skr 1.3 lcd displays quotation

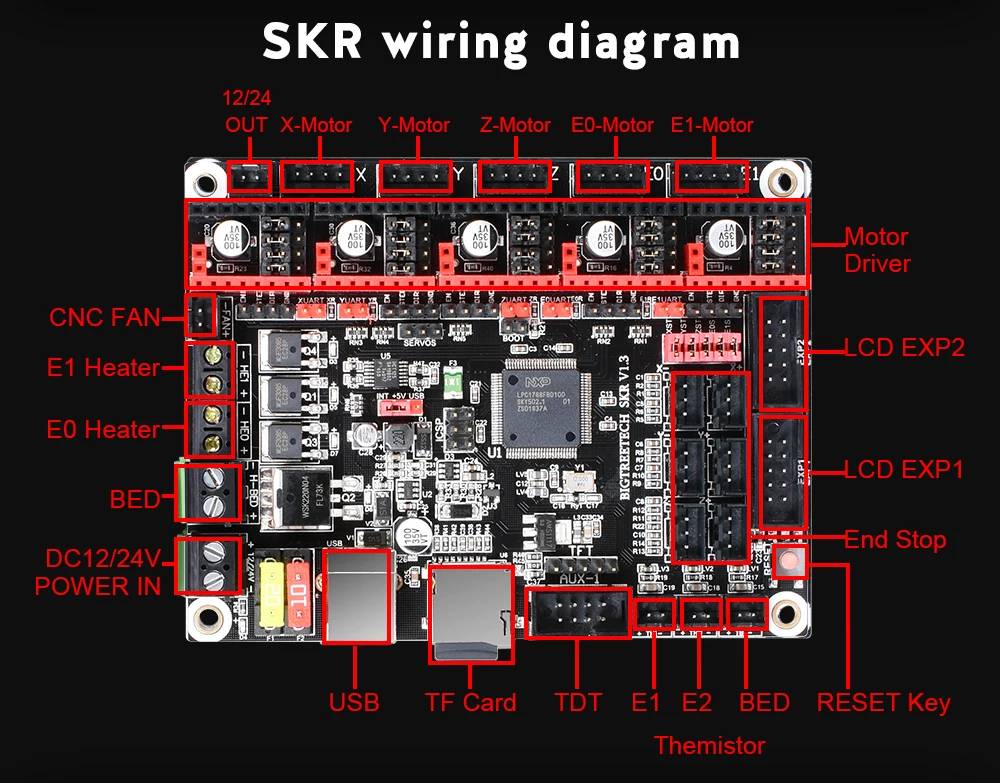

Hey so I am doing the whole SKR 1.3 conversion thing as part of a bigger project and I just thought this might be an appropriate place to share the screen I chose to use for my setup. It is the tft35 from Bigtreetech but it is v3.0. I got mine here: https://www.amazon.com/BIGTREETECH-D.../dp/B07W1PB11F

#define TOOLCHANGE_FS_WIPE_RETRACT 0 // (mm) Cutting retraction out of park, for less stringing, better wipe, etc. Adjust with LCD or M217 G.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

So I will go into detail on what as transpired thus far. Im not new to this either, so let"s get started.Ender 3 custom hotend, thermistor, and upgraded motors. everything else is stockConfigured skr with firmware that came with the MCU, marlins 2.0.x, and the fork from bigtreetech github repo. None of these would allow me to control the steppers in UART (using tmc2208 v1.2). Now I know they are sold with the v3.0 drivers, but I have these and know they work as I pulled them from my working MKS Gen l v1.0, which this skr was replacing.They seemed fine as I was able to get a driver status as ok from the enabled drivers, but when trying to move them (x and y axes), they did nothing, no stutter, no hum.... heck the motors did not even energize, as if the signal to send power failed. Now I tried this with 4 different drivers, one at a time for both x and y axes, and attempted with both tmc2208"s and 5160"s.So after many failed attempts with uart with many different configs files from a slew of sources (github, my own, and a friends skr config, nothing worked to get them into UART mode (well working in UART mode). So I settled for standalone mode for the drivers, not Ideal but it was better than having the machine just collect dust.So i moved on to test all motors, endstops etc etc. heater worked with no issues and with slice engineering 450°C thermistor all reading correctly. machine homed correctly..... but I could not move them away from the endstops after they homed (had to cut power and then pwr back up (I blamed the firmware at the time). So I moved on to check the fans. ***BTW I used the bigtreetech version of the firmware, from github, to set up on the skr, and adjusted anything that was not needed (mainly BLTouch crap, and stepper adjustments very few and minor settings... nothing outside what the average user would edit as I wanted to make sure everything basic worked first)***When in the LCD there are options for a fan 1 speed and fan2 speed. So I assumed one for the hotend heatsink and one for print cooling. So I selected fan1 speed and set it to 50% (yes a percentage was in the menu, instead of the normal 0-255 pwr range). I select the 50% with the rotary encoder on the STOCK ENDER 3 LCD and the machine immediately "shuts down". I use quotes because there was power still going into the MCU, just not providing it power to operate.After this "loss of power", the board would no longer communicate via USB and the only lights on the board shows any activity were 2 LED DIODES on the board directly in front of the the hotend mosfet and fan mosfet. Power cycled again and no change to MCU pwr status or communication. LCD no longer powers on (again stock Ender 3 LCD connected com1 on the MCU and exp3 on the LCD, will have to test on another board(s) I own).Not sure if my drivers are still working at this point, after all the previous frustration with trying to get UART working and then this after settling for not using UART with these drivers and I was going to order the TMC2208 UART v3.0 driver, which the only difference from the v1.2 is that they come uart ready (instead of having to solder j pads and pins on the stepstick. But now I have no working SKR, TO BOTHER SPENDING THE MONEY ON THE V3.0 DRIVERS.Will be reaching out to Biqu/ Bigtreetech once I determine my components connected to the board are not damaged (motors, lcd, fans, any component directly attached to the board.Giving 2 stars as the board "worked" kinda will either decrease this rating or increase depending on how Mfg responds to my inquiry regarding this matter ( pray for them that my motors are still good (Nema 17 Stepper Motor Bipolar 2A 59Ncm(84oz.in) 48mm Body 15.00 USD after tax) and that would be 4 total motors, 4 drivers (2 tmc2208"s and 2a4988"s), my stock LCD, endstops, and what else may not be working that was previously working.

This is the placeholder for my Wanhao i3 (aka Monoprice Maker Select V2) conversion to a 32 bit board with 2209 drivers using the SKR 1.4 non turbo board. I attempted a Marlin 1.1.x load with BLTouch on my i3 and the BLTouch never would work. I removed the C7 capacitor just like the BLTouch instructions said; however, I tried to home the machine (G28 code) after removing the capacitor and the nozzle would crash into the bed and keep driving down. I manually tested the Z-Endstop with my multimeter at the switch and at the circuit board connector and it did indeed work and provide continuity. Removing the C7 must have damaged something on the board, so without a way to stop the nozzle from breaking the bed I’ve resorted to upgrading the mainboard on this machine. Initially I followed Chasetec’s instructions to simply upgrade my Melzi board to include BLTouch. He has some great info there if you’re on a stock machine and want to explore better firmware like Marlin. Now I’m reading an outdated guide on upgrading to an SKR 1.4 board. My hope is to document my build log here and provide an updated working guide for others trying to go from Melzi on their i3 to a SKR 1.4.

The firmware took SEVERAL iterations to get working even slightly correctly. The biggest issue I had was that I didn’t want to cut the diagnostic pins on the 2209 drivers. I don’t think I have room to bend them like the 1.3 revision of the board was able to do. This means I’ll have to play with sensorless homing. **Update** I actually gave up on sensorless homing. It has too many sensitivity problems in my experience. I could never get the thing to home right so I disabled it completely. This means I did 3 main things. I inverted the end stop logic on the X and Y, Bent the diagnostic pins on my 2209’s for X & Y toward the motor wire connectors (Z0 etc), and removed the code for sensorless homing.

Quote from Marcelo: I’m using a BL Touch (Classic) in my RepRap, and when I bought my Ender 3 Pro I also bought the Creality BL Touch Kit (bought mine on Amazon, but is the original Creality kit – https://www.amazon.com/gp/product/B07SCLF42D/). During installation on the original board, I observed on the Creality installation guide (Guide) that the long cable that come in the kit had a difference on pin-out while compared with my original BL Touch. If you look on the guide linked above, frame 5, you will see that Servo (3 pin) pin-out on the pinboard A (the adapter that comes in the kit to connect the BL Touch together with LCD display in the original Creality board (the one that came on my Ender 3 Pro was Creality3D V1.1.4) has the following sequence:

which is different from the cable that come in the Creality BL Touch Kit (in Creality kit the GND is in the middle, in SKR 1.4 (or 1.4 Turbo) VCC is in the middle.

So if you are using an Creality BL Touch kit and switching to SKR 1.4 (or 1.4 Turbo) please verify your wiring to match BTT SKR 1.4 board. In my case I had to exchange the position of VCC and GND pins in the cable connector (the 3 pin connector). This can be done using and X-Acto knife (or similar), raising the retainer, pulling out gently the wire with the metallic connector, and inserting it on the correct position (in my case I had to invert blue and red wires, but please check your cable properly!!!).

IMPORTANT: if you bought a BL Touch from other vendor please check the cabling. I had an original BL Touch bought from Antclabs that the wires already match the BTT SKR 1.4. SO PLEASE BE CAREFUL!!!

Look into SKR1.4 manual (SKR 1.4 manual), page 8, and connect your BL touch as showed there. The 3 pin connector is connected on the Servo connector, and the 2 pin connector is connected to the Probe connector.

Start with a cold hot end and bed so it’s as close to room temperature as possible. I have a spool of ABS sitting here and I print that at around 240C before the conversion, so now I’ll send the following command to start the auto PID tuning: “M303 S240”. We will let the machine ramp up the temperatures as we watch the progress window for the cycles to complete. Once complete it will print out our K values for our firmware. Overwrite your values in the configuration.h and save it. You should now use your menus to replace the PID values for the nozzle via the LCD or you can use gcode like this:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey