lcd panel light diffuser free sample

PC Light Diffusion sheet is made of Polycarbonate (PC for short), endowing PC diffusion plates with high transparency, good surficial brightness and perfect flatness. All raw material we use is imported from Bayer of German and Teijin of Japan. Through designing optical textures on production rolls and testing different addictive formulas, we manage to keep the balance between transparency and haze degree, and achieve uniformed light diffusion effect. On account of consistent modification and improvement, Our product is in accordance with the highest standards of industry and meets the demand of customers. It also performs well in a wide range temperature from -40 ℃to 120 ℃, Our product has passed RoHS, REACH, USA UL94 fire resistance of V-2 and V-0,Glowing-Wire test of 650℃ and 850℃,UK TP(a) and 5-year Anti-UV.

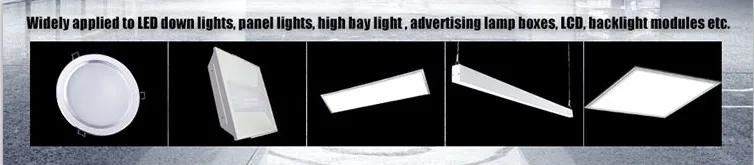

Our company focuses on developing, producing and selling PC light diffusion sheets and films which are widely applied to LED down lights, panel lights, high bays,advertising lamp boxes, LCD backlight modules etc. They are well known as a goodmatch for quality, durable light sources.

LED Panel Diffuser Material light diffuser plate coming from a light source and achieves uniform brightness on the screeen. It"s designed to allow varying amounts visible light to pass through. Creat the desired light effect by adding a light diffuser film to a light source. It comes in normal and pattern types. Application: LED,LCD laptops,monitors,and GPS navigation devices, tablets,notebooks PCs,and TVs,etc

The Hisense U8H matches the excellent brightness and color performance of much pricier LCD TVs, and its Google TV smart platform is a welcome addition. But it’s available in only three screen sizes.

The Hisense U8H is the best LCD/LED TV for most people because it delivers the performance of a much pricier TV yet starts at under $1,000, for the smallest (55-inch) screen size. This TV utilizes quantum dots, a full-array backlight with mini-LEDs, and a 120 Hz refresh rate to deliver a great-looking 4K HDR image. It’s compatible with every major HDR format. And it’s equipped with two full-bandwidth HDMI 2.1 inputs to support 4K 120 Hz gaming from the newest Xbox and PlayStation consoles. Add in the intuitive, fully featured Google TV smart-TV platform, and the U8H’s price-to-performance ratio is of inarguable value.

Chief among the U8H’s many strengths is its impressive peak brightness. When sending it HDR test patterns, I measured an average brightness of 1,500 nits, with peaks just north of 1,800 nits (a measurement of luminance; see TV features, defined for more info). To put that into perspective, consider that the 65-inch version of our budget 4K TV pick (the TCL 5-Series) typically costs around half as much as the 65-inch U8H but achieves only around 30% to 40% of its brightness. On the other side of the coin, the 65-inch version of our upgrade pick (the Samsung QN90B) costs almost twice as much as the 65-inch U8H, but it achieves only nominally higher brightness. Adequate light output creates convincing highlights and image contrast and (when necessary) combats ambient light from lamps or windows. It is a necessity for any TV worth buying—especially if you hope to watch HDR movies or play HDR games—and the U8H simply outpaces most TVs in its price range (and some in the next price bracket up, too).

Key to this functionality is the U8H’s employment of mini-LED backlighting with local dimming, which allows this TV to produce very bright light while still maintaining satisfyingly deep black levels that are typically free of blooming (or light bleed that’s visible around bright objects against a dark backdrop). This not only ensures impressive image contrast, it also makes the U8H a viable choice for most rooms, whether they’re brighter than average or dimmed down like a movie theater.

That’s not to say the U8H has pixel-precise light control—it’s not an OLED TV, after all—but it does a terrific job most of the time. In fact, in our tests, the U8H bested last year’s upgrade pick, the Samsung QN90A, in certain scenarios: The intro to Guillermo del Toro’s Cabinet of Curiosities on Netflix features the filmmaker against a pitch-black backdrop. Though last year’s QN90A failed to maintain perfect control over dimming elements during this scene (the black backdrop brightened distractingly once a sufficient amount of brighter content appeared on screen), the U8H did not. (For the record, the newer QN90B also passed this test.) The U8H’s mini-LEDs also help the screen look uniformly bright: Although the U8H is still not as good as an OLED TV in this respect, it shows very little indication of being a backlight-driven display, even during tricky scenes with large swaths of dim lighting.

The U8H’s brightness, black-level integrity, and local-dimming abilities make this an excellent TV for watching HDR content. The U8H is capable of playing HDR content in all of the major formats (HDR10, HDR10+, Dolby Vision, and HLG), but when it comes to impressive HDR, what’s under the hood is much more important than format compatibility. The most crucial thing for good HDR is high brightness and deep color saturation, and the U8H’s quantum dots achieve the latter. It’s not as simple as just having quantum dots, however: While many TVs (even the budget options) have quantum dots nowadays, what is often not taken into account is that brightness directly affects color saturation. For example, both the 2022 TCL 6-Series and the Hisense U8H are equipped with quantum dots, mini-LED backlights, and local dimming. But because the U8H is notably brighter than the 6-Series, it also achieves a higher total color volume. During our color-volume testing, the U8H exhibited color ranges at more than 100% of the DCI-P3 color space (the range of color needed to properly display HDR content), and it is capable of roughly 10% more total color volume compared with the 6-Series.

What does this mean in real-world terms? It means that the Hisense U8H truly excels as a modern 4K HDR TV, whether you’re watching the latest episode of Rings of Power or playing Overwatch 2. While watching HDR content side by side on the U8H and on our upgrade pick, the Samsung QN90B, I was truly surprised by how similar they looked at times, given that our upgrade pick is much more expensive. That said, though the U8H achieves impressive results where light output and color volume are concerned, it also exhibited some occasional video processing and upscaling issues (see Flaws but not dealbreakers), which videophiles and AV enthusiasts may take umbrage with. But in general, the picture quality punches well above its weight, metaphorically speaking.

And thanks to Hisense’s inclusion of Filmmaker Mode, it’s easy to rein in the U8H’s brightness abilities for a more-subdued and filmic experience in a darker room. Our measurements revealed that this mode has a very accurate white balance, mostly accurate colors (green is a bit oversaturated, but not egregiously so), and a perfect “dark room” gamma (which controls how quickly the video signal transitions from dark to light). Additionally, the TV’s 120 Hz refresh rate means it can play Blu-ray discs at 24 fps without the judder that’s usually present on TVs with 60 Hz refresh rates.

In terms of design, the Hisense U8H is not as svelte as our upgrade pick, but it’s plenty sturdy and doesn’t look or feel cheap. Two narrow, metal feet jut out from beneath the panel and steadily hold the TV. They can be attached in two separate spots, either closer in toward the middle of the panel or out toward the edges, to account for different-size TV stands. The feet are also equipped with cable organization clasps—a nice touch for keeping your TV stand free of cable clutter. Though the TV is primarily plastic, its bezels are lined with metal strips, providing a bit more durability in the long run. I moved it around my home, and it was no worse for wear, but we’ll know more after doing some long-term testing.

The Hisense U8H has some difficulties with banding, or areas of uneven gradation, where transitions that should appear smooth instead look like “bands” of color (sometimes also called posterization). Like many current 4K HDR TVs, the U8H uses an 8-bit panel rather than a 10-bit panel, which affects the color decoding and color presentation process. This is usually relevant only with HDR video and games. When playing games on the PlayStation 5 and Xbox Series X, I saw a few instances where the content wasn’t rendered correctly and displayed ugly splotches of color on the screen. However, this almost always occurred during static screens (such as a pause menu or loading screen); I rarely spotted it during actual gameplay. Hisense has stated that it would address the problem in a future firmware update, but at the time of writing it was still present. This is a flaw that may give dedicated gamers pause, but we don’t consider it to be a dealbreaker for most people.

Finally, like most TVs that use vertical alignment (VA) LCD panels, the U8H has a limited horizontal viewing angle, which may be a bit annoying if you’re hoping to entertain a large crowd. Our upgrade pick uses a special wide-angle technology to address this.

If you’re watching in a darker room and want the most accurate picture you can get—preserving the director’s intent—select the U8H’s Filmmaker Mode as your picture mode. In a brighter room, we recommend the Theater Day picture mode. In either case, you should go into the backlight settings, disable the automatic light sensor, and set the backlight to your personal preference. This is true whether you’re watching SDR or HDR content.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

The local dimming method of backlighting allows to dynamically control the level of light intensity of specific areas of darkness on the screen, resulting in much higher dynamic-contrast ratios, though at the cost of less detail in small, bright objects on a dark background, such as star fields or shadow details.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

The evolution of energy standards and the increasing public expectations regarding power consumption made it necessary for backlight systems to manage their power. As for other consumer electronics products (e.g., fridges or light bulbs), energy consumption categories are enforced for television sets.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is too low or the user is sensitive to flicker, this may cause discomfort and eyestrain similar to the flicker of CRT displays at lower refresh rates.

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; https://ieeexplore.ieee.org/document/6520956

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

What are optical films and what are the eight different types of optical films? This article highlights these answers and also mentions usages of optical films.

In a broad sense, optical films are film products with optical properties. The two common types of optical films are backlight module and polarizing. The prominent applications of these films are OLED (Organic Light Emitting Diode) panels and TFT (Thin Film Transistor) LCD liquid crystal panels. Based on the material used to make films, the optical films can be bifurcated into functional thin films and selective separation membrane.

The functional thin film is mainly used for optical technology and selective separation membrane plays a crucial role in the waste water management system. The demand for optical films has increased due to the large sizes of LCD panels. This factor creates opportunities for the polarizing films. According to a report published by Research Dive, the optical films market is anticipated to garner revenue of $30.1 billion by 2024 with a healthy growth rate of 7.1% in the forecast period.

Optical films consist of different types of sheets that are bifurcated on the basis of application and working protocols. The significant optical films are as follows:Diffuser Film:

These type of films breakup the light and tend to distribute it evenly. The light rays are distributed in various directions; thus this results in diffuse-glare-free light. Diffuser films ensure that there is uniformity in brightness and they also reduce unpleasant spots that have linear and point sources of light. Various applications of diffuser films are as follows:Used in backlight

These are mainly installed on the windows due to their high energy efficiency nature. Reflective films reflect heat from the sunlight and store this heat in the glass of the window; thus preventing the heat from entering the building. The heating and cooling costs are reduced significantly due to the installation of reflective films. Some added benefits of these films are that they enhance privacy, shatter resistant, low glare, and UV light.Reflective Polarizer Film:

A Japanese company called as DuPoint Teijin Films Ltd has managed to create liquid polarizer that is used in LCD (Liquid Crystal Display). This is a combination of multilayer film technology and polymer that aids in recycling of the rejected polarized light back to the viewer; thus augmenting the output. Reflective polarizer film is used in STN (Super Twisted Nematic) display and reflection mode TN (Twisted Nematic).Indium Tin Oxide (ITO) Film:

This is made by using micro replication film structure technique in which the prism structure is created by acrylic resin. According to the geometric optics principle, the emitted light is passed via circulation of the prism film and the backlight film. This is converged at the front to generate a high brightening effect. Normal prism film is mainly used at LCD backlight units that aids in luminance by directing the light from the source of light.Multifunctional Prism Film:

This is an advanced type of film that combines prism and diffusion functions in one place. Multifunctional prism film makes use of beads, doping, and surface micro-lens structures that directs the light with higher efficiency than the normal prism film.Polarizing Film:

This blocks the light and allows the light to pass through liquid crystals in the LCD panel. Polarizing film is the core element of the LCD panel that facilitates image display on the screen. Some of the vital benefits of polarizing films are as follows:High luminescence

Micro-lens array structure is utilized for combining prism and diffusion functions. The conventional prism sheets are replaced by micro-lens films in the LCD TV panels. This enhances the light efficiency of the LCD and is also cost effective in nature. Micro-lens films are manufactured by using IC (Integrated Circuit) technologies such as photo-resist processing, photolithography, and reactive ion etching. Some of the applications of micro-lens are as follows:Fiber couplers

The light-emitting diode (LED) is today"s most energy-efficient and rapidly-developing lighting technology. Quality LED light bulbs last longer, are more durable, and offer comparable or better light quality than other types of lighting. Check out the top 8 things you didn"t know about LEDs to learn more.

LED is a highly energy-efficient lighting technology, and has the potential to fundamentally change the future of lighting in the United States. Residential LEDs -- especially ENERGY STAR rated products -- use at least 75% less energy, and last up to 25 times longer, than incandescent lighting.

Widespread use of LED lighting has a large potential impact on energy savings in the United States. By 2035, the majority of lighting installations are anticipated to use LED technology, and energy savings from LED lighting could top 569 TWh annually by 2035, equal to the annual energy output of more than 92 1,000 MW power plants.

Light Source: LEDs are the size of a fleck of pepper, and can emit light in a range of colors. A mix of red, green, and blue LEDs is sometimes used to make white light.

Direction: LEDs emit light in a specific direction, reducing the need for reflectors and diffusers that can trap light. This feature makes LEDs more efficient for many uses such as recessed downlights and task lighting. With other types of lighting, the light must be reflected to the desired direction and more than half of the light may never leave the fixture.

Lifetime: LED lighting products typically last much longer than other lighting types. A good quality LED bulb can last 3 to 5 times longer than a CFL and 30 times longer than an incandescent bulb.

LED lighting is available in a wide variety of home and industrial products, and the list is growing every year. The rapid development of LED technology has resulted in increased product availability, improved manufacturing efficiency, and lower prices. Below are some of the most common types of LED products.

The high efficiency and directional nature of LEDs makes them ideal for many industrial uses. LEDs are increasingly common in street lights, parking garage lighting, walkway and other outdoor area lighting, refrigerated case lighting, modular lighting, and task lighting.

Because LEDs are small and directional, they are ideal for lighting tight spaces such as countertops for cooking and reading recipes. Since there can be variation in light color and directionality, it is important to compare products to find the best fixture for your space.

Recessed downlights are commonly used in residential kitchens, hallways, and bathrooms, and in a number of office and commercial settings. DOE estimates there are more than 600 million recessed downlights installed in U.S. homes and businesses.

With performance improvements and dropping prices, LED lamps can affordably and effectively replace 40, 60, 75, and even 100 Watt incandescent bulbs. It"s important to read the Lighting Facts Label to make sure the product is the right brightness and color for its intended use and location.

LEDs consume far less electricity than incandescent bulbs, and decorative LED light strings such as Christmas tree lights are no different. Not only do LED holiday lights consume less electricity, they also have the following advantages:

LCD displays don’t emit light by themselves. They need a light source, and LED backlights are now dominating the market. In this article, Orient Display’s Bill Cheung provides a complete overview of LED backlight technology, discussing different types, driver technologies, color deviation, brightness options and more.

LCD (liquid crystal display) has long been the dominant technology in the display world. Certainly, there are some emerging competing display technologies—such as OLED (Organic Light Emitting Diode) [1] and micro-LED—that have the potential to threaten LCD’s position in the market. But both are currently only used for niche and high-end markets.

An LCD display can’t emit light by itself. In order to have an LCD display [2] used in a dim environment, a backlight has to be used as the light source. There are a few different technologies that are able to produce backlight ranging from EL (electroluminescent), CCFL (cold cathode fluorescent lamps) and LED (light emitting diode). However, a breakthrough in blue LED technology by Shuji Nakamura [3] led to LED backlights dominating the market.

One of the greatest benefits of LED backlighting is its long lifetime. Normally, LED lifetime can be measured with half-life when the original brightness decreases by 50%. With different LED chip manufacturing materials, technologies and environment used, the LED life can vary from 20,000 hours to well over 100,000 hours.

LED backlights have low power consumption and produce much less heat than other backlight technologies, which extends the durability and performance of the other display components. Furthermore, this reduces the risk of fire and explosion. LED backlights are also driven with DC (direct current) and low voltage (can be as low as 1.5V), which are good for battery drive and emit no interference to the circuitry. With the development of LED technology, the LED chips become small. So, it is possible to produce very thin backlight (0.5mm thick or thinner).

Although white LED is the most popular color, LED backlight can be made into different single colors, bi-colors and tri-colors [4] (Figure 1) (Figure 2). With RGB LED backlight color mixing, normal 8 color LED backlight can be produced (Figure 3).

LED backlight can be classified as bottom (array) lit and side (edge) lit backlights, and each have their plusses and minuses. The advantages of the bottom lit (array) backlight are that it is uniform and bright. Its disadvantage is high current draw, thickness, heat dissipation and cost. Meanwhile, the advantages of the side lit backlight are its thinness, flexibility in design, low current and lower cost. The main disadvantage of the side lit backlight is its non-uniformity—hot spots can be seen from most of the side lit backlight from certain angle. Figure 4 compares the bottom lit and side (edge) lit backlight LCD types.

Now let’s look at LED backlight structures. An LED backlight can be simplified into layers starting with a LED chip, light guide, diffusor and reflector (Figure 5). This is the lowest cost structure. Except for some very low current efficiency LCD displays—such as utility meters, battery-powered clock, watch, GPS and so on—most LCD displays need backlights to be visible in the dim lighting. Most often the backlight is actually at the back of the LCD. In rare cases, this light can be done as front light. The traditional LCD structure with LED backlight shown in Figure 6.

Direct current driving: This is the simple and low-cost way to drive a LED backlight, however, be mindful of the current limit otherwise the LED life can deteriorate quickly. The solution is simply to add a current limiting resistor in the circuit. Current limitation resistors value calculation formula: R = (V0– Vf)/If.Also be mindful of reverse drive, otherwise, the LED chip can break down easily.

LED driver with constant current: The advantage of constant current LED driver is that it will be the best option to use when building your own fixture or working with high powered LED because they avoid violating the maximum current specified for the LEDs, therefore avoiding burnout/thermal runaway. They are easier for designers to control applications, and help create a more consistent bright light.

There are a variety of ways to connect a backlight and LCD module electrically. It can be done with wires that are soldered on the LCD or LCD module. It can be connected using pins, which can be soldered onto the LCD or LCD module. A third way is to use a FPC (flexible printed circuit), which can be soldered or plugged in a ZIF (zero insertion force) connector. And finally, there is the connector method. With this method you use connectors which can be plugged into mating connectors.

As the LED is manufactured via the semiconductor process, there are some color deviations that can be a quality control issue. One way to solve the issue is through a process of selection and sorting after manufacturing the LEDs. The LEDs are sorted into different categories or bins. How this sorting is done and what each bin actually contains is defined differently by each LED manufacturer. The backlight manufacturer can choose from which bin they take the LEDs for backlight color hue.

In actual LED backlight production, most customers will accept the LED color for two big categories: white with yellowish (warm) and white with bluish (cold). Of course, the LED brightness will also need to be defined. For general application, most customers will accept a brightness tolerance of 70 percent.

It is extremely hard to estimate the LED backlight lifetime or MTBF (mean time between failures) because there are so many variable factors. However, the most important is the temperature on the LED chip. The factors that can affect the LED chip temperature include: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink design), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so forth.

To test the LED life is also very time consuming, requiring at least 1,000 hours. That’s the reason why no LED manufacturers can guarantee LED backlight life and most backlight manufacturers also are reluctant to provide lifespan data. As for LCD manufacturers, they need to discuss it with the customer to understand the applications and provide suggestions. It is normal that the LCD datasheet lists the typical life time and avoids providing a minimum lifetime. From Figure 10, we can see that over room temperature, the current needs to decrease as the temperature increases. At over 85°C, the LED is not usable.

To estimate LED backlight lifetime, you can use ballpark estimation or theoretical calculation. Let’s first examine the ballpark method. To take white LED as example, the nominal biasing current is 20mA. If we use a safe lifetime estimation, we can estimate using Table 1.

Now let’s use the theoretical calculation approach. As we previously mentioned, LED life is affected by a lot of factors: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink designed), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so on. LED chip manufacturers are not willing to give absolute values of LED chip lifetimes, but there is a theoretical calculation that we can use.

Finally, let’s look at ways to increase LED backlight brightness. There are many ways to increase LED backlight brightness, but all these measures are balanced with performance and cost. Here are some of the methods:

For the LCD module side, using better aperture opening ratio, anti-reflection coating on surface, optical bonding. This results in higher cost. Actually, this measure is not to increase LED backlight brightness directly but to increase to the visibility to users.

Bill Cheung is an engineering lead and marketing manager at Orient Display, an LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. You can browse Orient Display"s knowledge base [7] to learn more about LCDs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey