tft display vs amoled factory

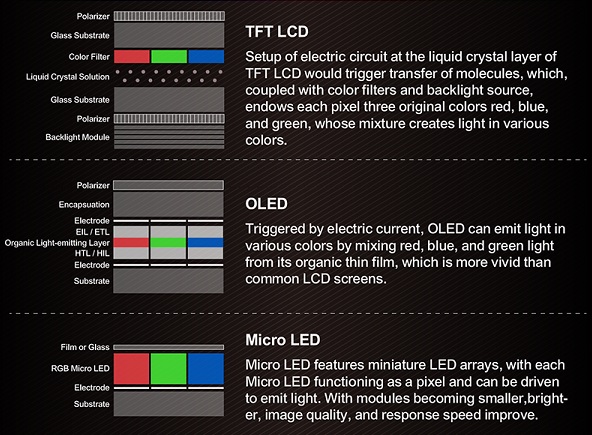

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

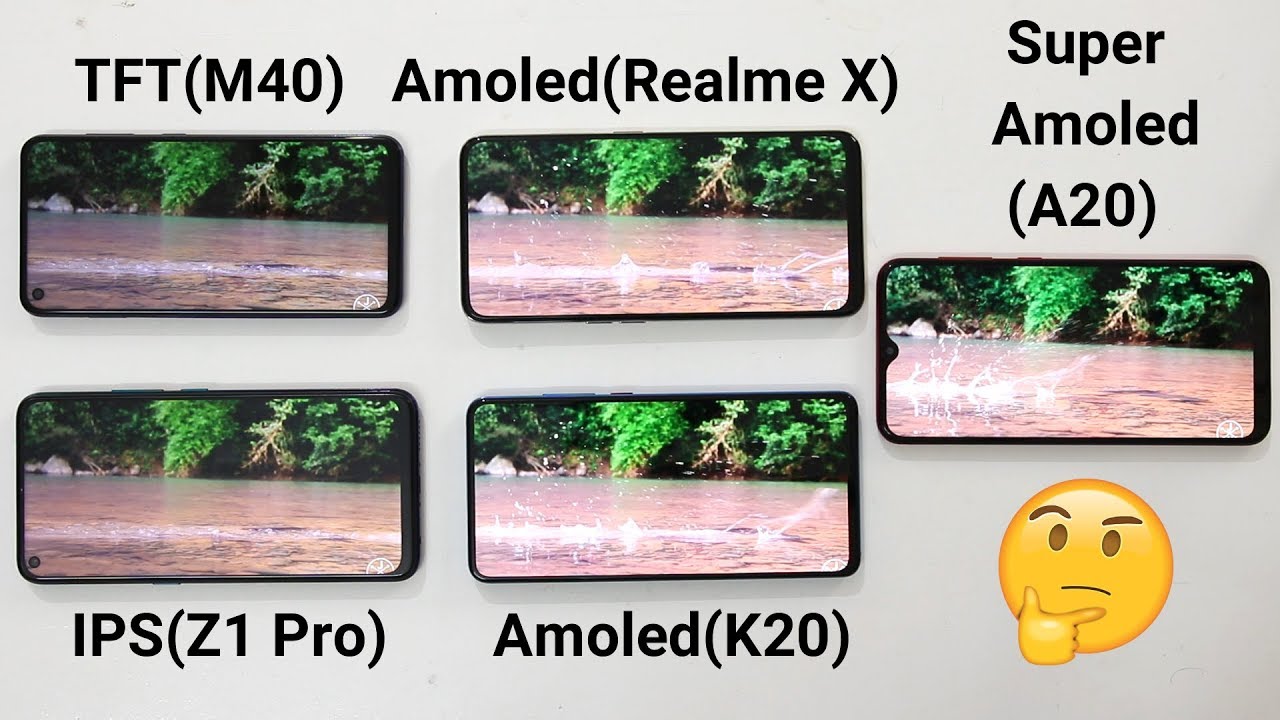

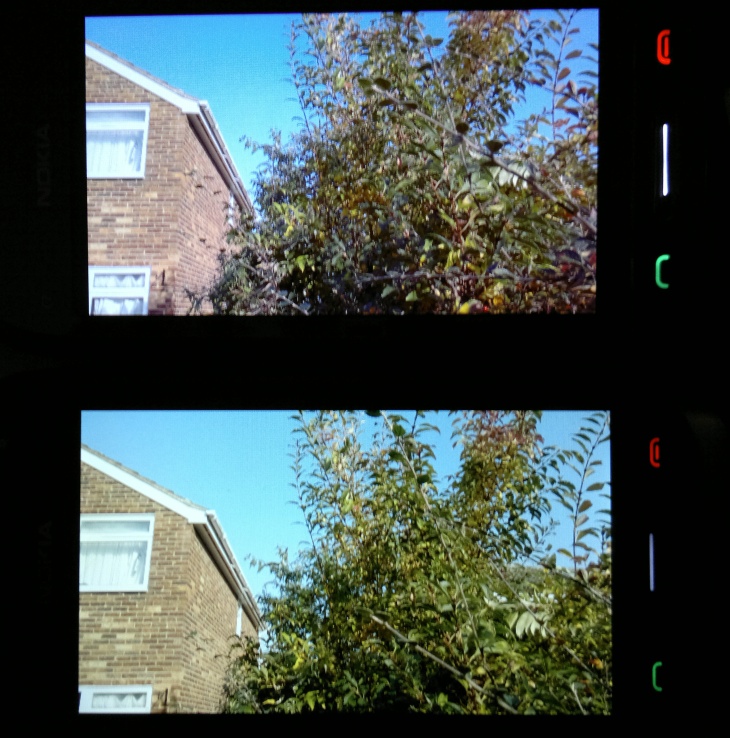

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

The color display is fantastic. Color intensity, sharpness, and luminance settings that are second to none and can be customized to meet the needs of any application.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

Due to the apparent glass panels, there is limited functionality. For instance, there are ineffective for outdoor use because the glass can display glares from its natural lighting)

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

While red and green AMOLED sheets have a greater lifespan (46,000 to 230,000 hours), azure compounds have significantly shorter longevity (up to roughly 14,000 hours).

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

Tried and trusted TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination.

By contrast the Active Matrix OLED (AMOLED) display requires no backlight and can light up or turn off each of their pixels independently. As the name suggests, they are made of organic material.

An AMOLED display has many other benefits which make it a superior looking display including exceptional vieiwng angles and a display that looks practically black when it is switched off.

So, why use a TFT display? Well, it is a mature technology meaning the manufacturing processes are efficient, yields high and cost much lower than AMOLED.

TFT displays also have a much longer lifespan than AMOLED displays and are available in a far greater range of standard sizes, which can be cut down to fit a space restricted enclosure for a relatively low cost adder.

Which type of display you choose really depends on your application, environment and users, so why not get in touch with us today to discuss your requirements.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

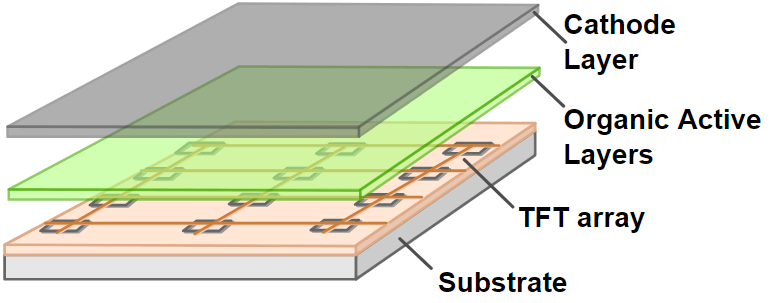

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

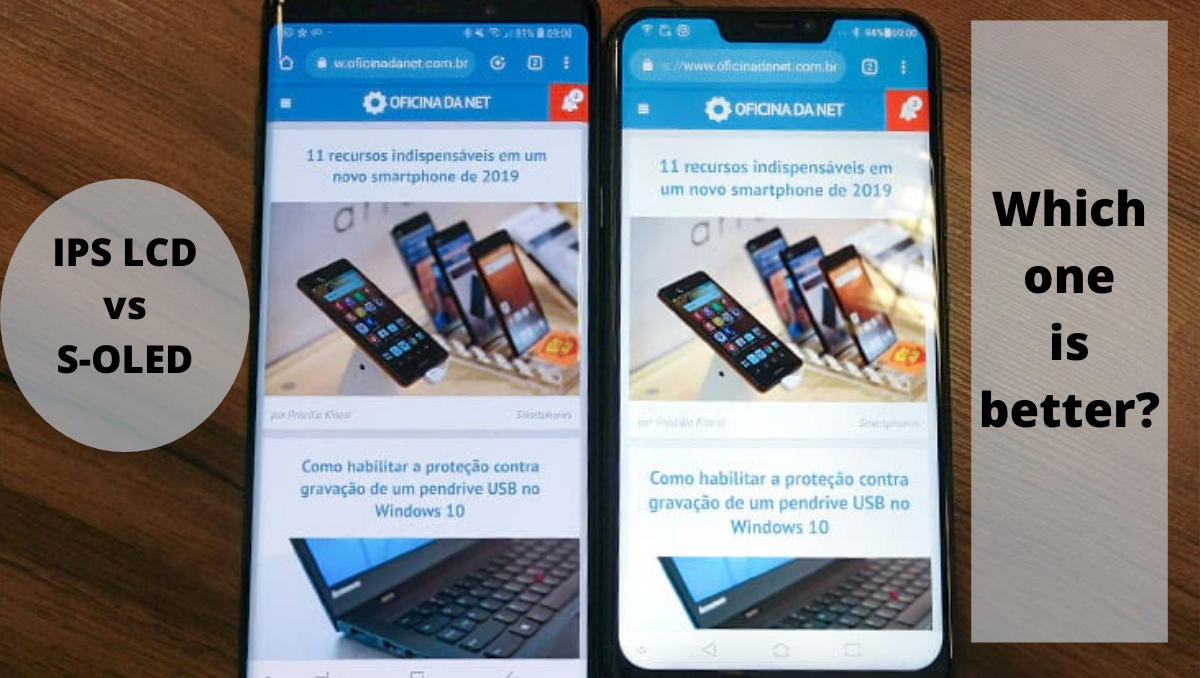

This rise of small, powerful components has also led to significant developments in display technology. The most recent of which, AMOLED, is now the main competitor for the most common display used in quality portable electronics – the TFT–LCD IPS (In-Plane Switching) display. As more factories in the Far East begin to produce AMOLED technology, it seems likely we will enter a battle of TFT IPS versus AMOLED, or LCD vs LED. Where a large percentage of a product’s cost is the display technology it uses, which provides best value for money when you’re designing a new product?

TFT IPSdisplays improved on previous TFT LCD technology, developed to overcome limitations and improve contrast, viewing angles, sunlight readability and response times. Viewing angles were originally very limited – so in-plane switching panels were introduced to improve them.

Modern TFT screens can have custom backlights turned up to whatever brightness that their power limit allows, which means they have no maximum brightness limitation. TFT IPS panels also have the option for OCA bonding, which uses a special adhesive to bond a touchscreen or glass coverlens to the TFT. This improves sunlight readability by preventing light from bouncing around between the layers of the display, and also improves durability without adding excess bulk; some TFT IPS displays now only measure around 2 mm thick.

AMOLED technology is an upgrade to older OLED technology. It uses organic compounds that emit light when exposed to electricity. This means no backlight, which in turn means less power consumption and a reduction in size. AMOLED screens tend to be thinner than TFT equivalents, often produced to be as thin as 1 mm. AMOLED technology also offers greater viewing angles thanks to deeper blacks. Colours tend to be greater, but visibility in daylight is lower than IPS displays.

As manufacturers increasingly focus on smaller devices, such as portable smartphones and wearable technology, the thinness and high colour resolution of AMOLED screens have grown desirable. However, producing AMOLED displays is far more costly as fewer factories offer the technology at a consistent quality and minimum order quantities are high; what capacity there is is often taken up the mobile phone market Full HD TFT IPS displays have the advantage of being offered in industry standard sizes and at a far lower cost, as well as offering superior sunlight visibility.

The competition between displays has benefitted both technologies as it has resulted in improvements in both. For example, Super AMOLED, a marketing brand by Samsung, involves the integration of a touchscreen layer inside the screen, rather than overlaid on it. The backlight in TFT technology means they can never truly replicate the deep blacks in AMOLED, but improvements have been made in resolution to the point where manufacturers like Apple have been happy to use LCD screens in their smartphones, even as they compete with Samsung’s Super AMOLED.

Aside from smartphones, many technologies utilise displays to offer direct interaction with customers. To decide whether TFT LCD will survive the rise of AMOLED technology, we must first recap the advantages of LCD. The backlit quality means that whites are bright and contrast is good, but this will wear down a battery faster than AMOLED. Additionally, cost is a significant factor for LCD screens. They are cheaper, more freely available and are offered in industry standard sizes so can be ordered for new products without difficulty.

It seems hard to deny that AMOLED will someday become the standard for mobile phones, which demand great colour performance and are reliant on battery life. Where size is an issue, AMOLED will also grow to dominance thanks to its superior thinness. But for all other technologies, particularly in industrial applications, TFT-LCD offers bright, affordable display technology that is continually improving as the challenge from AMOLED rises.

AMOLED (Active Matrix Organic Light Emitting Diode) and TFT (Thin Film Transistor) are the two types of displays that are used in mobile phones. TFT is actually a process of producing the displays and is used even by AMOLED but for most purposes, TFT is used to refer to LCD displays. The difference between them is the material as AMOLED uses organicmaterials, mainly carbon, while TFT does not.

There are differences between the two that are quite tangible. For starters, AMOLED generates its own light rather than relying on a backlight like a TFT-LCD does. This consequently means that AMOLED displays are much thinner than LCD displays; due to the absence of a backlight. It also results in much better colors than a TFT is capable of producing. As each pixel’s color and light intensity can be regulated independently and no light seeps from adjacent pixels. A side by side comparison of the two displays with the same picture should confirm this. Another effect of the lack of a backlight is the much lower power consumption of the device. This is very desirable when it comes to mobile phones where every single feature competes for the limited capacity of the battery. As the screen is on 90% of the time that the device is being used, it is very good that AMOLED displays consume less. Just how much of a difference is not very fixed though as it really depends on the color and intensity of the image. Having a black background with white text consumes much less energy than having black text on a white background.

The biggest disadvantage that AMOLED has is the shorter lifespan of the screen compared to TFT. Each pixel in the display degrades with each second that it is lit and even more so the brighter it is. Â Despite improvements on the lifetime of AMOLED displays, AMOLED still only lasts a fraction of the lifetime of a TFT display. With that said, an AMOLED display is able to outlast the usable lifetime of the device before parts of it start to degrade.

The main hindrance to the massive adaptation of AMOLED is the low production numbers. TFT has been in production for much longer and the infrastructure is already there to meet the demands.

It"s an organic light-emitting display. OLED display technology is different from the traditional LCD display mode, without backlight. It uses a very thin coating of organic materials and a glass substrate, which emit light when an electric current passes through. Moreover, OLED screen module can be made lighter and thinner, with larger viewing angle, and can significantly save power.

AMOLED is panel-self luminous. The TFT is illuminated on the LCD panel by backlight. AMOLED effect is more colorful and brighter. The screen can be seen clearly outside during the day. The most important is that the power consumption of AMOLED is much lower. AMOLED screen is more expensive than TFT LCD touch screen. The life of AMOLED screens is also longer.

AMOLED, after all, is a new technology, which has a bright future. TFT LCD touch screen can be thinned, and LTPS technology is still relatively stable. AMOLED module has low qualified rate and long lead time. So if the size and resolution are the same, buy the cheapest one.

Kingtech LCD is one of the leading TFT LCD OEM / ODM LCD display manufacturers in China. Customizing industrial equipment, medical, POS, logistics equipment, smart home applications and other projects is allowed.

Devices like smartphones, media players, TVs, laptops, tablets, digital cameras, and other such gadgets require a technology that serves better quality visuals and excellent battery life.

The difference Between AMOLED and TFT is their production and quality. The cost of producing Active-Matrix Organic LED is higher than the Thin-Film Transistor LCDs.

Parameters of ComparisonAMOLEDTFTFull FormsThe full form of an AMOLED Display is an Active-Matrix Organic Light-Emitting Diode.The full form of the TFT is a Thin-Film Transistor.

OLED displays a thin type of film display technology. AMOLED is also a sub-form of it that is consists of organic compounds of the electroluminescent and pixel technology.

The full form of an AMOLED Display is an Active-Matrix Organic Light-Emitting Diode. The AMOLED display is the variant of Light-Emitting Diodes (LEDs).

Its closest technology version is its older form, out of which it is improvised, OLEDs (Organic Light-Emitting Diodes). The display looks black after turning it off.

The product is costlier than TFT. All-round viewing angles. Bright and vibrant colors are available with these LEDs. It provides visuals with loss-resolution quality.

Just like AMOLED, this tech also improves image qualities, contrasts, and their addressability. But it provides visuals with high-resolution quality, even better than the former.

The display does not entirely look black after turning it off. And the Color inversion at extreme viewing angles. Limited contrast options are available.

But it is cheaper than the AMOLED. It is available on easily affordable devices and smartphones. Its closest technology version available is its upgraded form, IPS LCDs (In-Plane Switching LCDs) with improvised features.

Active-Matrix Organic LED displays are available in bright and vibrant colors. On the other hand, Thin-Film Transistor LCDs have limited contrast options.

Both screens are made up of Pixels. A pixel is made up of 3 sections called sub-pixels. The three sections are red, green and blue (primary colors for display tech).

The light is generated from a “backlight”. A series of thin films, transparent mirrors and an array of white LED Lights that shine and distribute light across the back of the display.

On some lower quality LCD screens, you can see bright spots in the middle or on the perimeters of screens. This is caused by uneven light distribution. The downside to using backlights, is that black is never true black, because no matter what, light has to be coming through, so it will never have as dark of a screen as an AMOLED screen. Its comparable to being able to slow a car down to 2 mph versus coming to a complete stop.

Each pixel is its own light source, meaning that no backlight is necessary. This allows the screen assembly to be thinner, and have more consistent lighting across the whole display.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

TFT active-matrix is a key technology for display manufacturing such as AMLCD and AMOLED display. Past, current and future TFT technologies are reviewed and discussed with the use of amorphous silicon (a-Si), low-temperature poly-Si (LTPS), organic and oxide semiconductors. TFT technologies based on a-Si:H and LTPS are mature enough, but the TFTs with oxide and organic semiconductors are still many issues to be solved for large scale manufacturing. Currently, display manufacturing based on a-IGZO TFT backplane is hot issue because a-Si:H production line can be easily modified to that for IGZO TFTs.

AMOLED is Active Matrix OLED. An Active Matrix OLED uses a TFT (Thin Film Transistor) transistor-per-pixel architecture. Using a transistor-per-pixel allows higher resolution displays to be made and avoids the problems associated with high duty cycle passive displays.

In an AMOLED, once a pixel is turned on, it can stay on for the entire frame time. Compare this to a 1/64 duty cycle PMOLED (Passive Matrix OLED) where a pixel can be on at most 1/64 of the frame time.

Manufacturing of AMOLED displays is much more difficult than PMOLED displays. Currently, this has AMOLED displays priced much higher than a similar backlit color TFT LCD display.

AMOLED (active-matrix organic light-emitting diode, OLED display device technology. OLED describes a specific type of thin-film-display technology in which organic compounds form the electroluminescent material, and active matrix refers to the technology behind the addressing of pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for passive-matrix OLED operation.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays.

AMOLED was developed in 2006. Samsung SDI was one of the main investors in the technology, and many other display companies were also developing it. One of the earliest consumer electronics products with an AMOLED display was the BenQ-Siemens S88 mobile handsetiriver Clix 2 portable media player.Nokia N85 followed by the Samsung i7110 - both Nokia and Samsung Electronics were early adopters of this technology on their smartphones.

Manufacturers have developed in-cell touch panels, integrating the production of capacitive sensor arrays in the AMOLED module fabrication process. In-cell sensor AMOLED fabricators include AU Optronics and Samsung. Samsung has marketed its version of this technology as "Super AMOLED". Researchers at DuPont used computational fluid dynamics (CFD) software to optimize coating processes for a new solution-coated AMOLED display technology that is competitive in cost and performance with existing chemical vapor deposition (CVD) technology. Using custom modeling and analytic approaches, Samsung has developed short and long-range film-thickness control and uniformity that is commercially viable at large glass sizes.

The amount of power the display consumes varies significantly depending on the color and brightness shown. As an example, one old QVGA OLED display consumes 0.3 watts while showing white text on a black background, but more than 0.7 watts showing black text on a white background, while an LCD may consume only a constant 0.35 watts regardless of what is being shown on screen.

AMOLED displays may be difficult to view in direct sunlight compared with LCDs because of their reduced maximum brightness.Super AMOLED technology addresses this issue by reducing the size of gaps between layers of the screen.PenTile technology is often used for a higher resolution display while requiring fewer subpixels than needed otherwise, sometimes resulting in a display less sharp and more grainy than a non-PenTile display with the same resolution.

The organic materials used in AMOLED displays are very prone to degradation over a relatively short period of time, resulting in color shifts as one color fades faster than another, image persistence, or burn-in.

As of 2010, demand for AMOLED screens was high and, due to supply shortages of the Samsung-produced displays, certain models of HTC smartphones were changed to use next-generation LCD displays from the Samsung-Sony joint-venture SLCD in the future.

Flagship smartphones sold in 2020 and 2021 used either a Super AMOLED. Super AMOLED displays, such as the one on the Samsung Galaxy S21+ / S21 Ultra and Samsung Galaxy Note 20 Ultra have often been compared to IPS LCDs, found in phones such as the Xiaomi Mi 10T, Huawei Nova 5T, and Samsung Galaxy A20e.ABI Research, the AMOLED display found in the Motorola Moto X draws just 92 mA during bright conditions and 68 mA while dim.

"Super AMOLED" is a marketing term created by Samsung for an AMOLED display with an integrated touch screen digitizer: the layer that detects touch is integrated into the display, rather than overlaid on top of it and cannot be separated from the display itself. The display technology itself is not improved. According to Samsung, Super AMOLED reflects one-fifth as much sunlight as the first generation AMOLED.One Glass Solution (OGS).

Future displays exhibited from 2011 to 2013 by Samsung have shown flexible, 3D, transparent Super AMOLED Plus displays using very high resolutions and in varying sizes for phones. These unreleased prototypes use a polymer as a substrate removing the need for glass cover, a metal backing, and touch matrix, combining them into one integrated layer.

Also planned for the future are 3D stereoscopic displays that use eye-tracking (via stereoscopic front-facing cameras) to provide full resolution 3D visuals.

Kim, Yang Wan; Kwak, Won Kyu; Lee, Jae Yong; Choi, Wong Sik; Lee, Ki Yong; Kim, Sung Chul; Yoo, Eui Jin (2009). "40 Inch FHD AM-OLED Display with IR Drop Compensation Pixel Circuit". SID Symposium Digest of Technical Papers. 40: 85. doi:10.1889/1.3256930. S2CID 110871831.

Lee, Myung Ho; Seop, Song Myoung; Kim, Jong Soo; Hwang, Jung Ho; Shin, Hye Jin; Cho, Sang Kyun; Min, Kyoung Wook; Kwak, Won Kyu; Jung, Sun I; Kim, Chang Soo; Choi, Woong Sik; Kim, Sung Cheol; Yoo, Eu Jin (2009). "Development of 31-Inch Full-HD AMOLED TV Using LTPS-TFT and RGB FMM". SID Symposium Digest of Technical Papers. 40: 802. doi:10.1889/1.3256911. S2CID 110948118.

Hamer, John W.; Arnold, Andrew D.; Boroson, Michael L.; Itoh, Masahiro; Hatwar, Tukaram K.; Helber, Margaret J.; Miwa, Koichi; Levey, Charles I.; Long, Michael; Ludwicki, John E.; Scheirer, David C.; Spindler, Jeffrey P.; Van Slyke, Steven A. (2008). "System design for a wide-color-gamut TV-sized AMOLED display". Journal of the Society for Information Display. 16: 3. doi:10.1889/1.2835033. S2CID 62669850.

Lin, Chih-Lung; Chen, Yung-Chih (2007). "A Novel LTPS-TFT Pixel Circuit Compensating for TFT Threshold-Voltage Shift and OLED Degradation for AMOLED". IEEE Electron Device Letters. 28 (2): 129. Bibcode:2007IEDL...28..129L. doi:10.1109/LED.2006.889523. S2CID 11194344.

Sarma, Kalluri R.; Chanley, Charles; Dodd, Sonia R.; Roush, Jared; Schmidt, John; Srdanov, Gordana; Stevenson, Matthew; Wessel, Ralf; Innocenzo, Jeffrey; Yu, Gang; O"Regan, Marie B.; MacDonald, W. A.; Eveson, R.; Long, Ke; Gleskova, Helena; Wagner, Sigurd; Sturm, James C. (2003). "Active-matrix OLED using 150°C a-Si TFT backplane built on flexible plastic substrate (Proceedings Paper)". SPIE Proceedings. 5080: 180. doi:10.1117/12.497638. S2CID 12958469. "Archived copy" (PDF). Archived from the original (PDF) on 28 June 2011. Retrieved 2010-09-06.link)

Reid Chesterfield, Andrew Johnson, Charlie Lang, Matthew Stainer, and Jonathan Ziebarth, "Solution-Coating Technology for AMOLED Displays Archived 16 May 2011 at the Wayback Machine", Information Display Magazine, January 2011.

Dong, Mian; Choi, Yung-Seok Kevin; Zhong, Lin (2009). "Power modeling of graphical user interfaces on OLED displays". Proceedings of the 46th Annual Design Automation Conference on ZZZ - DAC "09. p. 652. doi:10.1145/1629911.1630084. ISBN 9781605584973. S2CID 442526.

"AMOLED vs LCD: differences explained". Android Authority. 8 February 2016. Archived from the original on 27 December 2016. Retrieved 6 February 2017.

Tim Carmody (10 November 2010). "How Super AMOLED displays work". Wired. Wired.com. Archived from the original on 28 September 2012. Retrieved 10 October 2012.

Ashtiani, Shahin J.; Reza Chaji, G.; Nathan, Arokia (2007). "AMOLED Pixel Circuit With Electronic Compensation of Luminance Degradation". Journal of Display Technology. 38 (1): 36. Bibcode:2007JDisT...3...36A. doi:10.1109/JDT.2006.890711. S2CID 44204246.

"AMOLED vs LCD: Which screen is best for your phone?". digitaltrends.com. 29 August 2014. Archived from the original on 29 March 2018. Retrieved 6 May 2018.

OLED displays have become increasingly common and accessible over the past few years. While they were once reserved for premium smartphones, you’ll now find OLED displays at every smartphone price point. Not every OLED display is equal, though – differences in materials and manufacturing processes can result in varying display qualities. In that vein, let’s explore the differences between POLED vs AMOLED, and what these acronyms mean in the real world.

Before differentiating between POLED and AMOLED, it’s worth understanding the fundamentals of OLED display technology. To that end, let’s ignore the P and AM prefixes for now.

If you look at an OLED display under a microscope, you’ll see these diodes arranged in various red, green, and blue configurations in order to produce a full range of colors. OLED has a key advantage over conventional LCDs – individual light emitters can be switched completely off. This gives OLED deep blacks and an excellent contrast ratio.

Naturally, light emitters in an OLED display need a power source in order to function. Manufacturers can use either a passive wiring matrix or an active wiring matrix. Passive matrix displays provide current to an entire row of LEDs, which isn’t ideal but it is cheap. An active matrix, on the other hand, introduces a capacitor and thin-film transistor (TFT) network that allows each pixel to be driven individually. This driving matrix is part of the panel that sits on top of a base substrate.

Today, virtually all high-resolution OLED displays use active-matrix technology. This is because a passive matrix requires higher voltages the more pixels you introduce. High voltage reduces LED lifetimes, making a passive matrix OLED impractical.

AMOLED simply refers to an Active Matrix OLED panel. The AMOLED branding has become synonymous with Samsung Display’s OLED panels over the years. However, all smartphone OLED panels, including those from Samsung’s rivals like LG Display use active-matrix technology too – they just aren’t marketed as such.

In case you’re wondering what Super AMOLED means, it’s another bit of branding to indicate the presence of an embedded touch-sensitive layer. Similarly, Dynamic AMOLED refers to a display with HDR capabilities, specifically support for Samsung’s favored HDR10+ standard.

Now that we know the layered structure of an OLED display, we can move on to the plastic part. While the first wave of OLED panels was built using glass substrates, the desire for more interesting form factors has seen manufacturers use more flexible plastic components. This is where the P in POLED comes from.

Manufacturers have experimented with a range of plastics for flexible displays, including polyethylene terephthalate (PET) and polyethylene naphthalate (PEN). OLED manufacturers have settled on using polyimide plastics (PI) that can better withstand high TFT manufacturing temperatures. The type of substrate and heating process used also defines the flexibility of the display.

The somewhat confusing part is that Samsung’s AMOLED displays use plastic substrates. And as the name suggests, LG Display’s POLED technology clearly uses plastic as well. In summary, it’s absolutely possible to build a plastic substrate, active-matrix OLED panel. That’s exactly what both of the big two panel manufacturers are doing when it comes to mobile displays.

Even though LG and Samsung-made OLED panels qualify as both POLED and AMOLED simultaneously, the companies aren’t exactly producing identical panels. The quality of the TFT layer and plastic compound can make a difference to display performance, as can the type of emitters and sub-pixel layout.

Over the years, we’ve seen OLED display manufacturers converge on a set of standard parameters. For example, both LG and Samsung use a diamond PenTile sub-pixel layout for smartphone displays. This just means that both should offer similar long-term reliability.

Even when it comes to other attributes like power consumption, brightness, low brightness performance, and panel uniformity, it’s unclear if one has an upper hand. That said, most smartphone makers — from Apple to OnePlus — turn to Samsung’s AMOLED panels for their flagship devices.

In the past, LG used POLED displays in its own flagship smartphones like the Velvet and Wing. However, these panels fell slightly short of the competition in certain aspects like peak brightness and color gamut coverage. These shortfalls led to speculations that Samsung has a leg up over the competition, but the accuracy of these claims is anyone’s guess.

So does that mean you should avoid POLED? Not quite — it’s still fundamentally OLED technology, which offers numerous advantages over IPS LCD. Moreover, you’ll mostly find POLED displays in mid-range and budget smartphones these days, where they should have no problem matching Samsung’s own lower-end AMOLED panels. As a relatively smaller player, LG may also offer more competitive pricing as compared to Samsung.

For most consumers, the choice of POLED vs AMOLED will be of little consequence. The underlying principle – an active-matrix OLED on a flexible plastic substrate – applies equally to both, after all. Despite the different names, LG Display and Samsung aren’t worlds apart in their approach to producing OLED panels for smartphones.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey