igzo tft display supplier

Nintendo will partner with Sharp to put the company"s IGZO (indium gallium zinc oxide) displays in the Switch, according to a report from the Wall Street Journal.

The Journal reported back in March that Sharp was set to be a new supplier for the Switch"s display technology, which is currently a silicon display provided by Taiwanese suppliers. Now, Executive Vice President Katsuaki Nomura says the company will be providing IGZO displays to "a video game client," according to the Journal.

integrated into large-scale touchscreens, designed for desktop computer use. The new type of thin-film transistor (TFT) backplane in these displays allows for "electron mobility" that"s 20 to 50 times faster than traditional "amorphous silicon" IPS displays, like those found in the Switch currently, Sharp says.

That, in turn, allows the display to be quickly switched on and off while showing still images, leading to "reduce[d] power consumption to a fifth or even a tenth that of conventional screens." Such power reductions could help improve the Switch"s portable battery life, a selling point Nintendo has been stressing for both of its upcoming models. Advertisement

Improved electron mobility also means IGZO displays can have slightly faster response times than traditional displays. Monitor comparison site Display Ninja suggests the change could help get those times down from 4ms to around 1ms. That"s not the kind of change most users would consciously notice, but it could help at the margins for games with high frame rates.

IGZO displays are also capable of providing greater color accuracy, increased brightness, and better pixel density than more widespread panel types, according to Display Ninja. The last of these could be particularly important for the Switch Lite, which packs the Switch"s 720p portable resolution into a 5.5-inch diagonal display instead of the standard Switch"s 6.2-inch one.

U.S would have smartphones, accounting for around 81% of the region"s population. Multiple industrial manufacturers are seeking to release cutting-edge smartphones with cutting-edge features like 5G connectivity and IGZO screens in response to the spike in adoption of smartphones and the appearance of impending 5G technology. This is anticipated to help the IGZO display market in U.S flourish.

China consumer electronics company announce the launch of its initial 85-inch 8K 120Hz screen world showcase industry conferencing. The TV offers a contrast of much more over 5000:1 on its 1G1D elevated Display screen, which would be IGZO technology, and consumes 30% less electricity than TVs of a similar size. It is projected that many new product introductions would boost IGZO display sales in the following years.

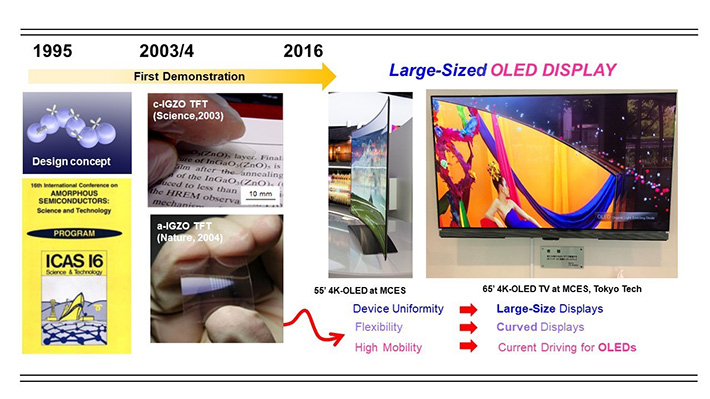

Indium gallium zinc oxide (IGZO) is a semiconducting material, consisting of indium (In), gallium (Ga), zinc (Zn) and oxygen (O). IGZO thin-film transistors (TFT) are used in the TFT backplane of flat-panel displays (FPDs). IGZO-TFT was developed by Hideo Hosono"s group at Tokyo Institute of Technology and Japan Science and Technology Agency (JST) in 2003 (crystalline IGZO-TFT)electron mobility of amorphous silicon, which has often been used in liquid-crystal displays (LCDs) and e-papers. As a result, IGZO-TFT can improve the speed, resolution and size of flat-panel displays. It is currently used as the thin-film transistors for use in organic light-emitting diode (OLED) TV displays.

In 2012, Sharp was first to start production of LCD panels incorporating IGZO-TFT.smartphones, tablets, and 32" LCDs. In these, the aperture ratio of the LCD is improved by up to 20%. Power consumption is improved by LCD idling stop technology, which is possible due to the high mobility and low off current of IGZO-TFT.pixel-density panels for notebook applications.LCD of an ultrabook PC supplied by Fujitsu,Razer Blade 14" (Touchscreen Variant) Gaming Laptop and a 55" OLED TV supplied by LG Electronics.

IGZO"s advantage over zinc oxide is that it can be deposited as a uniform amorphous phase while retaining the high carrier mobility common to oxide semiconductors.transistors are slightly photo-sensitive, but the effect becomes significant only in the deep violet to ultra-violet (photon energy above 3 eV) range, offering the possibility of a fully transparent transistor.

The current impediment to large-scale IGZO manufacturing is the synthesis method. The most widely used technique for Transparent Conducting Oxide (TCO) synthesis is Pulsed Laser Deposition(PLD).laser is used to focus on nano-sized spots on solid elemental targets. Laser pulse frequencies are varied between the targets in ratios to control the composition of the film. IGZO can be deposited onto substrates such as quartz, single-crystal silicon, or even plastic due to its ability for low-temperature deposition. The substrates are placed in a PLD vacuum chamber, which controls oxygen pressure in order to ensure favorable electrical properties. After synthesis, the film is annealed, or gradually exposed to air to adjust to the atmosphere.

An IGZO display is any display panel that uses indium gallium zinc oxide or IGZO as the primary semiconducting material in its thin-film transistor or TFT. Hence, it is not a display technology but rather, a specific backplane technology for driving and addressing transmissive or emissive components of a particular panel.

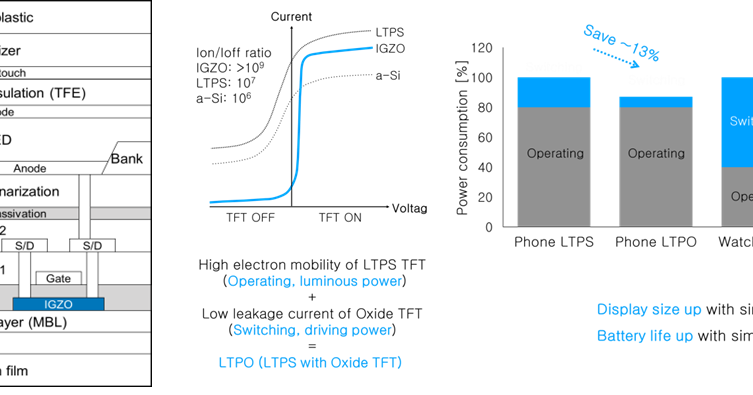

Some of the notable examples of a display technology include LCD technologies such as in-plane switching or IPS LCD and twisted nematic or TN LCD, as well as organic light-emitting diode or OLED technology, and microLED technology. On the other hand, there are three major backplane technologies: IGZO TFT, amorphous silicon or a-Si TFT, and low-temperature polysilicon or LTPS TFT.

• Note that a-Si-TFT is not transparent but can be stretched thin enough to allow an adequate amount of light to pass through. An IGZO-TFT is naturally transparent, thus translating to specific advantages such as brighter display panels and energy efficiency, reduced need for backlighting in the case of LCDs, and reduced brightness output in OLED and LED displays.

• Another advantage of IGZO display is that it has 30 to 50 times more electron mobility than a-Si display. Better electron flow means higher resolutions and faster pixel response time to allow the manufacturing of smaller panels with high pixel density. Earlier prototypes using indium gallium zinc oxide featured a 6-inch panel at 2560×1600 pixels or 498 pixels per inch.

• Note that transparency and better electron mobility also mean that these displays are more power-efficient than those based on amorphous silicon. Furthermore, it has a lower leakage current than both amorphous and low-temperature polysilicon TFT, thus allowing it to retain an active pixel state longer, especially when displaying still images such as photographs and documents.

• Manufacturing IGZO displays also require the use of rare-earth materials. More specifically, indium and gallium are rare. They are costly to extract from their point of origin and procure from the suppliers. This drawback introduces cost and supply risks for manufacturers of display panels and consumer electronic devices.

• Another disadvantage is that producing displays based on this semiconductor is more complicated than manufacturing a-Si TFT display panels. The current challenge to mass-producing indium gallium zinc oxide is the relevant synthesis method using Pulsed Laser Deposition or PLD. However, PLD requires expensive equipment and lengthier time. These requirements can hamper large-scale production.

• It is also worth mentioning that LTPS displays have key advantages over IGZO displays and a-Si displays. More specifically, it has better and faster electron flow, allows the production of small-sized screens with high pixel density, and more efficient power consumption.

Miyata, Y., Furuta, M., Yoshioka, T., and Kawamura, T. 1992. “Low-Temperature Polycrystalline Silicon Thin-Film Transistors for Large-Area Liquid Crystal Display.” Japanese Journal of Applied Physics. 31(P. 1, No. 12B): 4559-4562. DOI: 1143/jjap.31.4559

U.S would have smartphones, accounting for around 81% of the region"s population. Multiple industrial manufacturers are seeking to release cutting-edge smartphones with cutting-edge features like 5G connectivity and IGZO screens in response to the spike in adoption of smartphones and the appearance of impending 5G technology. This is anticipated to help the IGZO display market in U.S flourish.

China consumer electronics company announce the launch of its initial 85-inch 8K 120Hz screen world showcase industry conferencing. The TV offers a contrast of much more over 5000:1 on its 1G1D elevated Display screen, which would be IGZO technology, and consumes 30% less electricity than TVs of a similar size. It is projected that many new product introductions would boost IGZO display sales in the following years.

Liquid crystal display (LCD) performance is about to take another leap forward. Existing LCDs have given us remarkable quality in HDTV, tablets and smartphones, as well as reasonably low power consumption. But Sharp Corporation is on the verge of delivering a new technology that will enable much higher resolution and significantly lower power consumption.

This new technology is the result of breakthroughs in basic research, material science and display panel fabrication, and it’s based on a compound that replaces silicon in the manufacture of thin-film transistors. It’s called IGZO, for Indium Gallium Zinc Oxide (In Ga Zn O). Thin-film transistors are at the heart of every LCD, and IGZO improves the performance of LCD panels in three significant ways: lower power consumption, higher resolution and a new operating mode for touch-sensitive displays.

The science behind IGZO is revolutionary because it improves on silicon in several important ways. The thin-film transistors that power LCD displays act as switches, delivering an electrical charge to each liquid-crystal cell that flips it from opaque to transparent. As shown in the story “The science behind the breakthrough technology,” IGZO transistors have high electron mobility and much lower leakage current characteristics than the two dominant silicon TFT processes. IGZO TFTs are smaller, so displays can have higher resolution with less loss in light transmission. Based on the license from the Japanese Science and Technology Agency, Sharp’s breakthrough is the large-scale manufacture of IGZO panels, effectively moving the technology into the hands of manufacturers and consumers. Furthermore, Sharp Corporation and Semiconductor Energy Laboratory Co., Ltd. jointly developed a new oxide semiconductor (IGZO) technology with high crystallinity.

Low power consumption is critical for portable devices. IGZO TFTs have dramatically lower leakage current when the TFT is off. When static, non-video content is being displayed, IGZO can also operate in a mode where pauses are inserted between the drive/refresh cycles, with almost no flicker (see story, “The science behind the breakthrough technology”). The result is further reduction in power consumption. Designers can then build devices with increased battery life, smaller size or both.

Consumers have always been quick to adopt products with higher resolution, and the revolutionary devices enabled by IGZO enable portable devices to have resolution that rivals that of a sheet of paper. Further, operation in the drive/pause mode allows greater touch sensitivity and accuracy for fingers and styluses on touch-operated devices. IGZO also enables Ultra-High Definition monitors, also known as Ultra HD or Quad Density Full Definition.

Sharp and its partners are already delivering and will soon deliver IGZO-based smartphones, tablets and monitors. Some existing and forthcoming models are described in the accompanying story, “Inventing the Future.”

Sharp’s engineers and product developers see an exciting future for IGZO as it not only replaces silicon in many existing applications, but also enables forward-looking products that cover lifestyle, workplace and quality-of-life devices. Sharp’s bold step into large-scale production of IGZO places it squarely on the path to the future.

IGZO: Indium Gallium Zinc Oxide has been known for its semiconductor properties for years. Dr. Noboru Kimizuka and his colleagues at National Institute for Research in Inorganic Materials (Japan) were the first in the world to succeed in the synthesis of IGZO crystal in 1985, and they actively studied various homologous structures such as IGZO for more than 10 years.

In 2004, Prof. Hideo Hosono and his team at Tokyo Institute of Technology discovered that IGZO, when fabricated on a thin-film transistor, has an electron mobility one digit higher than that of amorphous silicon TFT, and the results of their studies were reported in the science technology magazine, Nature, in November of this year.

Since then, many universities, companies and research institutions started their research and development, conscious of its application to flat panel displays and other electronic devices.

Sharp Corporation and Semiconductor Energy Laboratory Co., Ltd. jointly developed a new oxide semiconductor (IGZO) technology with high crystallinity.

LCD: Liquid Crystal Display has become the dominant technology for flat screens, whether in HDTV, computers, tablets or smartphones. Based on a fluid that polarizes light in the presence of an electrical field, LCD is scalable, inherently low power and relatively inexpensive. Sharp has been an innovator in LCD since its inception.

Leakage: The tendency of the electrons to migrate through the insulating layer inside a transistor. It causes increased power consumption. Leakage increases exponentially as the device gets thinner, a particular problem for TFTs. IGZO has extraordinarily low leakage.

Silicon: One of the first commercial semiconductor materials; still the most widely used, but being challenged by newer, specialized materials. LCD panels typically use amorphous silicon (a-Si) or low-temperature polysilicon (LTPS) for their TFTs.

TFT; Thin-film transistor: TFTs are the nearly transparent transistors used in LCD panels to drive each subpixel (the red, blue and green elements that make up each full-color pixel).

Ultra-High Definition (UHD): The next step beyond current HDTV standards. Two standards have been defined, 4K and 8K. 4K displays have approximately 4000 horizontal pixels and 2000 vertical pixels, while 8K displays will have approximately 8000 horizontal and 4000 vertical pixels.

New drivers are opening up new frontiers in the display industry, resulting in technological innovation and the expansion and diversification of the market. This article summaries some of these recent developments and research from IDTechEx"s brand new report "Metal Oxide TFT Backplanes for Displays 2013-2018: Analysis, Trends, Markets" (http://www.IDTechEx.com/oxide).

The display industry has been experiencing rapid change. The centre of gravity has shifted away from Japan to Korea. This trend was made abundantly clear recently when Panasonic and Sharp announced that they are expecting a staggering combined loss of $15.2 billion in 2012. In fact, Sharp has already expressed "material doubt" about its survival.

This trend has been in the making during the past decade and the Japanese display giants are set to lose all the profits they accumulated during the past twenty years. There are many reasons for this decline, but chief amongst them has been the inability to bet on the right future technologies for the right markets. The market and technological landscape in the display has been experiencing rapid change, and Korean companies have largely made the right bets and investment decisions.

This changing market and technological scene not only creates opportunities and risks for display manufactures, but for all those involved in existing and emerging value chains. Many material suppliers, equipment makers and technology providers will stand to benefit, while others will see their market share and revenues dwindle.

Metal oxide thin film transistors (TFTs) are a key emerging technology in this space. They offer a set of compelling characteristics that make them a good fit in the emerging scene of the display industry. Their set of properties makes a good match for sustaining several underlying market megatrends that are shaping the industry. Indeed, Sharp has already launched 7-inch LCD display tablet based on IGZO backplanes. The intended benefits are high resolution, low power consumptions and of course product differentiation.

Metal oxide TFTs are however stepping into crowded technological space in which many backplane solutions already exist, including various forms of silicon and organic TFTs. Many are mature, proven and cost-effective solutions, while others offer a different package of characteristics than metal oxides. None however are one-size-fits-all solutions for all market needs and segments.

At the same time however, there are still numerous unresolved technical challenges, including the question of persistent photoconductivity and narrow processing window. Metal oxides are a broad family of materials and the final choice of the best material system and the best corresponding device architecture are not yet settled. The specifics of the manufacturing process and recipes too are in a state of flux. But it is nonetheless clear that they will play a role in future displays.

Several major trends have been driving technological innovation in the display industry since its early days. These trends include image quality, screen size, portability and form factor. While these trends still remain strong undercurrents, new drivers are being introduced that will play a more prominent role in shaping the future of the industry.

These new drivers will open up new frontiers, both on the technology and the market side. Indeed, they enable displays to both expand their existing markets and to diversify into new spaces. They will also fragment the market, at least initially. These major drivers that are set to change the display landscape include product differentiation, flexibility, 3D, transparency, system-on-panel, power savings, interconnectivity and screen size, and new front plane technologies.

Critically, these new trends can only be sustained so long as the underlying technology can deliver the required performance demands. This is critical because the new functional needs will stretch many existing solutions beyond their performance limits, suggesting that alternative solutions will be required. One vital piece of technology that largely sets the limits of display industry is the backplane technology. The backplane is responsible for turning the individual pixels ON and OFF. It is composed of thin film transistors, which act as the switches.

The over-arching trends in the industry are also changing the backplane requirements on several fronts. Product differentiation is resulting in multiplicity of lighting/display technologies, with each demanding a different power output and refresh rate from the backplane. For example, OLED is being increasingly adopted as a means of differentiating products. This in turn is changing the power out and spatial uniformity requirements that the backplane technology must satisfy.

Flexible displays are being developed to offer robustness in the short term, while in the long term they will aim at resolving the conflict between two diverging mega trends by making large-sized and portable devices possible. This push towards flexibility is opening up room for a new value chain consisting of new material systems. This is because many existing solutions are failing the flexibility tests, including many existing backplane solutions.

3D and ultra-high resolution displays mandate higher refresh rates, stretching the switching speed requirements past the capability limits of today"s dominant technologies, such as amorphous silicon (aSi) TFTs. System-on-panel thinking is requiring ever more processing power to be integrated onto the panel, and therefore the backplane.

This new report by IDTechEx (Metal Oxide TFT Backplanes for Displays 2013-2018: Analysis, Trends, Markets www.IDTechEx.com/oxide) analyzes major drivers that are shaping the display industry. The major trends examined in detail include product differentiation, size and scaling, power savings, prolonged lifetime, 3D, mechanical flexibility, rimless designs, etc. It analyses how these market drivers create market fragmentation and market opportunities.

Figure 2. Radar chart showing the technological suitability of different backplane technologies for sustaining megatrends in the OLED display industry

Most of the 8.5-generation and 10.5-generation TFT LCD production lines of Chinese panel makers retain the ability to produce indium gallium zinc oxide (IGZO) TFT LCD panels, and these panels still have many advantages. According to the digital research report, IGZO technology can produce higher resolution panels and further upgrades to produce AMOLED panels by using an additional 1 to 2 masking processes compared to a-Si TFT LCD technology.

Although CEC-Panda LCD technology is the first to produce IGZO panels, BOE has recently successfully entered the Apple notebook supply chain, and its shipments are likely to catch up with CEC-Panda in the foreseeable future.

BOE and CEC-Panda are currently using their 8.5G lines to launch IGZO panels of various sizes for use in televisions, displays, notebooks and mobile phones. Compared with the 6G LTPS line, the 8.5G line can produce mobile phone panels more efficiently, and it can cut PCs and TV panels more economically. Therefore, Chinese panel makers may continue to promote IGZO technology.

From the MOSFET, the TFT was born. The TFT varies from standard MOSFETs, or bulk MOSFETs, because, as the name implies, it uses thin films. The TFT began a new era of electronics. In 1968, just six years after the first TFT development, Bernard J. Lechner of RCA shared his idea of the TFT Liquid Crystal Display (LCD), something that would boom in popularity in our modern times. The TFT LCD was then first created in 1973 at the Westinghouse Research Laboratories. These LCDs were composed of pixels controlled by transistors. In FETs, substrates were just the semiconductor material, but in manufacturing TFT LCDs, glass substrates were used so that the pixels could be displayed.

But that was not the end of TFT developments. Soon after, in 1974, T. Peter Brody, one of the developers of the TFT LCD, and Fang-Chen Luo created the first active-matrix LCD (AM LCD). An active matrix controls each pixel individually, meaning that each pixel’s respective TFT had its signal actively preserved. This opened doors to better performance and speed as displays became more complex.

Though TFTs can use a variety of materials for their semiconductor layers, silicon has become the most popular, creating the silicon-based TFT, abbreviated as Si TFT. As a semiconductor device, the TFT, as well as all FETs, use solid-state electronics, meaning that electricity flows through the structure of the semiconductor layer rather than vacuum tubes.

Due to the variety in silicon’s possible structures, the Si TFT’s characteristics can vary as well. The most common form is amorphous silicon (A-Si), which is deposited during the first step of the semiconductor fabrication process onto the substrate in low temperatures. It is most usable when hydrogenated into the form A-Si:H. This then significantly alters the properties of A-Si; without the hydrogen, the material struggles with doping (the introduction of impurities to increase mobility of charges); in the form A-Si:H, however, the semiconductor layer becomes much more photoconductive and dopable. The A-Si:H TFT was first developed in 1979 which is stable at room temperature and became the best option for AM LCDs which consequently began rising in popularity after this breakthrough.

The biggest difference between these forms, notably A-Si and poly-Si, is that charge carriers are much more mobile and the material is much more stable when it comes to using poly-Si over A-Si. When creating complicated and high-speed TFT-based displays, poly-Si’s characteristics allow for this. Yet, A-Si is still very important due to its low-leakage nature, meaning that leakage current is not lost as heavily when a dielectric insulator is not totally non-conductive.

Several years later, another development was made in 2012 in the form of indium gallium zinc oxide (IGZO) which allowed for a more powerful display in terms of refresh rates and more efficiency in terms of power consumption. This semiconducting material, as stated in the name, uses indium, gallium, zinc, and oxygen. Though it is a form of zinc oxide (ZnO), the addition of indium and gallium allows this material to be deposited in a uniform amorphous phase but also maintaining the oxide’s high carrier mobility.

As TFTs began to increase their presence in display technology, transparent semiconductors and electrodes became more appealing to the manufacturers. Indium tin oxide (ITO) is an example of a popular transparent oxide used for its appearance, good conductivity, and ease of deposition.

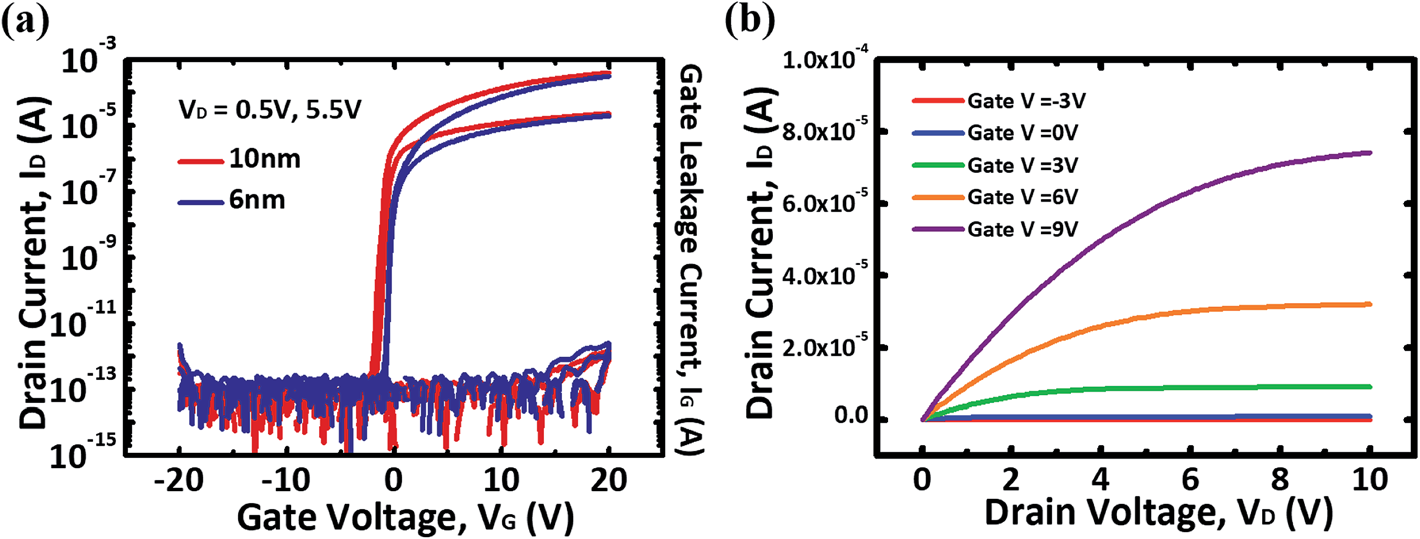

Research of the TFT with different materials has led to the application of threshold voltage, or how much voltage is needed to turn on the device. This value is greatly dependent on thickness and choice of the oxide. When it comes to the oxide, this relates back to the idea of leakage current. With thinner layers and certain types of oxide, the leakage current may be greater, but this in turn could lower threshold voltage, as leakage into the device will also increase. In order to tap into the TFT’s potential for low power consumption, the lower the threshold voltage, the better the device’s appeal.

Another branch of development that stemmed from the TFT is that of organic TFTs (OTFT). First created in 1986, OTFTs usually use solution-casting of polymers, or macromolecules. This device made people hesitant, as it tended to have a slow carrier mobility, meaning slow response times. However, researchers have carried out experimentation with the OTFT because it has potential to be applied to displays different from those that traditional TFTs are used for, such as flexible, plastic displays. This research still continues today. With its simpler processing than traditional silicon technology, the OTFT holds much potential for modern day and future technologies.

The Nintendo Switch is likely getting some additional stealth upgrades that should improve its display. Japanese electronics manufacturer Sharp says it is providing its IGZO screen to Nintendo for use in its hybrid handheld/home console, according to a Wall Street Journal report. IGZO has a number of improvements over the current tech that Switch is using. Most notably, it is significantly more power efficient.

Sharp and Nintendo are not saying which Switch devices will feature IGZO display tech, but it seems likely that we will see it in both the improved Switch with better battery life and the Switch Lite.

IGZO is a type thin-film-transistor in-plane switching (TFT-IPS) display technology. That’s a lot of techno-gibberish. All you really need to know is that IPS is good for mobile devices and monitors. The Switch was already has IPS panels, but they used the old amorphous silicon (aSi) version of the tech. IGZO-TFT IPS panels use indium gallium zinc oxide. Again, what matters here is that these materials are up to 80%-to-90% more power efficient than aSi-TFT IPS. That’s going to save the Switch’s battery life for more gaming.

As panel-technology website Display Ninja explains, electrons move through IGZO about 20-to-50 times quicker than aSi. That reduced resistance means you don’t need as much energy to power the screens. As you might expect, this is a huge benefit to a device like the Switch, which runs on a rechargeable battery.

This new display — along with the more power-efficient Tegra processor from Nvidia — could contribute to why the new Switch devices have such improved battery life over the original model.

IGZO’s faster electrons also means that it can deliver faster response times. This is huge for IPS panels, which have typically topped out at 4ms response times. That’s slower than TN panels that can get as low as 1ms response times, which is why those display are common in monitors with high refresh rates up to 240Hz.

Other benefits of IGZO is that it can produce better colors and increase pixel density. Nintendo probably won’t take advantage of the latter because the Tegra chip would require significantly more power to render more pixels than 720p. But better color could really improve the image.

Beyond the power consumption, however, the biggest advantage of IGZO is its potential brightness. It can get a lot brighter than aSi-TFT IPS while still using less power.

IGZO is still not a common display in many devices. But I’ve actually used one in my Razer Phone 2. This smartphone’s IGZO panel is a 5.7-inch screen with a 1440×2560 resolution that can run at 120Hz and reach 300 nits peak brightness.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey