oled or lcd screen supplier

FFALCON innovation released the new generation of consumer XR glasses FFALCON Air 1S. uses BirdBath+MicroOLED technology to create a 130-inch high-definition screen experience for users.

The OnePlus Nord Watch features a 1.78 inch AMOLED rectangular screen with a 368x448 resolution and a 60Hz refresh rate. The watch has no built-in GPS, so it can only receive its location from a smartphone via Bluetooth 5.2.

Now LCD is the most common VR device screen on the market, and a few VR products use OLED screens and Mirco-OLED screens. Micro OLED is unfamiliar for VR players. Arpara 5K PC VR, the world"s first VR device, is using the micro-OLED display.

This enhanced IPS LCD Screen is 2.9 inch 480*720, Panox Display`s convertor board on FPC make higher resolution compatible with GBA circuit board. This makes 3*3 pixels display one pixel as the original display.

Leica has released a new thermal camera for modern hunting, it has extreme precision and maximum repeatability, superior image quality, and an extra-large field of view. Which use using a 0.39 inch 1024x768 pixels Micro OLED with a 50 Hz refresh rate.

HUD stands for Head Up Display, it help driver focus on driving, and read driving information at a glance with the digital umbers. These HUD are using a round shape 1.39 inch AMOLED.

As the new energy vehicle market continues to develop in ways that exceed initial expectations, the automotive industry continues to promote the trend towards "electrification, intelligence, Internet connection" and other technological innovations that, when combined, are driving the continuous demand for on-board displays.

According to India"s latest report, Samsung"s Image Display Division purchased about 48 million panels in 2021 and shipped 42 million units. In 2022, meanwhile, it plans to purchase 56 million panels and ship 48 million units in 2022. The panels it purchases will be made up of 53 million OPEN Cell LCD TVs, 1 million QD OLED panels, and 2 million WOLED TV panels.

With the explosive growth of new energy vehicles and vehicle intelligence in 2021, in-vehicle display technology has also undergone a period of rapid development. First, end-users and OEMs have begun to pursue multi-screen, high-resolution, and large-size displays. And, secondly, major panel manufacturers have actively adopted diversification strategies based on their own particular strengths and adjusted their own layouts accordingly.

AM-OLED shows the current is still in the technology leading period, folding, screen camera, narrow frame, high refresh rate, low power consumption, ultra-thin display technology popular with the market, terminal application penetration accelerated, and gradually from smartphones, smart wear small main penetration areas to the car, laptop size expansion, industry in rapid expansion period, no previous display industry facing cyclical fluctuations, the overall industry pattern initially formed.

Yanshun Chen, BOE’s chairman, recently revealed at the performance exchange meeting that BOE"s flexible AMOLED product shipments totaled nearly 60 million pieces in 2021. According to consulting agency data, the company enjoys a global market share of 17%, meaning it ranks second in the world. The company’s goal in 2022 is to ship more than 100 million pieces, a figure which constitutes full production capacity. Production capacity will then be boosted further in 2023, when the company’s Chongqing"s flexible OLED production line starts mass production.

Silicon-based OLED is characteristically small in size, lightweight, high resolution, high contrast, all while delivering stable performance with low power consumption. It is the most suitable microdisplay technology for near-eye display devices. As such, silicon-based OLED displays are most commonly used in AR/VR smart wearable products.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Truly Semiconductors is a wholly owned subsidiary of the Hong Kong-listed company Truly International Holdings. Founded in 1991, and headquartered in Hong Kong, the company’s production base is located in the beautiful coastal city of Shanwei City in Guangdong Province, China.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

In 2002, it signed an IPS patent authorization contract with Hitachi of Japan and started to plan a 5th-generation plant to make the product line more complete and meet the needs of different customers.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

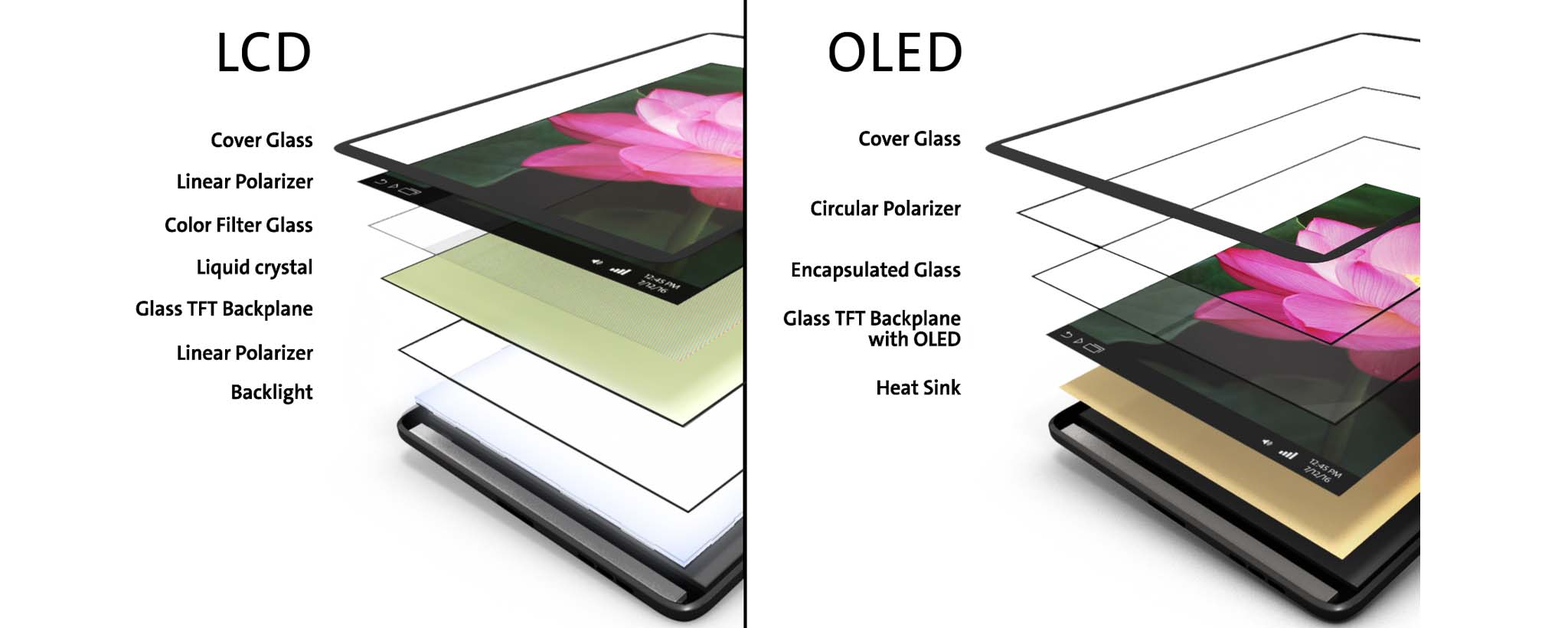

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

About products and suppliers:An OLED display is made from highly sophisticated technology. It is widely used across many industries and in many electronic and tech gadgets such as smartphones, TVs, laptops, car windows and more. A few key aspects that shoppers look for in an OLED display are the viewing angles, color range, image quality and the higher refresh rates. Buyers can find the right screen for their needs and specifications at Alibaba.com.

The flexible OLED screen ensures an enhanced viewing experience, as it provides high-quality images with better contrast. It also provide a much wider and varied color range. This presents all the many colors and shades with great attention to detail. OLED displays are also very flexible and agile, which goes a long way in providing the viewers with a fuller viewing angle.

These flexible OLED display screens are compatible and incorporated in a wide variety of electronic and technological gadgets. They can be used as curved, rolled and even foldable screens. Thus, OLED screens are quite flexible and available in many shapes and sizes that can be used in a smartphone, neon boards, windshields of cars, computer and TV screens and much more.

Alibaba.com features an exciting range of high-quality OLED displays of varied thicknesses, shapes and sizes. This provides the users with a fulfilling experience by providing high-quality images, wider viewing angles and improved color ranges. Individuals can explore a world of new possibilities with the OLED display options available at Alibaba.com. Many vendors offer wholesale discounting options on high-volume orders as well.

NVD is a custom OLED display supplier to OEMs in the consumer, medical, industrial, and other markets. Our custom OLED displays offer ultra-thin designs (no back light), wide viewing angles, and fast, temperature independent response times. These benefits make OLEDs an excellent solution for fitness trackers, thermostats, medical devices, and many other applications.

Our custom OLED display capabilities include passive and active matrix OLEDs in standard sizes as well as customized designs, including custom FPCs, custom rounded substrate edges, integrated touch sensors and/or cover lenses, plus flexible and/or transparent options. Whatever your requirements specify, we can deliver a solution that suits your needs.

When you choose us to be your PMOLED or AMOLED display supplier, rest assured that we will stand with you throughout the entire project scope. From concept to production, our experienced sales and technical staff are here to help.

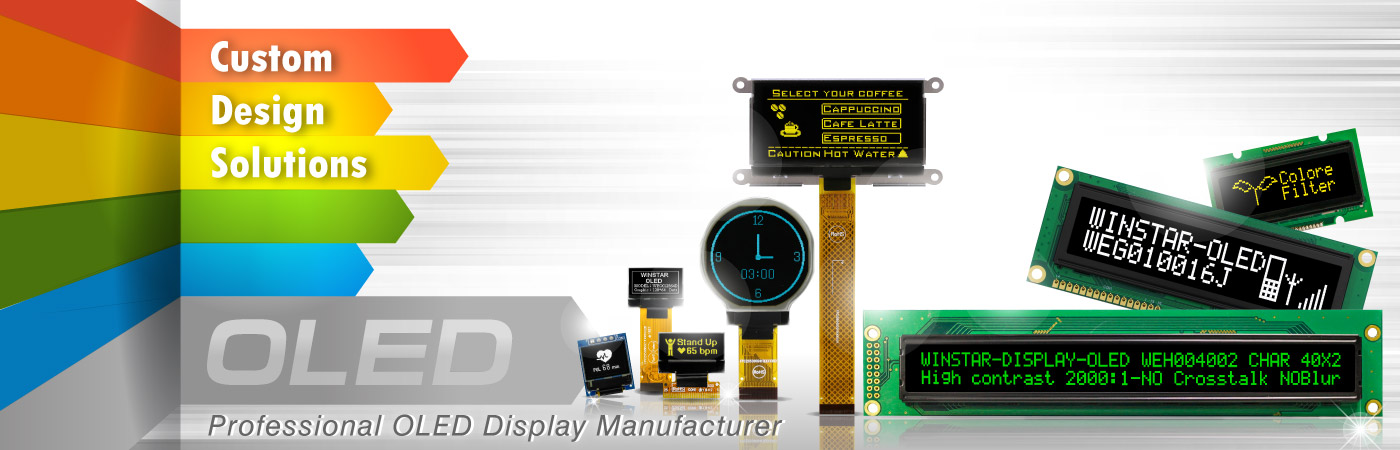

Winstar Display Co., Ltd has factories with 1,500 employees in Taiwan, China and oversea branches. As a professional LCD panel, OLED Panel, LCD module, TFT display and OLED display manufacturer & supplier, we are specializing in Chip-On-Board (COB), Surface Mount Technology (SMT), Chip-On-Glass (COG), Tape-Automated-Bonding (TAB) and OLED display technologies.

Winstar is a full ISO accredited company, and as such our main emphasis is on the quality control of our production lines, rapid RMA management and creative conception. As customer orientated manufacturer, we are always at the forefront of LCD and OLED technology. As well as a range of standard products, Winstar are experts in working with customers in order to realize complete bespoken solutions, and are able to offer assistance from original design concept through to volume production.

By adopting computerized management system, automatic manufacturing process and advanced technology, Winstar can able to continuously supporting our worldwide customers with qualified and reliable products.

OLED stands forOrganicLightEmittingDiode. OLED displays are self-illuminating and its pixels are made up of organic compounds which eliminate the need for additional backlighting components. Because we are able to exclude unnecessary components, you are able to deliver a display that provides your customers with a thin, modern looking display, that provides the flexibility to create diverse and adaptable displays. OLED displays provide viewers with an immersive viewing experience with the highest contrast, most vivid and real colors.

Depending on what you need, OLED could be much more preferable of a display as opposed to LCD displays. In order to better understand OLED technology, let us give some insight on its alternative: LCD. Within an LCD display lies the source of light emitting onto the screen. This is called a backlight. This can result in even pitch black colors giving off a more brightened appearance. OLED does not use a backlight to illuminate its images. Instead, OLED utilizes the organic compounds within its pixels to produce light all on their own, eliminating luminescence on dark areas of images. The final result leaves the viewer with an eye-popping and breathtaking impression of colors.

OLED is certainly the more dramatic of typical display technology, and its future is certainly bright (pun intended). The use of organic compounds to produce light means this technology has the potential to reengineer how displays are made or observed. One of the most exciting developments in recent years is that this technology is starting to be used to create completely transparent displays; A screen that resembles nothing more than a clear glass window can emit moving pictures from what looks like out of thin air!

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

How do we do it? Our agile workforce – from engineers and developers to supply chain experts – work together to respond quickly to a dynamically changing market, customizing solutions to fit each customer’s unique requirements.

Since 2001 we’ve provided product development, engineering design services, and turn-key solutions for all industries. Work with our engineers to develop the ideal display for your unique application.

For more than 20 years, Newhaven Display International has provided custom display solutions worldwide across various industries including medical, agriculture, industrial, handheld, audio/video, automotive, consumer, appliance, security, casino, military, energy, POS, test & measurement, and telecom.

Our US-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Adjust length, position, and pinout of your cables or add additional connectors. Get a cable solution designed to make your connections streamlined and secure.

Enhance your user experience with capacitive or resistive touchscreen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

Easily modify any connectors on your display to meet your application’s requirements. Soldering for pin headers, boxed headers, right angles headers, and any other connectors which your display may require.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Custom backlight configurations can be made with voltage/input current, brightness or colors/NVIS. Perhaps it is just changing the assembly type from array to side LEDs.

We have complete control over our display products" design, manufacturing, and quality control processes. Our USA based Engineers will work with you on a prototype to validate and test your design.

Cable Customization Touchscreen Add-Ons Interface Customization Connector Customization PCB Modifications Cover Glass Additions Mounting Add-Ons Custom Backlight Keypads

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Crystalfontz America is the leading supplier of LCD, TFT, OLED and ePaper display modules and accessories. We specialize in providing our customers the very best in display products, cables and connectors.

In addition to our large catalog of displays, we offer LCD development kits, breakout boards, cables, ZIF connectors and all of the LCD software and drivers you need to develop your product or project. We are located in the U.S. so we can get product to you fast!

OLED Display modules are self- emitting without backlight so it makes OLED modules slimmer and lower power consumption. With advantages in wider viewing angle up to 175 degree, higher contrast, faster response, OLED display modules are the most advanced technology and optimal option among the monochrome displays products.

Raystar’s OLED teams are with rich experience in management, design, manufacturing, research in developing the new and high quality OLED character and graphic modules. It is ideal display for consumer and industrial applications such as Audio, Automotive control panels, Medical devices, White goods or Home automation products and more. OLED display panel modules will be the next and the best displays to apply for your design.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey