oxide tft lcd price

1.What advantages do you have?A. Fast delivery time, can support sample services, products are in stock, can be supplied at any time, 24 hours online service, products have passed strict certification, and the buyer has good results.2.Q: How can I get the samples?A: Send inquiry → Offer quotation →Confirm quotation & pay tooling charge → Provide drawing → confirm drawing → make tooling & samples → Samples finished → Delivery via freight or sea collect.3.Q: How long can I expect to get the sample?A: Contour drawing: 2-4 days Sample time: 7-15 days.4.Q: Can you design the lcd in acccordance with our demand?A: Sure.We will give you the best tooling charge.5.Q: How to place orders ?A: If you confirm samples ok, Please send us your purchase order by Email or Fax , Then we will send you an Invoice for deposit payment. We need to know the following information of your order.

Oxide thin-film transistor (TFT) liquid crystal display (LCD) panels are increasingly adopted in mobile PCs due to their feature of high resolution while consuming low power. Global shipments of large oxide TFT LCD panels of 9 inches or larger are expected to grow from 20 million units in 2016 to 55.6 million units in 2017, according to new analysis from IHS Markit (Nasdaq: INFO). Of those, 51 million units are estimated to be applied to mobile PCs, which include notebook PCs and tablet PCs, up 200 percent from 17 million units in 2016.

“Demand for high-resolution panels has increased as media content for mobile PCs became available in higher resolutions,” said David Hsieh, senior director at IHS Markit. “Apple’ and Microsoft’s use of oxide TFT LCD panels for products – iPad, iPad Pro, and Surface, respectively – helped increase the oxide mobile PC panel market and encouraged other PC brands to follow suit.”

Low-temperature polysilicon (LTPS) and oxide TFT LCD solutions are major candidates for displaying high-resolution images, and they are expected to account for more than 19 percent of the entire mobile PC display market in 2017, according to the Large Area Display Market Tracker by IHS Markit.

While LTPS can deliver higher resolution images and consume less power than oxide TFT LCD or a-Si TFT LCD, it has its own limits: its production cost is high and the yield rate is low. In addition, it is less efficient to produce large panels. Albeit not as high resolution as LTPS, oxide TFT LCD panels still display high-resolution images better than the a-Si solution, and they are suitable to produce large panels at lower production cost than LTPS.

LG Display and Sharp have expanded their oxide mobile PC panel shipments aggressively by 180 percent and 370 percent, respectively. CEC Panda in China is estimated to increase its shipments from about 600,000 units in 2016 to 4.2 million in 2017. As some oxide panel suppliers are reducing their focus on the mobile PC display business, display makers in China and Taiwan, such as BOE and Innolux, are expected to produce more oxide panels in future, IHS Markit said.

LG Display"s oxide TFT technology can be applied to various display products. Since its performance is more than 50 times higher than that of the existing a-Si TFT, it can be applied to the entire product lines from mobiles to laptops and large TVs.

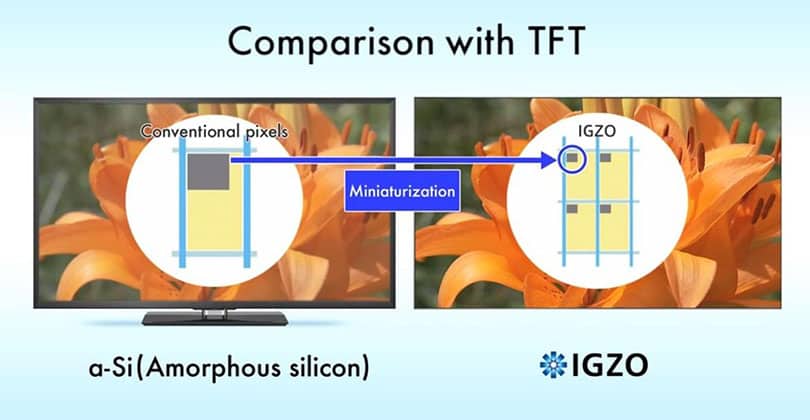

By reducing the size of the TFTs that make up individual pixels and increasing their performance, a display with high resolution and rich colors can be achieved.

By applying oxide TFT, the size of the circuit part of the panel outside the screen can be drastically reduced, making it possible to create a slim design display.

Oxide TFT is highly energy-efficient because the leakage current is very small when the screen is not working, so it can extend the battery life of notebooks or tablets.

LG Display is a pioneer in the industry"s first successful mass-production by researching and developing oxide TFT technology for the longest period of time. LG Display guarantees product reliability that customers can trust and use for a long time.

in-TOUCH products with built-in touch function can maintain slim design and superior image quality compared to add-on (out-cell) touch products with added touch electrodes. It is a technology unique to LG Display that can be applied not only in IT but also in various fields such as home application, health, industrial, and medical products. in-Touch has a built-in touch electrode in the LCD, optimized for slim & light products that can perform touch operation without additional touch electrodes or cover glass.

The statistic illustrates large oxide TFT LCD panel unit shipments in 2016 and 2017, by type. Large oxide TFT LCD panel shipments for tablet PCs are projected to reach 32.6 million units worldwide in 2017.Read moreGlobal large oxide TFT LCD panel shipments by type in 2016 and 2017 (in million units)*CharacteristicTVTablet PCNotebook PCMonitor-----

IHS. (November 6, 2017). Global large oxide TFT LCD panel shipments by type in 2016 and 2017 (in million units)* [Graph]. In Statista. Retrieved December 28, 2022, from https://www.statista.com/statistics/784229/global-large-oxide-tft-lcd-panel-shipment-by-type/

IHS. "Global large oxide TFT LCD panel shipments by type in 2016 and 2017 (in million units)*." Chart. November 6, 2017. Statista. Accessed December 28, 2022. https://www.statista.com/statistics/784229/global-large-oxide-tft-lcd-panel-shipment-by-type/

IHS. (2017). Global large oxide TFT LCD panel shipments by type in 2016 and 2017 (in million units)*. Statista. Statista Inc.. Accessed: December 28, 2022. https://www.statista.com/statistics/784229/global-large-oxide-tft-lcd-panel-shipment-by-type/

IHS. "Global Large Oxide Tft Lcd Panel Shipments by Type in 2016 and 2017 (in Million Units)*." Statista, Statista Inc., 6 Nov 2017, https://www.statista.com/statistics/784229/global-large-oxide-tft-lcd-panel-shipment-by-type/

IHS, Global large oxide TFT LCD panel shipments by type in 2016 and 2017 (in million units)* Statista, https://www.statista.com/statistics/784229/global-large-oxide-tft-lcd-panel-shipment-by-type/ (last visited December 28, 2022)

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

4.5.Comparing the key attributes of different TFT technologies (a-Si, pc-Si, nc-Si, OTFT, graphene, CNT, etc). Parameters include manufacturing technique, mobility, uniformity, stability, and commercialisation stage and primary uses

7.1.Radar chart assessing the merits of different backplane technologies (LTPS, oxide, a-Si, organics) for LCD displays. The parameters considered are resolution, size, flexibility, on-pixel processing, and 3D. Here, the scale is from

7.2.Radar chart assessing the merits of different backplane technologies (LTPS, oxide, a-Si, organics) for OLED displays. The parameters considered are resolution, size, flexibility, on-pixel processing, and 3D. Here, the scale is fro

7.7.Announced annual production capacity (area) of various OLED display manufactures in 2015-2016. Two categories are developed: 1) LTPS backplanes and 2) oxide backplanes

The display industry is continuing to move toward mid-to-large-size, immersive displays in high-performance tablets, notebooks and 8K TVs. As these trends become industry standards, the oxide market emerges as an important opportunity for enabling the next-generation of high-performance displays. These displays feature: higher resolution and faster refresh rates; enhanced circuitry integration to achieve slim bezels; and cost savings for panel makers by improving the panel aperture ratio and enabling large gen size manufacturing.

To achieve these technical requirements, new breakthroughs are needed in thin-film-transistor (TFT) technologies. Among the display industry’s current offerings, amorphous silicon TFT (a-Si TFT) maintains a leading position among all applications, while low-temperature poly-silicon TFT (LTPS) is the predominant display technology for enabling high-performance handheld displays. The key differences between a-Si and LTPS are that an a-Si TFT has a simpler process, structure, and is easier to scale up in terms of manufacturing. However, LTPS offers better TFT performance to achieve higher resolutions and lower power consumption. The drawbacks of LTPS come in size limitations and increased manufacturing costs. For these reasons, neither a-Si or LTPS can fully meet the technical requirements for this next generation of high-performance displays.

All of these industry requirements create new process and glass composition challenges, which present the need to develop an advanced oxide TFT glass technology.

For decades, the dominant technology for flat panel displays was an amorphous silicon (a-Si) backplane. The vast majority of displays were made using a-Si backplanes due to the simplicity in manufacturing process, good economics, and scalability to larger sizes. As demands for brighter and/or higher resolution displays grew due to the introduction and proliferation of handheld mobile devices, alternative backplane technologies, such as low temperature polysilicon (LTPS), became more prevalent. LTPS is similar to a-Si, but requires higher processing temperatures and a more complicated manufacturing process. This results in advanced properties for the backplane, such as >50X higher electronic mobility. These properties allow smaller TFTs (enabling higher resolutions and brighter displays) and faster refresh rates. While clearly a superior technology to a-Si, the higher temperatures and more complex manufacturing process make LTPS considerably more expensive than a-Si. Additionally, LTPS is not easily scaled to larger sizes to enable better panel economics.

The ideal backplane technology would combine the simplicity, economics, and scalability to larger panel sizes of a-Si with the heightened performance of LTPS. This is exactly what oxide TFT technologies offer. The most commonly implemented oxide TFT technology is based on Indium-Gallium-Zinc-Oxide or “IGZO” technologies.

Though the mobility of oxide TFT is not as high as LTPS, it is an order of magnitude better than a-Si technology and capable of driving OLED displays and 8K 120Hz + LCD TVs. Additionally, the low off-current of an oxide TFT could enable low refresh frequency without flicker effects on static images (a comparison of different TFT technologies are shown in Table 1). While, like LTPS, oxide TFT backplanes have improved electrical properties relative to a-Si backplanes, oxide TFT backplanes can scale up to Gen 10.5 at reasonable costs (unlike LTPS), thereby enabling high-end, large-size LCD and OLED TVs. It is for this “just right” compromise of a-Si and LTPS properties that oxide TFT is garnering so much attention from panel makers worldwide. It offers the ability to manufacture displays far superior to a-Si at sizes and costs unachievable by LTPS.

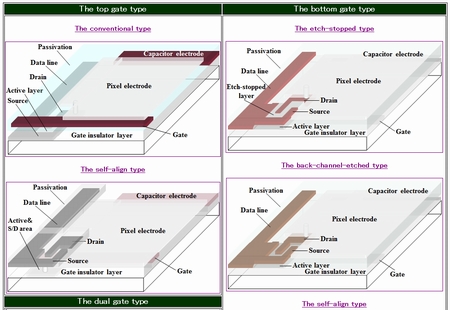

There are two major oxide TFT processes to consider: etch-stop and back channel etch (BCE). The key difference between the processes is the use of an etch-stop layer, also known as ESL, that is required to protect the IGZO channels during the etching process.

Oxide TFT reliability was the major concern in early stage of oxide TFT development. The oxide TFT channel was usually damaged in subsequent processes, so an etch stop structure was designed to protect the oxide TFT channel. The etch-stop (ESL) oxide TFT manufacturing process begins with a bottom gate structure which is covered by a gate insulator and TFT islands. After the gate insulator (GI) layers and TFT patterning, a patterned SiO2 layer is deposited to cover the IGZO channel area in order to protect oxide TFT from following source/drain (S/D) etching. This enables better TFT reliability, and after the S/D etching, then followed by passivation, ITO layer as the Figure 1 shows. In the ESL process, temperatures may go up to 300-400°C for up to an hour or more. While these are higher temperatures than some a-Si processes, it is considerably lower than the typical LTPS processes that can exceed 500°C.

The BCE oxide TFT process (Figure 2) is very similar to the ESL oxide TFT process in the first two photo etching processes (PEP) steps. However, a high temperature (400-500°C) annealing process enhances the TFT reliability that allows the removal of the ESL. The higher temperature annealing step requires a thermally stable glass that can withstand harsh manufacturing environments and processing times relative to the conventional oxide (ESL) or a-Si processes.

To panel makers, the BCE oxide TFT process is similar to the a-Si process, which has been widely used for the past two decades. Also, there is one photo-mask process reduction compared to the ES oxide TFT process, therefore, BCE oxide TFT is becoming a mainstream process of oxide TFT manufacturing.

While the oxide TFT process has clear technical benefits for the manufacture of large and high-performance TVs, it presents a unique set of challenges for the glass substrate used in the process.

When put through a typical TFT backplane process, glass substrates will change shape or size (i.e., strain) which is called a change in total pitch (TP). One of the most important glass substrate attributes is total pitch variation (TPV), which is the deviation from predictable glass movement within a glass sheet and from sheet-to-sheet. For a glass substrate to have good TPV performance, the substrate must have the required balance of physical properties to resist the various causes of strain of the substrate: elastic distortion, stress relaxation, and compaction. These sources of strain, and the corresponding glass property that resists them, are discussed below.

In TFT processes, there are several sources of stress applied to the glass substrate, such as film stresses and gate metals. In oxide TFT, the latter is particularly significant due to the substantial thickness and covered area of the gate metal. The pitch change associated with these stresses is determined by the size of the stress, the elastic modulus of the glass, and the thickness of the substrate. Since the stresses are determined by the TFT manufacturer and the industry is continually driving to thinner and thinner substrates, the only attribute within the control of the glass manufacturer is to increase the elastic modulus to increase the stiffness of the substrate. Also, because the stresses in the TFT process can vary across a sheet or sheet-to-sheet, a higher elastic modulus will reduce the strain due to variations in the applied stresses, thereby minimizing TPV from this potential cause.

The stresses from applied films and gate metal can also contribute to the overall TPV through the relaxation of those stresses during subsequent thermal treatments. As the substrate progresses through the various steps of the TFT process, the films, gate metal, and substrate itself will all undergo stress relaxation. As the stress state of the composite changes with time and temperature, the concomitant strain will accordingly change, causing a pitch change and an increase in TPV. The glass substrate resists this stress relaxation in proportion to its effective viscosity at the process temperatures. In a-Si TFT processes, the temperatures are low enough that there is a minimal amount of stress relaxation due to the glass substrate having a relatively high viscosity at these low temperatures (the viscosity of the glass increases as the temperature decreases). In oxide TFT processing, however, temperatures are higher and, therefore, the potential for stress relaxation is greater due to the lower effective viscosity of the glass. This is particularly acute for the BCE oxide TFT process, which has process steps with temperatures in excess of 400°C. Traditional glass substrates which are sufficient for the typical a-Si applications may also be sufficient for the lower temperature ESL oxide TFT processes. However, the higher temperature BCE oxide TFT process may require a substrate with a higher effective viscosity at temperatures in the range of 400°C.

The effective viscosity of the glass substrate also plays a role in the amount of viscous relaxation the glass substrate undergoes in the TFT process due to structural relaxation of the glass itself. This is commonly referred to as “compaction” or “shrinkage” in the glass industry. Compaction is due to the evolution of the glass structure from a non-equilibrium state toward a structure closer to equilibrium with the customer process. The amount of this viscous relaxation that occurs is proportional to the degree to which the glass is out of equilibrium, and inversely proportional to the effective viscosity of the glass at the TFT process temperatures. Consequently, a higher viscosity glass is beneficial for minimizing TPV, just like in stress relaxation. In glass property terms, a higher viscosity glass is a glass with a higher “annealing point” therefore glass manufacturers will often tout the high annealing point of their glass compositions.

Corning’s proprietary fusion process manufactures glass panels at Gen 10.5 sizes (2940 x 3370mm), enabling higher glass utilization for larger-screen sizes. For example, one sheet of Gen 10.5 glass could create eight 65” display panels, or six 75” display panels. This enhanced glass utilization greatly reduces cost for panel makers and is key for enabling the oxide TFT market"

For oxide TFT to be used in IT or handheld products, one of the key features is a thin and light form factor. To achieve this, the display panel usually needs to be thinned down to roughly 0.15mm / 0.15mm (for the two pieces of glass in the display) using the chemical slimming process. A faster etch rate is clearly desired to enable higher throughput and lower costs but this often comes at the cost of the generation of “sludge.” Sludge can create problems in the etch vendors’ processes and end up causing more cost than the fast etch rate reduced. By using a glass that balances maximizing etch rate while minimizing sludge generation, panel makers optimize their throughput and costs.

The technology challenges and technical requirements outlined fuel an industry need for a new glass substrate with the right balance of physical properties for oxide TFT technology. For displays applications, this includes low total pitch variation, low total thickness variation, and low sag. This package of glass attributes, alongside the ability to scale-up manufacturing to large-gen sizes, will help enable the next-generation of mid-to-large-size, immersive displays in 8K TVs.

These applications require a shift toward oxide technology, versus the current a-Si and LTPS TFT technologies. As the push for oxide increases, new process and technical challenges emerge for panel makers. To build a display that meets these performance expectations, panel makers require a thermally and dimensionally stable glass to improve yields while achieving the desired resolution.

Aoki Y, Wiemann C, Feyer V, Kim H-S, Schneider CM, Ill-Yoo H, Martin M (2014) Bulk mixed ion electron conduction in amorphous gallium oxide causes memristive behavior. Nat Comm 5:1

Chen C-Y, Lin L-F, Lee J-Y, Wu W-H, Wang S-C, Chiang Y M, Chen Y-H, Chen C-C, Chen Y-H, Chen C-L, Shih T-H, Liu C-H, Ting H-C, Lu H-H, Tsai L, Lin H-S, Chang L-H, Lin Y-H (2013) A 65-inch amorphous oxide thin film transistors active-matrix organic light-emitting diode television using side by side and fine metal mask technology. SID 2013 Digest, p 247

Cheong W-S, Lee J-M, Lee J-H, Park S-HK, Yoon SM, Byun C-W, Yang S, Chung SM, Cho KI, Hwang C-S (2009) Effects of interfacial dielectric layers on the electrical performance of top-gate In-Ga-Zn-Oxide thin-film transistors. ETRI J 31:660–666

Cho SH, Park S-HK, Hwang C-S, Ryu MK, Eom IY, Kim JW, Yang J-H, Kim H-O, Kwon O-S, Park E-S, Lim SK (2014) High mobility and highly stable aluminum-doped indium zinc tin oxide thin-film transistors. SID 2014 Digest, p 473

Cobb B, Rodriguez FG, Maas J, Ellis T, Steena J-L, Myny K, Smout S, Vicca P, Bhoolokamb A, Rockeléb M, Steudel S, Heremansb P, Marinkovic M, Pham D-V, Hoppe A, Steigerd J, Anselman R, Gelinck G (2014) Flexible low temperature solution processed oxide semiconductor TFT backplanes for use in AMOLED displays. SID 2014 Digest, pp 161–163

Fukumoto E, Arai T, Morosawa N, Tokunaga K, Terai Y, Fujimori T, Sasaoka T (2010) High mobility oxide semiconductor TFT for circuit integration of AM-OLED. In: Proceedings of the IDW’10, p 631

Görm P, Hölzer P, Riedl T, Kowalsky W, Wang J, Weimann T, Hinze P, Kipp S (2007) Stability of transparent zinc tin oxide transistors under bias stress. Appl Phys Lett 90:063502

Goyal A, Iwasaki T, Itagaki N, Den T, Kumomi H (2009) Favorable elements for an indium-based amorphous oxide TFT channel: study of In-X]O (X=B, Mg, Al, Si, Ti, Zn, Ga, Ge, Mo, Sn) systems. Mater Res Soc Symp Proc 1109:1109-B04-03

Han C-W, Kang H, Shin Y-H, Shin H-J, Kim B-C, Kim H-S, Kim B-S, Tak Y-H, Oh C-H, Ahn B-C (2014a) Large-sized and UHD curved OLED TV employing white OLEDs and oxide TFTs. In: Proceedings of the IDW 2014, AMD4-4L

Hayashi R, Sato A, Ofuji M, Abe K, Yabuta H, Sano M, Kumomi H, Nomura K, Kamiya T, Hirano M, Hosono H (2008) Improved amorphous In-Ga-Zn-O TFTs. SID 2008 Digest, p 621

Hosono H, Nomura K, Ogo Y, Uruga T, Kamiya T (2008) Factors controlling electron transport properties in transparent amorphous oxide semiconductors. J Non Cryst Sol 354:2796–2800

Hsieh H-H, Tsai T-T, Chang C-Y, Wang H-H, Huang J-Y, Hsu S-F, Wu Y-C, Tsai T-C, Chuang C-S, Chang L-H, Lin Y-H (2010) A 2.4-in. AMOLED with IGZO TFTs and inverted OLED devices. SID 10 Digest, pp 140–143

Ito M, Kon M, Okubo T, Ishizaki M, Sekine N (2005) A flexible active-matrix TFT array with amorphous oxide semiconductors for electronic paper. In: Proceedings of the IDW/AD’05, pp 845–846

Ito M, Kon M, Ishizaki M, Miyazaki C, Imayoshi K, Tamakoshi M, Ugajin Y, Sekine N (2006) A novel display structure for color electronic paper driven with fully transparent amorphous oxide TFT array. In: Proceedings of the IDW 2006, p 585

Ito M, Kon M, Miyazaki C, Ikeda N, Ishizaki M, Ugajin Y, Sekine N (2007) “Front Drive” display structure for color electronic paper using fully transparent amorphous oxide TFT array. IEICE Trans Electron E90-C:2105–2111

Ito M, Miyazaki C, Ikeda N, Kokubo Y (2009) Transparent amorphous oxide TFT and its application to electronic paper. In: Proceedings of the AMFPD 2009 S-2

Jeong JH, Yang HW, Park J-S, Jeong JK, Mo Y-G, Kim HD, Song J, Hwang CS (2008) Origin of subthreshold swing improvement in amorphous indium gallium zinc oxide transistors. Electrochem Solid-State Lett 11:H157–H159

Kamiya T, Nomura K, Hosono H (2009a) Origins of high mobility and low operation voltage of amorphous oxide TFTs: Electronic structure, electron transport, defects and doping. IEEE J Display Technol 5:273

Kamiya T, Nomura K, Hosono H (2009b) Electronic structure of the amorphous oxide semiconductor a-InGaZnO4-x: Tauc-Lorentz optical model and origins of subgap states. Phys Status Solidi A 206:860–867

Kamiya T, Nomura K, Hosono H (2010b) Subgap states, doping and defect formation energies in amorphous oxide semiconductor a-InGaZnO4 studied by density functional theory. Phys Status Solidi A 207:1698–1703

Kamiya T, Nomura K, Hosono H (2010c) Origin of definite Hall voltage and positive slope in mobility-donor density relation in disordered oxide semiconductors. Appl Phys Lett 96:122103

Kawamura T, Uchiyama H, Saito S, Wakana H, Mine T, Hatano M, Torii K, Onai T (2008) 1.5-V operating fully-depleted amorphous oxide thin film transistors achieved by 63-mV/dec subthreshold slope. Digest Int Electron Devices Meet 2008:1–4

Kawashima E, Nishimura M, Yoshimura N, Kawashima H, Kasami M, Tomai S, Shibata M, Yano K (2013) Effects of water during DC sputter deposition for amorphous indium tin zinc oxide (A-ITZO) thin films. In: 8th international symposium transparent oxide and related materials for electronics and optics (TOEO8) 15aI02

Kikuchi Y, Nomura K, Yanagi H, Kamiya T, Hirano M, Hosono H (2010) Device characteristics improvement of a-In–Ga–Zn–O TFTs by low-temperature annealing. Thin Solid Films 518:3017–3021

Kim SI, Kim CJ, Park JC, Song I, Kim SW, Yin H, Lee E, Lee JC, Park Y (2008) High performance oxide thin film transistors with double active layers. Int Electron Devices Meeting. doi:10.1109/IEDM.2008.4796617

Kloeppel A, Liu J, Scheer E (2013) Large area sputtered Al2O3 films for high mobility AM-TFT backplanes on PVD array system PiVot 55kVi2. SID 2013 Digest, p 647

Kobayashi Y, Matsuda S, Matsubayashi D, Suzawa H, Sakakura M, Hanaoka K, Okazaki Y, Yamamoto T, Hondo S, Hamada T, Sasagawa S, Nagai M, Hata Y, Maruyama T, Yamamoto Y, Yamazaki S (2014) Electrical characteristics and short-channel effect of c-axis aligned crystal indium gallium zinc oxide transistor with short channel length. Jpn J Appl Phys 53:04EF03

Kumomi H, Yaginuma S, Omura G, Goyal A, Sato A, Watanabe M, Shimada M, Kaji N, Takahashi K, Ofuji M, Watanabe T, Itagaki N, Shimizu H, Abe K, Tateishi Y, Yabuta H, Iwasaki T, Hayashi R, Aiba T, Sano S (2009) Materials, devices, and circuits of transparent amorphous-oxide semiconductor. J Disp Technol 5:531

Kwon JY, Son KS, Jung JS, Kim TS, Ryu MK, Park KB, Kim JW, Lee YG, Kim CJ, Kim SI, Park YS, Lee SY, Kim JM (2007) 4 inch QVGA AMOLED display driven by GaInZnO TFT. In: Proceedings of the IDW’07, p 1783

Lee D-H, Chang Y-J, Herman GS, Chang C-H (2007) A general route to printable high-mobility transparent amorphous oxide semiconductors. Adv Mater 19:843–847

Lee J-H, Kim D-H, Yang D-J, Hong S-Y, Yoon K-S, Hong P-S, Jeong C-O, Park H-S, Kim SY, Lim SK, Kim SS, Son K-S, Kim T-S, Kwon J-Y, Lee S-Y (2008) World-largest (15-inch) XGA AMLCD panel using IGZO oxide TFT. SID 08 Digest, pp 625–628

Miyase T, Watanabe K, Sakaguchi I, Ohashi N, Domen K, Nomura K, Hiramatsu H, Kumomi H, Hosono H, Kamiya T (2014) Roles of hydrogen in amorphous oxide semiconductor In-Ga-Zn-O: comparison of conventional and ultra-high-vacuum sputtering. ECS J Solid State Sci Technol 3:Q3085–Q3090

Nomura K, Ohta H, Ueda K, Kamiya T, Hirano M, Hosono H (2003) Thin film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 300:1269–1272

Nomura K, Kamiya T, Ohta H, Uruga T, Hirano M, Hosono H (2007) Local coordination structure and electronic structure of the large electron mobility amorphous oxide semiconductor In-Ga-Zn-O: experiment and ab initio calculations. Phys Rev B 75:035212

Nomura K, Kamiya T, Ohta H, Hirano M, Hosono H (2008a) Defect passivation and homogenization of amorphous oxide thin-film transistor by wet O2 annealing. Appl Phys Lett 93:192107

Nomura K, Kamiya T, Yanagi H, Ikenaga E, Yang K, Kobayashi K, Hirano M, Hosono H (2008b) Subgap states in transparent amorphous oxide semiconductor, In-Ga-Zn-O, observed by bulk sensitive x-ray photoelectron spectroscopy. Appl Phys Lett 92:202117

Nomura K, Aoki T, Nakamura K, Kamiya T, Nakanishi T, Hasegawa T, Kimura M, Kawase T, Hirano M, Hosono H (2010b) Three-dimensionally stacked flexible integrated circuit: amorphous oxide/polymer hybrid complementary inverter using n-type a-InGaZnO and p-type poly-(9,9-dioctyluorene-co-bithiophene) thin-film transistors. Appl Phys Lett 96:263509

Nomura K, Kamiya T, Hosono H (2013) Effects of diffusion of hydrogen and oxygen on electrical properties of amorphous oxide semiconductor, In-Ga-Zn-O. ECS J Solid State Sci Technol 2:P5–P8

Ochi M, Morita S, Takanashi Y, Tao H, Goto H, Kugimiya T, Kanamaru M (2013) High reliability of back channel etch-type TFTs using new oxide semiconducting material. In: Proceedings of the IDW’13, p 368

Ofuji M, Abe K, Shimizu H, Kaji N, Hayashi R, Sano M, Kumomi H, Nomura K, Kamiya T, Hosono H (2007) Fast thin-film transistor circuits based on amorphous oxide semiconductor. IEEE Electron Device Lett 28:273–275

Ogo Y, Hiramatsu H, Nomura K, Yanagi H, Kamiya T, Hirano M, Hosono H (2008a) p-channel thin-film transistor using p-type oxide semiconductor, SnO. Appl Phys Lett 93:032113

Ogo Y, Hiramatsu H, Nomura K, Yanagi H, Kamiya T, Kimura M, Hirano M, Hosono H (2009) Tin monoxide as an s-orbital-based p-type oxide semiconductor: electronic structures and TFT application. Phys Status Solidi A 206:2187–2191

Ohara H, Sasaki T, Noda K, Ito S, Sasaki M, Toyosumi Y, Endo Y, Yoshitomi S, Sakata J, Serikawa T, Yamazaki S (2009) 4.0 in. QVGA AMOLED display using In-Ga-Zn-Oxide TFTs with a novel passivation layer. SID 09 Digest, p 284

Orita M, Ohta H, Hirano M, Narushima S, and Hosono H (2001) Amorphous transparent conductive oxide InGaO3(ZnO)m (m ≤ 4): a Zn 4s conductor. Philo Mag B 81:501–515

Ozaki H, Kawamura T, Wakana H, Yamazoe T, Uchiyama H (2011) Wireless operations for 13.56-MHz band RFID tag using amorphous oxide TFTs. IEICE Electron Express 8:225–231

Park J-S, Kim T-W, Stryakhilev D, Lee J-S, An S-G, Pyo Y-S, Lee D-B, Mo YG, Jin D-U, Chung HK (2007) Flexible full color organic light-emitting diode display on polyimide plastic substrate driven by amorphous indium gallium zinc oxide thin-film transistors. Appl Phys Lett 95:013503

Park JS, Kim TS, Son KS, Jung JS, Lee K-H, Kwon J-Y, Bonwon K, Lee S (2010a) Influence of illumination on the negative-bias stability of transparent hafnium–indium–zinc oxide thin-film transistors. Electron Device Lett 31:440–442

Park JS, Maeng W-J, Kim H-S, Park J-S (2012) Review of recent developments in amorphous oxide semiconductor thin-film transistor devices. Thin Solid Films 520:1679–1693

Park SHK, Ryu M-K, Oh H, Hwang C-S, Jeon J-H, Yoon S-M (2013) Double-layered passivation film structure of Al2O3/SiNx for high mobility oxide thin film transistors. J Vac Sci Technol B 31:020601

Rockelé M, Pham D-V, Steiger J, Botnaras S, Weber D, Vanfleteren J, Sterken T, Cuypers D, Steudel S, Myny K, Schols S, Putten B, Genoe J, Heremans P (2011) Low-temperature and low-voltage, solution-processed metal oxide n-TFTs and flexible circuitry on large-are polyimide foil. In: Proceedings of the IDW’11, p 1267

Ryu M, Kim T S, Son K S, Kim H-S, Park J S, Seon J-B, Seo S-J, Kim S-J, Lee E, Lee H, Jeon S H, Han S, Lee S Y (2012) High mobility zinc oxynitride-TFT with operation stability under light illuminated bias-stress conditions for large area and high resolution display applications. In: IEDM12, 5.6

Saito N, Ueda T, Miura K, Nakano S, Sakano T, Maeda Y, Yamaguchi H, Amemiya I (2013) 10.2-inch WUXGA flexible AMOLED display driven by amorphous oxide TFTs on plastic substrate. SID 2013 Digest, p 443

Shih T-H, Ting H-C, Lin P-L, Chen C-L, Tsai L, Chen C-Y, Lin L-F, Liu C-H, Chen C-C, Lin H-S, Chang L-H, Lin Y-H, Hong H-J (2014) Development of oxide-TFT OLED-TV technologies. SID 2014 Digest, pp 766–769

Shimura T, Nomura K, Yanagi H, Kamiya T, Hirano M, Hosono H (2008) Specific contact resistances between amorphous oxide semiconductor In–Ga–Zn–O and metallic electrodes. Thin Solid Films 516:5899–5902

Song I, Kim S, Yin H, Kim CJ, Park J, Kim S, Choi HS, Lee E, Park Y (2008) Short channel characteristics of gallium–indium–zinc–oxide thin film transistors for three-dimensional stacking memory. IEEE Electron Device Lett 29:549–552

Tanabe T, Kusunoki K, Sekine Y, Furutani K, Murakawa T, Nishi T, Hirakata Y, Godo H, Koyama J, Yamazaki S, Ozaki K, Handa T, Sakakura M (2011) Low power consumption LC display using crystalline oxide semiconductor FETs with ultra-low off-state current. In: Proceedings of the AMFPD 2011, p 7

Tanabe T, Amano S, Miyake H, Suzuki A, Komatsu R, Koyama J, Yamazaki S, Okazaki K, Katayama M, Matsukizono H, Kanzaki Y, Matsuo T (2012) New threshold voltage compensation pixel circuits in 13.5-inch Quad Full High Definition OLED display of crystalline In-Ga-Zn-Oxide FETs. SID 2012 DIGEST, p 88

Terai Y, Arai T, Morosawa N, Tokunaga K, Fukumoto E, Kinoshita T, Fujimori T, Sasaoka T (2011) A polycrystalline oxide TFT driven AM-OLED display. In: Proceedings of the IDW’11, p 61

Ueda N, Ogawa Y, Okada K, Oda A, Katoh S, Uchida S, Yamamoto K, Matsuo T, Kawamori H (2014) Advantages of IGZO platform in ultra-high-resolution LCD applications. In: Proceedings IDW’14, pp 177–180

Wager JF, Yeha B, Hoffman RL, Keszler DA (2014) An amorphous oxide semiconductor thin-film transistor route to oxide electronics. Curr Opinion in Sol State Mater Sci 18:53–61

Wang Y-L, Covert LN, Anderson TJ, Lim W, Lin J, Pearton SJ, Norton DP, Zavada JM, Renc F (2008) RF characteristics of room-temperature-deposited, small gate dimension indium zinc oxide TFTs. Electrochem Solid State Lett 11:H60–H62

Yamauchi Y, Kamakura Y, Isagi Y, Matsuoka T, Malotaux S (2013) Study of novel floating-gate oxide semiconductor memory using indium–gallium–zinc oxide for low-power system-on-panel applications. Jpn J Appl Phys 52:094101

Yamazaki S (2014) Future possibility of C-Axis aligned crystalline oxide semiconductors comparison with low-temperature polysilicon. SID 2014 Digest, p 9

Yamazaki S, Suzawa H, Inoue K, Kato K, Hirohashi T, Okazaki K, Kimizuka N (2014a) Properties of crystalline In-G-Zn-oxide semiconductor and its transistor characteristics. Jpn J Appl Phys 53:04ED18

Yamazaki S, Atsumi T, Dairiki K, Okazaki K, Kimizuka N (2014b) In-Ga-Zn-Oxide semiconductor and its transistor characteristics. ECS J Sol State Sci Technol 3:Q3012–Q3022

Yoon J-S, Hong S-J, Kim J-H, Kim D-H, Tani R, Nam W-J, Song B-C, Kim J-M, Kim P-Y, Park K-H, Oh C-H, Ahn B-C (2014) 55-inch OLED TV using optimal driving method for large-size panel based on InGaZnO TFTs. SID 2014 Digest, p 849

Yu G, Shieh C-L, Musolf J, Foong F, Xiao T, Wang G, Ottosson K, Chen Z, Chang F, Yu C, Park J-W (2014) MOTFT backpanel for 880 ppi white and 440 ppi, true full-color AMOLED. SID 2014 Digest, p 267

Zhang H-j, Su C-Y, Li W-H, Shi L-Q, Lv X-W, Hu Y-t, Tseng C-Y, Wang Y-F, Lo C-C (2014) A 31-in. FHD AMOLED TV driven by amorphous IGZO TFTs. In: Proceedings of the IDW’14, p 263

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

From the MOSFET, the TFT was born. The TFT varies from standard MOSFETs, or bulk MOSFETs, because, as the name implies, it uses thin films. The TFT began a new era of electronics. In 1968, just six years after the first TFT development, Bernard J. Lechner of RCA shared his idea of the TFT Liquid Crystal Display (LCD), something that would boom in popularity in our modern times. The TFT LCD was then first created in 1973 at the Westinghouse Research Laboratories. These LCDs were composed of pixels controlled by transistors. In FETs, substrates were just the semiconductor material, but in manufacturing TFT LCDs, glass substrates were used so that the pixels could be displayed.

But that was not the end of TFT developments. Soon after, in 1974, T. Peter Brody, one of the developers of the TFT LCD, and Fang-Chen Luo created the first active-matrix LCD (AM LCD). An active matrix controls each pixel individually, meaning that each pixel’s respective TFT had its signal actively preserved. This opened doors to better performance and speed as displays became more complex.

Though TFTs can use a variety of materials for their semiconductor layers, silicon has become the most popular, creating the silicon-based TFT, abbreviated as Si TFT. As a semiconductor device, the TFT, as well as all FETs, use solid-state electronics, meaning that electricity flows through the structure of the semiconductor layer rather than vacuum tubes.

Due to the variety in silicon’s possible structures, the Si TFT’s characteristics can vary as well. The most common form is amorphous silicon (A-Si), which is deposited during the first step of the semiconductor fabrication process onto the substrate in low temperatures. It is most usable when hydrogenated into the form A-Si:H. This then significantly alters the properties of A-Si; without the hydrogen, the material struggles with doping (the introduction of impurities to increase mobility of charges); in the form A-Si:H, however, the semiconductor layer becomes much more photoconductive and dopable. The A-Si:H TFT was first developed in 1979 which is stable at room temperature and became the best option for AM LCDs which consequently began rising in popularity after this breakthrough.

The biggest difference between these forms, notably A-Si and poly-Si, is that charge carriers are much more mobile and the material is much more stable when it comes to using poly-Si over A-Si. When creating complicated and high-speed TFT-based displays, poly-Si’s characteristics allow for this. Yet, A-Si is still very important due to its low-leakage nature, meaning that leakage current is not lost as heavily when a dielectric insulator is not totally non-conductive.

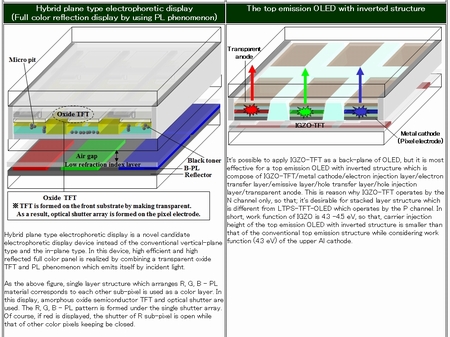

Several years later, another development was made in 2012 in the form of indium gallium zinc oxide (IGZO) which allowed for a more powerful display in terms of refresh rates and more efficiency in terms of power consumption. This semiconducting material, as stated in the name, uses indium, gallium, zinc, and oxygen. Though it is a form of zinc oxide (ZnO), the addition of indium and gallium allows this material to be deposited in a uniform amorphous phase but also maintaining the oxide’s high carrier mobility.

As TFTs began to increase their presence in display technology, transparent semiconductors and electrodes became more appealing to the manufacturers. Indium tin oxide (ITO) is an example of a popular transparent oxide used for its appearance, good conductivity, and ease of deposition.

Research of the TFT with different materials has led to the application of threshold voltage, or how much voltage is needed to turn on the device. This value is greatly dependent on thickness and choice of the oxide. When it comes to the oxide, this relates back to the idea of leakage current. With thinner layers and certain types of oxide, the leakage current may be greater, but this in turn could lower threshold voltage, as leakage into the device will also increase. In order to tap into the TFT’s potential for low power consumption, the lower the threshold voltage, the better the device’s appeal.

Another branch of development that stemmed from the TFT is that of organic TFTs (OTFT). First created in 1986, OTFTs usually use solution-casting of polymers, or macromolecules. This device made people hesitant, as it tended to have a slow carrier mobility, meaning slow response times. However, researchers have carried out experimentation with the OTFT because it has potential to be applied to displays different from those that traditional TFTs are used for, such as flexible, plastic displays. This research still continues today. With its simpler processing than traditional silicon technology, the OTFT holds much potential for modern day and future technologies.

(6 November, 2017) – Oxide thin-film transistor (TFT) liquid crystal display (LCD) panels are increasingly adopted in mobile PCs due to their feature of high resolution while consuming low power. Global shipments of large oxide TFT LCD panels of 9 inches or larger are expected to grow from 20 million units in 2016 to 55.6 million units in 2017, according to new analysis from

. “Apple’ and Microsoft’s use of oxide TFT LCD panels for products – iPad, iPad Pro, and Surface, respectively – helped increase the oxide mobile PC panel market and encouraged other PC brands to follow suit.”

Low-temperature polysilicon (LTPS) and oxide TFT LCD solutions are major candidates for displaying high-resolution images, and they are expected to account for more than 19 percent of the entire mobile PC display market in 2017, according to the

While LTPS can deliver higher resolution images and consume less power than oxide TFT LCD or a-Si TFT LCD, it has its own limits: its production cost is high and the yield rate is low. In addition, it is less efficient to produce large panels. Albeit not as high resolution as LTPS, oxide TFT LCD panels still display high-resolution images better than the a-Si solution, and they are suitable to produce large panels at lower production cost than LTPS.

LG Display and Sharp have expanded their oxide mobile PC panel shipments aggressively by 180 percent and 370 percent, respectively. CEC Panda in China is estimated to increase its shipments from about 600,000 units in 2016 to 4.2 million in 2017. As some oxide panel suppliers are reducing their focus on the mobile PC display business, display makers in China and Taiwan, such as BOE and Innolux, are expected to produce more oxide panels in future, IHS Markit said.

Figure 98: China Export and Import Value & Volume, 2018-2019 ($)Metal Oxide (MO)-TFT Backplanes Market China Export and Import Value & Volume, 2018-2019 ($)

The most common semiconducting layer is made of amorphous silicon (a-Si). a-Si thin film transistor - liquid crystal display (TFT-LCD) has been the dominant technology for the manufacturing of active matrix TFT-LCD for over 20 years. a-Si is a low cost material in abundant supply.

a-Si is a low cost material in abundant supply. However, the electron mobility of a-Si is very low (around 1cm2/Vs) and can’t physically support high refresh rates such as the 240Hz needed for HDTV. Due to their high electron mobility, new materials such as metal oxide (MO) and low temperature polysilicon (LTPS) are now replacing a-Si to manufacture the industry’s two main types of screens: LCD and organic light-emitting diode (OLED) displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey