lcd panel index factory

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

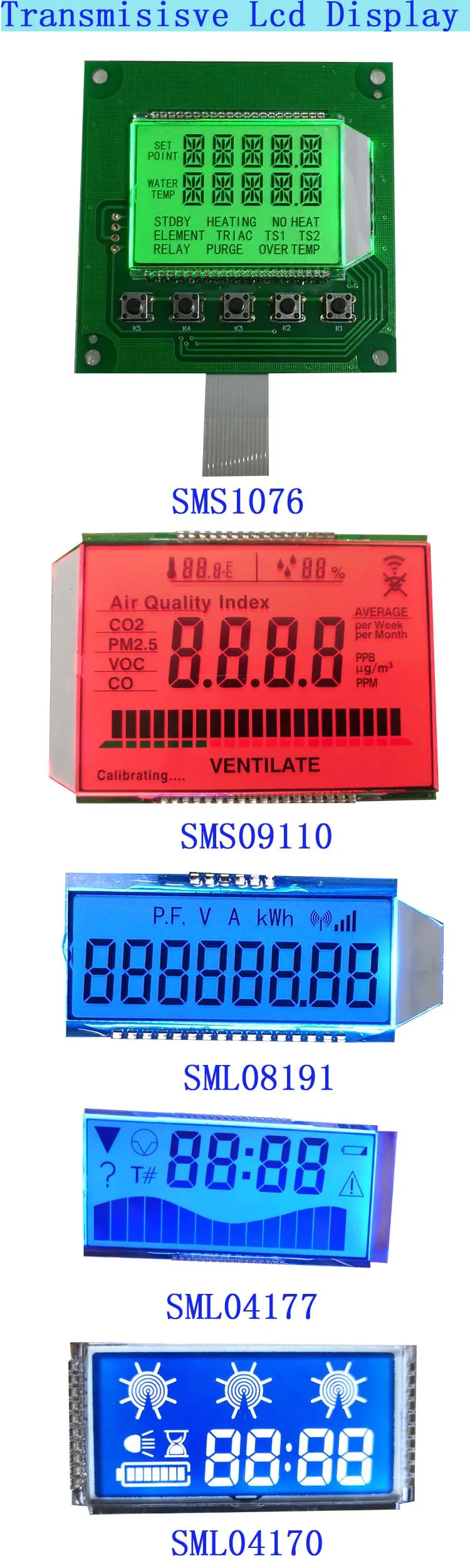

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

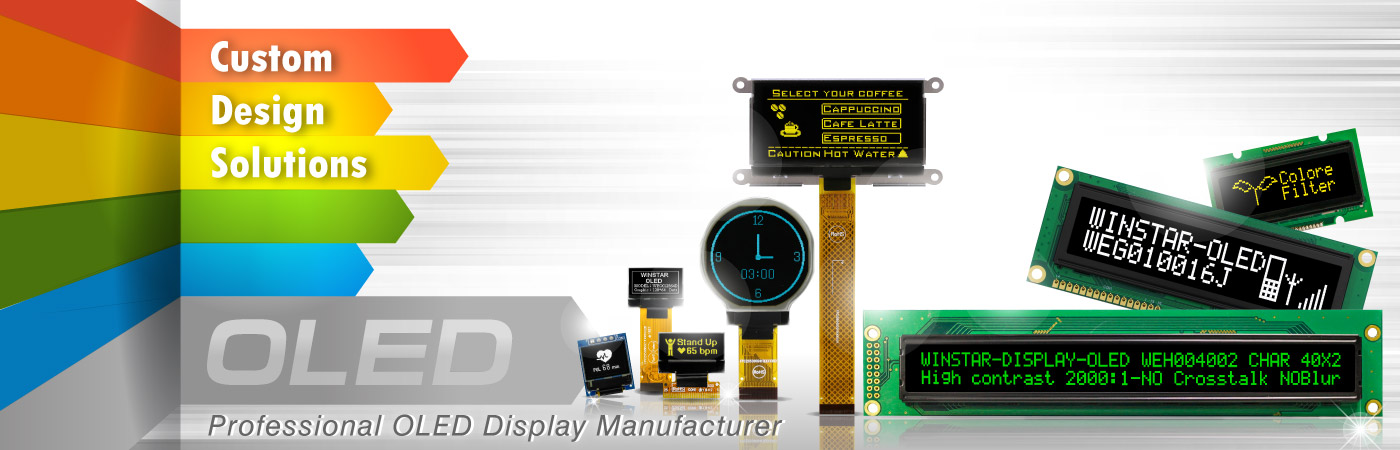

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

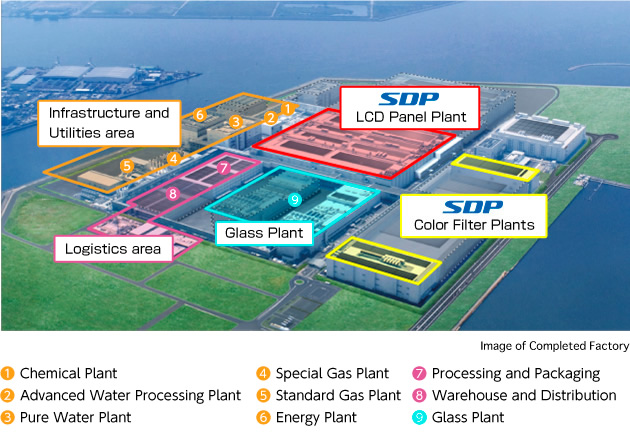

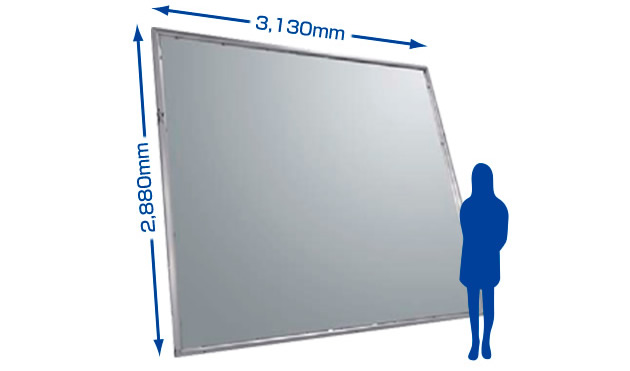

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

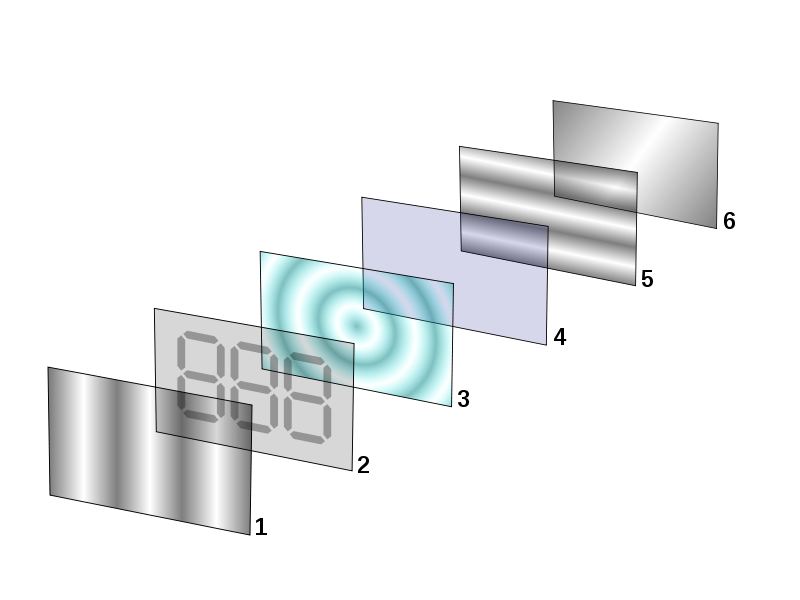

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

It’s the end of an era for LCD panels, or at least for those manufactured by Samsung. The Korean firm has been teasing the end of its LCD manufacturing for years, but now, the deadline is about to be reached. From June 2022, Samsung Display will no longer produce liquid-crystal displays (LCD). This does not mean that the end of LCD panels in smartphones, computers, and other electronics. It’s just Samsung leaving the segment due to tough competition from its Chinese and Taiwanese counterparts.

Instead of keeping a tepid LCD business, the company will shift efforts to OLED (organic light-emitting diode) and QD displays. The OLED panels have become the “best” for the smartphone market. There is still a predominance of LCD screens, but most of the flagship, premium mid-range, and even conventional smartphones are getting OLED displays nowadays. LCDsare still very popular in the segment of PCs and laptops, however.

According to Display Supply Chain Consultants (DSCC), the average price index of LCD panels, measured against 100 in January 2014, will fall to 36.6 in September of this year. The figure has dropped farther from the record low of 41.5 in April of this year. It’s also 58 percent lower than the record high of 87 in June 2021.

Unfortunately, no investment plan details have since been announced. However, the employees of the LCD business should retain their jobs. The company will likely move them to the Quantum Dot Display business. Worth noting, that Samsung has been trying to leave the LCD segment since 2020. The initial plan was to close the business at the end of 2020. However, these plays have been delayed by Samsung Electronics. The sudden increase in the prices of the LCD panels during the COVID-19 pandemic urged Samsung Display to keep the manufacturing for a while. This resulted in an entire 2021 of continuous manufacturing. Now, however, the business seems to have reached the deadline.

The display affiliate was first formed in 1991, as an LCD business arm under Samsung Electronics. It formally launched in 2021, as Samsung Display. It has merged with three local and Japanese makers of active-matrix organic light-emitting diodes (AMOLED), for the production of advanced types of displays. The company will no longer produce the panels for Samsung TVs which will likely push forward the portfolio of QD and OLED smart TVs.

The mid-range segment of smartphones may not suffer a big impact. After all, there are countless LCD makers still operating in the industry. As far as the mobile segment is concerned, the company is doing a good job. The Galaxy S22 series is successful in China, and the company is preparing the terrain for the Galaxy Z Fold 4. The flagships and the foldable offer the best Samsung has been developing in display tech.

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

A few India-based enterprises have decided or plan to set up display panel plants in India, but this is unlikely to have substantially impact on the existing global display supply chain in the foreseeable future, as the total panel production capacity in India will be much smaller than that in China, South Korea, Taiwan and Japan.

India-based oil, gas and metal producer Vedanta has acquired Japan-based LCD glass substrate maker AvanStrate and applied to the India government for setting up a 8.6G TFT-LCD plant in India. Vedanta in February 2022 signed an MoU with Taiwan-based Foxconn Electronics to establish a joint-venture maker of semiconductors. As Taiwan-based LCD panel maker Innolux is AvanStrate"s client and has a 8.6G LCD plant in southern Taiwan, Vedanta could cooperate with Innolux via AvanStrate.

With subsidies under India government"s PLI scheme and UP Electronics Manufacturing Policy 2017 set by the state government of Uttar Pradesh, northern India, Samsung Display (SDC) invested US$654 million to set up a panel module factory in the state and started production in April 2021.

China-based panel maker China Star Optoelectronics Technology (CSOT) has invested INR18.3 billion to set up a factory to produce 5- to 65-inch LCD modules in Andhra Pradseh, southeastern India. With annual production capacity of 8.0 million LCD modules, the factory is intended to mainly support TCL, CSOT"s parent company, to sell LCD TVs in the India market. TCL expects to sell 10 million LCD TVs for a market share of 7% in India in 2022. TCL currently ranks fourth in the India TV market and aims to surpass Sony, ranking third with a market share of 12% at present, by the end of 2022.

Taiwan-based LCD panel maker AU Optronics (AUO) has evaluated the feasibility of investing in India. There are problems concerning culture and government efficiency in India, AUO chairman Paul Peng has said.

There are many factors that need to be considered in setting up overseas factories, including ecosystem support, infrastructure and local talent, Peng said. India is not ideal in terms of these three factors, and exiting panel makers are quite unlikely to set up panel lines in India for the time being, Peng noted.

China-based panel makers had kept expanding production capacities for nearly 10 years and, as a result they together occupied over 60% of global production capacity for LCD panels as of 2021, followed by Taiwanese makers with 20%, South Korean ones with 10% and Japanese ones with 6%.

Since major Chinese makers are still expanding LCD panel production capacities, China"s combined share of global total will reach 70% in the mid- to long-term.

In view of diminishing competitiveness in LCD, SDC terminated LCD panel production in June 2022 and has shifted focus to AMOLED. Taiwanese LCD panel makers are expected to benefit from SDC"s exit but are still far less competitive against Chinese fellow makers in production capacity. Therefore, they have chosen not to expand production capacities and have focused on high value-added LCD panels.

The QLn"s display can be modified by storing a customized index.wml file in E: memory of the printer. The default (factory) index.wml file is not overwritten since it is stored in protected Z: memory. Once the E: memory index.wml is deleted the printer will use the index.wml in Z: memory.

ESP chips can generate various kinds of timings that needed by common LCDs on the market, like SPI LCD, I80 LCD (a.k.a Intel 8080 parallel LCD), RGB/SRGB LCD, I2C LCD, etc. The esp_lcd component is officially to support those LCDs with a group of universal APIs across chips.

In esp_lcd, an LCD panel is represented by esp_lcd_panel_handle_t, which plays the role of an abstract frame buffer, regardless of the frame memory is allocated inside ESP chip or in external LCD controller. Based on the location of the frame buffer, the LCD panel allocation functions are mainly grouped into the following categories:

Drivers for some LCD and touch controllers are available in IDF Component Registry. The list of available and planned drivers with links is in this table.

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

ESP chips can generate various kinds of timings that needed by common LCDs on the market, like SPI LCD, I80 LCD (a.k.a Intel 8080 parallel LCD), RGB LCD, I2C LCD, etc. The esp_lcd component is officially to support those LCDs with a group of universal APIs across chips.

In esp_lcd, an LCD panel is represented by esp_lcd_panel_handle_t, which plays the role of an abstract frame buffer, regardless of the frame memory is allocated inside ESP chip or in external LCD controller. Based on the location of the frame buffer, the LCD panel allocation functions are mainly grouped into the following categories:

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command tranfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command tranfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

In March 2012 at Kameyama Plant No. 2, Sharp began producing the world’s first high-performance LCD panels incorporating IGZO oxide semiconductors. Sharp is expanding production scale through April to meet market demand.

Kameyama Plant No. 2 first started operations in August 2006, manufacturing highly advanced LCD panels for TVs. Production systems have subsequently been reorganized to focus on producing small- and medium-sized LCD panels for the world’s rapidly growing smartphone and tablet terminal markets.

Employing advanced IGZO oxide semiconductors enables Sharp to produce LCDs with smaller thin-film transistors and increased pixel transparency, thus allowing for lower energy consumption. In addition, proprietary UV2A*3 photo-alignment technology employed in Sharp’s AQUOS LCD TVs enables these displays to achieve high image quality.

Sharp will encourage the application of its new high-resolution LCD panels to high-definition notebook PCs and LCD monitors—which are both expected to grow in demand—as well as to mobile devices. Sharp will also contribute to creating markets for attractive new products.

*3 Ultraviolet-induced multi-domain Vertical Alignment (UV2A) is a photo-alignment technology that precisely controls the alignment of LCD molecules in a simple LCD panel structure.

The most advanced facility for the integrated production of LCD TVs from the manufacturing of LCD panels to assembly of final products was completed in Kameyama, Mie Perfecture, Japan, and started operation. The plant also provides rationalization in the process of production, inspection and delivery, as well as technology development, resulting in high production efficiency and high value-added performance.

Plant No. 2 will adopt large-size 8th generation glass substrates of 2,160 x 2,400 mm, which are optimum for the production of 40-inch-class and 50-inch-class models. Eight 40-inch-class panels or six 50-inch-class panels can be obtained from this single 8th generation substrate. Compared with the substrates of Plant No. 1 (1,500 x 1,800 mm for eight 32-inch-class panels) the size will be roughly double.

With the expansion of the supply of large LCD panels from the Kameyama factories, Sharp is greatly advancing LCD TV production to meet increasing market needs.

TOKYO, Dec 12 (Reuters) - Sharp Corpsaid on Friday it would close two LCD output lines making small and mid-sized panels in Japan, and move production to a newer and more cost-efficient plant as the global downturn hits demand for electronic goods.

Sharp said the LCD lines set to be closed in January were built more than 10 years ago, while its Kameyama No.1 plant, which will shift from production of TV panels to output of smaller displays, is one of Sharp’s flagship factories.

The world’s third-largest LCD TV maker said it is on track to bring onstream its advanced LCD panel factory in the western Japan city of Sakai by March 2010.

Shares in Sharp were down 6.2 percent at 607 yen in afternoon trade, underperforming the Tokyo stock market"s electrical machinery index, which fell 5.3 percent. (Reporting by Yumi Horie and Kiyoshi Takenaka; Editing by Michael Watson)

The makers of LCD panels for laptops and TVs are pressing on with churning out the glass, no matter how bad the industry is doing, reports trade pub DigiTimes. In an article on its Web site, the paper says that despite an expected 10% to 20% drop in the first quarter of 2009 in already low utilization of factories at AU Optronics, Chi Mei Optoelectronics (CMOPF.PK), and Chungwa Picture Tubes, the companies are not going to cease production entirely. Instead, they are asking employees to take unpaid holidays, for example, among drastic measures to keep lines running despite the fact that it is must be quite uneconomical to do so at this point. Notes DigiTimes, According to AUO, the panel supplier is looking to utilize less manpower, and hence lower productivity, to compliment its poor outlook for the first quarter of next year. The company will start its annual maintenance at the end of this month, but said it has no plans to cease production completely.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey