hitachi lcd modules produced manufacturer

Glass plate inspection system for contamination control when manufacturing small and medium sized LCD and organic EL panels. Proprietary Hitachi technology allows front surface / back surface separate detection for thin glass plates.

IPS stands for In-Plane-Switching (lateral electric field) mode LCD, a type of TFT LCD display technology that has a higher picture quality when viewed at any angle. IPS is distinguished by a wide viewing angle, along with minimal gray-scale inversion and viewing-angle dependency, producing lifelike images. In particular, IPS-Pro*, which was developed for use in TVs, achieves an even higher picture quality with an approximate 50% increase in transmissivity and a contrast ratio at least 3 times that of initial IPS technology. In terms of viewing angle, IPS-Pro technology delivers a contrast ratio of at least 100:1 at any angle, compared with the contrast ratio of 10:1 normally used for measuring LCD viewing angles. IPS Alpha will sell panels manufactured using this leading-edge technology under the "IPSα panel" brand worldwide.

IPS LCD is an abbreviation of In-Plane-Switching (i.e. a horizontal electric field) TFT LCD and a horizontal electric field LCD with high image quality, which facilitates the display of "beautiful pictures from any angle." The IPS method is based on the wide viewing angle feature, which optimizes the visibility of flat color tones and gray levels from any viewing positions, as well as allowing images to appear naturally from any angle. In particular, the company has achieved IPS-Pro technology (*), with a higher image quality developed for TVs, transmittance up 50% and a contrast ratio three times superior to that of the early IPS method. While the viewing angle is generally displayed at a contrast ratio of 10:1, this technology enables a contrast ratio of 100 or more in all directions. The IPS Alpha distributes panels produced using this advanced technology as "IPS Alpha Panels" worldwide.

Kaohsiung Opto-Electronics (KOE), a subsidiary of Japan Display Inc. (JDI), has been formed to design, develop and manufacture TFT LCD display modules previously made by Hitachi Display Products.

Japan Display Inc. is the consolidated display business of Hitachi, Sony and Toshiba—creating the world’s largest manufacturer of small to medium sized LCD modules. The business merger resulted from the formation of a subsidiary named Kaohsiung Opto-Electronics, which is charged with the development and production of high quality, high performance TFT display modules for high-end applications and industrial markets.

In the Americas, a new organization, Kaohsiung Opto Electronics Americas Inc. (KOE Americas) will replace Hitachi Electronic Devices (USA) Inc. for LCD sales, design support and light manufacturing. KOE Americas will supply and support a wide range of standard passive STN and color TFT displays from 3.5-inches to 21.3-inches.

“KOE Americas will support its Americas customer base through an established Manufacturer’s Rep and distribution sales channels and regional sales management. Building upon the legacy established over 40 years at Hitachi Displays, KOE Americas to enter the market as a strong and confident, premium brand display supplier,” said Keith Brown, vice president of operations and sales of KOE Americas.

Kaohsiung Opto-Electronics has design and manufacturing facilities in Taiwan, including house design, production and procurement of key components such as LCD glass, color filters, LCD drivers and backlights. The company plans to increase its product portfolio to capture a greater market share in both TFT and custom STN displays.

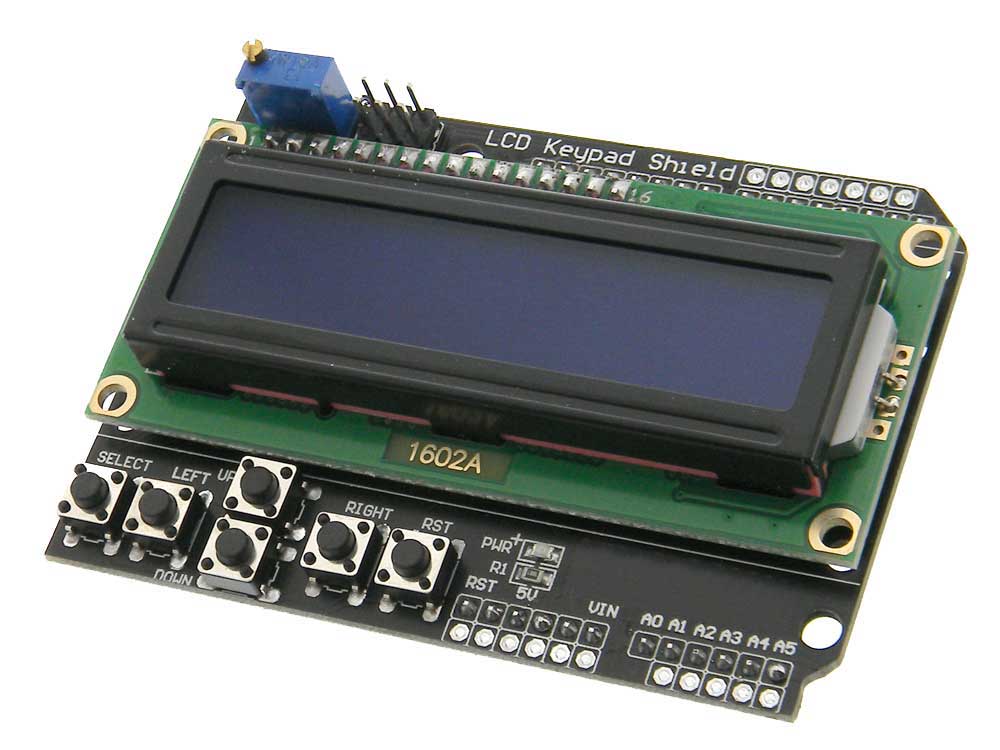

The Hitachi HD44780 LCD controller is an alphanumeric dot matrix liquid crystal display (LCD) controller developed by Hitachi in the 1980s. The character set of the controller includes ASCII characters, Japanese Kana characters, and some symbols in two 28 character lines. Using an extension driver, the device can display up to 80 characters.

The Hitachi HD44780 LCD controller is limited to monochrome text displays and is often used in copiers, fax machines, laser printers, industrial test equipment, and networking equipment, such as routers and storage devices.

Compatible LCD screens are manufactured in several standard configurations. Common sizes are one row of eight characters (8×1), and 16×2, 20×2 and 20×4 formats. Larger custom sizes are made with 32, 40 and 80 characters and with 1, 2, 4 or 8 lines. The most commonly manufactured larger configuration is 40×4 characters, which requires two individually addressable HD44780 controllers with expansion chips as a single HD44780 chip can only address up to 80 characters.

Character LCDs may have a backlight, which may be LED, fluorescent, or electroluminescent. The nominal operating voltage for LED backlights is 5V at full brightness, with dimming at lower voltages dependent on the details such as LED color. Non-LED backlights often require higher voltages.

Character LCDs use a 16 contact interface, commonly using pins or card edge connections on 0.1 inch (2.54 mm) centers. Those without backlights may have only 14 pins, omitting the two pins powering the light. This interface was designed to be easily hooked up to the Intel MCS-51 XRAM interface, using only two address pins, which allowed displaying text on LCD using simple MOVX commands, offering cost effective option for adding text display to devices.

Selecting 4-bit or 8-bit mode requires careful selection of commands. There are two primary considerations. First, with D3–D0 unconnected, these lines will always appear low (binary 0000) to the HD44780. Second, the LCD may initially be in one of three states:

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Hitachi, Ltd., ("Hitachi"), Toshiba Corporation ("Toshiba") and Matsushita Electric Industrial Co., Ltd., ("Matsushita") today reached a basic agreement to jointly establish a company (the "JV") to manufacture and sell LCD panels for flat-panel TVs. Plans call for the joint venture to commence operations in January 2005.

The JV will build an amorphous TFT LCD panel production line at the Mobara facility of Hitachi Displays, Ltd. ("Hitachi Displays"), Hitachi"s wholly owned subsidiary. Scheduled to begin mass production in the second quarter of the year ending March 31, 2007 (fiscal 2006), the JV will expand production capacity in stages, ultimately reaching the equivalent of 2.5 million 32-inch TV LCD panels a year by the second half of fiscal 2008. The expected capital investment for establishing this facility is 110.0 billion yen. While Hitachi Displays, Toshiba and Matsushita own majority shares, the JV plans to solicit investments from other companies involved in the manufacture of LCD panels, including device makers and material suppliers.

Sales are growing for flat-panel TVs, which combine a high-quality picture and large screen with a space-saving profile. Worldwide demand for LCD TVs was approximately 3.0 million units in 2003 and is estimated to expand fivefold by 2006. Furthermore, in order to meet increasing consumer demand for high-definition picture quality, TV manufacturers targeting the high-end market segment seek to differentiate their products not just with proprietary image processing technologies, but also by using LCD panels with outstanding picture quality. Reflecting this, mergers and acquisitions and strategic alliances in the LCD panel field, along with other developments in the industry, are resulting in fierce competition worldwide, fueling a growing need for TV manufacturers to ensure a stable supply of high-quality panels at low prices.

Against this backdrop, Hitachi, Toshiba and Matsushita have decided to establish a JV to manufacture LCD panels using Hitachi Displays" world-leading IPS(a) mode system technology. Boasting a wide viewing angle and outstanding color reproduction, these panels bring out the best in high-resolution content, such as digital TV broadcasts. The JV will provide the three companies with a reliable supply of LCD panels that are ideal for TVs and that will bolster the competitiveness of their respective LCD TV businesses in the high-end market. The JV, with Hitachi, Toshiba and Matsushita as its major customers, will operate a stable, capital-efficient production line, mass producing IPS-mode LCD panels, which provide outstanding picture quality at lower cost. Close collaboration with the JV is expected to achieve synergies in Hitachi, Toshiba and Matsushita"s respective production of finished products, allowing them to achieve LCD TVs that are even more competitive in terms of performance and price.

In-Plane-Switching (IPS) mode system, is a type of TFT LCD display technology. IPS is distinguished by a wide 170-degree viewing angle, both horizontally and vertically, along with minimal gray-scale inversion and viewing-angle dependency, reproducing lifelike images, which is made possible because the liquid crystal molecules can rotate while remaining parallel to the substrate when a voltage is applied, yielding perfect orientation of the crystals. The advanced super(AS) -IPS mode system for use in televisions, large-screen monitors and other applications achieves an approximate 30% improvement in the aperture ratio over conventional IPS technology. Furthermore, AS-IPS realizes a higher level of brightness and reproduces colors more realistically thanks to high-purity color filters and other proprietary technologies.

Hitachi, Ltd., ("Hitachi"), Toshiba Corporation ("Toshiba") and Matsushita Electric Industrial Co., Ltd., ("Matsushita") today reached a basic agreement to jointly establish a company (the "JV") to manufacture and sell LCD panels for flat-panel TVs. Plans call for the joint venture to commence operations in January 2005.

The JV will build an amorphous TFT LCD panel production line at the Mobara facility of Hitachi Displays, Ltd. ("Hitachi Displays"), Hitachi"s wholly owned subsidiary. Scheduled to begin mass production in the second quarter of the year ending March 31, 2007 (fiscal 2006), the JV will expand production capacity in stages, ultimately reaching the equivalent of 2.5 million 32-inch TV LCD panels a year by the second half of fiscal 2008. The expected capital investment for establishing this facility is 110.0 billion yen. While Hitachi Displays, Toshiba and Matsushita own majority shares, the JV plans to solicit investments from other companies involved in the manufacture of LCD panels, including device makers and material suppliers.

Sales are growing for flat-panel TVs, which combine a high-quality picture and large screen with a space-saving profile. Worldwide demand for LCD TVs was approximately 3.0 million units in 2003 and is estimated to expand fivefold by 2006. Furthermore, in order to meet increasing consumer demand for high-definition picture quality, TV manufacturers targeting the high-end market segment seek to differentiate their products not just with proprietary image processing technologies, but also by using LCD panels with outstanding picture quality. Reflecting this, mergers and acquisitions and strategic alliances in the LCD panel field, along with other developments in the industry, are resulting in fierce competition worldwide, fueling a growing need for TV manufacturers to ensure a stable supply of high-quality panels at low prices.

Against this backdrop, Hitachi, Toshiba and Matsushita have decided to establish a JV to manufacture LCD panels using Hitachi Displays" world-leading IPS(a) mode system technology. Boasting a wide viewing angle and outstanding color reproduction, these panels bring out the best in high-resolution content, such as digital TV broadcasts. The JV will provide the three companies with a reliable supply of LCD panels that are ideal for TVs and that will bolster the competitiveness of their respective LCD TV businesses in the high-end market. The JV, with Hitachi, Toshiba and Matsushita as its major customers, will operate a stable, capital-efficient production line, mass producing IPS-mode LCD panels, which provide outstanding picture quality at lower cost. Close collaboration with the JV is expected to achieve synergies in Hitachi, Toshiba and Matsushita"s respective production of finished products, allowing them to achieve LCD TVs that are even more competitive in terms of performance and price.

In-Plane-Switching (IPS) mode system, is a type of TFT LCD display technology. IPS is distinguished by a wide 170-degree viewing angle, both horizontally and vertically, along with minimal gray-scale inversion and viewing-angle dependency, reproducing lifelike images, which is made possible because the liquid crystal molecules can rotate while remaining parallel to the substrate when a voltage is applied, yielding perfect orientation of the crystals. The advanced super(AS) -IPS mode system for use in televisions, large-screen monitors and other applications achieves an approximate 30% improvement in the aperture ratio over conventional IPS technology. Furthermore, AS-IPS realizes a higher level of brightness and reproduces colors more realistically thanks to high-purity color filters and other proprietary technologies.

Alibaba.com offers 183 hitachi lcd module products. About 85% % of these are lcd modules, 1%% are construction machinery parts, and 1%% are digital signage and displays.

A wide variety of hitachi lcd module options are available to you, such as original manufacturer, odm.You can also choose from tft, standard and tn hitachi lcd module,

A wide variety of hitachi lcd display options are available to you, You can also choose from modern, hitachi lcd display,As well as from 1 year, {2}, and {3}. And whether hitachi lcd display is hotel, {2}, or {3}.

Hitachi Display Products Group has been voted best LCD supplier and manufacturer by Assodel, the Italian association of electronic component suppliers and distributors. Hitachi was presented with the prestigious award at the annual Assodel gala dinner held in Milan, Italy. Assodel has over 160 members, 410 customers and represents 95% of semiconductor and 70% of component distribution in Italy.

oduced in 2003 by Assodel, its annual award ceremony is held for distributors to show their recognition and appreciation of the manufacturers that they believe have provided them with the best levels of service, support and product innovation. The award for the displays category was accepted by Fabio Munero and Stefano Borlini of Hitachi Display Products Group.

Fabio Munero, sales manager for Hitachi DPG in Italy commented “Hitachi Displays is very proud to receive this award and we would like to thank our distribution partners who are working to develop business with customers in the Italian market.” He continued, “The Assodel Award is recognition from distributors and the local electronics community for Hitachi’s focus on developing LCD modules dedicated to the industrial market.”

Mark Stanley, sales and marketing manager Hitachi DPG added, “Italy is a key European market for us and we see this award as a great achievement. We look forward to continuing the positive and profitable relationships we have with our Italian distributors. Hitachi will continue to be fully committed to producing LCD modules with exceptional performance, high quality and long term availability enabling our distributors to respond to market demands and maintain the highest levels of support to their customers.”

The Assodel Awards are awarded on the basis of a vote by members. Each manufacturer is rated on a number of criteria including innovation, product quality, after-sales support and technology. Hitachi DPG performed particularly well on the product quality and technology ratings.

Hitachi introduce ultra high brightness TFT displays Ultra high brightness TFT displays ideal for outdoor applications Maidenhead, UK. 3 March 2011. Hitachi Display Products Group (DPG) has introduced two new ultra high brightness (UHB) TFT display modules which are ideal for sunlight readable applications. The two new transmissive mode displays feature high brightness LED backlighting providing an exceptional brightness of 1000cd/m². The long life LED backlights employed provide 70K hours of operation to half brightness lifetime. The high level of brightness achieved with Hitachi’s new UHB LED backlit displays has previously only been achieved with displays using power hungry CCFL backlights. The new 6.5” TX17D01VM2EAB and 10.4” TX26D14VM2EAA UHB display modules feature contrast ratios of 600:1 and 800:1 respectively, enabling clear, concise images while on-board circuitry allows simple and easy adjustment of the LED backlight brightness. These display modules also feature an anti-reflective (AR) polariser coating which helps to disperse light in multiple directions effectively eliminating reflections and therefore making them perfect for outdoor and direct sunlight applications.

“The introduction of these two new displays continues Hitachi’s active programme of expanding the range of industrial LCD panels with long life LED backlights, LVDS data interfaces and extended operating temperature ranges,” commented Steve Donohoe Technical Manager, Hitachi DPG, “Hitachi is now able to offer customers technology leading display products featuring high brightness LED backlighting that are ideally suited to operation in high ambient light environments.” The 6.5” TX17D01VM2EAB UHB display has a resolution of 640 x 480 (VGA), a 6-bit RGB interface supporting a colour palette of up to 262K colours and mechanical outline dimensions of 153mm (w) x 118mm (h) x 9.1mm (d). The 10.4” TX26D14VM2EAA UHB display features a resolution of 640 x 480 (VGA), an 8-bit digital RGB data interface supporting up to 16.7M colours and outline dimensions of 243.0mm (w) x 185.1mm (h) x 11mm (d). Both UHB displays support an operating temperature range of -20° to +70°C.

The new 6.5” and 10.4" UHB TFT display modules are supplied through Hitachi Display Products Group distribution partners and are available across Europe immediately. For more information, please visit www.hitachi-displays-eu.com or call +44(0)1628 585 000. Hitachi Display Products Group is part of Hitachi Europe Ltd.

About Hitachi Display Products Group Hitachi Display Products Group (DPG) is part of Hitachi Europe Ltd. It is responsible for pan-European sales and distribution of Hitachi’s leading liquid crystal display products. Offering a comprehensive range of monochrome and colour display component modules, the company supports customers in a range of sectors including mobile phone, medical, white goods, automotive and industrial industries. Hitachi Display Products Group offers a range of standard liquid crystal modules and is also able to develop and manufacture customised displays. For further information on Hitachi LCD modules, please visit the display products group web site http://www.hitachi-displays-eu.com About Hitachi, Ltd.Hitachi, Ltd., (NYSE: HIT / TSE: 6501), headquartered in Tokyo, Japan, is a leading global electronics company with approximately 360,000 employees worldwide. Fiscal 2009 (ended March 31, 2010) consolidated revenues totaled 8,968 billion yen ($96.4 billion). Hitachi will focus more than ever on the Social Innovation Business, which includes information and telecommunication systems, power systems, environmental, industrial and transportation systems, and social and urban systems, as well as the sophisticated materials and key devices that support them. For more information on Hitachi, please visit the company"s website at http://www.hitachi.com .

About Hitachi Europe Ltd.Hitachi Europe Ltd., is a wholly owned subsidiary of Hitachi, Ltd., Japan. Headquartered in Maidenhead, UK, it has operations in 11 countries across Europe, the Middle East and Africa and employs approximately 460 people. Hitachi Europe comprises of nine business areas: air conditioning and refrigeration systems; digital media and consumer products; display products; industrial components and equipment; manufacturing systems; information systems; power and industrial systems; power devices and procurement and sourcing. Hitachi Europe also has three Research and Development laboratories and a Design Centre. For more information about the company, please visit http://www.hitachi.eu . For more information please contact: Hitachi Display Products Group Mark Stephenson tel: +44 (0)1628 585 000 email: mark.stephenson@hitachi-eu.com

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey