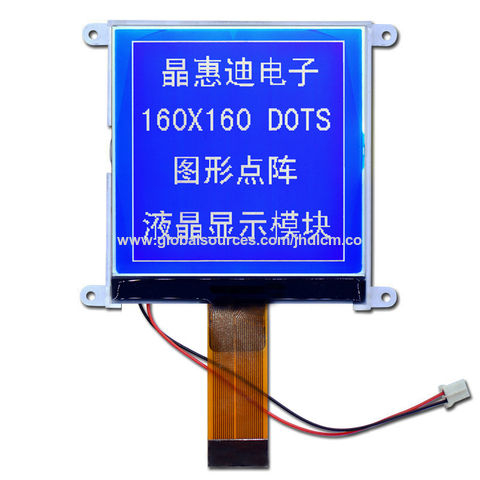

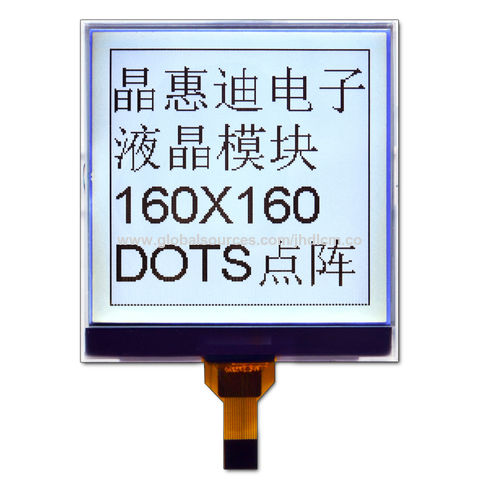

cog 160x160 lcd module supplier

A 3.9″ monochrome, 240×160 dot matrix, COG (Chip on Glass) Graphic LCD Module in FSTN Positive LCD Mode with Wide Temperature Range (Operating Temp: -20°C to 70°C, Storage Temp: -30°C to 80°C), and White LED Backlight. It has a six O’clock viewing direction and a transflective polarizer recommended for applications that will be used both indoor and outdoor. This product is assembled chip on glass with 1/160 Duty cycle and 1/12 Bias. This LCD uses controller IC UC1698 or equivalent. This is an ROHS compliant product manufactured with ISO standards and procedures.

Description Upgrade your product with our 128*64 LCD with 128*64 resolution! This 1.3 inch LCD display is a transmissive type monochrome passive matrix liquid crystal display (LCD) which uses amorphous thin film transistor as switching devices. This product is composed of a LCD panel, a drive...

Description 128*64 graphic LCD module , built-in ST7 567 or compatible controller. Many of our LCD display modules use an industry standard compatible controller, if you are looking for a industry LCD displays, a 1 28 * 64 graphic LCD module might be exactly what you need . Image Details...

Description We"ve got thousands of LCD displays perfect for your design. Whether you need a TFT, LCD, OLED display module, we carry them all. We also provide free world-class product support and a full complement of accessories; including touch screens, cables, development boards, and...

Description This white on blue background 128x64 pixel COG graphic LCD display module has an integrated Sitronix ST756 7 controller. The graphic LCD is very low power to drive the display. General Specification LCD drawing Image Details Application Widely used in money counting machine,...

Dr Pan: Hello, Greg. COG is the abbreviation for chip on glass. It is a technology, which IC is bonded directly onto ITO glass. COG technology is usually used in small size dot matrix monochrome LCD module and TFT LCD module.

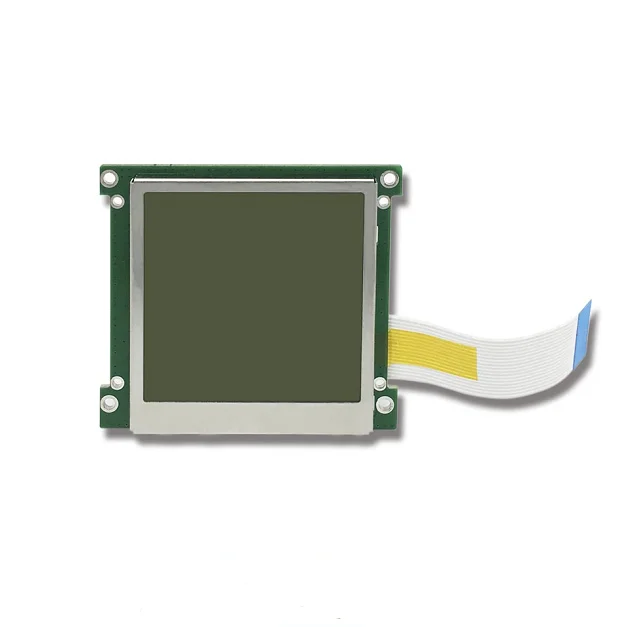

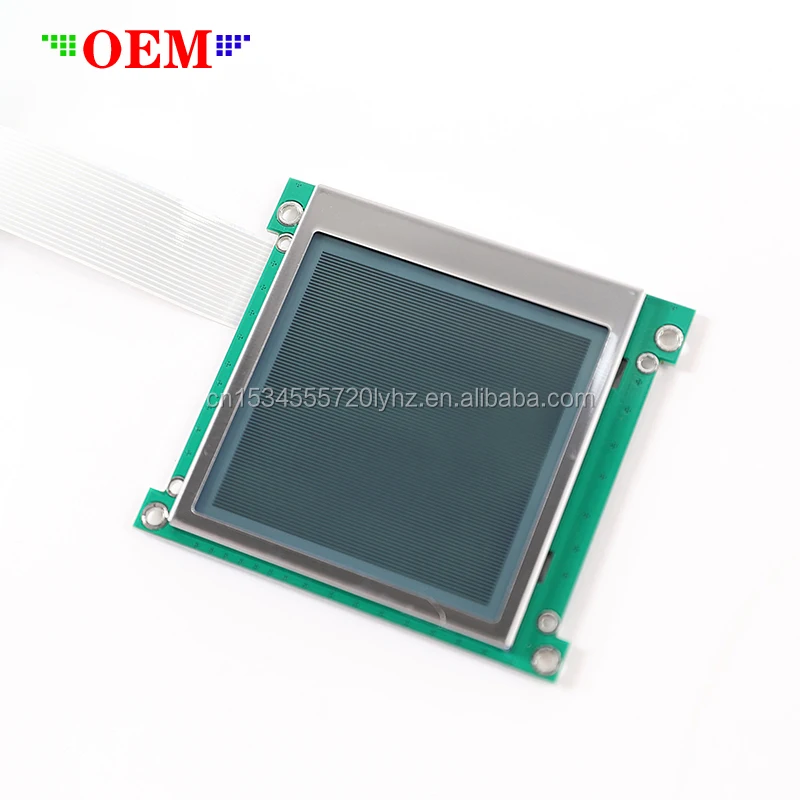

NO.1, it can greatly reduce the size of the LCD module because it doesn’t have PCB and it can be as thin as 2.0mm (maybe thinner). The thinner the more expensive.

NO.3, it is cost effective over COB LCD and can totally replace COB LCD in function, especially in graphic LCD modules, because it reduces the number of IC.

NO.4, for some dot matrix LCD modules, it is not possible to apply COB LCD technology because it is too crowded to place so many points on the view area. COG LCD is an economical and feasible solution because the pitch is smaller .

Enjoy your cooperation with our company-----Shenzhen Sunfly Technology Co., Ltd; we are ready to be your long term and reliable LCD supplier in coming future!

Chip-On-Glass (COG) is a flip chip bonding method which is used for connect assembly of bare integrated circuits (ICs) on glass substrate directly by using Anisotropic Conductive Film (ACF). The pitch of the IC bumps (footprint) can be scaled down according to customers" requirements (contact pitch of glass substrate). This method reduces the assembly area to the highest possible packing density, which especially important to those applications that space saving is crucial. It allows a cost-effective mounting of driver chips because integrating flex PCB is no longer required. The IC is bonded directly onto the glass substrate and is suitable for handling high-speed or high-frequency signals.

COG technology is one of the high-tech mounting methods which use Gold Bump or Flip Chip IC"s, and implemented in most compact applications. Chip-On-Glass integrated circuits were first introduced by Epson. In flip-chip mounting, the IC chip is not packaged but is mounted directly onto the PCB as a bare chip. Because there is no package, the mounted footprint of the IC can be minimized, along with the required size of the PCB. This technology reduces the mounting area and is better suited to handling high-speed or high frequency signals.

COG is primarily used for source driver ICs within TFT display technologies where they are used for LCD, plasma, e-ink, OLED or 3D technologies. This is essential for consumer electronic products such as notebooks, tablets, cameras or mobile phones with the need for small size and light-weight components.

COG can only be used at a certain resolution level where the lines are not too fine. At very fine pitches COG becomes difficult to test, and TAB would be the preferred approach.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey