oled or lcd screen manufacturer

There are plenty of new and confusing terms facing TV shoppers today, but when it comes down to the screen technology itself, there are only two: Nearly every TV sold today is either LCD or OLED.

The biggest between the two is in how they work. With OLED, each pixel provides its own illumination so there"s no separate backlight. With an LCD TV, all of the pixels are illuminated by an LED backlight. That difference leads to all kinds of picture quality effects, some of which favor LCD, but most of which benefit OLED.

LCDs are made by a number of companies across Asia. All current OLED TVs are built by LG Display, though companies like Sony and Vizio buy OLED panels from LG and then use their own electronics and aesthetic design.

So which one is better? Read on for their strengths and weaknesses. In general we"ll be comparing OLED to the best (read: most expensive) LCD has to offer, mainly because there"s no such thing as a cheap OLED TV (yet).

Take this category with a grain of salt. Both TV types are very bright and can look good in even a sunny room, let alone more moderate indoor lighting situations or the dark rooms that make TV images look their best. When it comes down to it, no modern TV could ever be considered "dim."

At the other side of light output is black level, or how dark the TV can get. OLED wins here because of its ability to turn off individual pixels completely. It can produce truly perfect black.

The better LCDs have local dimming, where parts of the screen can dim independently of others. This isn"t quite as good as per-pixel control because the black areas still aren"t absolutely black, but it"s better than nothing. The best LCDs have full-array local dimming, which provides even finer control over the contrast of what"s onscreen -- but even they can suffer from "blooming," where a bright area spoils the black of an adjacent dark area.

Here"s where it comes together. Contrast ratio is the difference between the brightest and the darkest a TV can be. OLED is the winner here because it can get extremely bright, plus it can produce absolute black with no blooming. It has the best contrast ratio of any modern display.

Contrast ratio is the most important aspect of picture quality. A high contrast-ratio display will look more realistic than one with a lower contrast ratio.

One of the main downsides of LCD TVs is a change in picture quality if you sit away from dead center (as in, off to the sides). How much this matters to you certainly depends on your seating arrangement, but also on how much you love your loved ones.

A few LCDs use in-plane switching (IPS) panels, which have better off-axis picture quality than other kinds of LCDs, but don"t look as good as other LCDs straight on (primarily due to a lower contrast ratio).

OLED doesn"t have the off-axis issue LCDs have; its image looks basically the same, even from extreme angles. So if you have a wide seating area, OLED is the better option.

Nearly all current TVs are HDR compatible, but that"s not the entire story. Just because a TV claims HDR compatibility doesn"t mean it can accurately display HDR content. All OLED TVs have the dynamic range to take advantage of HDR, but lower-priced LCDs, especially those without local-dimming backlights, do not. So if you want to see HDR content it all its dynamic, vibrant beauty, go for OLED or an LCD with local dimming.

In our tests comparing the best new OLED and LCD TVs with HDR games and movies, OLED usually looks better. Its superior contrast and lack of blooming win the day despite LCD"s brightness advantage. In other words LCD TVs can get brighter, especially in full-screen bright scenes and HDR highlights, but none of them can control that illumination as precisely as an OLED TV.

OLED"s energy consumption is directly related to screen brightness. The brighter the screen, the more power it draws. It even varies with content. A dark movie will require less power than a hockey game or ski competition.

The energy consumption of LCD varies depending on the backlight setting. The lower the backlight, the lower the power consumption. A basic LED LCD with its backlight set low will draw less power than OLED.

LG has said their OLED TVs have a lifespan of 100,000 hours to half brightness, a figure that"s similar to LED LCDs. Generally speaking, all modern TVs are quite reliable.

Does that mean your new LCD or OLED will last for several decades like your parent"s last CRT (like the one pictured). Probably not, but then, why would you want it to? A 42-inch flat panel cost $14,000 in the late 90"s, and now a 65-inch TV with more than 16x the resolution and a million times better contrast ratio costs $1,400. Which is to say, by the time you"ll want/need to replace it, there will be something even better than what"s available now, for less money.

OLED TVs are available in sizes from 48 to 88 inches, but LCD TVs come in smaller and larger sizes than that -- with many more choices in between -- so LCD wins. At the high end of the size scale, however, the biggest "TVs" don"t use either technology.

If you want something even brighter, and don"t mind spending a literal fortune to get it, Samsung, Sony, and LG all sell direct-view LED displays. In most cases these are

You can get 4K resolution, 50-inch LCDs for around $400 -- or half that on sale. It"s going to be a long time before OLEDs are that price, but they have come down considerably.

LCD dominates the market because it"s cheap to manufacture and delivers good enough picture quality for just about everybody. But according to reviews at CNET and elsewhere, OLED wins for overall picture quality, largely due to the incredible contrast ratio. The price difference isn"t as severe as it used to be, and in the mid- to high-end of the market, there are lots of options.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

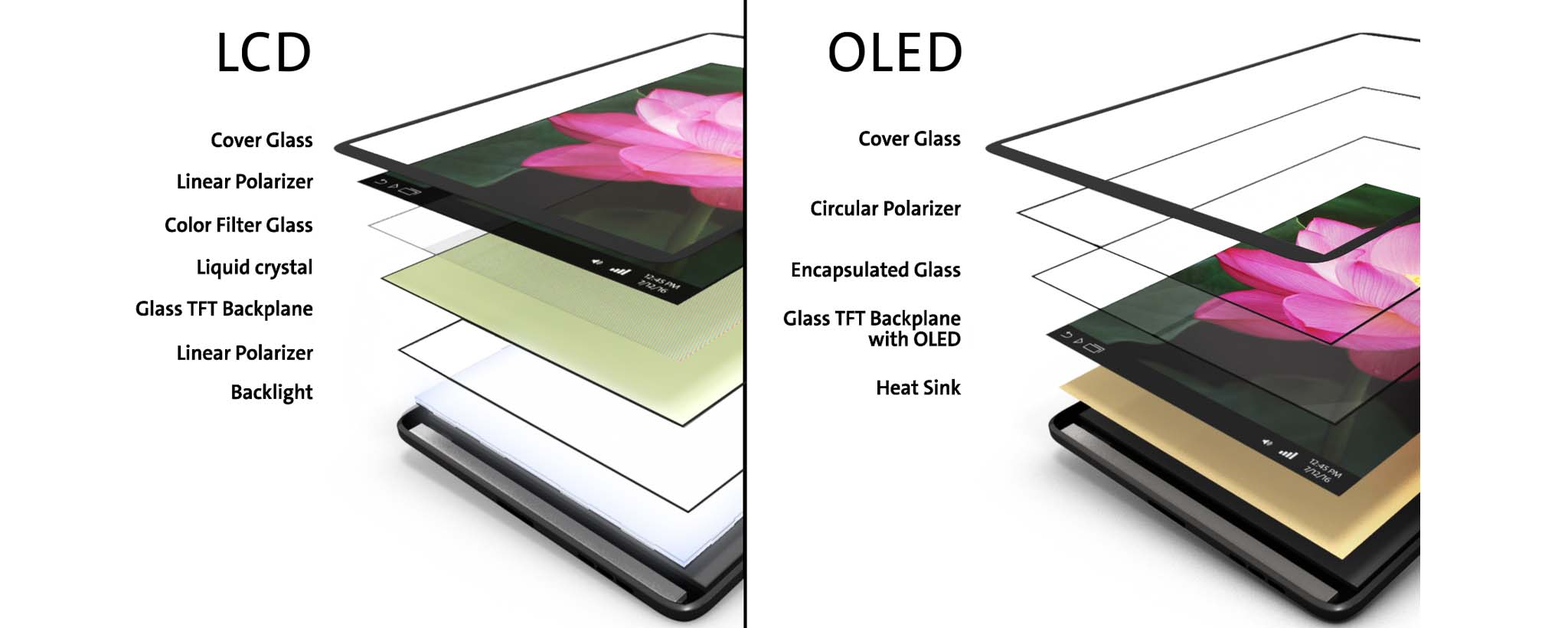

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

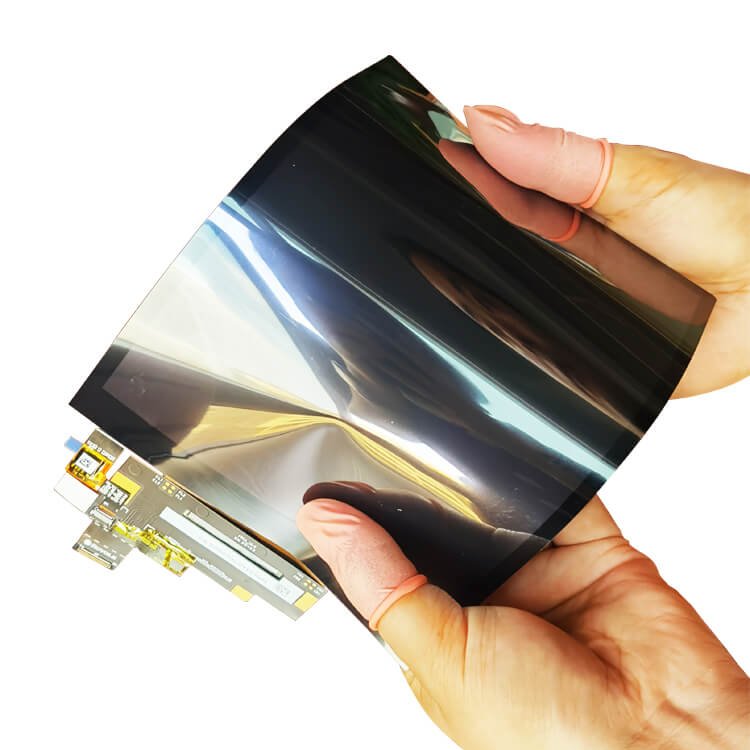

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

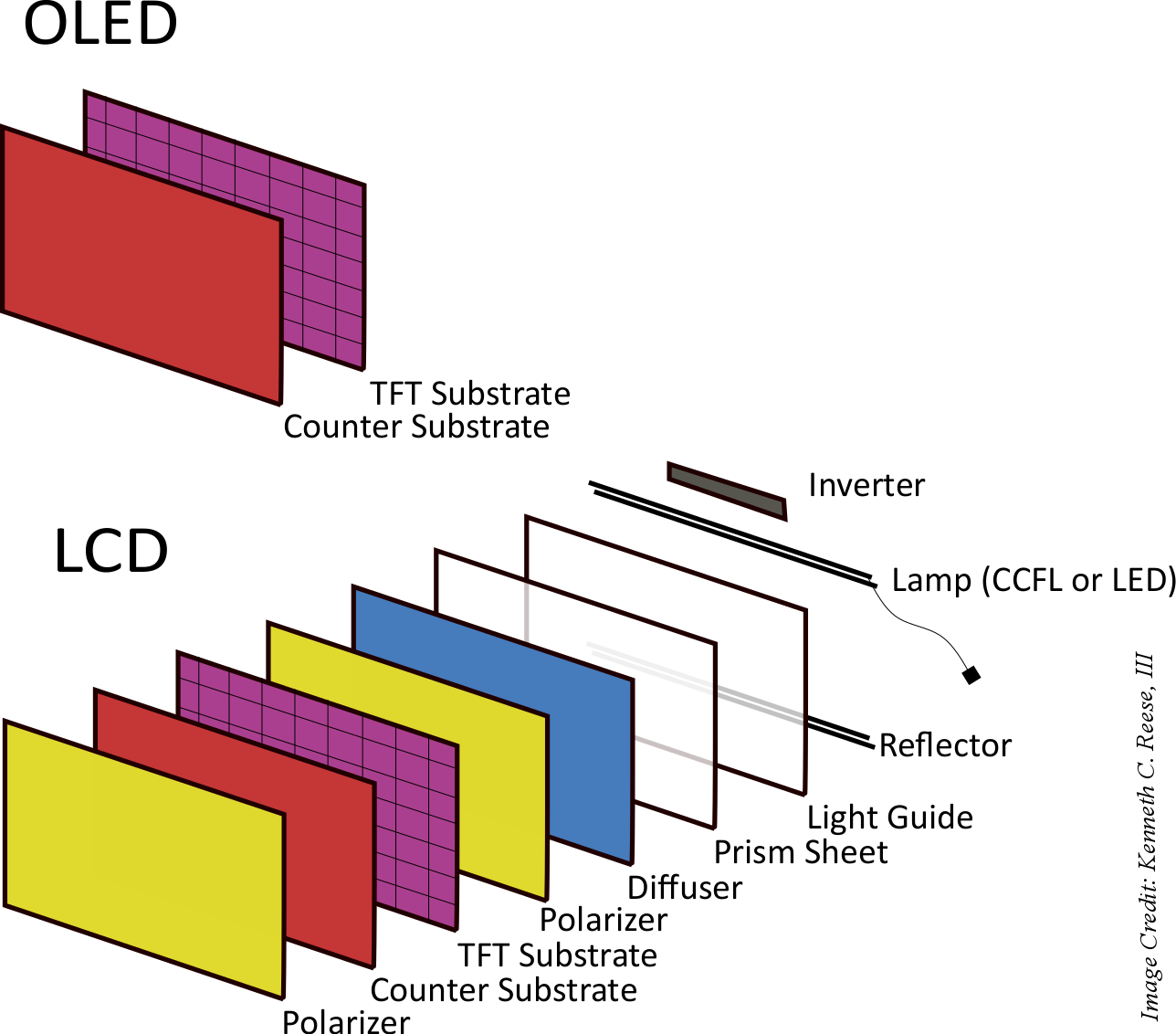

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

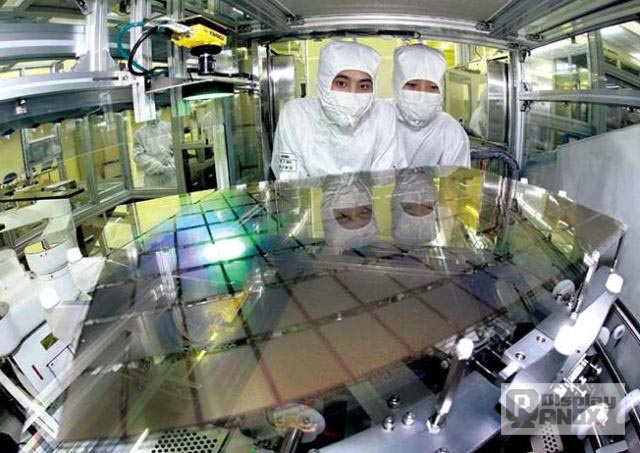

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Truly Semiconductors is a wholly owned subsidiary of the Hong Kong-listed company Truly International Holdings. Founded in 1991, and headquartered in Hong Kong, the company’s production base is located in the beautiful coastal city of Shanwei City in Guangdong Province, China.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

In 2002, it signed an IPS patent authorization contract with Hitachi of Japan and started to plan a 5th-generation plant to make the product line more complete and meet the needs of different customers.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

CSoT started developing OLED technologies back in 2012. In 2013 it was reported that CSOT will invest over $4 billion to build a 8.5-Gen Oxide-TFT LCD+OLED TV fab, but that did not materialize. In 2017 CSoT started to construct a 6-Gen LTPS flexible AMOLED production line in Wuhan, China, in a $5.08 billion investment. CSoT is now producing mobile AMOLED displays at that fab, and is developing high-end technologies, including LTPO, microlens arrays and polarizer-free OLEDs.

Dresden Microdisplay was established in April 2010 as a spin-off from the Fraunhofer Institute with an aim to commercialize the Fraunhofer"s OLED microdisplay technology.

Everdisplay started mass producing AMOLED displays towards the end of 2014 in a 4.5-Gen line with a monthly capacity of 20,000 substrates (EDO was China"s first AMOLED maker). Since then the company added its second production fab, a 6-Gen flexible AMOLED line in Shanghai.

CMO’s OLED subsidiary was called Chi Mei EL Corporation (CMEL) and was producing AMOLED displays until the merger (the company was producing panels up to 7.6” in size). TPO was developing small (3” and 4”) AMOLED displays but had some technical difficulties.

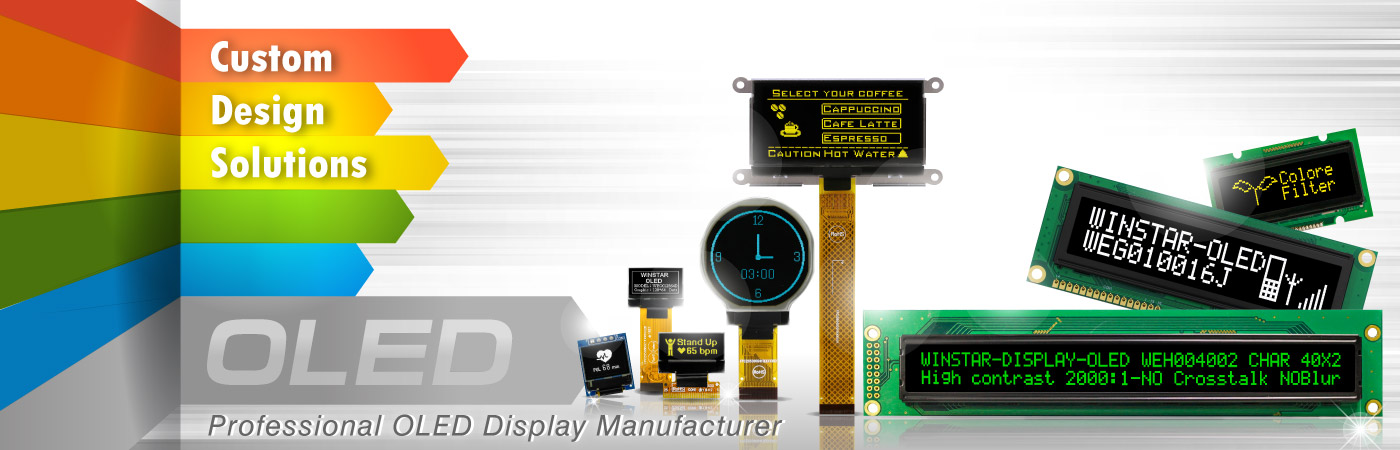

Winstar Display Co., Ltd has factories with 1,500 employees in Taiwan, China and oversea branches. As a professional LCD panel, OLED Panel, LCD module, TFT display and OLED display manufacturer & supplier, we are specializing in Chip-On-Board (COB), Surface Mount Technology (SMT), Chip-On-Glass (COG), Tape-Automated-Bonding (TAB) and OLED display technologies.

Winstar is a full ISO accredited company, and as such our main emphasis is on the quality control of our production lines, rapid RMA management and creative conception. As customer orientated manufacturer, we are always at the forefront of LCD and OLED technology. As well as a range of standard products, Winstar are experts in working with customers in order to realize complete bespoken solutions, and are able to offer assistance from original design concept through to volume production.

By adopting computerized management system, automatic manufacturing process and advanced technology, Winstar can able to continuously supporting our worldwide customers with qualified and reliable products.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

OLED Display modules are self- emitting without backlight so it makes OLED modules slimmer and lower power consumption. With advantages in wider viewing angle up to 175 degree, higher contrast, faster response, OLED display modules are the most advanced technology and optimal option among the monochrome displays products.

Raystar’s OLED teams are with rich experience in management, design, manufacturing, research in developing the new and high quality OLED character and graphic modules. It is ideal display for consumer and industrial applications such as Audio, Automotive control panels, Medical devices, White goods or Home automation products and more. OLED display panel modules will be the next and the best displays to apply for your design.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

Not sure which one will be best for you? Don’t worry! We’re here to help you figure out the right display for your project or application. In this post we’ll break down the pros and cons of these display types so you can decide which one is right for you.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

Contrast refers to the difference between the lightest and darkest parts of an image. High contrast will produce sharper images and more easily readable text. It’s a crucial quality for high fidelity graphics and images or to make sure that a message on a display is very visible.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

Have you ever looked at a screen from an angle and noticed that the images became washed out or shadowy? The further away you get from the “front and center” view, the worse the image appears to be. This is an example of viewing angles in action – the wider the viewing angle, the better the images on screen will appear as you view them from different vantage points.

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

Since 2001 we’ve provided product development, engineering design services, and turn-key solutions for all industries. Work with our engineers to develop the ideal display for your unique application.

For more than 20 years, Newhaven Display International has provided custom display solutions worldwide across various industries including medical, agriculture, industrial, handheld, audio/video, automotive, consumer, appliance, security, casino, military, energy, POS, test & measurement, and telecom.

Our US-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Adjust length, position, and pinout of your cables or add additional connectors. Get a cable solution designed to make your connections streamlined and secure.

Enhance your user experience with capacitive or resistive touchscreen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

Easily modify any connectors on your display to meet your application’s requirements. Soldering for pin headers, boxed headers, right angles headers, and any other connectors which your display may require.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Custom backlight configurations can be made with voltage/input current, brightness or colors/NVIS. Perhaps it is just changing the assembly type from array to side LEDs.

We have complete control over our display products" design, manufacturing, and quality control processes. Our USA based Engineers will work with you on a prototype to validate and test your design.

Cable Customization Touchscreen Add-Ons Interface Customization Connector Customization PCB Modifications Cover Glass Additions Mounting Add-Ons Custom Backlight Keypads

NVD is a custom OLED display supplier to OEMs in the consumer, medical, industrial, and other markets. Our custom OLED displays offer ultra-thin designs (no back light), wide viewing angles, and fast, temperature independent response times. These benefits make OLEDs an excellent solution for fitness trackers, thermostats, medical devices, and many other applications.

Our custom OLED display capabilities include passive and active matrix OLEDs in standard sizes as well as customized designs, including custom FPCs, custom rounded substrate edges, integrated touch sensors and/or cover lenses, plus flexible and/or transparent options. Whatever your requirements specify, we can deliver a solution that suits your needs.

When you choose us to be your PMOLED or AMOLED display supplier, rest assured that we will stand with you throughout the entire project scope. From concept to production, our experienced sales and technical staff are here to help.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

OLED vs. IPS LCD is a topic that comes up whenever consumers upgrade to a newer TV or a smartphone. Should you buy a TV that uses an IPS LCD display or should you pick up a TV with an OLED screen? Well, the answer isn’t so straightforward because they both have their advantages and disadvantages. In this article, we will explain how these screen technologies work and which one you should opt for while buying a TV.

IPS LCD (In-Plane Switching Liquid Crystal Display) and OLED (Organic Light-Emitting Diode) are the two most commonly used screen technologies. Older technologies, such as TN (Twisted Nematic) and PLS (Plane-to-Line Switching) displays, have almost disappeared (except in the world of PC monitors and budget laptops) because IPS LCD and OLED are clearly better in almost all aspects. Other technologies such as Mini-LED, MicroLED, and QNED technologies are extremely new and they won’t become mainstream for a few years.

So, when you are finally deciding which TV to buy, the real battle is between OLED and IPS LCD. So where do these stand? Which is better for you? Which one should you pick for your new home theatre? Read on for more information on the OLED vs IPS LCD battle.

IPS LCD displays are perhaps the most common display type days, especially in TVs and laptops. Laptops, entry-level and mid-range smartphones, and most TVs use LCD displays. So, how do IPS displays work? IPS displays use an array of LCD pixels that shift colour as required. However, they don’t emit light on their own. That’s the reason they need a backlight made up of LEDs (Light-Emitting Diodes). The backlight can be arranged in various layouts: towards the edges, spread across the whole display, or separated into different sections.

IPS screens display the black colour by changing the alignment of LCDs so that pixels block the transmission of light, but some light still gets through. That’s the reason IPS LCD displays can’t display true deep black colour. Instead, they display dark grey and there is some ‘backlight bleed’.

OLED displays have traditionally been restricted to high-end devices. Even today, only high-end TVs and laptops feature OLED displays. In the world of smartphones, though, OLED technology has been democratised and even mid-range smartphones these days use OLED displays with high brightness and high refresh rates.

In a nutshell, OLED displays don’t use separate backlight sources. Instead, every pixel can reproduce its own light (also known as self-emissive displays). So, there’s no need for an additional backlight and each pixel can be turned on or off as needed. Since there is no need for a separate backlight plane, OLED displays are much thinner than LCD displays. They also offer a much better contrast ratio and viewing angles. However, the organic material used in OLED pixels tends to “burn” over the years that results in ghosting. Moreover, they can’t be as bright as LCD, Mini-LED, or Micro-LED displays.

We have given you a brief overview of IPS and OLED technologies. But which one is better? And which of these will be right for you? Here’s a list of pros and cons to help you in your purchase decision, where it is for smartphones or TVs.

OLEDs have a quicker response time: OLEDs individually-lit pixels can switch on/off or change colour faster. This makes for lower ghosting during fast-and-frenetic action scenes or while playing games. Ghosting refers to when the image on the screen seems to be following itself around or is blurry at the edges.

OLED TVs are slimmer and flexible: As we mentioned earlier, OLED displays don’t need a bulky backlight plane, so OLED TVs are really slim. The next wave of display technologies – foldable and rollable displays – will also be powered by OLED.

IPS LCD TVs offer higher brightness: IPS LCD TVs use a powerful backlight which also lets them get much brighter than their OLED counterparts. This can make for better HDR and even offer a better viewing experience if your TV room gets a lot of sunlight.

IPS TVs suffer from backlight bleed and blooming: This is less of an issue with high-end IPS TVs, but some cheaper models may suffer from glow (bright, greyish areas near the corners of the screen) or backlight bleed (patches or leaks of light, usually around the edges).

OLED TVs can suffer burn-in: OLED displays are at risk of burn-in, a condition in which a static image left on for too long can get permanently ‘burned’ onto the display and may appear like a ghostly dark patch.

OLEDs may get dimmer with age: OLEDs use organic substances which tend to decay over time. So, OLED displays lose brightness with age. It is quite slow and modern OLED TVs are not as affected by this as older OLED TVs, and this really shouldn’t be an issue, but you need to be aware of this.

IPS TVs are much cheaper: OLED is a relatively newer technology and is more expensive to manufacture. Currently, very few companies make OLED display panels. LG Display makes most of the OLED panels found on OLED TVs, while Samsung Display, CSOT, LG Display, and BOE make OLED screens for smartphones and smaller products. Most manufacturers also tend to restrict OLED tech to their largest, most feature-packed range, fueling the perception of OLED being expensive.

Periodic visitors to the TV section of large electronics stores are usually impressed by how display technology constantly improves. At each new visit, the screens are larger, thinner, brighter, and often cheaper than they were during the previous trip to the shop a year or two earlier.

Long researched in labs worldwide, OLED displays are becoming a market reality, especially in mobile phones. OLEDs offer the potential for vast improvements in image quality and also open up new possibilities for device design—such as TVs that can be rolled up. But for the time being, several challenges must be overcome for OLEDs to become mainstream in TVs. In particular, manufacturing costs need to come down and durability has to improve. As the following pages show, chemistry will play a key role in enabling the growth of the OLED display market.

Visitors to a store today will see that more than two-thirds of TV screens on the market are now larger than 40 inches. They’ll notice that Samsung and a few other firms are pushing a technology called quantum dots that seems to enhance colors and brightness. At some point, a TV model promoted by LG might attract attention, but perhaps more for its higher price than the performance improvement it offers. Alone among its competitors, LG manufactures a line of TVs making use of organic light-emitting diode technology.

Long the focus of research at academic and corporate labs worldwide, OLED displays are starting to trickle into the market. Although they currently represent only a small slice of the total pie and are so far mostly used in mobile phones, OLEDs are poised to rapidly gain market share in the coming years.

This growth will open up billions of dollars of market opportunity for chemical companies that supply materials to the electronics industry. But at the same time, such firms are keen to hold on to the business they have with makers of displays based on incumbent liquid-crystal display, or LCD, technology.

“The OLED display industry is at tipping point,” says David K. Flattery, business development manager for OLEDs at DuPont. “LG is the only producer of OLED TVs currently, but several others are building pilot plants, and we expect a few to proceed with commercialization.”

Like DuPont, market research firms expect the market for OLED displays—in both TVs and smaller devices such as smartphones—to grow significantly. IDTechEx, for example, forecasts that global sales of OLED displays will increase from $16 billion this year to $42 billion in 2020. Samsung, which uses OLEDs in its Galaxy smartphones, is currently the top manufacturer of OLED displays. But others, such as LG, are entering the market, lured by what OLED technology makes possible.

“OLED displays can be lighter, they can be flexible, and they allow designers more leeway with the shape of their devices,” says Guillaume Chansin, senior technology analyst at IDTechEx. Theoretically, he adds, OLEDs can be far more energy-efficient than the LCDs found in most TVs today. And because they are now manufactured on a plastic substrate instead of a glass one, “OLED displays can make phone screens shatterproof, or even foldable.”

The promise of OLEDs has generated much interest among researchers for decades. In an LCD, images are generated by a backlight—a light-emitting diode nowadays—that sends light through liquid crystals, polarizers, color filters, and several image-enhancing filters. The color black in an LCD is created not by turning off the backlight but by electro-orienting the liquid crystals to affect the angle at which the passing light hits the polarizers.

OLED displays are much simpler and thus can be far thinner than LCDs. Instead of a backlight, OLEDs feature pixels that individually emit the red, green, and blue lights required to form an image. OLEDs consist of organic molecules positioned between two electrodes. As current flows from the cathode to the anode, electrons and electron holes in the molecules combine, emitting flashes of light.

An OLED can be manufactured using a variety of substrates, including glass, plastic, and metal. It consists of several layers of organic materials sandwiched between two electrodes. When a voltage is applied across the OLED, a current of electrons flows from the cathode to the anode, adding electrons to the emissive layer and taking them away—or creating electron holes—at the anode. At the boundary between these layers, electrons find holes, fall in, and give up a photon of light. The color of the light depends on the type of organic molecule in the emissive layer. The most advanced OLEDs use electron and hole injection and transport layers to modulate electron movement.

An OLED can be manufactured using a variety of substrates, including glass, plastic, and metal. It consists of several layers of organic materials sandwiched between two electrodes. When a voltage is applied across the OLED, a current of electrons flows from the cathode to the anode, adding electrons to the emissive layer and taking them away—or creating electron holes—at the anode. At the boundary between these layers, electrons find holes, fall in, and give up a photon of light. The color of the light depends on the type of organic molecule in the emissive layer. The most advanced OLEDs use electron and hole injection and transport layers to modulate electron movement.

In an OLED display, black is created by leaving the corresponding pixels off rather than by blocking a backlight. OLED advocates claim that the resulting “true black” is one reason OLEDs can display sharper images. And energy is saved, because the parts of an OLED display that are dark don’t consume electricity.

Although the basic concept behind OLEDs is elegant and simple, turning it into practice has been another matter entirely. The color blue is a perennial headache because the molecules that create it don’t last as long as their red and green counterparts. The bonds in the blue molecules tend to break down, partly because they are fluorescent rather than phosphorescent and require more electricity to operate. In addition, the charge carriers in blue OLEDs recombine through the absorption of ultraviolet light. Moreover, from a performance point of view, the energy efficiency of blue OLEDs is also lower than for other colors.

When it comes to blue, says a spokesperson for the Japanese OLED materials supplier Idemitsu, display manufacturers can only convert about 40% of the electricity used into visible color. For red and green, the efficiency is already at 100%, she adds.

And OLED displays are prone to image retention, says Tadashi Uno, a senior analyst at the market research firm IHS Technology. This occurs when a display keeps showing the ghost of a previous image. Unless that problem is completely resolved, OLED will not gain widespread adoption among manufacturers of TVs and laptop computers. Currently, a temporary solution for owners of mobile phones with OLED displays is to download an app that reduces image retention.

The cost of making OLED displays is another issue. The core compounds at the heart of OLED displays are often made with expensive substances such as iridium, a rare metal that sells for nearly $19 per gram.

What’s more, the standard technique for depositing organic materials on an OLED substrate is a vacuum evaporation process in which a mask is laid over a substrate, molecules are deposited, the mask is taken off, and the mask is cleaned in a vacuum chamber. Industry insiders estimate that the process “wastes” between 70 and 90% of the expensive materials coated on the mask.

Despite these challenges, the number of OLED displays hitting the market is steadily rising, with some occasional setbacks. In 2013, both Samsung and LG launched OLED TVs, but Samsung quickly withdrew from the market because of prohibitive production costs.

However, with its launch of the Galaxy S4 smartphone that same year, Samsung put OLEDs in the hands of millions of customers worldwide. Last year, LG launched a new series of TVs with a higher resolution than its 2013 model. So far, LG’s TVs do not implement a full OLED design but rather use OLED technology as a

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey