lcd panel manufacturing in india made in china

Searching for the best TFT LCD module manufacturers in India? Well, that is admittedly a daunting task. With the growing number of TFT LCD display suppliers and manufacturers, it’s truly hard to pick which ones are reputable and which ones are not.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and a consumer’s mindset.

Hence, we’ve rounded up 7 famous and reputable Indian LCD module manufacturers. These companies all produce quality display and screen-related products such as:

Videocon Industries Ltd is a well-known Indian manufacturer of TFT display modules, color TVs, home appliances, and consumer electronics. Videocon is a large company based in Mumbai, India.

Videocon has several manufacturing plants across different countries. It also boasts of several brands under its name, including Videocon Telecom, DigiWorld, Next, and Planet M.

The company takes pride in being India’s pioneer in color TV production and retail. Before the advent of the TFT display module, Videocon has been the world’s third-largest picture tube (CRT) manufacturer.

Videocon is popular for its high-quality products. Videocon manufactures an LCD display screen for LCD TV sets. A lot of Indians trust Videocon’s television sets.

Videocon assembles and manufactures their TFT LCD module products in world-class factories. The company’s main factories are in India. However, they also have manufacturing plants in Mainland China, Mexico, Poland, and Italy.

All of Videocon’s TFT LCD display products passed strict quality control checks. Testing is done throughout the entire manufacturing and assembly process. Furthermore, quality checks are done from the raw materials phase until the products’ release.

Videocon’s TFT display screens and TVs are affordable of good quality. The company knows how to manufacture quality TV sets at pocket-friendly prices since it is a pioneer in the Indian color TV industry.

Videocon’s mobile phone range is equipped with the latest touch LCD display technology. Smartphones are assembled in the company’s TFT touch screen factory. Hence, customers are ensured of high-performance mobile phones with a crisp touch screen LCD display.

To sum it up, Videocon Industries Limited is a strong TFT LCD display manufacturer. The company’s quality manufacturing plants, good end-products, and affordable prices make it among the famous TF LCD manufacturers in India.

Teronix is an Indian electronics company based in New Delhi. It specializes in TV sets with LED and LCD screen module technology. The company also offers a range of smart mobiles and power banks.

Teronix has been in the electronics industry since 2017. But the company has proven that it has what it takes to be a reputable LCD manufacturer in India. Teronix has risen to popularity among Indian consumers because of the following qualities:

The company’s products are all high-quality and durable. Teronix sees to it that its range of smart LCD and LED TVs, along with their other products, reach their customers in good condition, and perform at their best all the time.

Teronix knows that good quality LCD module and other electronic parts are the cores of high-performance products. Hence, their assembly and product research units are stocked with the latest technology to produce the best possible products. Furthermore, Teronix’s research and assembly hubs are strategically located in Delhi.

Special teams are assigned to run quality control tests for all of Teronix’s products. Tests are done before and after launch to ensure that their LED TV range and power banks are all working well with no defects. Also, Teronix has a minimum quality test duration of 3 years.

BPL Limited is a recognized Indian leader in health care equipment and consumer electronics. The Bangalore-based company operates business groups which include:

The company started manufacturing televisions and telecom equipment in the 1980s. BPL joined forces with Japanese company Sanyo in 2006 to strengthen BPL’s consumer electronics brand, including TF-LCD display products and color televisions. The joint venture ended in 2007, leaving BPL to focus on its healthcare equipment sector.

1. BPL takes pride in its superior-quality television sets. The TVs are made with combinations of TFT-LCD display and LED output. The products are manufactured by third-party TFT LCD suppliers. Then, the TV parts are assembled at a plant in Baddi, Himachal Pradesh.

2. BPL also takes the lead when it comes to medical display equipment. BPL uses different combinations of TFT display, VGA output, LED, and touch LCD display to manufacture the following devices:

3. The company upholds strict quality standards in all TFT LCD display products. This is achieved through quality tests at all stages of production and assembly. Even the third-party suppliers providing the raw materials for TFT-LCD modules are required to run through tests to ensure quality.

4. BPL is known to create innovative products ever since its heydays. This continues up to now, as BPL strives to improve market research to manufacture better televisions, consumer electronics, and healthcare equipment.

In a nutshell, BPL continues to be an industry leader in India’s consumer electronics and medical equipment industries. BPL provides households and health facilities with top-notch TFT-LCD display module sets used in televisions and health monitoring equipment. And in recent years, BPL has clearly shown no signs of slowing down.

Dixon Technologies Limited is a long-standing company providing consumer electronics, LED and LCD TVs, light fixtures, appliances, mobile phones, and CCTV systems. The company was founded in 1993 with its current headquarters in New Delhi and Uttar Pradesh.

Dixon’s creed is providing consumers with world-class products at affordable prices. Consequently, the company is among the top TFT LCD manufacturers in India because:

Dixon is proud to create its products in local factories. For instance, the company has an LCD display module factoryin Tirupati, Andhra Pradesh. Furthermore, the company also operates three facilities in Uttarakhand and three more in Noida, Uttar Pradesh.

Dixon is an Original Design Manufacturer (ODM) company. This means that the company takes its designs from its Research and Development Center. Eventually, Dixon turns them into original products that stand out on the market.

Reasonable prices also make Dixon’s LCD module products and TVs appealing to the public. Couple that with features that are on par with the world’s best TV sets. Dixon believes that quality shouldn’t be sacrificed at the expense of affordability.

In conclusion, Dixon Technologies (India) Limited is among India’s famous TFT LCD manufacturers simply because it provides original, feature-packed, high-quality, and pocket-friendly products to both tech companies and end-consumers.

Oriole Electronics is an electronics company based in Mumbai. It was established in 1972 and is among the famous long-standing TFT LCD manufacturers in India.

Oriole is an Original Equipment Manufacturer (OEM). Hence, the company produces high-quality products marketed under its name. However, product parts and components are sourced from reputable third-party suppliers.

Oriole’s strongest quality lies in its extensive experience in the TFT LCD and electronics industry. The company’s experience puts them at an edge against many younger industry competitors. All these thanks to several insights and expertise the company collected since 1972.

Furthermore, Oriole is dedicated to meeting its client’s needs as much as it can. The company partners with its customers throughout the product cycle, making sure that client inputs are incorporated into the products’ final design and functionality. This type of customer partnership uniquely reflects Oriole’s commitment to creating products that truly meet its customers’ various needs.

Another Oriole advantage is its in-house Research and Development team. Oriole’s R&D team conceptualizes products for its customers. They also formulate quality control guidelines that are strictly implemented during the production and testing phases. All these things are done to ensure the highest quality of Oriole’s TFT, LCD modules, and other product ranges.

Speaking of quality, Oriole is also ISO 9001:2008 certified. This credential ultimately proves the company’s utmost dedication to quality processes. Also, this ensures consistent operations of Oriole’s TFT LCD display factory network throughout India.

To wrap it all up, Oriole Electronics is indeed a quality display module manufacturer in India. Superior quality products, customized services, and affordable rates – all of these are testaments to Oriole’s good reputation.

RandServ proudly provides and even encourages custom manufacturing services. The company responds to unique client needs by creating LCD display modules and designs according to customer requirements. RandServ lets clients specify custom shapes, display sizes, and interactive touch support integration.

Another good point of RandServ is its superior-quality product range. The company may be new to the industry, but its products are made with world-class technology and attention to detail. RandServ’s electronic, TFT, LCD, and LED technologies make their end-products among the most long-lasting and robust electronic/digital products in the Indian market today.

Businesses across several industries tend to neglect ethical business practices. But not RandServ. The company takes pride in its clean business practices and integrity. Commitment to ethical standards enabled RandServ to steadily grow as a reputable LCD screen manufacturer.

In conclusion, RandServ Systems deserves a spot in our 7 famous TFT LCD manufacturers list mainly because of three things – cutting-edge LCD and digital products, customized client services, and high regard for ethical business practices.

Royal Display India is a reputable TFT display supplier and manufacturer based in Mumbai. Royal Display is relatively new, being in the business since 2003. But the company didn’t let their newness stop them from growing into a successful LCD display supplier and manufacturer.

A major factor that Royal Display holds in regard is value for money. The company keeps this in mind when creating and supplying display modules to their clients. Furthermore, Royal Display firmly believes that people need not shell out several bucks to get world-class quality products.

Another considerable advantage of Royal Display is its spacious manufacturing and warehousing units. Both are located in Maharashtra. The manufacturing unit boasts of specialized techniques used to produce modules for TFT, LCD, and OLED. Meanwhile, the warehouse unit is large enough to accommodate bulk orders from clients.

To wind this up, Royal Display is a young yet quality manufacturer for LCD modules and other related display screens in India. The company continues to grow with its plethora of quality display products coupled with many satisfied clients.

To conclude, Teronix is a young but reputable and promising LCD manufacturer in India. Lots of satisfied customers flock to them because of their dedication to high-quality products and top-notch manufacturing technologies.

To conclude this post, we’ve rounded up 7 Famous TFT LCD Manufacturers in India. Some of them are industry pioneers, while some are novices. However, we’re sure all these reputable companies will be a good source of products for all your display module needs.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

A few India-based enterprises have decided or plan to set up display panel plants in India, but this is unlikely to have substantially impact on the existing global display supply chain in the foreseeable future, as the total panel production capacity in India will be much smaller than that in China, South Korea, Taiwan and Japan.

Under the Indian government"s Production Linked Incentive (PLI) scheme, Elest, a subsidiary of India-based Rajesh Exports - which is among the globally top-500 enterprises - will invest INR240 billion (US$3.01 billion) to set up a 6G AMOLED plant in Telangana State, central India, to produce smartphone, tablet and notebook applications.

The plant will introduce AMOLED technology from advanced R&D centers around the world and create about 3,000 jobs, Rajesh said. But Rajesh did not disclose information on technological cooperation.

India-based oil, gas and metal producer Vedanta has acquired Japan-based LCD glass substrate maker AvanStrate and applied to the India government for setting up a 8.6G TFT-LCD plant in India. Vedanta in February 2022 signed an MoU with Taiwan-based Foxconn Electronics to establish a joint-venture maker of semiconductors. As Taiwan-based LCD panel maker Innolux is AvanStrate"s client and has a 8.6G LCD plant in southern Taiwan, Vedanta could cooperate with Innolux via AvanStrate.

With subsidies under India government"s PLI scheme and UP Electronics Manufacturing Policy 2017 set by the state government of Uttar Pradesh, northern India, Samsung Display (SDC) invested US$654 million to set up a panel module factory in the state and started production in April 2021.

Samsung Electronics, SDC"s parent company, has cumulatively invested over US$1.1 billion in India and has been shifting production lines from China and Vietnam to India. The company has set up two large production bases and five R&D bases in India.

According to DIGITIMES Research, Samsung Electronics" factories in India produced about 60 million smartphones in 2021 and are expected to produce 93 million in 2022 and 108 million in 2026, with the proportion of total smartphone output from India to rise from 20% in 2020 to 29% in 2026.

Although Samsung is expanding its production in India, clustering and production of its South Korea-based supply chain makers in India are currently much smaller than those in Vietnam.

China-based panel maker China Star Optoelectronics Technology (CSOT) has invested INR18.3 billion to set up a factory to produce 5- to 65-inch LCD modules in Andhra Pradseh, southeastern India. With annual production capacity of 8.0 million LCD modules, the factory is intended to mainly support TCL, CSOT"s parent company, to sell LCD TVs in the India market. TCL expects to sell 10 million LCD TVs for a market share of 7% in India in 2022. TCL currently ranks fourth in the India TV market and aims to surpass Sony, ranking third with a market share of 12% at present, by the end of 2022.

Taiwan-based LCD panel maker AU Optronics (AUO) has evaluated the feasibility of investing in India. There are problems concerning culture and government efficiency in India, AUO chairman Paul Peng has said.

Some cities in India are ambitious to create manufacturing hubs through developing industrial districts of which some have development potential and are likely to replace some locations in China, Peng noted. However, India is impossible to completely replace China in terms of investment in manufacturing, Peng indicated.

Besides, infrastructure in India and Vietnam is insufficient and, in the case of Vietnam, surging investment has sharply shored up factory land prices and this will affect foreign enterprises" willingness to invest, Peng said. In fact, it is very difficult for Thailand, Indonesia and even Taiwan to completely replace China in manufacturing, Peng noted.

Supply chains are indeed gradually shifting from concentrated production in a few places to distributed production in multiple locations, Peng indicated, adding that distributed production carries risks such as more complicated management for supply chains and increases in production cost.

There are many factors that need to be considered in setting up overseas factories, including ecosystem support, infrastructure and local talent, Peng said. India is not ideal in terms of these three factors, and exiting panel makers are quite unlikely to set up panel lines in India for the time being, Peng noted.

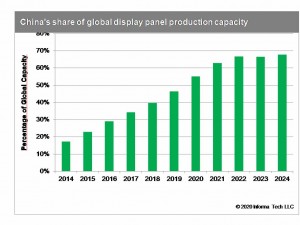

China-based panel makers had kept expanding production capacities for nearly 10 years and, as a result they together occupied over 60% of global production capacity for LCD panels as of 2021, followed by Taiwanese makers with 20%, South Korean ones with 10% and Japanese ones with 6%.

Since major Chinese makers are still expanding LCD panel production capacities, China"s combined share of global total will reach 70% in the mid- to long-term.

In view of diminishing competitiveness in LCD, SDC terminated LCD panel production in June 2022 and has shifted focus to AMOLED. Taiwanese LCD panel makers are expected to benefit from SDC"s exit but are still far less competitive against Chinese fellow makers in production capacity. Therefore, they have chosen not to expand production capacities and have focused on high value-added LCD panels.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Display Manufacturing Companies In India, Lcd Touch Screen Panel, Display With Touch Screen, Lcd Panel And Controller,Square Tft Lcd Display Panel. We will make greater efforts to help domestic and international buyers, and create the mutual benefit and win-win partnership between us. we are eagerly waiting for your sincerely cooperation. The product will supply to all over the world, such as Europe, America, Australia,Georgia, Montreal,Plymouth, Mexico.We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

MUMBAI: Vedanta Group"s owner Anil Agarwal is setting up the country’s first LCD panel manufacturing plant in Maharashtra with an investment of $10 billion ( Rs 68,000 crore).

The investment is through a new company called Twinstar Display Technologies, which is promoted by holding company Volcano Investments, chairman Agarwal said in an exclusive interview with ET. The metals tycoon is set to sign a memorandum of understanding with Maharashtra government on the first day of "Make in India" week.

"All over the world you see Made in China electronics, but India can also manufacture its own electronics," Agarwal said. "We worked with the government and agreed this project has to be aMade in India product." Agarwal said the company will endeavour to make India a significant export hub of display units with the setting up of the unit, known as Panel FAB. India’s LCD market is entirely import-dependent.

The plant will be set up in Pune or Nagpur. Although Twinstar Display is an independent company, it is being monitored by Vedanta"s technology arm, Sterlite Technologies, till the time a full-fledged team takes over in the new company. The final structure of the company will be decided at a later date.

Twinstar Display may look for an international strategic partner or collaborate on technology with companies abroad, Agarwal said. "This is the time to strike. This is the time to build your capacity because it will be cheaper.

This is the time when people and talent are available," he said. The project is being set up under Maharashtra’s new policy on fabrication units that aims to boost domestic manufacturing of electronics and reduce import bill.

The Central Bureau of Investigation cited two instances of "quid pro quo" while seeking the custody of former ICICI Bank chief Chanda Kochhar and her husband, who were arrested on Friday in a corruption case.

The Centre"s subsidy bill is expected to fall in the next fiscal year even after making foodgrain free for the poor as the additional allocation under the Covid-19 relief scheme will end in December this year.

The Department of Telecommunications (DoT) is not in favour of reserving spectrum in the mid-band for captive private networks as suggested by the Telecom Regulatory Authority of India (Trai), dealing a possible setback to firms such as Infosys, GMR and Tata Communications.

Stay on top of technology and startup news that matters. Subscribe to our daily newsletter for the latest and must-read tech news, delivered straight to your inbox....moreless

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

In Topway, we work side by side to help you overcome any technical and none technical challenges that may arise during product design, manufacture or installation. We can even take care of component sourcing and manufacturing for you.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

2015, sold to giantplus and tce photomasks, gen 3 still operated by giantplus, gen 4 line sold to giantplus, equipment sold and line demolished, remainder operated by tce

Cantwell, John; Hayashi, Takabumi (January 4, 2019). Paradigm Shift in Technologies and Innovation Systems. Springer Nature. ISBN 9789813293502 – via Google Books.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

The delegation said that owing to the better industrial environment and investor-friendly policies, Samsung decided to establish the Display Manufacturing Unit, which was located in China, in Noida, and the work of establishing it has been completed, an official release said.

During the meeting with the delegation, the chief minister said that Samsung"s Noida factory is a classic example of success of the "Make in India" programme, and added that this will help the youth of the state to get employment in the state.

Electronics major Samsung has completed the construction of the display manufacturing unit that is shifted from China to Noida in Uttar Pradesh, a release said on Sunday.

A delegation of electronics major Samsung led by the company"s Southwest Asia President & CEO Ken Kang called upon Uttar Pradesh Chief Minister Yogi Adityanath on Sunday.

The delegation said that owing to the better industrial environment and investor-friendly policies, Samsung decided to establish the Display Manufacturing Unit, which was located in China, in Noida, and the work of establishing it has been completed, an official release said.

During the meeting with the delegation, the chief minister said that Samsung"s Noida factory is a classic example of success of the "Make in India" programme, and added that this will help the youth of the state to get employment in the state.

MUMBAI: Vedanta Group"s owner Anil Agarwal is setting up the country’s first LCD panel manufacturing plant in Maharashtra with an investment of $10 billion ( Rs 68,000 crore).

The investment is through a new company called Twinstar Display Technologies, which is promoted by holding company Volcano Investments, chairman Agarwal said in an exclusive interview with ET. The metals tycoon is set to sign a memorandum of understanding with Maharashtra government on the first day of "Make in India" week.

"All over the world you see Made in China electronics, but India can also manufacture its own electronics," Agarwal said. "We worked with the government and agreed this project has to be aMade in India product." Agarwal said the company will endeavour to make India a significant export hub of display units with the setting up of the unit, known as Panel FAB. India’s LCD market is entirely import-dependent.

The plant will be set up in Pune or Nagpur. Although Twinstar Display is an independent company, it is being monitored by Vedanta"s technology arm, Sterlite Technologies, till the time a full-fledged team takes over in the new company. The final structure of the company will be decided at a later date.

Twinstar Display may look for an international strategic partner or collaborate on technology with companies abroad, Agarwal said. "This is the time to strike. This is the time to build your capacity because it will be cheaper.

This is the time when people and talent are available," he said. The project is being set up under Maharashtra’s new policy on fabrication units that aims to boost domestic manufacturing of electronics and reduce import bill.

The Central Bureau of Investigation cited two instances of "quid pro quo" while seeking the custody of former ICICI Bank chief Chanda Kochhar and her husband, who were arrested on Friday in a corruption case.

The Centre"s subsidy bill is expected to fall in the next fiscal year even after making foodgrain free for the poor as the additional allocation under the Covid-19 relief scheme will end in December this year.

The Department of Telecommunications (DoT) is not in favour of reserving spectrum in the mid-band for captive private networks as suggested by the Telecom Regulatory Authority of India (Trai), dealing a possible setback to firms such as Infosys, GMR and Tata Communications.

Stay on top of technology and startup news that matters. Subscribe to our daily newsletter for the latest and must-read tech news, delivered straight to your inbox....moreless

South Korean electronics giant has finally moved its display manufacturing unit from China to Noida, Uttar Pradesh as construction for the new factory is completed. According to a PTI Report, Samsung decided to move its display manufacturing facility due to more investor-friendly policies and a better industrial environment.

Samsung already operates the world’s biggest smartphone manufacturing plant in Noida which was opened in 2020. Now, the company is looking to combine the supply chain by moving its display manufacturing unit from China. This particular factory may manufacture displays for smartphones, TVs and monitors.

The new plant by Samsung will further the Indian Government’s ‘Make in India’ programme and will also generate more jobs for the state and make Uttar Pradesh a manufacturing hub. Uttar Pradesh chief minister Yogi Adityanath met a Samsung delegation on Sunday and assured all help needed in carrying out business activities in the state. Samsung’s delegation was led by CEO Ken Kang (India and South-West Asia) who met with the chief minister and brought him up to speed on the company’s business activities in the state.

In an official release by the state government, Adityanath said investors and companies of the country and from abroad were enthusiastic about setting up manufacturing units and industries in the state. The Samsung delegation also appreciated the state government’s decision to allow nosiness activity during the COVID-19 lockdown.

It is worth noting that even though Samsung is a part of the mobile production linked incentive (PLI) scheme, the company is currently not participating in the scheme for the telecom sector. The company is not interested in the telecom PLC scheme at the moment as it already has enough telecom equipment manufacturing plants in South Korea, Vietnam and China.

Samsung is currently helping Reliance Jio conduct its 5G trials in the country and since the company also works with one telecom operator, the company believes it has enough capacity to comfortably manufacture equipment Jio will require for its network rollout operations.

China is home to various TFT LCD panel manufacturers, all offering exceptional services and high-end products. China remains one of the top sources for TFT LCD panel manufacturing, as they have been producing some of the best quality panels available on the market. Many Chinese technology companies specialize in providing these superior TFT LCDs, and several of them have even managed to make it into the top ten list of China"s leading TFT LCD panel producers. These companies are known for their efficient service, impressive product lineup, reliability, innovative approach to design, and customer service excellence. If you are looking for an excellent China-based supplier for TFT LCD panels, it would be wise to consider one of these top 10 China TFT LCD manufacturers.

China is a leading producer of TFT LCD panels, with industry leaders such as BOE Technology Group Co., Ltd. (BOE) at the forefront of innovation. Founded in 1993, BOE has developed a comprehensive business structure featuring port products and services for information exchange as well as healthcare solutions like its revolutionary MLED technology. In 2021, BOE boasted an impressive 70,000 independent patent applications, and more than 90% of its new patent applications are for invention patents. Additionally, over 35% of those inventions" patents can be found overseas in the United States, Europe, Japan, South Korea, and other countries. China"s TFT LCD panel manufacturers continue developing their technology by innovating on existing models such as LCD screens and LCD panels to provide better solutions for customers worldwide.

China-based Tianma is a highly reputable TFT LCD panel manufacturer with over 30 years of expertise in the display solutions industry. Since 1983, the company has grown to become a trusted China TFT LCD panel provider, and in 1995, it obtained a public listing on China"s Shenzhen Stock Exchange. With tech and production capabilities at the top of their game, Tianma specializes in SLT-LCD, LTPS TFT-LCD, AMOLED, In-cell/On-cell integrated touch technology, Flexible Displays, Force Touch TED Plus, fingerprint recognition under/on-screen and Mini/Micro LED segments. They have set the benchmark for future innovative developments in terms of LCD panels, LCD screens, and more. Offering unbeatable support services around the globe that are coupled with advanced technology makes Tianma a forerunner for China TFT LCD panel manufacturers.

China"s IVO is one of the top 10 China TFT LCD panel manufacturers and has been making a name for itself since 2005. From its Kunsan Jiangsu base, it now employs more than 3000 staff, including 400 dedicated R&D employees. IVO also boasts a G-5 TFT panel production line, and its products are used in a variety of cutting-edge applications: 60% for notebook displays, 23% for smartphones, and 11% for automotive uses. This makes it an important player in the China TFT LCD market as well as gaining great recognition worldwide in the notebook display industry.

With China being one of the leading suppliers in the global TFT LCD market, 4th in the top 10 manufacturers is TCL CSOT. This China TFT LCD panel manufacturer has been expanding its production capacity with continuous developments in technology and gaining a more solid global presence. According to the latest TV shipment stats, China"s CSOT has ranked 3rd in the world for producing TVs and 1st for supplying domestic 6 major brands since 2014. Furthermore, it holds strong places on the world scale when it comes to 55-inch UD product shipments (1st worldwide) and 32-inch UD product shipments (2nd). G6 LTPS-LCD production line is also amongst its highly lauded products, boasting second place in small and medium sizes with the most accelerated growth rate. Focused on independent innovation-driven development, TCLCSOT reinforces its position as China"s leader in TFT LCD screen technology by accumulating 12185 patent applications since 2019.

China"s TFT LCD panel manufacturer, Truly Semiconductor Co., Ltd., was established in 1991 and dedicated to TN-LCD production and became the first China-based CSTN/LCD line producer in 1995. In 2003 they obtained the OLED patents from Kodak, followed by mass production of TFT-LCD modules in 2012 and breakthrough technology in mobile 3D displays. Their 2013 production launch of naked-eye 3D displays for phones and tablet computers solidified their position as China"s top 10 TFT LCD manufacturers. To expand its portfolio further, it invested in Truly (Huizhou) Smart Display Co., Ltd., which specializes in G4.5 AMOLED and TFT displays. Truly sets an example for China"s other TFT LCD panel manufacturers through its sustained 25 years of research and development, innovation, and brand recognition.

Foxconn Technology Group founded China’s TFT LCD panel manufacturing company, Innolux, in 2003. With its headquarters and factory located in Longhua Foxconn Technology Park in Shenzhen and over 14 production bases situated across China like Nanjing, Ningbo and Foshan, Innolux is known for its comprehensive vertical integration that enables cutting-edge display technology research and development. The high quality and reliability of TFT LCD panels manufactured by Innolux have made them available to be used by some of the major global electronics giants like Apple, Lenovo, Hewlett-Packard Panda, Nokia, and Motorola. Furthermore, its amalgamation with Chi Mei Electronics and Tong Bao Optoelectronics in March 2010 has led to a significant improvement in the level of the world plane display industry.

Founded in 2001, China"s top 3 TFT LCD panel manufacturer HKC has come a long way since its inception. The company designs, manufactures, and markets a full range of TFT LCDs from 1 inch to 60 inches with an annual sales amount reaching up to half a billion USD. As it looks for global expansion opportunities, HKC has established branch companies in Russia and India and formed strategic relationships with customers worldwide. In 2010, the China-based firm moved into a new industrial park and is now capable of producing 1 million displays per month. Thanks to advanced technologies and excellent quality control standards, HKC has been praised by its customers both at home and abroad and continues to prove itself as a reliable China TFT LCD panel manufacturer.

Panda is one of China"s top 10 TFT LCD manufacturers, utilizing cutting-edge technology from China Electronics (CEC) to offer a wide range of products such as crystal resonators, thermal-sensitive crystals, ordinary oscillators, voltage-controlled oscillators, and temperature-compensated oscillators. These are used in various applications of TFT LCD screens that can be found in products like LCD TVs, monitors, and laptops. Panda studies customers" requirements with utmost care and provides reliable services and quality products. With the help of its diverse pricing strategy, it assists its clients in finding value for their money across global markets.

China has a flourishing automotive technology industry, and Eagle Tech is one of China"s top ten TFT LCD panel manufacturers. They understand the special requirements of their use environment, such as moisture-proof, dust-proof, anti-glare, high brightness, sun leakage resistance, and temperature resistance, in order to ensure the optimal performance of their displays. Having years of experience in providing Resistive touch screens, PCAP touch screens, and IPS panels make Eagle Tech the trusted electronic display manufacturer for automotive technologies to meet consumer expectations.

China is the leading source of TFT LCD panel manufacturers, and Eagle Tech has been making a name for itself as one of China"s top 10 TFT LCD manufacturers. Not only do they offer quality automotive TFT LCDs in sizes ranging from 3.5" to 21.5", but their products boast excellent durability as well; if you are looking for a reliable China TFT LCD provider that can deliver quality products for your applications, look no further than Eagle Tech.

TFT LCD manufacturing is an incredibly important part of the technology industry, and Century Technology (Shenzhen) Co., Ltd. (CTC) is one of China"s top 10 TFT LCD manufacturers. In addition, CTC invests in global optoelectronics industry personnel who specialize in TFT-LCD research and development, as well as manufacturing display panel products such as laptops, PCs, monitors, and LCD TVs. The production line project was installed during the eleventh five-year plan to position CTC at the forefront of TFT-LCD production lines for the Pearl River Delta region. Looking ahead to late 2008, this ambitious project will be put into action – it is sure to leave a lasting impact on the growth of TFT production globally.

China is the world"s largest producer and exporter of TFT LCD panels, making it a great resource for any company looking to purchase them. China is home to some of the world"s most respected TFT LCD manufacturers, with the top 10 China-based TFT LCD panel manufacturers providing displays that consistently exceed industry requirements. All ten have been commended for their amazing product designs, expertise, and quality standards. Collectively, these companies serve customers all over the world by producing panels that are reliable and high-performance – making China an important resource for businesses seeking out cost-effective TFT LCD panels.

China is quickly becoming the leader in TFT LCD technology. The top 10 China TFT LCD manufacturers are a testament to this, as they provide outstanding quality at competitive prices without sacrificing any of the standards that people have grown to expect from China"s expertise and craftsmanship.

It"s clear that China is fast becoming an unstoppable force when it comes to LCD panel production and innovative screen solutions. With its ability to make efficient panels for various applications, China is respected around the world for its skillful production of TFT LCD panels and screens. Additionally, with these reliable manufacturers trying to ensure maximum customer satisfaction with competitive pricing and high-quality products, China has become a trusted source of LCD screens worldwide.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Last week I had the opportunity to tour BOE Technology Group’s Gen 10.5 factory in Hefei, the capital of China’s Anhui Province.This was the third factory, or “fab” that Beijing-based BOE built in Hefei alone, and in terms of capability, it is now the most advanced in the world.BOE has a total of 12 fabs in Beijing, Chongqing, and several other major cities across China; this particular factory was named Fab 9.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

It obviously costs a lot to equip and run such a fab.Including all of the specialized production tools, press reports say BOE spent RMB 46 billion (US$6.95 billion). Even though you don’t see a lot of people on the floor, it takes thousands of engineers to keep the place running.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey