igzo tft display brands

IGZO is an acronym for Indium Gallium Zinc Oxide and it’s actually a different type of semiconductor found in the TFT backplane; it’s not a different panel technology altogether.

In comparison to standard aSi-TFT IPS displays, an IGZO-TFT IPS display greatly saves on power consumption, while giving equally accurate and vibrant colors. However, they are much more expensive.

To clear away the confusion, IGZO is not a type of panel but a different type of transistor in the TFT (thin-film-transistor) backplane. Therefore, it can be implemented in all types of panels including TN, VA, IPS and even OLED.

Standard transistors in most of these panels are made of amorphous silicon. So, in this article, we’ll be comparing aSi-TFT IPS panels to the IGZO-TFT IPS panels.

The IGZO (Indium Gallium Zinc Oxide) compound semiconductor was licensed by Samsung and Sharp. However, it was Sharp who first implemented IGZO into their smartphones, tablets and 32-inch LCDs.

The IGZO transistor is made from rare metals such as the Indium and Gallium, and therefore it is costly. For instance, the NEC PA322UHD is a 4K resolution monitor with a 14-bit Look-Up Table for precise calibration and covers 99.2% of the Adobe RGB color space.

At the moment, the main advantage of IGZO is its very low power consumption. In comparison to the standard a-Si panel monitor, it can be up to 80%-90% more power efficient due to the higher electron mobility, which is 20-50 times faster than that of a regular panel.

While a-Si panel monitors require more power for the backlighting of higher pixel density displays, IGZO does not – in fact, it can create even brighter images at significantly lower power consumption.

This is ideal for portable devices with high pixel density. In short, IGZO can deliver a better resolution, speed and pixel density, no matter the size of the display.

While the difference between the IGZO-TFT and a-Si-TFT IPS panels may not be meaningful now, especially considering the difference in the price, IGZO will certainly greatly contribute to the future development of displays.

Since it can drastically reduce power consumption and offer stunning pixel density, resolution, and speed, high-quality touch-sensitive transparent displays are getting closer and closer to reality.

An IGZO display is any display panel that uses indium gallium zinc oxide or IGZO as the primary semiconducting material in its thin-film transistor or TFT. Hence, it is not a display technology but rather, a specific backplane technology for driving and addressing transmissive or emissive components of a particular panel.

Some of the notable examples of a display technology include LCD technologies such as in-plane switching or IPS LCD and twisted nematic or TN LCD, as well as organic light-emitting diode or OLED technology, and microLED technology. On the other hand, there are three major backplane technologies: IGZO TFT, amorphous silicon or a-Si TFT, and low-temperature polysilicon or LTPS TFT.

• Note that a-Si-TFT is not transparent but can be stretched thin enough to allow an adequate amount of light to pass through. An IGZO-TFT is naturally transparent, thus translating to specific advantages such as brighter display panels and energy efficiency, reduced need for backlighting in the case of LCDs, and reduced brightness output in OLED and LED displays.

• Another advantage of IGZO display is that it has 30 to 50 times more electron mobility than a-Si display. Better electron flow means higher resolutions and faster pixel response time to allow the manufacturing of smaller panels with high pixel density. Earlier prototypes using indium gallium zinc oxide featured a 6-inch panel at 2560×1600 pixels or 498 pixels per inch.

• Note that transparency and better electron mobility also mean that these displays are more power-efficient than those based on amorphous silicon. Furthermore, it has a lower leakage current than both amorphous and low-temperature polysilicon TFT, thus allowing it to retain an active pixel state longer, especially when displaying still images such as photographs and documents.

• Manufacturing IGZO displays also require the use of rare-earth materials. More specifically, indium and gallium are rare. They are costly to extract from their point of origin and procure from the suppliers. This drawback introduces cost and supply risks for manufacturers of display panels and consumer electronic devices.

• Another disadvantage is that producing displays based on this semiconductor is more complicated than manufacturing a-Si TFT display panels. The current challenge to mass-producing indium gallium zinc oxide is the relevant synthesis method using Pulsed Laser Deposition or PLD. However, PLD requires expensive equipment and lengthier time. These requirements can hamper large-scale production.

• It is also worth mentioning that LTPS displays have key advantages over IGZO displays and a-Si displays. More specifically, it has better and faster electron flow, allows the production of small-sized screens with high pixel density, and more efficient power consumption.

Miyata, Y., Furuta, M., Yoshioka, T., and Kawamura, T. 1992. “Low-Temperature Polycrystalline Silicon Thin-Film Transistors for Large-Area Liquid Crystal Display.” Japanese Journal of Applied Physics. 31(P. 1, No. 12B): 4559-4562. DOI: 1143/jjap.31.4559

Indium gallium zinc oxide (IGZO) is a semiconducting material, consisting of indium (In), gallium (Ga), zinc (Zn) and oxygen (O). IGZO thin-film transistors (TFT) are used in the TFT backplane of flat-panel displays (FPDs). IGZO-TFT was developed by Hideo Hosono"s group at Tokyo Institute of Technology and Japan Science and Technology Agency (JST) in 2003 (crystalline IGZO-TFT)electron mobility of amorphous silicon, which has often been used in liquid-crystal displays (LCDs) and e-papers. As a result, IGZO-TFT can improve the speed, resolution and size of flat-panel displays. It is currently used as the thin-film transistors for use in organic light-emitting diode (OLED) TV displays.

In 2012, Sharp was first to start production of LCD panels incorporating IGZO-TFT.smartphones, tablets, and 32" LCDs. In these, the aperture ratio of the LCD is improved by up to 20%. Power consumption is improved by LCD idling stop technology, which is possible due to the high mobility and low off current of IGZO-TFT.pixel-density panels for notebook applications.LCD of an ultrabook PC supplied by Fujitsu,Razer Blade 14" (Touchscreen Variant) Gaming Laptop and a 55" OLED TV supplied by LG Electronics.

IGZO"s advantage over zinc oxide is that it can be deposited as a uniform amorphous phase while retaining the high carrier mobility common to oxide semiconductors.transistors are slightly photo-sensitive, but the effect becomes significant only in the deep violet to ultra-violet (photon energy above 3 eV) range, offering the possibility of a fully transparent transistor.

The current impediment to large-scale IGZO manufacturing is the synthesis method. The most widely used technique for Transparent Conducting Oxide (TCO) synthesis is Pulsed Laser Deposition(PLD).laser is used to focus on nano-sized spots on solid elemental targets. Laser pulse frequencies are varied between the targets in ratios to control the composition of the film. IGZO can be deposited onto substrates such as quartz, single-crystal silicon, or even plastic due to its ability for low-temperature deposition. The substrates are placed in a PLD vacuum chamber, which controls oxygen pressure in order to ensure favorable electrical properties. After synthesis, the film is annealed, or gradually exposed to air to adjust to the atmosphere.

IGZO is composite of indium (Id), gallium (Ga), zinc (Z) and oxygen (O). An IGZO-TFT is artificially produced and used in flat panel displays, which are made of transparent crystalline oxide semiconductors. This newly-invented IGZO-TFT enables LCD and OLED displays to achieve new levels of performance. Because of its attractive features, it is being used in ASUS notebooks, ultrabooks by Fujitsu and Razor Blade gaming laptops. Sharp mass produces it successfully. Low power consumption with high performance and high resolution are the key features of this technology.

Low power consumption with high performance. A comparison between the conventional display method and new display methods is shown in Fig. 3. The former consumes more power because all pixels are driven continuously. IGZO consumes less power for backlighting or illumination in LED panel as compared to a-Si.

There are a number of TFTs arranged in a particular structure which will switch on or off depending on the contents being displayed on the screen. If the static image or video content is being displayed using IGZO that operates in pause mode (as it is in this case), there will be less leakage current and no flicker effect, which results in low power consumption. Thus, in IGZO-TFT technology, pixels maintain their charge throughout the cycle, which results in low power consumption and flicker-less high performance.

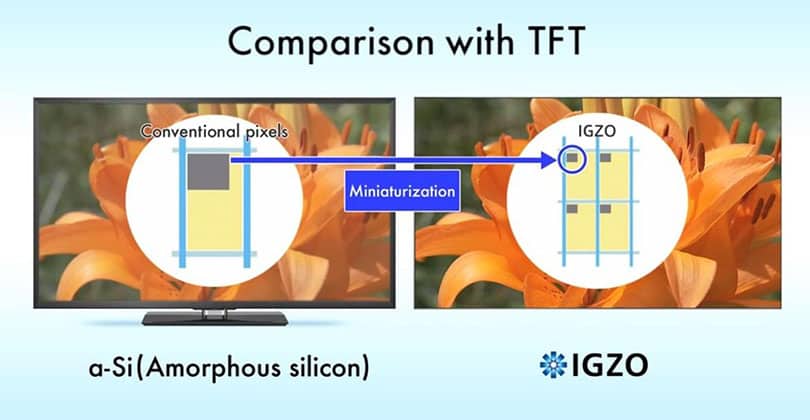

High resolution. In IGZO-TFT, as shown in Fig. 4, transistor size is small as compared to a-Si-TFT. Because of that, more numbers of pixels per area can be accommodated as compared to a-Si, which enables high resolution. On top of this, IGZO has a much lower leakage current and 20 to 50 times higher electron mobility as compared to a-Si, which results in fast response time or less processing delay.

To summarise, new display techniques using quantum dots and IGZO have changed the entire world of displays, especially in television domain. Their extraordinary features enable these to consume low power, perform better, give HD colour resolution, and televisions to be made thinner, lighter and more energy efficient.

Liquid crystal displays (LCD) began to replace cathode-ray tube-based televisions in the early 2000s. The pixels in these LCDs were, until 2012, driven exclusively by thin-film transistors (TFTs) that use amorphous hydrogenated silicon (a-Si:H) as the semiconducting channel. But as demand grew for ever larger displays, with better viewing and energy performance, a need for improved TFTs emerged. TFTs block light coming from the display, so they need to be small, which lowers their current-driving ability. Additionally, there was a push to move away from LCD technology and into organic light emitting diodes (OLEDs) in order to capitalize on their better performance, which includes direct emission and richer colours, but OLEDs need to be driven by large amounts of current, at levels a-Si:H TFTs cannot accommodate. What was needed was a new technology that could be used to create TFTs with a high charge carrier mobility, which could drive large currents.

Charge carrier mobility tells us how quickly charge carriers (electrons and holes) can move through a semiconductor, and determines the amount of current we can drive through a TFT of a given size. This is limited by the nature of the path that charge carriers take though a material. This path can be thought of in terms of the atomic orbitals and how they interconnect to make up the conduction and valence bands — the energetic levels at which the electrons and holes are free to move around. The sp3 hybridized orbitals in silicon are highly directional, and in the crystalline state the silicon–silicon bonds properly overlap, providing an efficient path to travel through. However, in amorphous silicon, structural disorder leads to disconnects and conduction cannot occur through the orbitals in the same way. Instead, the charge carriers have to hop across the orbitals, which leads to mobilities of at most 1 cm2 V–1 s–1 — about 2–3 orders of magnitude lower than in crystalline silicon.

After a few years verifying the validity of the hypothesis, we started research on transparent oxide TFTs. To develop high-mobility TFTs using transparent conductive oxides, the major issue was their high carrier concentrations (the TFTs can’t be turned off). Indium oxide is a typical transparent conductive oxide with a large mobility, but reducing its excessive carrier concentration is difficult due the ease with which oxygen vacancies form. We tested InGaO3(ZnO)m epitaxial films, where m = 4 and 5, as I believed the unique local structure around Ga3+ would help lower the carrier concentration. As expected, the carrier concentration in epitaxial InGaO3(ZnO)4 reduced to a suitable level, and when applied in TFTs showed excellent performance, with a mobility of approximately 80 cm2 V–1 s–1. We then fabricated thin films using amorphous InGaZnO4 (a-IGZO). The electron concentrations in the resulting a-IGZO thin films, which were deposited on glass substrates at room temperature, were below 1016 cm–3 and the TFTs exhibited mobilities of approximately 10 cm2 V–1 s–1 — an order of magnitude larger than that of a-Si:H TFTs. We also found that TFTs fabricated on plastic substrates offered almost identical performance (Fig. 1). At this point we applied for patents and then submitted our paper to Nature, which was published in 2004.

Demonstrations of IGZO TFT-based displays began to emerge in 2007, when Samsung Electronics first reported a-IGZO TFT-based high-definition LCDs. Demonstrations of IGZO TFT-based backplane LCDs in smart phones and tablet computers then appeared around 2012. Arguably the most striking application emerged in 2015, when LG Display demonstrated large-sized OLED televisions. Here the a-IGZO TFT was indispensable because of the need for high mobility and simple formation over large areas.

I believe the success of IGZO transistors is due to a number of factors. First is their high mobility, which is an order of magnitude higher than a-Si:H, and the excellent controllability of their carrier concentration. Second, the production process is almost the same as a-Si:H, except for the deposition of the channel layer (chemical vapour deposition is used for a-Si:H whereas sputtering is used for IGZO), making integration into current manufacturing workflows relatively painless. Third, synthesizing large-sized high-quality sputtering targets is relatively easy, which also makes thin-film deposition on large-sized substrates a relatively simple task. With these attributes, IGZO transistors provide a promising backplane technology to drive the future of flat panel displays.

4.5.Comparing the key attributes of different TFT technologies (a-Si, pc-Si, nc-Si, OTFT, graphene, CNT, etc). Parameters include manufacturing technique, mobility, uniformity, stability, and commercialisation stage and primary uses

5.1.Comparing the lifetime, resolution and uniformity requirements of different display products including HDTV, monitor, PDA, PMP, mobile phone and signage

6.6.Production process folded used to make a tri-folded OLED display. This was reported by Semiconductor Energy Laboratory and Nokia Research Centre at SID 2014

7.1.Radar chart assessing the merits of different backplane technologies (LTPS, oxide, a-Si, organics) for LCD displays. The parameters considered are resolution, size, flexibility, on-pixel processing, and 3D. Here, the scale is from

7.2.Announced and exiting production plans of major companies. The information includes backplane technology, display size, production throughput and plant territory

7.2.Radar chart assessing the merits of different backplane technologies (LTPS, oxide, a-Si, organics) for OLED displays. The parameters considered are resolution, size, flexibility, on-pixel processing, and 3D. Here, the scale is fro

7.5.Examples of key OLED display products on the market. The products include cameras, tablets, music players, mobile phones, TVs, etc and the producers include Nokia, Sony, Samsung, LG, HTC, Microsoft, Motorola, etc.

7.7.Announced annual production capacity (area) of various OLED display manufactures in 2015-2016. Two categories are developed: 1) LTPS backplanes and 2) oxide backplanes

8.10.Ten year forecast for market share for different backplane technologies in wearable electronic devices containing an OLED display (flexible or rigid)

8.12.Ten year market forecast for total market value for wearable electronic devices containing an OLED display (flexible or rigid) segmented by backplane technology

9.10.Panasonic is also working on flexible displays (in collaboration with European research institutes). At the SID 2013 symposium, they gave a presentation on a 4" OLED displays made on a PEN substrate.

U.S would have smartphones, accounting for around 81% of the region"s population. Multiple industrial manufacturers are seeking to release cutting-edge smartphones with cutting-edge features like 5G connectivity and IGZO screens in response to the spike in adoption of smartphones and the appearance of impending 5G technology. This is anticipated to help the IGZO display market in U.S flourish.

China consumer electronics company announce the launch of its initial 85-inch 8K 120Hz screen world showcase industry conferencing. The TV offers a contrast of much more over 5000:1 on its 1G1D elevated Display screen, which would be IGZO technology, and consumes 30% less electricity than TVs of a similar size. It is projected that many new product introductions would boost IGZO display sales in the following years.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey