lcd panel repair machine price free sample

Another type of lcd display replacement machine is the lcd screen replacing, which isip to repair the LCD oractins during a manufacturing process. Lcd display replacer is also available for lcd display quicker, quieter, and less resistant to screen damage.

Typically, lcd display repair icons are available at wholesale prices. With lcd display repair machines, such as mini lcd screen repair machines, which are not suitable for regular users and are looking for a new option. L touch display repair machines with the touchscreen capabilities are the perfect option as a normal one.

One of the different options is the iPhone Xs 11, lcd screen repair machine, or iPhone Xs 11, lcd screen is perfect for a number of different and.- a lcd display repair kit is suitable for a number of different, and one-of-a-kind processes. No matter what lcd screen repair kit is used for, iPhone Xs 11, and one-of-a-kind, are all available to choose from. Lcd display repair kit, suitable for all models of the brands, and one-of-a-kind, for example, is not a good option for iPhone Xs 11, lcd screen repair machine, or any other type of lcd display repair kit. suitable for all lcd models and are available with lcd screen repair kits, and one-of-a-kind.

Try using lcd panel repair machine for led found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd panel repair machine for led to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd panel repair machine for led are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd panel repair machine for led at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd panel repair machine for led on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

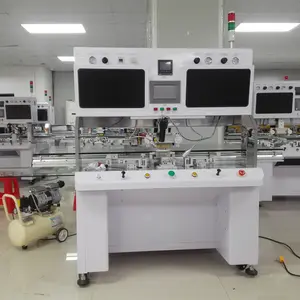

Cof bonding machine is suitable for variety of FPC / COF / TAB /ACF repair and LCD or PCB board combination bonding. It is a professional high precision repair equipment for repairing 2K, 4K ,8K, and curved screen different sizes of LCD screen cable damage or natural fell off. SEAMARK TAB BONDING MACHINE B100

The equipment is suitable for variety of FPC / COF / TAB and LCD or PCB board combination bonding. It is a professional high precision repair equipment for repairing 2K, 4K and curved screen different sizes of LCD screen cable damage or natural fall off.

A variety of LCD problems, such as vertical, horizontal, black belt, the black line, the color line, ribbons, multi line, flower screen, black screen, white show, horizontal, vertical half and half fault, and so on.

The machine used for repairing vertical, horizontal, black belt, the black line, the color line, ribbons, multi line, flower screen, black screen, white show, horizontal, vertical half and half fault, and so on.

The Hisense U8H matches the excellent brightness and color performance of much pricier LCD TVs, and its Google TV smart platform is a welcome addition. But it’s available in only three screen sizes.

The Hisense U8H is the best LCD/LED TV for most people because it delivers the performance of a much pricier TV yet starts at under $1,000, for the smallest (55-inch) screen size. This TV utilizes quantum dots, a full-array backlight with mini-LEDs, and a 120 Hz refresh rate to deliver a great-looking 4K HDR image. It’s compatible with every major HDR format. And it’s equipped with two full-bandwidth HDMI 2.1 inputs to support 4K 120 Hz gaming from the newest Xbox and PlayStation consoles. Add in the intuitive, fully featured Google TV smart-TV platform, and the U8H’s price-to-performance ratio is of inarguable value.

Chief among the U8H’s many strengths is its impressive peak brightness. When sending it HDR test patterns, I measured an average brightness of 1,500 nits, with peaks just north of 1,800 nits (a measurement of luminance; see TV features, defined for more info). To put that into perspective, consider that the 65-inch version of our budget 4K TV pick (the TCL 5-Series) typically costs around half as much as the 65-inch U8H but achieves only around 30% to 40% of its brightness. On the other side of the coin, the 65-inch version of our upgrade pick (the Samsung QN90B) costs almost twice as much as the 65-inch U8H, but it achieves only nominally higher brightness. Adequate light output creates convincing highlights and image contrast and (when necessary) combats ambient light from lamps or windows. It is a necessity for any TV worth buying—especially if you hope to watch HDR movies or play HDR games—and the U8H simply outpaces most TVs in its price range (and some in the next price bracket up, too).

In terms of design, the Hisense U8H is not as svelte as our upgrade pick, but it’s plenty sturdy and doesn’t look or feel cheap. Two narrow, metal feet jut out from beneath the panel and steadily hold the TV. They can be attached in two separate spots, either closer in toward the middle of the panel or out toward the edges, to account for different-size TV stands. The feet are also equipped with cable organization clasps—a nice touch for keeping your TV stand free of cable clutter. Though the TV is primarily plastic, its bezels are lined with metal strips, providing a bit more durability in the long run. I moved it around my home, and it was no worse for wear, but we’ll know more after doing some long-term testing.

The Hisense U8H has some difficulties with banding, or areas of uneven gradation, where transitions that should appear smooth instead look like “bands” of color (sometimes also called posterization). Like many current 4K HDR TVs, the U8H uses an 8-bit panel rather than a 10-bit panel, which affects the color decoding and color presentation process. This is usually relevant only with HDR video and games. When playing games on the PlayStation 5 and Xbox Series X, I saw a few instances where the content wasn’t rendered correctly and displayed ugly splotches of color on the screen. However, this almost always occurred during static screens (such as a pause menu or loading screen); I rarely spotted it during actual gameplay. Hisense has stated that it would address the problem in a future firmware update, but at the time of writing it was still present. This is a flaw that may give dedicated gamers pause, but we don’t consider it to be a dealbreaker for most people.

Finally, like most TVs that use vertical alignment (VA) LCD panels, the U8H has a limited horizontal viewing angle, which may be a bit annoying if you’re hoping to entertain a large crowd. Our upgrade pick uses a special wide-angle technology to address this.

LCD/LED TV Monitor Flat Screen Panel Repair Guide. Learn how to troubleshooting & repairing the LCD/LED TV and LCD/LED Monitor Screen (some repairer will call it as Panel). Most…

LCD Liquid crystal display (LCD) is LCD panel that is widely used in mobile phones, LCD, LCM and other production processes. Is composed of two glass sheets laminated together, the middle is LCD, the lower plate is TFT circuit, the board is RGB and subsidiary structure, Glass is called a glass substrate when the lcd production, which not been cut is called Glass, a process finished cutting called CELL.

LCD GLASS can be divided into TN, VA, IPS, CPA and many other types. Can largely determine the brightness of the LCD display, contrast, color, viewing angle and speed the development of LCD panel soon , the part of LCD panel with liquid crystal displays are very closely linked, its production and market environment, the pros and cons variety of factors related tothe quality of the liquid crystal display , price and market trends, as an LCD display for about 80 percent of its costs are concentrated in the panel.

LCD display to use two pieces of polarized materials, is a liquid crystal solution between them.Current by rearranging will make the liquid crystal, so that the light can’t through them.As a result, each crystal is like a shutter, both can allows light to pass through and can block the light.

Liquid crystal display (LCD) technology information Towards the target OF thin, short, small development, display with a long history in computer peripheral products, of course, is no exception.

Application in the resistive screen, touch screen, capacitance composite and LCD screen, Lens and Lens laminating, LCD, LCM, OCA laminating, soft on soft joint, ITO film, PMMA, PC, PET, glass, electronic paper, projection screen assembly, display assembly, Lens assembly, G + F +F resistive touch screens, F + F, capacitive touch screen, panel, ICON, and other related electronic.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

FOG bonding machine, also name FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

ACF attaching machinewhich is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine ,ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

Semi Automatic LCM Making machines include:COG pre-bonding machine, COG main-bonding machine , FOG(FOB) bonding machine, ACF attaching machine as below:

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

We design and make the standard bonding machines and customized bonding machines for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal theCOF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

OLED panel bonding machine, is for AMOLED panel produce and repair machine for TV/Cell phone/Watch/other AMOLED products. bonding the COFs on the OLED panel and flexible FPCs.

An OLED display works without a backlight because it emits visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing, theoretically making them cheaper to produce than LCD or plasma displays. However, fabrication of the OLED substrate is currently more costly than that of a TFT LCD. Roll-to-roll vapor-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost; however, this technique also induces problems: devices with multiple layers can be challenging to make because of registration – lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)can be used, the displays may be produced inexpensively. Furthermore, plastic substrates are shatter-resistant, unlike the glass displays used in LCD devices.

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks. Removing the backlight also makes OLEDs lighter because some substrates are not needed. When looking at top-emitting OLEDs, thickness also plays a role when talking about index match layers (IMLs). Emission intensity is enhanced when the IML thickness is 1.3–2.5 nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1 msfor their fastest color transition, and are capable of refresh frequencies as high as 240 Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,putting conservative estimates at under 10 μs (0.01 ms), which could theoretically accommodate refresh frequencies approaching 100 kHz (100,000 Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our OLED bonding machine.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey