raw lcd modules manufacturer

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Whether it’s a monitor on the car door or you need it in the trunk, if your looking to install a monitor on a not so common place, a raw monitor can help get the job done. Raw LCD Monitors are raw framed LCD monitors. A raw LCD module can be installed anywhere a LCD screen is required. Pair a raw screen with a power adapter to have a versatile monitor for home or commercial use.

When looking for raw lcd screen, make sure you check the specifications of the phone model for which you want a replacement screen. While many manufacturers do use the same screen, the lcd screen assembly may be different between models. Ask our suppliers for the specifics before making a purchase and they will be happy to help you out. Many are also downgrading to an aftermarket lcd screen from a led screen to extend the battery life of their phones.

Explore the extensive selection of wholesale raw lcd screen LCD displays, TFT, and HMI that can be used across a range of industries, including domestic, medical, industrial, automotive, and many others. You can choose from a number of standard industry sizes and find the raw lcs screen that are applicable to your required use. If you would like options that allow a smaller environmental footprint due to low power consumption, you can browse the Chip-on-Glass (COG) LCDs. COGs are designed without PCBs so have a slimmer profile.

Browse cutting-edge raw lcd screen on Alibaba.com at reasonable prices. raw lcd screen in varying display size and resolution are accessible on the site. The merchandise are useful in automotive, medical, and industrial screen displays. raw lcd screen having multiple interface types and display technology are in stock. raw lcd screen on Alibaba.com have high resolution and luminance to display precise details. They have a capacitive touch for convenient use. They can show multiple characters per line. raw lcd screen can be manufactured to suit smaller wearable devices or large projectors. They can be integrated with smart home systems for face recognition and office equipment. They feature multiple interfacing types like MPU or RS232. They are sturdy, thanks to a toughened glass structure with a considerable operating temperature range. The life span of raw lcd screen stretches up to several thousand pages hours get.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

If you are TFT LCD module users, we will provide you with the most suitable TFT LCD products, including the selection of control board, accessories, testing, maintenance and a series of services.

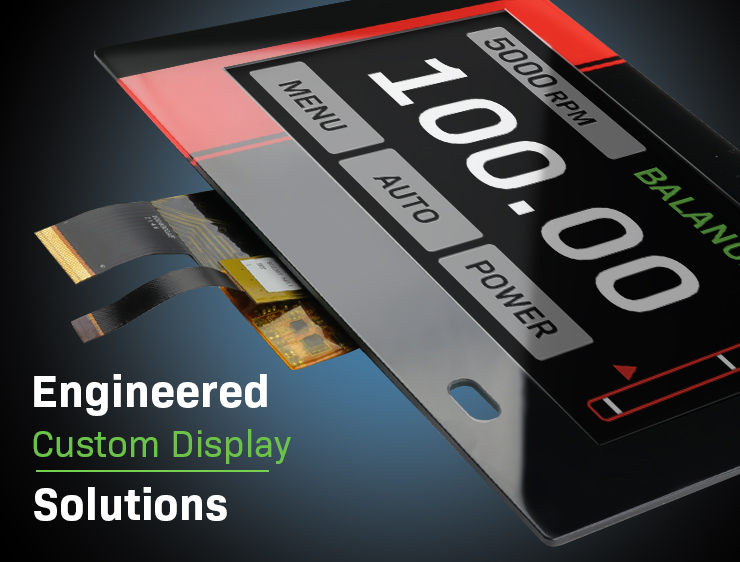

Whether you need a raw LCD or a full assembly with touch-sensitive film, cover glass, and custom bezel silk-screened with your logo, in one delivery, or with warehousing and logistics support, we’re here to help.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

This 7 inch TFT LCD display is made by TianMa,it suit for industry control, instrumentatiom,medical electronics, power electric equipment applications.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

Before ordering an LCD to be integrated into a long-term project, there are several questions an engineer should ask. The most important question that needs to be asked is what the estimated long-term availability of the display is.

This is a key question since you don"t want a production line down when your guaranteed LCD is no longer available. You will be forced to locate another source, and chances are, the replacement display won"t be a drop-in equivalent.

A different display means modifying some part of your design like your source code, mounting options, and the type of connection between your PCB and LCD. Finding replacement parts can easily eat up your time and resources.

Most LCD modules contain a controller that interfaces between the raw LCD and your processor. Hence, the word module means that it has some type of brain/controller attached to it. It is common for controllers to be phased out and replaced with an equivalent, but equivalent does not mean that your firmware will be 100% compatible. You may have to modify your code. Updating your code is not a big drain of time, but it makes it tricky to use new displays for warranty service on older products.

This is a Graphic LCD with green backlight that can display not just alphanumeric characters but also simple graphics. Great for doing neat menus and animations.read more...

Nuline is the largest supplier of custom developed LCD (Liquid Crystal Display) modules for the automotive industry in India. The LCD modules are developed as per customer specifications for 2 Wheeler and 4 wheeler instrumentread more...

Msquare is known as the leading company engaged in dealing and supplying & providing after sales support of branded LED/ Plasma / LCD DISPLAYS like VIDEO WALL developed by DELTA , Hitachi, LG, Toshiba or Samsung. This diplay products supplied by our company are of excellent resolution & picture quality. All the productsread more...

Bengaluru 16th Cross Shed No.39/24/1, Byraweshwara Industrial Estate Andhrahalli Main Road Bengaluru (bangalore) Rural, Bengaluru - 560091, Dist. Bengaluru, Karnataka

Nuline Technologies established its manufacturing facility for manufacturing Alpha Numeric LCD display modules in the year 1998 primarily to meet the domestic requirement. Nuline has established an excellent production facility using surface mount technology and have been manufacturing both alphanumeric and graphical displayread more...

With the support of or expert team members, we have been able to offer a wide range of LCD Display. These devices are available in various technical specifications. Our LCD Displays are acclaimed for their high tensile strength less maintenance cost, precise design and effective usage. We offer these at reasonableread more...

Product Description: Our company is the foremost known for offering LCD Display to the clients. This product is available in various specifications and can be customized as per the needs of the clients. LCD Display is best known for different attributes like compact design, less in maintenance, light weight and soread more...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey