tft lcd versus led future factory

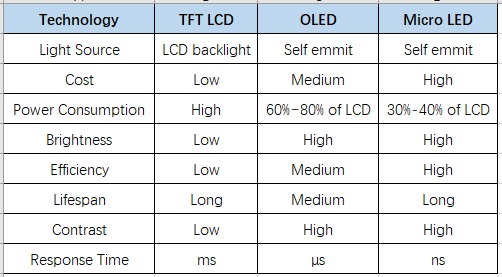

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

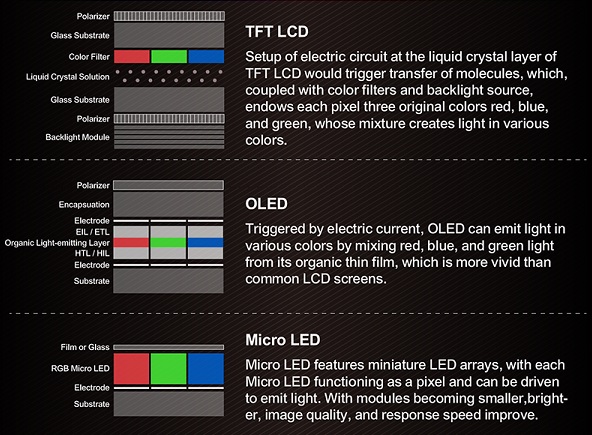

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

In recent years, China and other countries have invested heavily in the research and manufacturing capacity of display technology. Meanwhile, different display technology scenarios, ranging from traditional LCD (liquid crystal display) to rapidly expanding OLED (organic light-emitting diode) and emerging QLED (quantum-dot light-emitting diode), are competing for market dominance. Amidst the trivium strife, OLED, backed by technology leader Apple"s decision to use OLED for its iPhone X, seems to have a better position, yet QLED, despite still having technological obstacles to overcome, has displayed potential advantage in color quality, lower production costs and longer life.

Zhao: We all know display technologies are very important. Currently, there are OLED, QLED and traditional LCD technologies competing with each other. What are their differences and specific advantages? Shall we start from OLED?

Huang: OLED has developed very quickly in recent years. It is better to compare it with traditional LCD if we want to have a clear understanding of its characteristics. In terms of structure, LCD largely consists of three parts: backlight, TFT backplane and cell, or liquid section for display. Different from LCD, OLED lights directly with electricity. Thus, it does not need backlight, but it still needs the TFT backplane to control where to light. Because it is free from backlight, OLED has a thinner body, higher response time, higher color contrast and lower power consumption. Potentially, it may even have a cost advantage over LCD. The biggest breakthrough is its flexible display, which seems very hard to achieve for LCD.

Liao: Actually, there were/are many different types of display technologies, such as CRT (cathode ray tube), PDP (plasma display panel), LCD, LCOS (liquid crystals on silicon), laser display, LED (light-emitting diodes), SED (surface-conduction electron-emitter display), FED (filed emission display), OLED, QLED and Micro LED. From display technology lifespan point of view, Micro LED and QLED may be considered as in the introduction phase, OLED is in the growth phase, LCD for both computer and TV is in the maturity phase, but LCD for cellphone is in the decline phase, PDP and CRT are in the elimination phase. Now, LCD products are still dominating the display market while OLED is penetrating the market. As just mentioned by Dr Huang, OLED indeed has some advantages over LCD.

Huang: Despite the apparent technological advantages of OLED over LCD, it is not straightforward for OLED to replace LCD. For example, although both OLED and LCD use the TFT backplane, the OLED’s TFT is much more difficult to be made than that of the voltage-driven LCD because OLED is current-driven. Generally speaking, problems for mass production of display technology can be divided into three categories, namely scientific problems, engineering problems and production problems. The ways and cycles to solve these three kinds of problems are different.

At present, LCD has been relatively mature, while OLED is still in the early stage of industrial explosion. For OLED, there are still many urgent problems to be solved, especially production problems that need to be solved step by step in the process of mass production line. In addition, the capital threshold for both LCD and OLED are very high. Compared with the early development of LCD many years ago, the advancing pace of OLED has been quicker.While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen?

Liao: I want to supplement some data. According to the consulting firm HIS Markit, in 2018, the global market value for OLED products will be US$38.5 billion. But in 2020, it will reach US$67 billion, with an average compound annual growth rate of 46%. Another prediction estimates that OLED accounts for 33% of the display market sales, with the remaining 67% by LCD in 2018. But OLED’s market share could reach to 54% in 2020.

Huang: While different sources may have different prediction, the advantage of OLED over LCD in small and medium-sized display screen is clear. In small-sized screen, such as smart watch and smart phone, the penetration rate of OLED is roughly 20% to 30%, which represents certain competitiveness. For large size screen, such as TV, the advancement of OLED [against LCD] may need more time.

Xu: LCD was first proposed in 1968. During its development process, the technology has gradually overcome its own shortcomings and defeated other technologies. What are its remaining flaws? It is widely recognized that LCD is very hard to be made flexible. In addition, LCD does not emit light, so a back light is needed. The trend for display technologies is of course towards lighter and thinner (screen).

But currently, LCD is very mature and economic. It far surpasses OLED, and its picture quality and display contrast do not lag behind. Currently, LCD technology"s main target is head-mounted display (HMD), which means we must work on display resolution. In addition, OLED currently is only appropriate for medium and small-sized screens, but large screen has to rely on LCD. This is why the industry remains investing in the 10.5th generation production line (of LCD).

Xu: While deeply impacted by OLED’s super thin and flexible display, we also need to analyse the insufficiency of OLED. With lighting material being organic, its display life might be shorter. LCD can easily be used for 100 000 hours. The other defense effort by LCD is to develop flexible screen to counterattack the flexible display of OLED. But it is true that big worries exist in LCD industry.

LCD industry can also try other (counterattacking) strategies. We are advantageous in large-sized screen, but how about six or seven years later? While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen? People may not watch TV and only takes portable screens.

Some experts working at a market survey institute CCID (China Center for Information Industry Development) predicted that in five to six years, OLED will be very influential in small and medium-sized screen. Similarly, a top executive of BOE Technology said that after five to six years, OLED will counterweigh or even surpass LCD in smaller sizes, but to catch up with LCD, it may need 10 to 15 years.

Xu: Besides LCD, Micro LED (Micro Light-Emitting Diode Display) has evolved for many years, though people"s real attention to the display option was not aroused until May 2014 when Apple acquired US-based Micro LED developer LuxVue Technology. It is expected that Micro LED will be used on wearable digital devices to improve battery"s life and screen brightness.

Micro LED, also called mLED or μLED, is a new display technology. Using a so-called mass transfer technology, Micro LED displays consist of arrays of microscopic LEDs forming the individual pixel elements. It can offer better contrast, response times, very high resolution and energy efficiency. Compared with OLED, it has higher lightening efficiency and longer life span, but its flexible display is inferior to OLED. Compared with LCD, Micro LED has better contrast, response times and energy efficiency. It is widely considered appropriate for wearables, AR/VR, auto display and mini-projector.

However, Micro LED still has some technological bottlenecks in epitaxy, mass transfer, driving circuit, full colorization, and monitoring and repairing. It also has a very high manufacturing cost. In short term, it cannot compete traditional LCD. But as a new generation of display technology after LCD and OLED, Micro LED has received wide attentions and it should enjoy fast commercialization in the coming three to five years.

Peng: It comes to quantum dot. First, QLED TV on market today is a misleading concept. Quantum dots are a class of semiconductor nanocrystals, whose emission wavelength can be continuously tuned because of the so-called quantum confinement effect. Because they are inorganic crystals, quantum dots in display devices are very stable. Also, due to their single crystalline nature, emission color of quantum dots can be extremely pure, which dictates the color quality of display devices.

Interestingly, quantum dots as light-emitting materials are related to both OLED and LCD. The so-called QLED TVs on market are actually quantum-dot enhanced LCD TVs, which use quantum dots to replace the green and red phosphors in LCD’s backlight unit. By doing so, LCD displays greatly improve their color purity, picture quality and potentially energy consumption. The working mechanisms of quantum dots in these enhanced LCD displays is their photoluminescence.

For its relationship with OLED, quantum-dot light-emitting diode (QLED) can in certain sense be considered as electroluminescence devices by replacing the organic light-emitting materials in OLED. Though QLED and OLED have nearly identical structure, they also have noticeable differences. Similar to LCD with quantum-dot backlighting unit, color gamut of QLED is much wider than that of OLED and it is more stable than OLED.

Another big difference between OLED and QLED is their production technology. OLED relies on a high-precision technique called vacuum evaporation with high-resolution mask. QLED cannot be produced in this way because quantum dots as inorganic nanocrystals are very difficult to be vaporized. If QLED is commercially produced, it has to be printed and processed with solution-based technology. You can consider this as a weakness, since the printing electronics at present is far less precision than the vacuum-based technology. However, solution-based processing can also be considered as an advantage, because if the production problem is overcome, it costs much less than the vacuum-based technology applied for OLED. Without considering TFT, investment into an OLED production line often costs tens of billions of yuan but investment for QLED could be just 90–95% less.

Given the relatively low resolution of printing technology, QLED shall be difficult to reach a resolution greater than 300 PPI (pixels per inch) within a few years. Thus, QLED might not be applied for small-sized displays at present and its potential will be medium to large-sized displays.

Peng: Good questions. Ligand chemistry of quantum dots has developed quickly in the past two to three years. Colloidal stability of inorganic nanocrystals should be said of being solved. We reported in 2016 that one gram of quantum dots can be stably dispersed in one milliliter of organic solution, which is certainly sufficient for printing technology. For the second question, several companies have been able to mass produce quantum dots. At present, all these production volume is built for fabrication of the backlighting units for LCD. It is believed that all high-end TVs from Samsung in 2017 are all LCD TVs with quantum-dot backlighting units. In addition, Nanosys in the United States is also producing quantum dots for LCD TVs. NajingTech at Hangzhou, China demonstrate production capacity to support the Chinese TV makers. To my knowledge, NajingTech is establishing a production line for 10 million sets of color TVs with quantum-dot backlighting units annually.China"s current demands cannot be fully satisfied from the foreign companies. It is also necessary to fulfill the demands of domestic market. That is why China must develop its OLED production capability.

Huang: Based on my understanding of Samsung, the leading Korean player in OLED market, we cannot say it had foresight in the very beginning. Samsung began to invest in AMOLED (active-matrix organic light-emitting diode, a major type of OLED used in the display industry) in about 2003, and did not realize mass production until 2007. Its OLED production reached profitability in 2010. Since then, Samsung gradually secured a market monopoly status.

So, originally, OLED was only one of Samsung"s several alternative technology pathways. But step by step, it achieved an advantageous status in the market and so tended to maintain it by expanding its production capacity.

Another reason is customers’ demands. Apple has refrained itself from using OLED for some years due to various reasons, including the patent disputes with Samsung. But after Apple began to use OLED for its iPhone X, it exerted a big influence in the whole industry. So now Samsung began to harvest its accumulated investments in the field and began to expand the capacity more.

Liao: South Korean manufacturers including Samsung and LG Electronics have controlled 90% of global supplies of medium and small-sized OLED panels. Since Apple began to buy OLED panels from Samsung for its cellphone products, there were no more enough panels shipping to China. Therefore, China"s current demands cannot be fully satisfied from the foreign companies. On the other hand, because China has a huge market for cellphones, it would be necessary to fulfill the demands through domestic efforts. That is why China must develop its OLED production capability.

Huang: The importance of China"s LCD manufacturing is now globally high. Compared with the early stage of LCD development, China"s status in OLED has been dramatically improved. When developing LCD, China has adopted the pattern of introduction-absorption-renovation. Now for OLED, we have a much higher percentage of independent innovation.

Then it is the scale of human resources. One big factory will create several thousand jobs, and it will mobilize a whole production chain, involving thousands of workers. The requirement of supplying these engineers and skilled workers can be fulfilled in China.

The third advantage is the national supports. The government has input huge supports and manufacturers’ technological capacity is improving. I think Chinese manufacturers will have a great breakthrough in OLED.

Although we cannot say that our advantages triumph over ROK, where Samsung and LG have been dominating the field for many years, we have achieved many significant progresses in developing the material and parts of OLED. We also have high level of innovation in process technology and designs. We already have several major manufacturers, such as Visionox, BOE, EDO and Tianma, which have owned significant technological reserves.

Peng: As mentioned above, there are two ways to apply quantum dots for display, namely photoluminescence in backlightingFor QLED, the three stages of technological development [from science issue to engineering and finally to mass production] have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

units for LCD and electroluminescence in QLED. For the photoluminescence applications, the key is quantum-dot materials. China has noticeable advantages in quantum-dot materials.

China is internationally leading in electroluminescence at present. In fact, it was the 2014 Nature publication by a group of scientists from Zhejiang University that proved QLED can reach the stringent requirements for display applications. However, who will become the final winner of the international competition on electroluminescence remains unclear. China"s investment in quantum-dot technology lags far behind US and ROK. Basically, the quantum-dot research has been centered in US for most of its history, and South Korean players have invested heavily along this direction as well.

For electroluminescence, it is very likely to co-exist with OLED for a long period of time. This is so because, in small screen, QLED’s resolution is limited by printing technology.

Peng: If electroluminescence can be successfully achieved with printing, it will be much cheaper, with only about 1/10th cost of OLED. Manufacturers like NajingTech and BOE in China have demonstrated printing displays with quantum dots. At present, QLED does not compete with OLED directly, given its market in small-sized screen. A while ago, Dr. Huang mentioned three stages of technological development, from science issue to engineering and finally to mass production. For QLED, the three stages have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

Huang: When OLED was compared with LCD in the past, lots of advantages of OLED were highlighted, such as high color gamut, high contrast and high response speed and so on. But above advantages would be difficult to be the overwhelming superiority to make the consumers to choose replacement.

It seems to be possible that the flexible display will eventually lead a killer advantage. I think QLED will also face similar situation. What is its real advantage if it is compared with OLED or LCD? For QLED, it seems to have been difficult to find the advantage in small screen. Dr. Peng has suggested its advantage lies in medium-sized screen, but what is its uniqueness?

Peng: The two types of key advantages of QLED are discussed above. One, QLED is based on solution-based printing technology, which is low cost and high yield. Two, quantum-dot emitters vender QLED with a large color gamut, high picture quality and superior device lifetime. Medium-sized screen is easiest for the coming QLED technologies but QLED for large screen is probably a reasonable extension afterwards.

Huang: But customers may not accept only better wider color range if they need to pay more money for this. I would suggest QLED consider the changes in color standards, such as the newly released BT2020 (defining high-definition 4 K TV), and new unique applications which cannot be satisfied by other technologies. The future of QLED seems also relying on the maturity of printing technology.

Peng: New standard (BT2020) certainly helps QLED, given BT2020 meaning a broad color gamut. Among the technologies discussed today, quantum-dot displays in either form are the only ones that can satisfy BT2020 without any optical compensation. In addition, studies found that the picture quality of display is highly associated with color gamut. It is correct that the maturity of printing technology plays an important role in the development of QLED. The current printing technology is ready for medium-sized screen and should be able to be extended to large-sized screen without much trouble.

Xu: For QLED to become a dominant technology, it is still difficult. In its development process, OLED precedes it and there are other rivaling technologies following. While we know owning the foundational patents and core technologies of QLED can make you a good position, holding core technologies alone cannot ensure you to become a mainstream technology. The government"s investment in such key technologies after all is small as compared with industry and cannot decide QLED to become mainstream technology.

Peng: Domestic industry sector has begun to invest in these future technologies. For example, NajingTech has invested about 400 million yuan ($65 million) in QLED, primarily in electroluminescence. There are some leading domestic players having invested into the field. Yes, this is far from enough. For example, there are few domestic companies investing R&D of printing technologies. Our printing equipment is primarily made by the US, European and Japan players. I think this is also a chance for China (to develop the printing technologies).

Liao: Due to their lack of kernel technologies, Chinese OLED panel manufacturers heavily rely on investments to improve their market competitiveness. But this may cause the overheated investment in the OLED industry. In recent years, China has already imported quite a few new OLED production lines with the total cost of about 450 billion yuan (US$71.5 billion).Lots of advantages of OLED over LCD were highlighted, such as high color gamut, high contrast and high response speed and so on …. It seems to be possible that the flexible display will eventually lead a killer advantage.

The short of talent human resources perhaps is another issue to influence the fast expansion of the industry domestically. For an example, BOE alone demands more than 1000 new engineers last year. However, the domestic universities certainly cannot fulfill this requirement for specially trained OLED working forces currently. A major problem is the training is not implemented in accordance with industry demands but surrounding academic papers.

Liao: However, Chinese researchers’ priority pursuit of papers is in disjunction from industry demand. Majority of people (at universities) who are working on organic optoelectronics are more interested in the fields of QLED, organic solar cells, perovskite solar cells and thin-film transistors because they are trendy fields and have more chances to publish research papers. On the other hand, many studies that are essential to solve industry"s problems, such as developing domestic versions of equipment, are not so essential for paper publication, so that faculty and students shed from them.

Zhao: Today there are really good observations, discussions and suggestions. The industry-academics-research collaboration is crucial to the future of China"s display technologies. We all should work hard on this.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

MicroLED shows promise as a display technology, potentially offering power savings and a reduced screen thickness when put beside current-generation display panels. Apple has recognized the potential, and has invested heavily into developing the technology over the last few years, with a view to using it in the company"s future products.

To understand fully how MicroLED can benefit Apple, it is worth understanding how the commonly-used display technologies work in the first place, before examining how different MicroLED really is in a comparison.

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

Displays that use collections of LEDs as individual pixels do exist, but it isn"t usually found in consumer products. LED screens are commonly used for billboards, in attractions, and as a large-scale display for events.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

As the name implies, OLED uses an organic compound film that is put between two electrodes, which are used to provide charge. Instead of the charge changing how light passes through, the current instead causes the emissive electroluminescent layer to emit light, without the need for a rear light source.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

OLED also can be produced on plastic substrates instead of glass, allowing it to be used to create flexible displays. While this is currently embodied in curved and other non-flat screens in some devices, it has the potential to be employed in foldable smartphones or rolled up for storage, an area Apple is also allegedly examining.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

OLED panels are also affected by the presence of water, both in production and in use. Small amounts of water contacting the organic substrate can cause immediate damage to the display, rendering parts of the screen useless.

So far, Apple"s usage of OLED consists of the premium iPhone X and the Apple Watch. As the cost of production drops down, it is plausible for Apple to use OLED in more future products, providing a better screen for customers to use.

Thought to be the next big thing in display technology, MicroLED basically takes the idea of using LEDs for pixels in a large stadium-style screen and miniaturizes it all.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED doesn"t use an organic compound to produce light, making it less susceptible to failure compared to OLED. Just like OLED, it can be applied onto a flexible material, allowing it to be used for curved displays or non-stationary components, like a watch strap, and can result in an extremely thin display panel.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

While MicroLED is an attractive proposition for Apple, it is not the only technology under development by the company"s engineers. Apple has previously filed patent applications for a technology described as "Quantum Dot LED and OLED Integration for High Efficiency Displays."

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

The technology in theory can create an even thinner display than OLED, along with a more streamlined manufacturing process. True QD displays are also capable of high pixel densities of up to 1,000ppi, multiple times the density required to be called a Retina-quality display, and based on Apple"s hybrid invention, will also boast the response times of OLED technology.

As is usually the case, Apple does produce a considerable number of patent applications every week that are filed with the US Patent and Trademark Office, and not everything it files will be fully commercialized.

The QD patent application certainly shows Apple is thinking about display technology in multiple ways, and how it can be applied to future devices, but short of getting firm supply chain information or an official announcement from Apple directly, it is difficult to confirm which direction it will be heading.

Apple has been interested in using the technology for some time now, with the first notable sign being its acquisition of LuxVue in May 2014, alongside assorted related patents. A MicroLED specialist, LuxVue was rumored to have been the display producer for the ill-fated Google Glass headset, but was also the holder of assorted patents in the LED display field, including MicroLED.

At the time, the acquisition was thought to be an attempt by Apple to bring part of its display technology development in-house, with suggestions the MicroLED technology would be used in another rumored-at-the-time device, the Apple Watch. A more recent report suggests Apple is working with TSMC to make small panels for a future premium Apple Watch, potentially starting mass production by the end of the year.

Apple has also reportedly set up a secret facility just 15 minutes away from Apple Park, believed to be used for developing MicroLED. The 62,000 square-foot facility is thought to house around 300 engineers on a project named "T159," relating directly to the technology"s development.

The facility is also claimed to be sufficient in size to perform small scale manufacturing of display panels, allowing the company to keep development and testing in-house without involving third-parties. Considering Apple"s previous history in developing technologies before issuing information to manufacturing partners, it is possible that Apple is trying to work out the kinks in production before suppliers even attempt to make MicroLED panels.

Reports from last year also suggest Apple"s investment in MicroLED was a cause for concern for Samsung, LG, and other South Korean suppliers who provide display panels for the company"s products. Owning the process for MicroLED manufacturing could allow Apple to migrate away from its existing display suppliers in the coming years, reducing revenues and profits.

Aside from Apple"s development, there has been little in the way of announcements from other firms for products using the technology that could be bought by consumers in the coming months. The exception is Samsung, Apple"s main rival in the mobile marketplace and a major supplier of display panels, but its usage of MicroLED is not aimed at producing smaller screens.

At CES 2018, Samsung introduced The Wall, a 148-inch TV claimed to be the "world"s first consumer modular MicroLED" television. According to the South Korean electronics giant, The Wall"s modularity meant consumers would be able to customize their television"s size and shape to suit their needs.

The impending use of the technology in a high-priced consumer product could be considered proof that MicroLED display technology is maturing enough for use in devices. If the reports claiming Apple is getting close to mass producing panels is true, the inclusion of MicroLED in the Apple Watch could end up being the first mainstream usage of the technology.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

While red and green AMOLED sheets have a greater lifespan (46,000 to 230,000 hours), azure compounds have significantly shorter longevity (up to roughly 14,000 hours).

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Before you get a new monition for your organization, comparing the TFT display vs IPS display is something that you should do. You would want to buy the monitor which is the most advanced in technology. Therefore, understanding which technology is good for your organization is a must. click to view the 7 Best Types Of Display Screens Technology.

Technology is changing and becoming advanced day by day. Therefore, when you are looking to get a new monitor for your organization, LCD advantages, and disadvantage, you have to be aware of the pros and cons of that monitor. Moreover, you need to understand the type of monitor you are looking to buy.

That is why it is important to break it down and discuss point by point so that you can understand it in a layman’s language devoid of any technical jargon. Therefore, in this very article, let’s discuss what exactly TFT LCDs and IPS LCDs are, and what are their differences? You will also find out about their pros and cons for your organization.

The word TFT means Thin-Film-Translator. It is the technology that is used in LCD or Liquid Crystal Display. Here you should know that this type of LCD is also categorically referred to as active-matrix LCDs. It tells that these LCDs can hold back some pixels while using other pixels. So, the LCD will be using a very minimum amount of energy to function. TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the display monitor functions by using a very small amount of energy without running out of operation.

Now, it is time to take a look at its features that are tailored to improve the experience of the monitor users significantly. Here are some of the features of the TFT monitor;

No radiation, no scintillation, no harm to the user’s health. In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of a paperless office and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be normally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can not only be used as a mobile terminal display, or desktop terminal display but also can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and good characteristics of large-scale industrial production. TFT LCD industry technology is mature, a mass production rate of more than 90%.

TFT LCD screen from the beginning of the use of flat glass plate, its display effect is flat right angles, let a person have a refreshing feeling. And LCDs are easier to achieve high resolution on small screens.

The word IPS refers to In-Plane-Switching which is a technology used to improve the viewing experience of the usual TFT displays. You can say that the IPS display is a more advanced version of the traditional TFT LCD module. However, the features of IPS displays are much more advanced and their applications are very much widespread. You should also know that the basic structure of the IPS LCD is the same as TFT LCD if you compare TFT LCD vs IPS.

As you already know, TFT displays do have a very quick response time which is a plus point for it. But, that does not mean IPS displays a lack of response time. In fact, the response time of an IPS LCD is much more consistent, stable, and quick than the TFT display that everyone used to use in the past. However, you will not be able to gauge the difference apparently by watching TFT and IPS displays separately. But, once you watch the screen side-by-side, the difference will become quite clear to you.

The main drawback of the TFT displays as figured above is the narrow-angle viewing experience. The monitor you buy for your organization should give you an experience of wide-angle viewing. It is very much true if you have to use the screen by staying in motion.

So, as IPS displays are an improved version of TFT displays the viewing angle of IPS LCDs is very much wide. It is a plus point in favor of IPS LCDs when you compare TFT vs IPS. With a TFT screen, you cannot watch an image from various angles without encountering halo effects, blurriness, or grayscale that will cause problems for your viewing.

It is one of the major and remarkable differences between IPS and TFT displays. So, if you don’t want to comprise on the viewing angles and want to have the best experience of viewing the screen from wide angles, the IPS display is what you want. The main reason for such a versatile and wonderful viewing angle of IPS display is the screen configuration which is widely set.

Now, when you want to achieve wide-angle viewing with your display screen, you need to make sure it has a faster level of frequency transmittance. It is where IPS displays overtake TFT displays easily in the comparison because the IPS displays have a much faster and speedier transmittance of frequencies than the TFT displays.

Now the transmittance difference between TFT displays and IPS displays would be around 1ms vs. 25ms. Now, you might think that the difference in milliseconds should not create much of a difference as far as the viewing experience is concerned. Yes, this difference cannot be gauged with a naked eye and you will find it difficult to decipher the difference.

However, when you view and an IPS display from a side-by-side angle and a TFT display from a similar angle, the difference will be quite evident in front of you. That is why those who want to avoid lagging in the screen during information sharing at a high speed; generally go for IPS displays. So, if you are someone who is looking to perform advanced applications on the monitor and want to have a wider viewing angle, then an IPS display is the perfect choice for you.

As you know, the basic structure of the IPS display and TFT displays are the same. So, it is quite obvious that an IPS display would use the same basic colors to create various shades with the pixels. However, there is a big difference with the way a TFT display would produce the colors and shade to an IPS display.

The major difference is in the way pixels get placed and the way they operate with electrodes. If you take the perspective of the TFT display, its pixels function perpendicularly once the pixels get activated with the help of the electrodes. It does help in creating sharp images.

But the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As you already know the features of both TFT and IPS displays, it would be easier for you to understand the difference between the two screen-types. Now, let’s divide the matters into three sections and try to understand the basic differences so that you understand the two technologies in a compressive way. So, here are the difference between an IPS display and a TFT display;

Now, before starting the comparison, it is quite fair to say that both IPS and TFT displays have a wonderful and clear color display. You just cannot say that any of these two displays lag significantly when it comes to color clarity.

However, when it comes to choosing the better display on the parameter of clarity of color, then it has to be the IPS display. The reason why IPS displays tend to have better clarity of color than TFT displays is a better crystal oriental arrangement which is an important part.

That is why when you compare the IPS LCD with TFT LCD for the clarity of color, IPS LCD will get the nod because of the better and advanced technology and structure.

IPS displays have a wider aspect ratio because of the wide-set configuration. That is why it will give you a better wide-angle view when it comes to comparison between IPS and TFT displays. After a certain angle, with a TFT display, the colors will start to get a bit distorted.

But, this distortion of color is very much limited in an IPS display and you may see it very seldom after a much wider angle than the TFT displays. That is why for wide-angle viewing, TFT displays will be more preferable.

When you are comparing TFT LCD vs. IPS, energy consumption also becomes an important part of that comparison. Now, IPS technology is a much advanced technology than TFT technology. So, it is quite obvious that IPS takes a bit more energy to function than TFT.

Also, when you are using an IPS monitor, the screen will be much larger. So, as there is a need for much more energy for the IPS display to function, the battery of the device will drain faster. Furthermore, IPS panels cost way more than TFT display panels.

1. The best thing about TFT technology is it uses much less energy to function when it is used

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey