving such that it prolongs the battery time for mobile devices, such as smart phones and tablets.

We comprehensively reviewed the understanding of how human eyes physiologically perceive three-dimensional objects, and the optical principles behind autostereoscopic displays, including the concept of the light field, parallax barrier, lenticular lens, integral imaging, and electronic holography. On top of that, based on LCD, OLED, and Micro-LED, we investigated their pros and cons for the implementation of autostereoscopic displays. Among these technologies, Micro-LED has the advantages of high resolution, fast response time, ultra-thin encapsulation layer, and high brightness, and they are beneficial to improving the performance of autosteroscopic displays. Based on these features, we proposed several implementations of autostereoscpic displays with Micro-LED: a Micro-LED light-stripe backlight with a LCD, a high-resolution Micro-LED display with a micro-lens array or a high-speed scanning barrier/deflector, and a transparent floating display.

3. Ukai K., Howarth P.A. Visual fatigue caused by viewing stereoscopic motion images: Background, theories, and observations. Displays.2008;29:106–116. doi: 10.1016/j.displa.2007.09.004. [CrossRef]

6. Martínez-Corral M., Javidi B. Fundamentals of 3D imaging and displays: A tutorial on integral imaging, light-field, and plenoptic systems. Adv. Opt. Photonics.2018;10:512. doi: 10.1364/AOP.10.000512. [CrossRef]

9. Guo J., Diao Z., Yan S., Zhang E., Kong L. Immersive autostereoscopic display based on curved screen and parallax barrier. Chin. Opt. Lett.2021;19:013301. doi: 10.3788/COL202119.013301. [CrossRef]

10. Zhao W.X., Wang Q.H., Wang A.H., Li D.H. Autostereoscopic display based on two-layer lenticular lenses. Opt. Lett.2010;35:4127. doi: 10.1364/OL.35.004127. [PubMed] [CrossRef]

11. Huang T., Han B., Zhang X., Liao H. High-performance autostereoscopic display based on the lenticular tracking method. Opt. Express.2019;27:20421. doi: 10.1364/OE.27.020421. [PubMed] [CrossRef]

12. Bogaert L., Meuret Y., Roelandt S., Avci A., De Smet H., Thienpont H. Demonstration of a multiview projection display using decentered microlens arrays. Opt. Express.2010;18:26092. doi: 10.1364/OE.18.026092. [PubMed] [CrossRef]

15. Huang K.C., Chou Y.H., Lin L.C., Lin H.Y., Chen F.H., Liao C.C., Chen Y.H., Lee K., Hsu W.H. A study of optimal viewing distance in a parallax barrier 3D display. J. Soc. Inf. Disp.2013;21:263–270. doi: 10.1002/jsid.172. [CrossRef]

17. Jacobs A., Mather J., Winlow R., Montgomery D., Jones G., Willis M., Tillin M., Hill L., Khazova M., Stevenson H., et al. 2D/3D switchable displays. Shapu Giho/Sharp Tech. J.2003;85:15–18.

18. Nam H., Lee J., Jang H., Song M., Kim B. 7.3: Auto-Stereoscopic Swing 3D Display. SID Symp. Dig. Tech. Pap.2005;36:94. doi: 10.1889/1.2036606. [CrossRef]

19. Kim K.J., Kang H., Jang M.K., Ahn B.C., Chung I.J., Park T.S., Chang J.W., Lee K.I., Kim S.T. Development of a 42-in. 2-D/3-D switchable display using multi-view technology for public-information-display applications. J. Soc. Inf. Disp.2007;15:899. doi: 10.1889/1.2812990. [CrossRef]

20. Hamagishi G., Sakata M., Mashitani K., Inoue M., Taima K., Oyamada K., Kishimoto S.I. SID Symposium Digest of Technical Papers. Volume 29. Blackwell Publishing Ltd.; Oxford, UK: 1998. 32.1: Invited Paper: A Display System with 2-D/3-D Compatibility; p. 915. [CrossRef]

21. Tsai R.Y., Tsai C.H., Lee K., Wu C.L., Lin L.C.D., Huang K.C., Hsu W.L., Wu C.S., Lu C.F., Yang J.C., et al. Three-Dimensional Imaging, Visualization, and Display 2009. Volume 7329. International Society for Optics and Photonics; Chandigarh, India: 2009. Challenge of 3D LCD displays; p. 732903. [CrossRef]

24. Woodgate G.J., Harrold J. LP-1: Late-News Poster: High Efficiency Reconfigurable 2D/3D Autostereoscopic Display. SID Symp. Dig. Tech. Pap.2003;34:394. doi: 10.1889/1.1832295. [CrossRef]

25. Hong H.K., Jung S.M., Lee B.J., Im H.J., Shin H.H. 25.3: Autostereoscopic 2D/3D Switching Display Using Electric-Field-Driven LC Lens (ELC Lens) SID Symp. Dig. Tech. Pap.2008;39:348. doi: 10.1889/1.3069666. [CrossRef]

26. Chang Y.C., Jen T.H., Ting C.H., Huang Y.P. High-resistance liquid-crystal lens array for rotatable 2D/3D autostereoscopic display. Opt. Express.2014;22:2714. doi: 10.1364/OE.22.002714. [PubMed] [CrossRef]

27. Chen W.L., Chen F.H., Tsai C.H. 2D/3D Switchable Autostereoscopic Display Using Conventional Lenticular Plate; Proceedings of the 11th International Meeting on Information Display; Beppu, Japan. 5–7 January 2017; p. 64.

28. Honda T., Kajiki Y., Susami K., Hamaguchi T., Endo T., Hatada T., Fujii T. Three-Dimensional Video and Display: Devices and Systems: A Critical Review. Volume 10298. International Society for Optics and Photonics; Chandigarh, India: 2001. Three-dimensional display technologies satisfying “super multiview condition” p. 102980B. [CrossRef]

29. Nakanuma H., Kamei H., Takaki Y. Stereoscopic Displays and Virtual Reality Systems XII. Volume 5664. International Society for Optics and Photonics; Chandigarh, India: 2005. Natural 3D display with 128 directional images used for human-engineering evaluation; p. 28. [CrossRef]

30. Takaki Y., Nago N. Multi-projection of lenticular displays to construct a 256-view super multi-view display. Opt. Express.2010;18:8824. doi: 10.1364/OE.18.008824. [PubMed] [CrossRef]

31. Kikuta K., Takaki Y. Stereoscopic Displays and Virtual Reality Systems XIV. Volume 6490. International Society for Optics and Photonics; Chandigarh, India: 2007. Development of SVGA resolution 128-directional display; p. 64900U. [CrossRef]

32. Takaki Y., Dairiki T. Stereoscopic Displays and Virtual Reality Systems XIII. Volume 6055. International Society for Optics and Photonics; Chandigarh, India: 2006. 72-directional display having VGA resolution for high-appearance image generation; p. 60550X. [CrossRef]

33. Takaki Y. Multi-view 3-D display employing a flat-panel display with slanted pixel arrangement. J. Soc. Inf. Disp.2010;18:476. doi: 10.1889/JSID18.7.476. [CrossRef]

34. Kanebako T., Takaki Y. Stereoscopic Displays and Applications XIX. Volume 6803. International Society for Optics and Photonics; Chandigarh, India: 2008. Time-multiplexing display module for high-density directional display; p. 68030P. [CrossRef]

35. Inoue N., Kawakita M., Yamamoto K. 200-Inch Glasses-Free 3D Display and Electronic Holography Being Developed at NICT. IEEE; Piscataway, NJ, USA: 2013. pp. 1–2. [CrossRef]

36. Chen W.L., Tsai C.H., Wu C.S., Chen C.Y., Cheng S.C. A high-resolution autostereoscopic display system with a wide viewing angle using an LCOS projector array. J. Soc. Inf. Disp.2010;18:647. doi: 10.1889/JSID18.9.647. [CrossRef]

37. Takaki Y., Uchida S. Table screen 360-degree three-dimensional display using a small array of high-speed projectors. Opt. Express.2012;20:8848. doi: 10.1364/OE.20.008848. [PubMed] [CrossRef]

38. Aoyama K., Yokoyama K., Yano T., Nakahata Y. Eye-sensing light field display for spatial reality reproduction. Dig. Tech. Pap. SID Int. Symp.2021;52:669–672. doi: 10.1002/sdtp.14771. [CrossRef]

39. Lee H.J., Nam H., Lee J.D., Jang H.W., Song M.S., Kim B.S., Gu J.S., Park C.Y., Choi K.H. 8.2: A High Resolution Autostereoscopic Display Employing a Time Division Parallax Barrier. SID Symp. Dig. Tech. Pap.2006;37:81. doi: 10.1889/1.2433641. [CrossRef]

40. Kim D.S., Shestak S., Cha K.H., Park S.M., Hwang S.D. Three-Dimensional Imaging, Visualization, and Display 2009. Volume 7329. International Society for Optics and Photonics; Chandigarh, India: 2009. Time-sequential autostereoscopic OLED display with segmented scanning parallax barrier; p. 73290U. [CrossRef]

41. Gaudreau J.E. Stereoscopic Displays and Applications XXIII. Volume 8288. International Society for Optics and Photonics; Chandigarh, India: 2012. Full-resolution autostereoscopic display using an all-electronic tracking/steering system; p. 82881Z. [CrossRef]

42. Schultz J.C., Brott R., Sykora M., Bryan W., Fukamib T., Nakao K., Takimoto A. 11.5L: Late-News Paper: Full Resolution Autostereoscopic 3D Display for Mobile Applications. SID Symp. Dig. Tech. Pap.2009;40:127. doi: 10.1889/1.3256529. [CrossRef]

43. Chien K.W., Shieh H.P., Chu Y.M., Tsai C.Y., Lin Y.L., Hu C.J., Chang C.M., Hsu Y.C., Chen P.L. Three-Dimensional Display System and Method Thereof. 7,333,158. U.S. Patent.2008 February 19;

44. Cornelissen H.J. Display Device with Multi-Grooved Light Direction Element and First and Second Alternating Illuminated Light Sources Simultaneously Switched for 2D Display and Synchronously Switched for 3D Display. 7,518,663. U.S. Patent.2009 April 14;

47. Deng H., Wang Q.H., Luo C.G., Liu C.L., Li C. Accommodation and convergence in integral imaging 3D display. J. Soc. Inf. Disp.2014;22:158–162. doi: 10.1002/jsid.230. [CrossRef]

49. Sang X., Fan F.C., Jiang C.C., Choi S., Dou W., Yu C., Xu D. Demonstration of a large-size real-time full-color three-dimensional display. Opt. Lett.2009;34:3803–3805. doi: 10.1364/OL.34.003803. [PubMed] [CrossRef]

50. Xin Gao X.G., Xinzhu Sang X.S., Xunbo Yu X.Y., Wanlu Zhang W.Z., Binbin Yan B.Y.,

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey