lcd screen construction brands

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Toshiba is a famous multinational company with a history of 130 years. It covers a wide range of businesses, including social infrastructure construction, home appliances, digital products, and electronic components. It covers almost every aspect of production and life. Toshiba has the largest research and development institution in Japan. Through unremitting innovation and development, Toshiba has been at the forefront of science and technology in the world.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Manufacturer of indoor or outdoor digital and electronic food menu displays. Panel, graphic, multi-head, digital and LCD displays are offered. Available in 32 to 65 in. dimensions. Features include HD video quality, proprietary case design, integrated order confirmation systems, sunlight readability, windproof design, IP67 protection and single, dual or triple screen configurations. Displays are resistant to frost, rain, wind, snow, heat and cold. Standard displays are also offered. Used for restaurants, drive-thru and other quick-service purposes. Suitable for advertising and promotional applications. Made in the USA.

![]()

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Crystalfontz America is the leading supplier of LCD, TFT, OLED and ePaper display modules and accessories. We specialize in providing our customers the very best in display products, cables and connectors.

In addition to our large catalog of displays, we offer LCD development kits, breakout boards, cables, ZIF connectors and all of the LCD software and drivers you need to develop your product or project. We are located in the U.S. so we can get product to you fast!

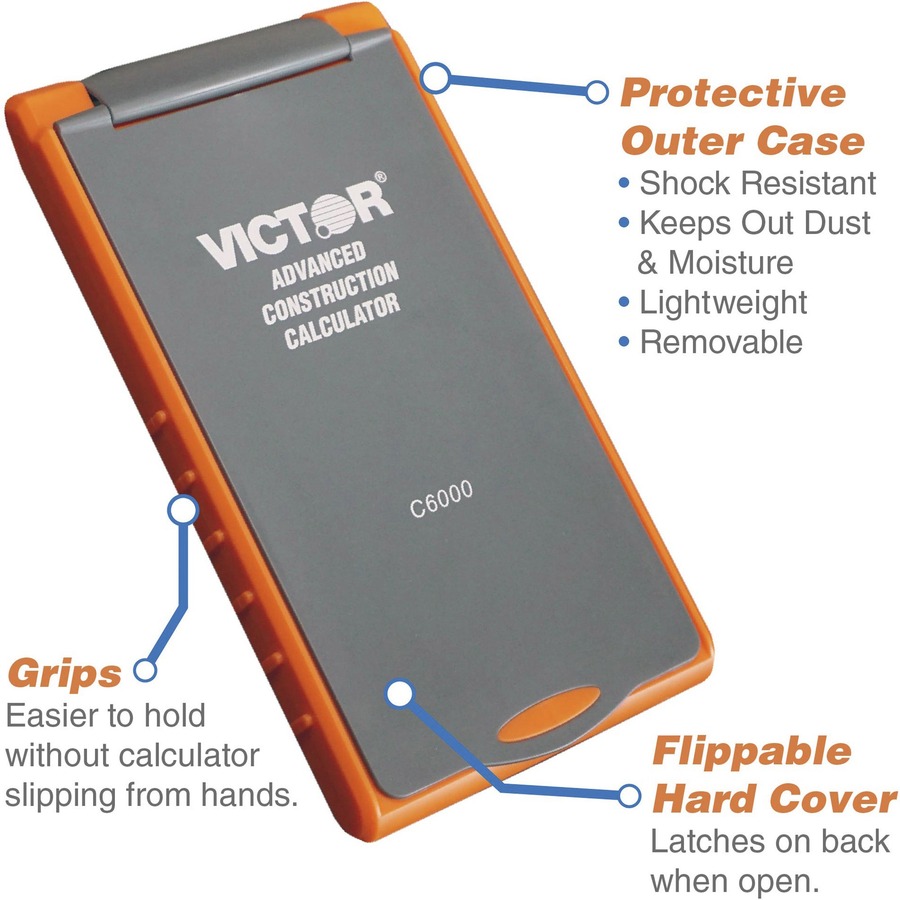

Construction is a tough and gritty industry that entails a great deal of physically exhausting labour from crew members and their equipment. Rugged LCD monitors are an absolute requirement in the many different kinds of harsh environments involved in construction work. To survive fieldwork, industrial touchscreen computers must be durable; dependable; weather-, shock-, and vibration-resistant; and readable in all conditions. It is imperative that these machines are built to last with the average construction crew’s dense working conditions kept in mind throughout the entire design process.

Every day on a construction site presents numerous opportunities for something to go terribly wrong, causing major or minor delays or even injuries. Industrial touchscreen displays and computers can help prevent these types of unfortunate situations from occurring. These machines are specially built to withstand the toughest physical working conditions while also increasing productivity, accuracy, and ensuring every task is completed within a reasonable timeframe. High-performance rugged touchscreen PCs can easily be integrated and implemented in any construction-related field to replace or update outdated systems. It is in every construction company’s best interest to stay in the know about new technological advancements in its field to ensure the safety of its crew and to alleviate some of the stress from their jobs. They need reliable equipment that works just as hard as they do.

The applications provided by industrial touchscreen PCs are meant to reduce and ease some of the immense pressures that are involved in the construction industry. These applications offer crew members and on-site forepersons the following conveniences:Tracking inventory

All of the above mentioned applications are crucial for ensuring on-site safety, security, and precision. When it comes to construction work, there is very little room for error, and mistakes due to negligence cannot be tolerated. That is why it is of great importance to use only the highest quality materials and equipment that will significantly contribute to navigating through difficult and stressful working environments. Cost-effectiveness and reliability must always be taken into consideration; therefore, construction companies need long-lasting and high-endurance products in their arsenal.

Nauticomp Inc. has been a leading provider of rugged displays for marine, military, and industrial applications for over 20 years. We have decades of experience designing, engineering, and manufacturing displays and monitors for use in harsh outdoor environments. Our waterproof, sunlight-readable, multifunction displays are the most durable and versatile monitors for hard-core construction environments. We also offer custom designs, building individualized monitors to meet our clients’ needs. We are dedicated to providing high-performance displays that are at the forefront of leading-edge display technology. Contact us at 1-705-328-2992 for Canadian service and at 1-800-267-9491 for U.S. service.

Construction is a tough and gritty industry that entails a great deal of physically exhausting labour from crew members and their equipment. Rugged LCD monitors are an absolute requirement in the many different kinds of harsh environments involved in construction work. To survive fieldwork, industrial touchscreen computers must be durable; dependable; weather-, shock-, and vibration-resistant; and readable in all conditions. It is imperative that these machines are built to last with the average construction crew’s dense working conditions kept in mind throughout the entire design process.

Every day on a construction site presents numerous opportunities for something to go terribly wrong, causing major or minor delays or even injuries. Industrial touchscreen displays and computers can help prevent these types of unfortunate situations from occurring. These machines are specially built to withstand the toughest physical working conditions while also increasing productivity, accuracy, and ensuring every task is completed within a reasonable timeframe. High-performance rugged touchscreen PCs can easily be integrated and implemented in any construction-related field to replace or update outdated systems. It is in every construction company’s best interest to stay in the know about new technological advancements in its field to ensure the safety of its crew and to alleviate some of the stress from their jobs. They need reliable equipment that works just as hard as they do.

The applications provided by industrial touchscreen PCs are meant to reduce and ease some of the immense pressures that are involved in the construction industry. These applications offer crew members and on-site forepersons the following conveniences:Tracking inventory

All of the above mentioned applications are crucial for ensuring on-site safety, security, and precision. When it comes to construction work, there is very little room for error, and mistakes due to negligence cannot be tolerated. That is why it is of great importance to use only the highest quality materials and equipment that will significantly contribute to navigating through difficult and stressful working environments. Cost-effectiveness and reliability must always be taken into consideration; therefore, construction companies need long-lasting and high-endurance products in their arsenal.

Nauticomp Inc. has been a leading provider of rugged displays for marine, military, and industrial applications for over 20 years. We have decades of experience designing, engineering, and manufacturing displays and monitors for use in harsh outdoor environments. Our waterproof, sunlight-readable, multifunction displays are the most durable and versatile monitors for hard-core construction environments. We also offer custom designs, building individualized monitors to meet our clients’ needs. We are dedicated to providing high-performance displays that are at the forefront of leading-edge display technology. Contact us at 1-705-328-2992 for Canadian service and at 1-800-267-9491 for U.S. service.

Among the world famous brands, the screen of South Korea"s samsung and LG is known to be produced and sold by themselves.Display screens of other niche brands, and those brands capable of self-production and self-marketing, also have an unassailable position in their own segments, facing various brands.For buyers, how to find suitable suppliers from these LCD panel manufacturers?

The world-renowned LCD panel production line is mainly controlled by several enterprises: au optronics in Taiwan;Chi mei electronics in Taiwan, China;Sharp, Japan;South Korea samsung, South Korea LG;Philips;Boe, etc.These companies supply the world"s main demand for liquid crystal displays.

LG Display is currently the world"s first LCD panel manufacturer. It is affiliated to LG group and headquartered in Seoul, South Korea.Its subsidiaries are: LG electronics, LG display, GS caltex, LG chemistry, LG life and health, etc., covering the fields of chemical energy, electronics and appliances, communication and service.LG Display"s customers include Apple, HP, DELL, SONY, Toshiba, PHILIPS, Lenovo, Acer and other world-class consumer electronics manufacturers.LG"s manufacturing base in China is in nanjing, shenyang.

Innolux is a tft-lcd panel manufacturing company founded by foxconn technology group in 2003.The factory is located in longhua foxconn technology park in shenzhen.Innolux has a strong display technology research and development team, coupled with foxconn"s strong manufacturing capacity, to effectively play the vertical integration benefits, to improve the level of the world plane display industry will have a pointer contribution.In March 2010, it merged with chi mei electronics and tong bao optoelectronics.

Au optronics, formerly known as acer technology, was founded in August 1996. It was renamed au optronics after the merger of au optronics and united optronics in 2001.Au optronics is the world"s first tft-lcd design, manufacturing and development company to be publicly listed on the New York stock exchange (NYSE).

Boe, founded in April 1993, is the largest display panel manufacturer in China and a provider of Internet of things technology, products and services.At present, boe has reached the world"s first place in the field of notebook LCD, flat LCD and mobile LCD. With its success in joining the apple supply chain, boe will become the world"s top three LCD panel manufacturers in the near future.

Sharp is known as "the father of LCD panel".Since its founding in 1912, sharp corporation has been developing the world"s first calculator and liquid crystal display, represented by the live pencil, which is the name of the company. At the same time, sharp corporation has been actively expanding new fields, contributing to the improvement of human living standards and social progress.Sharp is already owned by foxconn.

Toshiba is a famous multinational enterprise group with a history of 130 years. It has a wide range of business, including social infrastructure construction, household appliances, digital products, electronic components and other business fields, covering almost every aspect of production and life.

Toshiba, which has the largest research and development facility in Japan, developed the world"s first laptop computer, the first 16MB flash memory, and the world"s smallest 0.85-inch HDD.Build advanced HDDVD technology;Research and manufacture of new SED screens, Toshiba created many "world first".

The company has set up tft-lcd key materials and technology national engineering laboratory, national enterprise technology center, post-doctoral mobile workstation, and undertakes national development and reform commission, ministry of science and technology, ministry of industry and information technology and other major national special projects.The company"s strong technology and scientific research capabilities become the cornerstone of the company"s sustainable development.

At present, we look liquid crystal displays (LCDs) everywhere; however, they didn’t develop immediately. It took so much time to develop from the development of the liquid crystal to a large number of LCD applications. In the year 1888, the first Liquid crystals were invented by Friedrich Reinitzer (Austrian botanist). When he dissolved a material like a cholesteryl benzoate, then he observed that it initially it turns into a cloudy fluid & cleared up as its temperature rose. Once it is cooled, then the fluid became blue before lastly crystallizing. So, the first experimental liquid crystal display was developed by the RCA Corporation in the year1968. After that, the manufacturers of LCD have gradually designed ingenious differences &developments on the technology by taking this display device into an incredible range. So finally, the developments in the LCD have been increased.

A liquid crystal display or LCD draws its definition from its name itself. It is a combination of two states of matter, the solid and the liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens, TVs, cell phones, and portable video games. LCD’s technologies allow displays to be much thinner when compared to a cathode ray tube (CRT) technology.

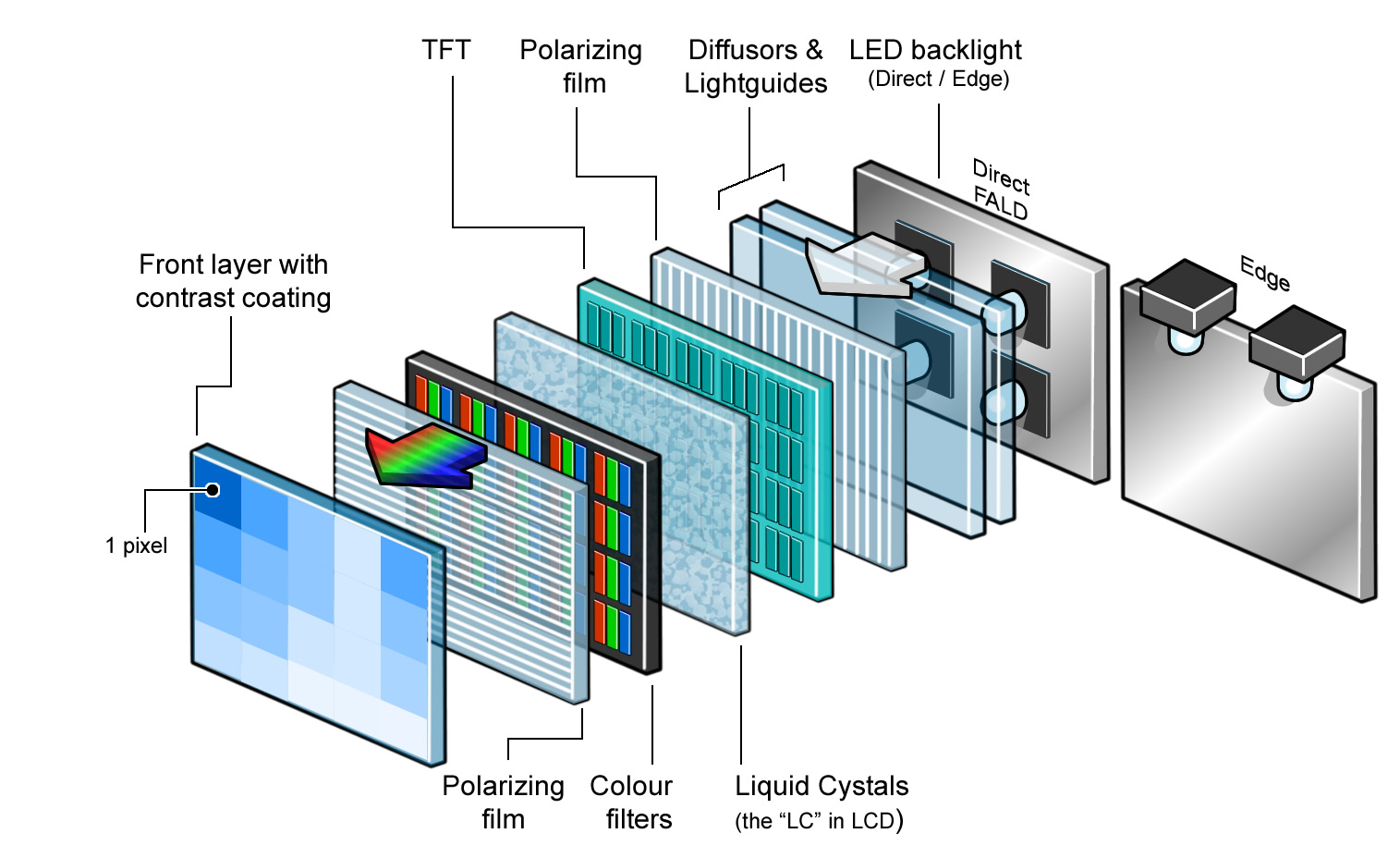

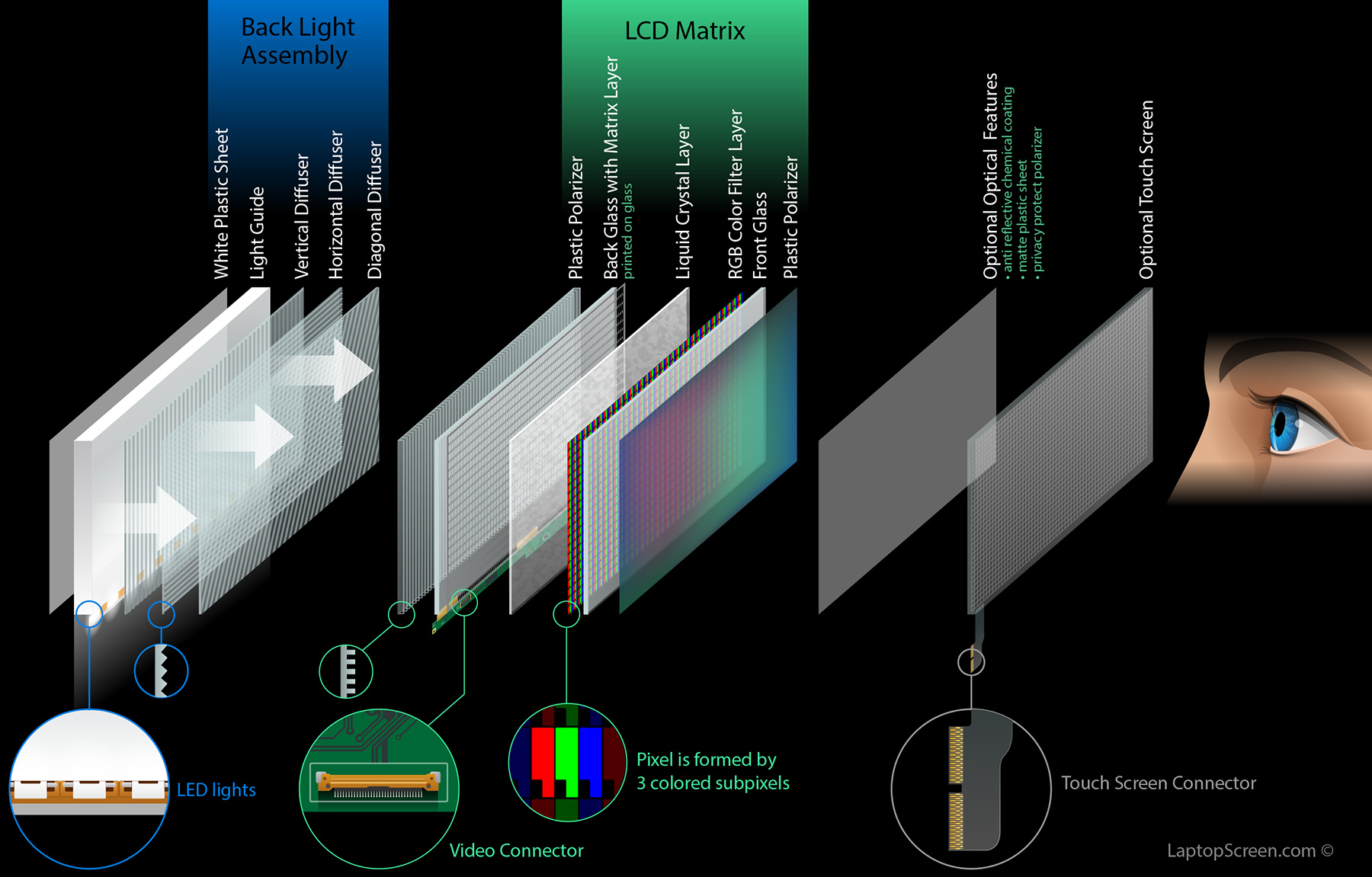

Liquid crystal display is composed of several layers which include two polarized panel filters and electrodes. LCD technology is used for displaying the image in a notebook or some other electronic devices like mini computers. Light is projected from a lens on a layer of liquid crystal. This combination of colored light with the grayscale image of the crystal (formed as electric current flows through the crystal) forms the colored image. This image is then displayed on the screen.

An LCD is either made up of an active matrix display grid or a passive display grid. Most of the Smartphone’s with LCD technology uses active matrix display, but some of the older displays still make use of the passive display grid designs. Most of the electronic devices mainly depend on liquid crystal display technology for their display. The liquid has a unique advantage of having low power consumption than the LED or cathode ray tube.

The liquid crystal display screen works on the principle of blocking light rather than emitting light. LCDs require a backlight as they do not emit light them. We always use devices which are made up of LCD’s displays which are replacing the use of cathode ray tube. Cathode ray tube draws more power compared to LCDs and is also heavier and bigger.

The principle behind the LCDs is that when an electrical current is applied to the liquid crystal molecule, the molecule tends to untwist. This causes the angle of light which is passing through the molecule of the polarized glass and also causes a change in the angle of the top polarizing filter. As a result, a little light is allowed to pass the polarized glass through a particular area of the LCD.

Thus that particular area will become dark compared to others. The LCD works on the principle of blocking light. While constructing the LCDs, a reflected mirror is arranged at the back. An electrode plane is made of indium-tin-oxide which is kept on top and a polarized glass with a polarizing film is also added on the bottom of the device. The complete region of the LCD has to be enclosed by a common electrode and above it should be the liquid crystal matter.

Next comes the second piece of glass with an electrode in the form of the rectangle on the bottom and, on top, another polarizing film. It must be considered that both the pieces are kept at the right angles. When there is no current, the light passes through the front of the LCD it will be reflected by the mirror and bounced back. As the electrode is connected to a battery the current from it will cause the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle to untwist. Thus the light is blocked from passing through. That particular rectangular area appears blank.

An LCD TV monitor utilizes the sunglasses concept to operate its colored pixels. On the flip side of the LCD screen, there is a huge bright light that shines out in the direction of the observer. On the front side of the display, it includes the millions of pixels, where each pixel can be made up of smaller regions known as sub-pixels. These are colored with different colors like green, blue, and red. Each pixel in the display includes a polarizing glass filter at the backside and the front side includes at 90 degrees, so the pixel looks dark normally.

Generally, every consumer doesn’t have much information regarding the different kinds of LCDs available in the market. So before selecting an LCD, they collect all the data like features, price, company, quality, specifications, service, customer reviews, etc. The truth is that promoters tend to get the benefit from the truth that most of the customers conduct extremely minimum research before purchasing any product.

In an LCD, motion blur can be an effect of how long a picture takes to switch and display on the screen. However, both of these incidents change very much among an individual LCD panel in spite of primary LCD tech. Selecting an LCD based on underlying technology must be more regarding price vs. preferred difference, viewing angles & reproduction of color than estimated blur otherwise other gaming qualities. The highest refresh rate, as well as response time, must be planned in any specifications of the panel. Another gaming tech like strobe will turn ON/OFF the backlight rapidly to decrease resolution.

The TN (Twisted Nematic) LCDs production can be done most frequently and used different kinds of displays all over the industries. These displays most frequently used by gamers as they are cheap & have quick response time as compared with other displays. The main disadvantage of these displays is that they have low quality as well as partial contrast ratios, viewing angles & reproduction of color. But, these devices are sufficient for daily operations.

IPS displays are considered to be the best LCD because they provide good image quality, higher viewing angles, vibrant color precision & difference. These displays are mostly used by graphic designers & in some other applications, LCDs need the maximum potential standards for the reproduction of image & color.

AFFS LCDs offer the best performance & a wide range of color reproduction as compared with IPS displays. The applications of AFFS are very advanced because they can reduce the distortion of color without compromising on the broad viewing angle. Usually, this display is used in highly advanced as well as professional surroundings like in the viable airplane cockpits.

The Passive-matrix type LCDs works with a simple grid so that charge can be supplied to a specific pixel on the LCD. The grid can be designed with a quiet process and it starts through two substrates which are known as glass layers. One glass layer gives columns whereas the other one gives rows that are designed by using a clear conductive material like indium-tin-oxide.

Active-matrix type LCDs mainly depends on TFT (thin-film transistors). These transistors are small switching transistors as well as capacitors which are placed within a matrix over a glass substrate. When the proper row is activated then a charge can be transmitted down the exact column so that a specific pixel can be addressed, because all of the additional rows that the column intersects are switched OFF, simply the capacitor next to the designated pixel gets a charge.

Both the displays like plasma and an LCD are similar, however, it works in a different way totally. Every pixel is a microscopic fluorescent lamp that glows through the plasma, whereas plasma is an extremely hot type of gas where the atoms are blown separately to make electrons (negatively charged) & ions (positively charged). These atoms flow very freely and generate a glow of light once they crash. The designing of the plasma screen can be done very bigger as compared with ordinary CRO (cathode-ray tube) TVs, but they are very expensive.

Thus, this is all about an overview of LCD and the structure of this from the backside to the front side can be done using backlights, sheet1, liquid crystals, sheet2 with color filters & screen. The standard liquid crystal displays use the backlights like CRFL (cold cathode fluorescent lamps). These lights are consistently arranged backside of the display to deliver reliable lighting across the panel. So the brightness level of all the pixels in the picture will have equal brightness.

I hope you have got a good knowledge of liquid crystal display. Here I leave a task for you. How is an LCD interfaced to a microcontroller? furthermore, any queries on this concept or electrical and electronic project Leave your answer in the comment section below.

Foxconn Technology Group on Friday said it will build an LCD screen fabrication facility in Mount Pleasant, a move that was put into question after reports earlier this week of the company reconsidering its plans.

The company said the decision came after “productive discussions between the White House and the company, and after a personal conversation between President Donald J. Trump and Chairman Terry Gou.” That Gen 6 plant will fabricate smaller, high-resolution LCD screens than the company had originally planned to make in its Mount Pleasant plant.

Reports from Reuters and Japanese news publication Nikkei Asian Review had called into question whether Foxconn would be fabricating any LCD screens in Wisconsin at all. The company earlier this week committed to building packaging plants, assembly facilities and research centers over the next 18 months in Mount Pleasant. But it fell short of committing to the Gen 6 fabrication plant to make TFT, or “thin-film-transistor” screens.

That fabrication plant could break ground over the next 18 months, according to a Friday statement from Racine County, the village of Mount Pleasant and the Racine County Economic Development Corp. The company in April is expected to hold open houses regarding its upcoming construction plans.

Foxconn first announced last year it was backing off from plans for a Gen 10.5 facility in Wisconsin to make very large LCD screens. Instead, the Gen 6 plant will produce small to mid-sized displays that would be used in televisions and by automakers.

"Over the last year at least, the capacity for the large LCD screen manufacturing in China has grown exponentially, and the cost has been cut in half," Sheehy said.

The actual fabrication of screens in Wisconsin is significant. The company is building Gen 10.5 plants in China, but such operations don’t exist in the United States. Fabricating the screens, versus assembling products around the finished LCD displays, was expected to attract a new supply chain of manufacturers to Foxconn’s plant.

Racine County Executive Jonathan Delagrave said the advanced manufacturing piece is important because it brings jobs paying $25 an hour and more. He said Foxconn has kept a direct line of communication with Racine County, and never communicated that screen fabrication was out of the picture.

LCD stands for liquid crystal display. This display technology uses liquid crystals to form images on the screen which are then made visible through ambient light or a light emitting diode (LED) backlight. Liquid crystal displays are currently the most popular display type on the market. If you have a display on your device, there is a high likelihood that it is a liquid crystal display (LCD).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey