lcd screen yellowing factory

The above-mentioned optical properties are of course the basic requirements of LOCA adhesives. The next challenge is to be certain that these optical qualities will be retained and consistent over time under real-world operating conditions. It is in this regard that b* number becomes a useful tool. The b* number is especially important in its consistency over time as yellowing of screens is considered highly undesirable and indicative of aging or failure in the eyes of consumers.

Many environmental conditions have been shown in the past to lead to a yellowing of LOCA materials over time and a corresponding deterioration in image quality. By measuring the CIELAB coordinates of a given device after initial manufacture, it is then possible to expose the device to harsh conditions and measure any changes in CIELAB numbers.

Each of these tests and all of them combined is designed to simulate years of real-world aging in environments such as in automobiles and appliances. By showing consistency over time under these conditions of the b* value, manufacturers can be confident of resistance to yellowing for LCD displays. In addition, customized testing is not uncommon in cases where a product may be exposed to unique or especially harsh conditions.

Chase Corporation, Westwood, Ma., founded in 1946, is a leading manufacturer of industrial products for high-reliability applications with a global customer base operating in diverse market sectors. Our HumiSeal® group specializes in the manufacture of polymers for the protection of PCBs. In addition, the HumiSeal group produces the Vivid Cure line of LOCA adhesives for LCD display manufacture. Our outstanding manufacturing and technical support groups can provide your organization with a reliable global supply, unmatched quality, and superior technical support.

So I recently bought an iPhone SE last week and when I got it, I noticed this yellow tint on top of the screen. It can be clearly seen when viewing calendar, messages or others apps that displays white images... I literally don"t know what"s happening with my phone.. When I got it checked on the nearest Apple Store, they said its just normal because their iPhone SEs there also have this yellow tint.. Then when I researched in the Internet, it says that it"s due to the glue residue thing on the screen.. It will disappear in a few weeks.. Other people says it"s a hoax and other people says its true.. I had this phone for already a week and a half and it"s still there.. Do you guys also have this issue? And does it really fades away in a few weeks? I do get really distracted on the yellow tint on top.. Thanks Guys .. By the way.. It turns two weeks tomorrow..

The floating "Dell™ - Self-Test Feature Check" dialog box should appear on-screen (against a black background) if the monitor cannot sense a video signal and is working correctly. While in self-test mode, the power LED remains green. Also, depending upon the selected input, one of the dialogs shown below will continuously scroll through the screen.

Today I received my 3rd iPhone 6 with yellow screen. When I received my 1st device I was sure that my screen is kinda yellow so I went to some local store to compare. All store"s devices were "whiter" (more blueish), crisper, more contrasty -just better. As said before, today I received 3rd phone with the same yelowish screen and I think I will sent it back with cash refund this time as I just don"t want to have worse phone that I saw in a store. It"s not acceptable. Moreover I had more or less similar issue with Macbook Pro delivered last week (half screen was yellow). Now I am waiting for the 2nd unit. Yellow screens for such money?

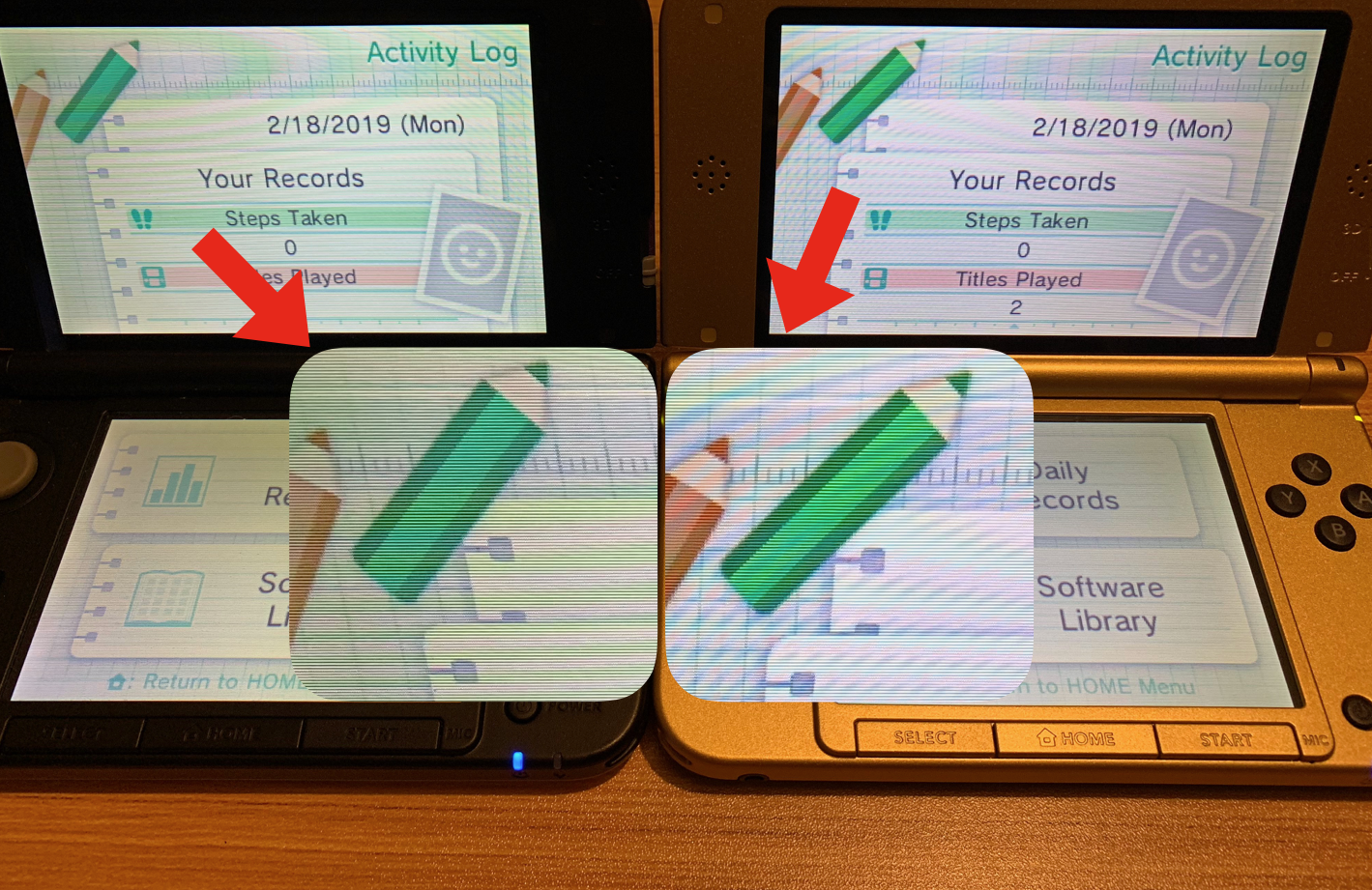

What your picture shows is two screens with different white points; the system on the left has a cooler white point (bluer white) that the system on the right (warmer white point, so yellower white). Neither is wrong - they are just different.

You can calibrate the screens. The best way to do this is to use a hardware colorimeter or spectrophotometer with calibration software, but a good quality system along these lines typically costs around US$150 and you can spend up into the thousands for spectrophotometer based solutions. I use hardware calibration here on screens intended for colour critical applications and the results are amazing, but this is well out of the range of most people. Most users tend to think that very blue (cool) whites are desirable on computer screens so would probably regard my properly calibrated and profiled screens as a bit yellow and perhaps also a bit dim; I follow standard industry practice for the majority of applications and calibrate to 6500K white point which is approximately daylight white.

A typical low to mid end notebook screen doesn"t perform well enough to justify a hardware calibration setup unless you can get an older one second hand, are aware of its limitations and figure out or know how to make it work with Windows 10. I am not going to offer instructions for the setup I am thinking of because you need some knowledge of colour management concepts to understand the limitations in what you are doing, also it is a faff to get the drivers to install.

Assuming calibration using hardware is out of the question, the next best thing is to follow the instructions @Riddle_Decipher posted, though be aware that whilst the process is described as calibration, it is not calibration to an objective standard but merely tuning the screen by eye to provide more subjectively pleasing results.

You should not be adjusting the white balance (color temperature) of your camera based on the image you see on the LCD screen. You should not even adjust exposure based on the image you see on the LCD screen. The LCD review is only there to validate things such as composition, focus, subject didn"t blink, etc. It"s not there to analyze color or exposure.

Regardless of how the image appears on the LCD (which is not color calibrated) the image may (and probably will) look different on your computer screen (especially if you"ve color-calibrated your computer"s display.)

/IDP31-156W_Front-left-_Banner20210125093541.jpg)

This is a voltage adjustment for the LCD display. DO NOT TOUCH IT. Messing with it can greatly shorten the lifetime of your LCD display. LCD displays must have an average of 0 volts DC on them (i.e. The positive and negative voltages put on them must nearly perfectly cancel out when you average the voltages over time.) If they don"t average out to 0 volts then the LCD plating materials will start to come off which slowly destroys the display over time.

The original Game Boy is a classic. Sure, it had no backlight, but there is something special about playing on that classic green screen. Unfortunately, some of these older systems are suffering a terrible fate — screen burn. Game Boy’s played best with lots of light — especially out in the sun. But that same sun did terrible things to the screen. A black splotch in the center of the LCD is the telltale sign of a burned Game Boy. You might think that screen replacement is the only option, but[The Retro Future] shows us how to repair this issue.

A reflective LCD is a layer cake made up of polarizers, two panes of glass, and a reflector. The burns often seen on Game Boy screens usually are in the polarizer and the optically clear glue which attaches the plastic polarizer to the glass. We’re guessing these burns happen when someone leaves their Game Boy out in the sun. Between the sun rays directly striking the top polarizer and the rays bounced back from the reflector at the rear of the screen, that poor polarizer doesn’t stand a chance.

Repairing the burn is a delicate operation, as one false move could crack the thin LCD glass. The first step is to carefully peel off the burned polarizer. This leaves a mess of dried glue, which can be scraped off or dissolved with alcohol. A new linear polarizer can then be placed on the front of the screen. [The Retro Future] chose not to glue the polarizer, but we’re betting some UV cure LOCA (Liquid Optically Clear Adhesive) from a cell phone screen protector would do the trick.

Is your obsessive side getting twitchy yet? Before we discuss upping your Xanax prescription, let"s review how the DSE demon begins its possession of your beloved screen.

Still, DSE may afflict cheaper versions, particularly if the anti-reflective coating on the glass that overlays the screen is of low quality or poorly applied. Furthermore, as the display ages, the phosphors in the screen may begin to wear out or malfunction, all of which can contribute to less uniform images, which is often apparent particular in scenes with fast panning shots.

In LCD and LED TVs, DSE is typically a bigger issue, one that"s due to the way these units are illuminated. Before we proceed, it"s worth mentioning that although marketing-speak often treats LED and LCD TVs as completely different technologies, they"re not different beasts.

LED units could be more accurately described as "LED-backlit LCD televisions," but salespeople and consumers alike are too lazy to utter that tongue-wearying phrase while haggling in a big-box store. What"s important to realize is that both categories rely on LCDs (liquid crystal displays), which act as shutters that either block light or allow it to pass, depending on the image that"s being rendered on the screen.

There are a variety of factors that affect LCD quality, notably illumination source. Older LCD TVs, for example, used multiple cold cathode fluorescent lamps (CCFL) to light LCDs from the rear. They provide generally smooth and even illumination, but they make the final product rather bulky.

More modern TVs rely on LEDs (light-emitting diodes) as a light source. Some models have what"s called full-array backlighting, in which the LEDs are stationed in regular intervals behind the screen, creating even lighting and excellent picture quality.

Other models incorporate what"s called edge lighting, which positions the LEDs along the edges of the screen. In general, the overall picture quality isn"t quite as good as a backlit screen, but manufacturers still use it because it allows them to build substantially slimmer TVs.

If you"ve ever pressed a little too hard on your smartphone or computer screen, you"ve likely witnessed a bit of discoloration, clear evidence of how sensitive LCDs are to physical pressure. Now, picture a huge manufacturing facility that cranks out thousands of these units per week. It"s easy to see how a bit of mishandling could alter the screen"s consistency.

The same goes for shipping. Some units travel long distances in cargo boxes, and then take bouncy rides in your car to their final resting place on your living room wall. That"s a lot of opportunities for tiny mishaps to affect LCD uniformity.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey