plastic lcd screen manufacturer

At iTech Company, we combine engineering and manufacturing experience to deliver the highest quality of industrial monitor displays. Our LCD Plastic Case Monitors features an optional touch screen functionality for interactive usage. For some outdoor applications, it may require a much higher brightness level. Our products offer from 200nits to 1000nits, which ensure readability even when used in direct sunlight. Its spill proof and anti-dust protection will give a longer product life time.Best suited for space limited retail and hospitality settings, these products deliver high resolution and clear images. Check out the specifications of each of our products for more info.

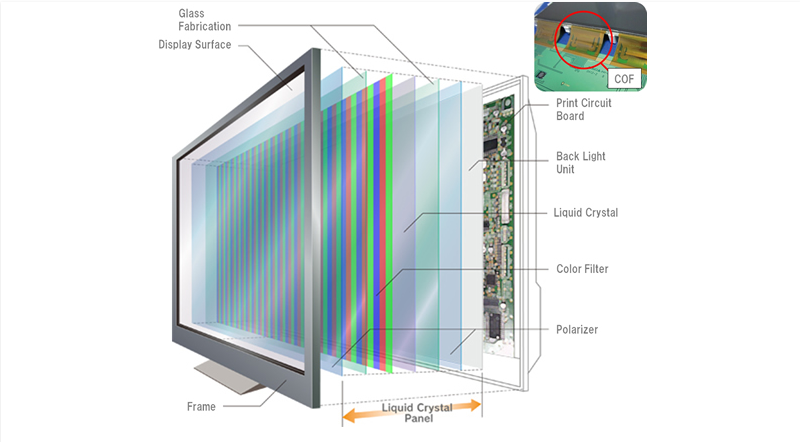

FPD (Flat Panel Display), LCD (Liquid Crystal Display), and TFT (Thin Film Transistor Display) - Flat panel displays are electronic viewing technologies used to enable people to see content in a range of entertainment, consumer electronics, personal computer, and mobile devices, and many types of medical, transportation and industrial equipment. A liquid-crystal display (LCD) is a flat-panel display or other electronic visual display that uses the light-modulating properties of liquid crystals. Liquid crystals do not emit light directly. LCDs are used in a wide range of applications including computer monitors, televisions, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. TFT LCDs are used in appliances including television sets, computer monitors, mobile phones, handheld video game systems, personal digital assistants, navigation systems and projectors. TFT LCDs are also used in car instrument clusters because they allow the driver to customize the cluster, as well as being able to provide an analogue-like display with digital elements. The production of these panels utilize a variety of materials for testing, and handling including LCD Lift Pins made from Celazole® PBI, and Vespel® PI.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Plastic Logic’s LECTUM displays are the most flexible, glass-free, active-matrix ePaper displays you can buy. They offer huge advantages over conventional, glass-based EPDs – they’re extremely robust, very flexible, and are available in a wide range of sizes, in both low and high volumes.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Most of EM"s Plastic LCD products are customer specific designs. EM is used to accommodate to the particular requests and to engineer solutions, which optimally fit the customer"s requirements.

The application possibilities are nearly endless with how Envision Plastics" No Molds Required fabrication technology can be used to manufacture custom plastic bezels, displays, and monitor housings. Examples of such fabricated plastic parts using the NMR Technology include:

With the NMR plastic fabrication technology we can add additional aesthetics by incorporating one direction cold formed radii on our custom fabricated parts. In addition to that cosmetic design feature, digital printing can also be added to showcase branding or text to enhance product usability.

Today’s vivid, immersive displays rely on layers of Corning glass to provide a stunning viewing experience. Wherever you look for news and entertainment, chances are Corning glass is there, too. We are the science and engineering powerhouse behind revolutionary display inventions, including glass cathode-ray bulbs for the first televisions and the LCD glass that made smartphones and laptop computers commonplace. We set the standard for the industry with Corning® EAGLE XG® Slim Glass substrates, manufacturing over 25 billion square feet — enough to pave the Great Wall of China 25 times, or cover nearly 390,000 football fields — while eliminating the equivalent of 6,000 truckloads of heavy metals from entering the environment. Today, we continue to enable the display industry and emerging technologies with our three-glass portfolio.

New design freedoms are taking shape with Corning LotusTMNXT Glass. Thanks to Corning Lotus NXT Glass, devices with OLED displays that curve, flex, or extend edge-to-edge across a device are all within reach. Flexible OLED devices use a plastic backplane substrate, which calls for Corning’s high-tech display glass to enable the manufacturing process —to date, it"s enabled more than 2 billion OLED devices. Corning Lotus NXT Glass continues to emerge as the leader most-advantaged glass for rigid and flexible OLED panels – outperforming competitors and enabling the designs and performance that consumers love.

Looking beyond incumbent LCD and OLED display technology, Corning"s display portfolio is finding new opportunities in emerging technology applications, including Quantum Dot, Micro LED and Mini LED. With our proven track record of successfully navigating the display technology roadmap, our proprietary fusion manufacturing platform and reliable supply network, our commitment to our customers and innovation, and our innovative portfolio, we are excited to support the next generation of displays.

Replace your faded or vandalized LCD Protector for a new clean look. Fits 7 inch LCD panel only. Please note that first generation G1900"s came with a 7 inch wide screen. Please verify screen size before ordering for your G1900.

LG Display has come up with another argument in favour of OLED televisions, saying that technology is more environmentally friendly than LCD because it uses a lot less plastic.

The company said in a disclosure this week that a 65-inch OLED TV uses just 0.43 kilograms of plastic, compared to the average of 5.2 kg of plastic that goes into the production of a similarly-sized LCD TV.

As a consequence, LG Display said it consumes far less plastic than other TV display makers do. During the first quarter the company said it shipped 15,000 OLED display panels in total. That means it used 71,550 tons less plastic than it would have used had it made LCD displays instead.

The reduction of plastic consumption is a major goal for any corporation that’s looking to reduce its carbon footprint. Less plastic consumption means that fewer harmful substances are emitted to the atmosphere. LG Display said that an analysis of its manufacturing operations and their environmental impact found that OLED TV panel production produces around 50% fewer emissions of volatile organic compounds than the production of LCD displays.

Because OLED panels emit fewer harmful substances, they’re also easier to recycle than LCD panels, LG said. The company found that the product recycling rate for OLED TV panels achieved a 92.2% score on its Eco Index, compared to just 72% for LCD TV panels. This is partly because LG Display uses recyclable iron in its panel parts wherever possible, it said.

Switzerland-based inspection, verification and testing authority SGS has also recognised LG Display for its eco-friendliness. Last year it noted that LG’s OLED manufacturing process reduces emissions of total volatile organic compounds by more than 50% compared to LCD. It also heralded the company’s “excellent resource efficiency and recycling rates”.

The eco-friendly nature of OLED is another strong argument in favor of LG’s display technology. The company has already won over hordes of enthusiasts that say OLED is superior to LCD in terms of colour, contrast and picture accuracy, and this year it introduced the new LG G1 OLED Evo TV with a brighter panel that brings it closer to matching the brightness of LCD TVs.

Further, LG recently highlighted some of the unique form factors OLED enables. The company has also cited OLED’s much lower blue light level, which makes it less harmful to human eyes when looking at a screen for long periods of time.

It"s a resistant layer and material that can"t be easily damping. and it is easy to clean and maintain. lcd protective film is durable and easy to clean.

The LCD protective film, screen printing, is one of the most common types of protective film. It is easy to use, and has the durability and longevity to protect film from furniture, and other delicacies such as those that require a protective layer or coating of the two. Lcd is easy to cut, protect film from furniture, and at the same time with little or no longevity. protect film with furniture, it can also be used for protective purposes or lightally.

With a variety of products available on Alibaba.com, you can find what you are looking for. LCD display film, lcd protective film, laminated LCD protective film, and the like-eded LCD protective film are available in bulk and at wholesale prices.

Remember when your LCD or OLED display had that brand-new, fresh-out-of-the-box shine, feel and look? You are in the right place if your display is now due for deep cleaning.

Only use a microfiber cloth and don"t use chemicals to clean a resistive touchscreen.Disconnect the display from the power supply and remove any screen protectors or liners.

Cleaning soldering residue on LCD with Isopropyl alcohol and a Q-Tip.Cleaning residue around soldering elements is not necessary if Newhaven Display performed the soldering.

Cleaning your electronic display is a simple task. However, it is essential to consider these steps to handle and clean it properly. You should now have a better understanding of what cleaning products are safe to use, how to clean the display screen glass, how to clean touchscreens and how to clean soldering residue.

Samsung Electronics has created a flexible LCD screen that measures 7 inches diagonally, another technology that may one day be used in products such as e-books.

The display is functionally similar to the LCD (liquid crystal display) panels used inside TVs and notebooks, but with a crucial difference. Instead of containing glass substrates, the screen features a substrate of flexible plastic, allowing the display to bend. The plastic will not break when flexed, according to Samsung, and its pliancy paves the way for flexible color screens.

Several different technologies are vying to become a standard for the flexible and low-energy screens that will be found in a range of consumer devices. Philips and

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey