pls tft lcd display technology quotation

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

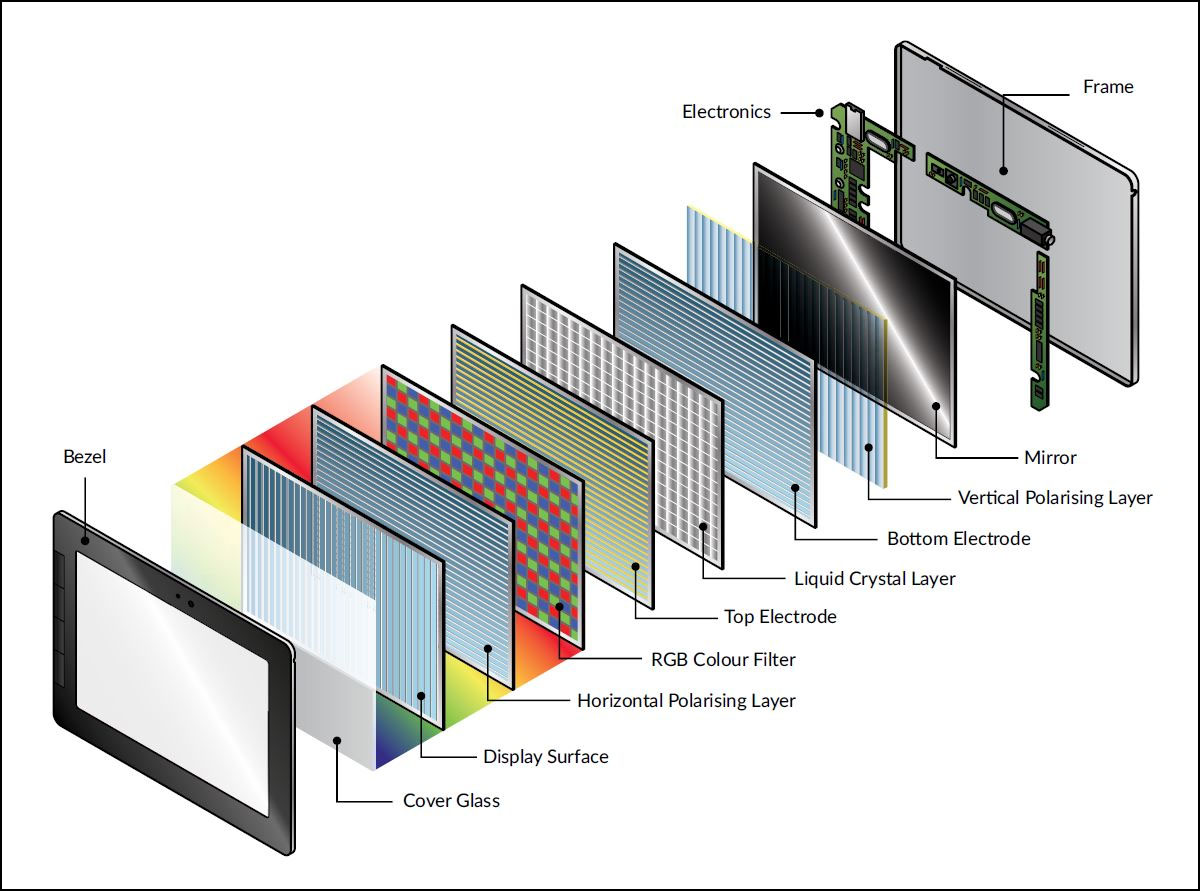

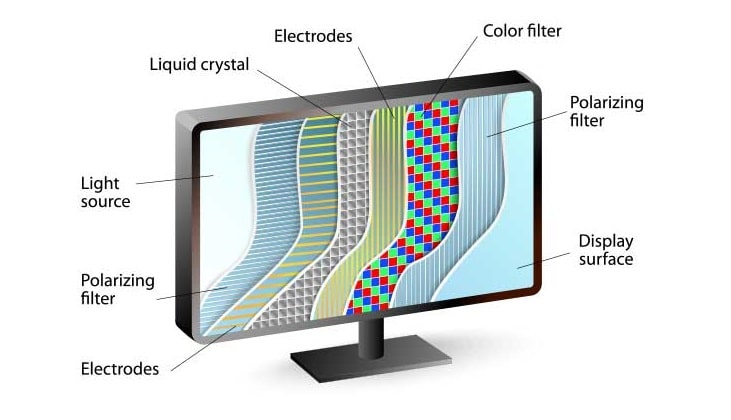

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

A wide variety of 50 inch tft lcd display options are available to you, You can also choose from original manufacturer, odm and agency 50 inch tft lcd display,As well as from tft, ips, and standard.

A wide variety of tft lcd display 4 options are available to you, You can also choose from original manufacturer, odm and agency tft lcd display 4,As well as from tft, ips, and standard.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

IPS (in-plane switching) is a screen technology for liquid-crystal displays (LCDs). In IPS, a layer of liquid crystals is sandwiched between two glass surfaces. The liquid crystal molecules are aligned parallel to those surfaces in predetermined directions (in-plane). The molecules are reoriented by an applied electric field, whilst remaining essentially parallel to the surfaces to produce an image. It was designed to solve the strong viewing angle dependence and low-quality color reproduction of the twisted nematic field effect (TN) matrix LCDs prevalent in the late 1980s.

The TN method was the only viable technology for active matrix TFT LCDs in the late 1980s and early 1990s. Early panels showed grayscale inversion from up to down,Vertical Alignment (VA)—that could resolve these weaknesses and were applied to large computer monitor panels.

Shortly thereafter, Hitachi of Japan filed patents to improve this technology. A leader in this field was Katsumi Kondo, who worked at the Hitachi Research Center.thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.Super IPS). NEC and Hitachi became early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and in-plane switching subsequently remain the dominant LCD designs through 2006.

In this case, both linear polarizing filters P and A have their axes of transmission in the same direction. To obtain the 90 degree twisted nematic structure of the LC layer between the two glass plates without an applied electric field (OFF state), the inner surfaces of the glass plates are treated to align the bordering LC molecules at a right angle. This molecular structure is practically the same as in TN LCDs. However, the arrangement of the electrodes e1 and e2 is different. Because they are in the same plane and on a single glass plate, they generate an electric field essentially parallel to this plate. The diagram is not to scale: the LC layer is only a few micrometers thick and so is very small compared with the distance between the electrodes.

Toward the end of 2010 Samsung Electronics introduced Super PLS (Plane-to-Line Switching) with the intent of providing an alternative to the popular IPS technology which is primarily manufactured

Alibaba.com offers 1013 pls lcd display products. About 15% % of these are mobile phone lcds, 5%% are lcd modules, and 1%% are digital signage and displays.

A wide variety of pls lcd display options are available to you, You can also choose from original manufacturer, odm and agency pls lcd display,As well as from tft, standard pls lcd display.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

Take your product to the next level with a capacitive touch screen LCD by Displaytech. Our PCAP (projected capacitive) touch screen technology is a premium alternative to a resistive touchscreen. We offer capacitive touchscreens for our 2.8-inch, 3.5-inch, 4.3-inch, 5-inch and 7-inch TFT LCD displays.

Capacitive touch technology allows for an enhanced product user interface since it supports gestures and proximity sensing. Unlike resistive touch screens which rely on pressure, capacitive touch responds to an electric current and can handle multi-finger touch points. This means that capacitive touchscreens can be used with your bare finger and it supports gestures such as pinch-to-zoom or swipe.

One of the most important aspects of any display you can understand is the panel technology being used. Specifications alone won’t give you the full picture of a displays performance, and we all know that manufacturers can exaggerate specs on paper to suit their marketing. With an understanding of the panel technology being used you will get a feel for the overall performance characteristics of the display and how it should perform in real terms. Our extensive panel search database helps you identify the panel technology (and manufacturer and part number where known) of many screens in the market. This article which follows will help you understand what the different panel technologies can offer you. A lot of manufacturers now list the panel technology as well in their specs, something which wasn’t included a in the past.

TN Film panels are the mostly widely used in the desktop display market and have been for many years since LCD monitors became mainstream. Smaller sized screens (15″, 17″ and 19″) are almost exclusively limited to this technology in fact and it has also extended into larger screen sizes over the last 7 years or so, now being a popular choice in the 20 – 28″ bracket as well. The TN Film panels are made by many different manufacturers, with the big names all having a share in the market (Samsung, LG.Display, AU Optronics) and being backed up by the other companies including most notably Innolux and Chunghwa Picture Tubes (CPT). You may see different generations of TN Film being discussed, but over the years the performance characteristics have remained similar overall.

TN Film has always been so widely used because it is comparatively cheap to produce panels based on this technology. As such, manufacturers have been able to keep costs of their displays down by using these panels. This is also the primary reason for the technology to be introduced into the larger screen sizes, where the production costs allow manufacturers to drive down retail costs for their screens and compete for new end-users.

The other main reason for using TN Film is that it is fundamentally a responsive technology in terms of pixel latency, something which has always been a key consideration for LCD buyers. It has long been the choice for gaming screens and response times have long been, and still are today, the lowest out of all the technologies overall. Response times typically reach a limit of around 5ms at the ISO quoted black > white > black transition, and as low as 1ms across grey to grey transitions where Response Time Compensation (overdrive) is used. TN Film has also been incorporated into true 120Hz+ refresh rate desktop displays, pairing low response times with high refresh rates for even better moving picture and gaming experiences, improved frame rates and adding 3D stereoscopic content support. Modern 120Hz+ refresh rate screens normally also support NVIDIA 3D Vision 2 and their LightBoost system which brings about another advantage for gaming. You can use the LightBoost strobed backlight system in 2D gaming to greatly reduce the perceived motion blur which is a significant benefit. Some screens even include a native blur reduction mode instead of having to rely on LightBoost ‘hacks’, providing better support for strobing backlights and improving gaming experiences when it comes to perceived motion blur. As a result, TN Film is still the choice for gamer screens because of the low response times and 120Hz+ refresh rate support.

The main problem with TN Film technology is that viewing angles are pretty restrictive, especially vertically, and this is evident by a characteristic severe darkening of the image if you look at the screen from below. Contrast and colour tone shifts can be evident with even a slight movement off-centre, and this is perhaps the main drawback in modern TN Film panels. Some TN Film panels are better than others and there have been improvements over the years to some degree, but they are still far more restrictive with fields of view than other panel technologies. The commonly quoted 170/160 viewing angles are an unfair indication of the actual real-life performance really, especially when you consider the vertical contrast shifts. Where viewing angles are quoted by a manufacturer as 160/160 or 170/160 that is a clear sign that the panel technology will be TN Film incidentally.

Movie playback is often hampered by ‘noise’ and artifacts, especially where overdrive is used. Black depth was traditionally quite poor on TN Film matrices due to the crystal alignment, however, in recent years, black depth has improved somewhat and is generally very good on modern screens, often surpassing IPS based screens and able to commonly reach contrast ratios of ~1000:1. TN Film is normally only a true 6-bit colour panel technology, but is able to offer a 16.7 million colour depth thanks to dithering and Frame Rate Control methods (6-bit + FRC). Some true 8-bit panels have become available in recent years (2014 onwards) but given the decent implementation of FRC on other 6-bit+FRC panels, the real-life difference is not something to concern yourself with too much.

VA technology was first developed by Fujitsu in 1996. However the limited viewing angles were its main disadvantage, and so further investment focused on addressing this problem. It was eventually solved by dividing each pixel into domains which worked synchronously. This lead the birth of the following technologies:

MVA technology, was later developed by Fujitsu in 1998 as a compromise between TN Film and IPS technologies. On the one hand, MVA provided a full response time of 25 milliseconds (that was impossible at the time with IPS, and not easily achievable with TN), and on the other hand, MVA matrices had wide viewing angles of 160 – 170 degrees, and thus could better compete with IPS in that parameter. The viewing angles were also good in the vertical field (an area where TN panels suffer a great deal) as well as the horizontal field. MVA technology also provided high contrast ratios and good black depth, which IPS and TN Film couldn’t quite meet at the time.

In MVA panels, the crystals in the domains are oriented differently, so if one domain lets light pass through, the neighboring domain will have the crystals at an angle and will shutter the light (of course, save for the display of white color, in which case all the crystals are placed almost in parallel to the matrix plane).

While some improvements have been made, the color-reproduction properties of these modern MVA technologies can still be problematic in some situations. Such panels give you vivid and bright colors, but due to the peculiarities of the domain technology many subtle color tones (dark tones often) are lost when you are looking at the screen strictly perpendicularly. When you deflect your line of sight just a little, the colors are all there again. This is a characteristic “VA panel contrast shift” (sometimes referred to as ‘black crush’ due to the loss of detail in dark colours) and some users pick up on this and might find it distracting. Thus, MVA matrices are somewhere between IPS and TN technologies as concerns color rendering and viewing angles. On the one hand, they are better than TN matrices in this respect, but on the other hand the above-described shortcoming prevents them from challenging IPS matrices, especially for colour critical work.

AU Optronics have more recently (around 2005) been working on their latest generation of MVA panel technology, termed ‘Advanced Multi Domain Vertical Alignment’ (AMVA). This is still produced today although a lot of their focus has moved to the similarly named, and not to be confused AHVA (Advanced Hyper Viewing Angle, IPS-type) technology. Compared with older MVA generations, AMVA is designed to offer improved performance including reduced colour washout, and the aim to conquer the significant problem of colour distortion with traditional wide viewing angle technology. This technology creates more domains than conventional multi-domain vertical alignment (MVA) LCD’s and reduces the variation of transmittance in oblique angles. It helps improve colour washout and provides better image quality in oblique angles than conventional VA LCD’s. Also, it has been widely recognized worldwide that AMVA technology is one of the few ways to provide optimized image quality through multiple domains.

AMVA still has some limitations however in practice, still suffering from the off-centre contrast shift you see from VA matrices. Viewing angles are therefore not as wide as IPS technology and the technology is often dismissed for colour critical work as a result. As well as this off-centre contrast shift, the wide viewing angles often show more colour and contrast shift than competing IPS-type panels, although some recent AMVA panel generations have shown improvements here (see BenQ GW2760HS for instance with new “Color Shift-free” technology). Responsiveness is better than older MVA offerings certainly, but remains behind TN Film and IPS/PLS in practice. The Anti-Glare (AG) coating used on most panels is light, and sometimes even appears “semi glossy” and so does not produce a grainy image.

AUO developed a series of vertical-alignment (VA) technologies over the years. This is specifically for the TV market although a lot of the changes experienced through these generations applies to monitor panels as well over the years. Most recently, the company developed its AMVA5 technology not only to improve the contrast ratio, but also to enable a liquid crystal transmission improvement of 30% compared to AMVA1 in 2005. This was accomplished by effectively improving the LC disclination line using newly developed polymer-stabilized vertical-alignment (PSA) technology. PSA is a process used to improve cell transmittance, helping to improve brightness, contrast ratio and liquid crystal switching speeds.

We have included this technology in this section as it is a modern technology still produced by Sharp as opposed to the older generations of MVA discussed above. Sharp are not a major panel manufacturer in the desktop space, but during 2013 began to invest in new and interesting panels using their MVA technology. Of note is their 23.5″ sized MVA panel which was used in the Eizo Foris FG2421 display. This is the first MVA panel to offer a native 120Hz refresh rate, making it an attractive option for gamers. Response times had been boosted significantly on the most part, bringing this MVA technology in line with modern IPS-type panels when it comes to pixel latency. The 120Hz support finally allowed for improved frame rates and motion smoothness from VA technology, helping to rival the wide range of 120Hz+ TN Film panels on the market.

Of particular note also are the excellent contrast ratios of this technology, reaching up to an excellent 5000:1 in practice, not just on paper. Viewing angles are certainly better than TN Film and so overall these MVA panels can offer an attractive all-round option for gaming, without some of the draw-backs of the TN Film panels. Viewing angles are not as wide as IPS panel types and there is still some noticeable gamma shift at wider angles, and the characteristic VA off-centre contrast shift still exists.

PVA was developed by Samsung as an alternative to MVA in the late 1990’s. The parameters and the development methods for PVA and MVA are so different that PVA can be truly regarded as an independent technology, although it is still a ‘Vertical Alignment’ technology type and has many similar characteristics. PVA is a Samsung only technology.

The liquid crystals in a PVA matrix have the same structure as in a MVA matrix – domains with varying orientation of the crystals allow keeping the same color, almost irrespective of the user’s line of sight and viewing angle. Viewing angles are not perfect though, as like with MVA matrices when you are looking straight at the screen, the matrix “loses” some shades, which return after you deflect your line of sight from the perpendicular a little. This ‘off-centre’ contrast shift, or ‘black crush’ as it is sometimes called is the reason why some colour enthusiasts prefer IPS-type displays. The overall viewing angles are also not as wide as IPS-type panels, showing more obvious colour and contrast shifts as you change your line or sight.

There was the same problem with traditional PVA matrices as with MVA offerings – their response time grew considerably when there’s a smaller difference between the initial and final states of the pixel. Again, PVA panels were not nearly as responsive as TN Film panels. With the introduction of MagicSpeed (Samsung’s overdrive / RTC) with later generations (see below), response times have been greatly improved and are comparable to MVA panels in this regard on similarly spec-ed panels. They still remain behind TN Film panels in gaming use, but the overdrive really has helped improve in this area. There are no PVA panels supporting native 120Hz+ refresh rates and Samsung have no plans to produce any at this time. In fact Samsung’s investment in PVA seems to have been cut back significantly in favour of their IPS-like PLS technology.

The introduction of overdrive to PVA panels lead to the next generation of Super Patterned Vertical Alignment (S-PVA) technology in 2004. Like P-MVA panels were to MVA, these are really just an extension of the existing PVA technology, but with the MagicSpeed (overdrive) technology, they have managed to make them more suitable for gaming than the older panels. One other difference is that the liquid crystal cell structure is a boomerang shape, splitting each sub pixel into two different sections with each aligned in opposite directions. This is said to help improve viewing angles and colour reproduction when viewed from the side. Limitations still exist with S-PVA and they don’t offer as wide viewing angles as IPS-type panels, and still suffer from the off-centre contrast shift we’ve described. Most S-PVA panels offered a true 8-bit colour depth, but some did feature Frame Rate Control (FRC) to boost a 6-bit panel (6-bit+FRC).

There is very little official information about this technology but some Samsung monitors started to be labelled as having an A-PVA panel around 2012 onwards. We suspect that nothing has really changed from S-PVA / cPVA panels, but that the term “Advanced” has been added in to try and distinguish the new models, and perhaps compete with LG.Display’s successful IPS technology and AU Optronics AMVA technology where they have also added the word “Advanced” for their latest generations (see AMVA and AH-IPS).

In Plane Switching (IPS – also known as ‘Super TFT’) technology was developed by Hitachi in 1996 to try and solve the two main limitations of TN Film matrices at the time, those being small viewing angles and low-quality color reproduction. The name In-Plane Switching comes from the crystals in the cells of the IPS panel lying always in the same plane and being always parallel to the panel’s plane (if we don’t take into account the minor interference from the electrodes). When voltage is applied to a cell, the crystals of that cell all make a 90-degrees turn. By the way, an IPS panel lets the backlight pass through in its active state and shutters it in its passive state (when no voltage is applied), so if a thin-film transistor crashes, the corresponding pixel will always remain black, unlike with TN matrices.

IPS matrices differ from TN Film panels not only in the structure of the crystals, but also in the placement of the electrodes – both electrodes are on one wafer and take more space than electrodes of TN matrices. This leads to a lower contrast and brightness of the matrix. IPS was adopted for colour professional displays due to its wide viewing angles, good colour reproduction and stable image quality. However, response times were very slow originally, making IPS unsuitable for dynamic content.

The original IPS technology became a foundation for several improvements: Super-IPS (S-IPS), Dual Domain IPS (DD-IPS), and Advanced Coplanar Electrode (ACE). The latter two technologies belong to IBM (DD-IPS) and Samsung (ACE) and are in fact unavailable in shops. The manufacture of ACE panels is halted, while DD-IPS panels are coming from IDTech, the joint venture of IBM and Chi Mei Optoelectronics – these expensive models with high resolutions occupy their own niche, which but slightly overlaps with the common consumer market. NEC is also manufacturing IPS panels under such brands as A-SFT, A-AFT, SA-SFT and SA-AFT, but they are in fact nothing more than variations and further developments of the S-IPS technology.

In 1998 production started for Super-IPS panels, and were mostly produced by LG.Philips (now LG.Display). They have gone through several generations since their inception. Initially S-IPS built upon the strengths of IPS by employing an advanced “multi-domain” liquid crystal alignmentt. The term S-IPS is actually still widely used in modern screens, but technically there may be subtle differences making them S-IPS, e-IPS, H-IPS, or p-IPS (etc) generations for example. See the following sections for more information.

Since their initial production in 1998 S-IPS panels have gained the widest recognition, mostly due to the efforts of LG.Philips LCD (now known as LG.Display), who were outputting rather inexpensive and high-quality 19″ – 30″ matrices. The response time was among the serious drawbacks of the IPS technology – first panels were as slow as 60ms on the “official” black-to-white-to-back transitions (and even slower on grey-to-grey ones!) Fortunately, the engineers dragged the full response time down to 25 ms and then 16ms later, and this total is equally divided between pixel rise and pixel fall times. Moreover, the response time doesn’t greatly grow up on black-to-gray transitions compared to the specification, so some older S-IPS matrices at the time could challenge TN Film panels in this parameter.

The IPS technology has always been at the top end when it comes to colour reproduction and viewing angles. Colour accuracy has always been a strong point, and even in modern displays the IPS matrices can surpass the performance of TN Film and VA equivalents. The viewing angles are a key part in this, since IPS matrices are free of the off-centre contrast shift that you can see from VA type panels. This is the reason why IPS is generally considered the preferred choice for colour critical work and professional colour displays, combining the excellent colour accuracy with truly wide viewing angles (178/178). S-IPS panels can show a purple colour when viewing dark images from a wide angle.

One main problem of the S-IPS technology traditionally was the low contrast ratio. Black depth was often a problem with S-IPS panels and contrast ratios of 500 – 600:1 were common for the early S-IPS offerings. However, these have been improved significantly, and contrast ratios are now much better as a result with modern IPS generations (see following sections). One other area which remains problematic for modern IPS panels is movie playback, again with noise being present, and only accentuated by the heavy application of overdrive technologies. S-IPS panels are sometimes criticized for their Anti-Glare (AG) coating, which can appear quite grainy and dirty looking, especially when viewing white/light backgrounds in office applications. Again that has been improved significantly in recent generations.

Sometimes you will see these terms being used, but S-IPS is still widely used as an umbrella for modern IPS panels. In 2002 Advanced Super IPS (AS-IPS) boosted the amount of light transmitted from the backlighting by around 30% compared with the standard Super IPS technology developed in 1998. This did help boost contrast ratios somewhat, but they could still not compete with VA panel types. In 2005 with the introduction of RTC technologies (Overdrive Circuitry – ODC) and dynamic contrast ratios, LG.Display started to produce their so called “Enhanced IPS” (E-IPS, not to be confused with e-IPS) panels. Pixel response times were reduced across G2G transitions to as low as 5ms on paper.

Enhanced S-IPS builds on S-IPS technology by providing the same 178° viewing angle from above and below and to the sides, and greatly improves the off-axis viewing experience by delivering crisp images with minimal colour shift, even when viewed from off-axis angles such as 45°. You will rarely see this E-IPS term being used to be honest. You may also occasionally see the name “Advanced S-IPS” (AS-IPS) being used, but this was just a name given specifically by NEC to the E-IPS panel developed and used in their very popular NEC 20WGX2 screen, released in 2006. The AS-IPS name was also (confusingly) used by Hitachi in some of their earlier IPS generations as shown below, back in 2002.

Above: Evolution of IPS as detailed by Hitachi Displays: “IPS technology was unveiled by Hitachi, Ltd. in 1995, and put to practical use in 1996. Since then, it has evolved into Super-IPS, Advanced-Super IPS, and IPS-Pro.”

In 2006 – 2007 LG.Display IPS panels have altered the pixel layout giving rise to ‘Horizontal-IPS’ (H-IPS) panels. In simple terms, the manufacturer has reportedly reduced the electrode width to reduce light leakage, and this has in turn created a new pixel structure. This structure features vertically aligned sub-pixels in straight lines as opposed to the arrow shape of older S-IPS panels.

In practice, it can be quite hard to spot the difference, but close examination can reveal a less ‘sparkly’ appearance and a slightly improved contrast ratio. Some users find a difference in text appearance as well relating to this new pixel structure but text remains clear and sharp. H-IPS will also often show a white glow from a wide angle when viewing black images, as opposed to the purple tint from S-IPS matrices. This is actually more noticeable than the S-IPS purple tint and is referred to as “IPS glow”. Some IPS panels in high end displays are coupled with an Advanced True Wide (A-TW) polarizer which helps improve blacks from wide viewing angles, and reduces some of the pale glow you can normally see. However, this A-TW polarizer is not included in every model featuring H-IPS and this should not be confused. It is very rarely used nowadays unfortunately. H-IPS panels from around this time are sometimes criticized for their Anti-Glare (AG) coating, which can appear quite grainy and dirty looking, especially when viewing white backgrounds in office applications.

Close inspection of modern IPS panels can show this new H-IPS pixel structure, although not all manufacturers refer to their models as featuring an H-IPS panel. Indeed, LG.Display don’t really make reference to this H-IPS version, although from a technical point of view, most modern IPS panels are H-IPS in format. As an example of someone who has referred to this new generation, NEC have used the H-IPS name in their panel specs for models such as the LCD2690WXUi2 and LCD3090WUXi screens.

The following technical report has feedback from the LG.Philips LCD laboratory workers: “Wedesigned a new pixel layout to improve the aperture ratioof IPS mode TFT-LCD (H-IPS). This H-IPS pixel layout design has reducedthe width of side common electrode used to minimize thecross talk and light leakage which is induced by interferencebetween data bus line and side common electrode of conventionalIPS mode. The side common electrodes of a pixel canbe reduced by horizontal layout of inter-digital electrode pattern whereconventional IPS pixel designs have vertical layout of inter-digital electrodes.We realized 15 inch XGA TFT LCD of H-IPS structurewhich has aperture ratio as much as 1.2 times ofcorresponding conventional IPS pixel design.” ©2004 Society for Information Display.

During 2009 LG.Display began to develop a new generation of e-IPS (it is unclear what the “e” actually stands for) panels which is a sub-category of H-IPS. They simplified the sub-pixel structure in comparison with H-IPS (similar to cPVA vs. S-PVA) and increased the transparency of the matrix by producing a wider aperture for light transmission. In doing so, they have managed to reduce production costs significantly by integrating the panels with lower cost, lower power backlight units. This allowed LG.Display to compete with the low cost TN Film panels and Samsung’s new cPVA generation. Because transparency is increased, they are able to reduce backlight intensity as you need less light to achieve the same luminance now.

These are new names which some manufacturers seem to promote a little around 2009 – 2010. It has been stated that these ‘new’ panels offer improved energy efficiency, but it’s unclear what the new letters stand for. Perhaps the ‘UH-IPS’ stands for ‘Ultra Horizontal-IPS’? It certainly seems these are just slightly updated versions of H-IPS panels as was e-IPS. It’s possible as well that UH-IPS is just the same thing as e-IPS, with different manufacturers using different terminology to try and separate their displays. We suspect that UH-IPS is either the same thing as e-IPS, or a sub-category of that development, which in turn is a sub-category of H-IPS.

Some spec sheets from LG.Display give some clues as to the differences. The lines separating the sub-pixels are smaller than with H-IPS and therefore the UH-IPS technology has an 18% higher aperture ratio. The drive for increased LCD panel transmissivity is not for the purpose specifically of increasing on screen brightness, but rather to maintain brightness and reduce backlight lamps, inverters, and optical films in order to lower panel costs. LG have used this terminology with some of their LED backlight monitors.

This was a new name which NEC introduced in early 2010 with their new PA series of screens. Thankfully they’ve been kind enough to tell us what the ‘p’ stands for in their marketing, giving rise to the generation of ‘Performance IPS’ panels. This new panel name is being used in the new 24″ – 30″ sized screens (PA241W, PA271W and PA301W). In fact the p-IPS name is just a sub-category of H-IPS technology, being created as a way for NEC to distinguish their new “10-bit” models from the rest of their range. In addition, when you look into the details of it the panels are actually an 8-bit module with 10-bit receiver, giving you an 8-bit + FRC module. This is capable of producing a 1.07 billion colour palette (10-bit) through FRC technology but it is not a true 10-bit colour depth.

It’s all very well saying a panel is capable of 10-bit colour depth (1.07 billion colour palette) as opposed to an 8-bit colour depth (16.7 million colours), but you need to take into account whether this is practically useable and whether you’re ever going to truly use that colour depth. Apart from the requirements of your application, operating system, graphics card and software, one more pertinent limitation is from a display point of view, where there must be an interface which can support 10-bit colour depth. At the moment DisplayPort and Dual-link DVI are the only options which can. A full 10-bit work flow is still extremely uncommon in the current market.

Regardless of whether you have a true10-bit colour depth being displayed, a screen with 10-bit capabilities still has its advantages. The monitor should still be capable of scaling the colours well, even from 24-bit sources. Most of these 10-bit panels will also be coupled with extended internal processing which will help improve accuracy and these are better translated onto a 10-bit panel than they would be onto an 8-bit panel, giving less deviation and less chance of banding issues.

This term was introduced by LG.Display in 2011 and primarily used when talking about their smaller panels, used in tablets and mobile devices. The term “Retina” (introduced by Apple) has also been used to describe these new panels, offering increased resolution and PPI. That seemed to be the main focus of AH-IPS panels when first introduced although they also offered an increased aperture size, allowing for greater light transmission and lower power consumption as a result. In the desktop monitor market the term “AH-IPS” has been used by several manufacturers in an effort to try and distinguish their new models, when in fact many could equally be described as H-IPS or e-IPS. With the high resolution aspect in mind, the modern 27″ 2560 x 1440 IPS panels could sensibly be referred to as AH-IPS and the term has been used for some of the very recent panels. In fact there have been a couple of other changes in IPS based screens at around the same time (2012) with the introduction of wide gamut GB-r-LED backlighting, and the change in the Anti-Glare (AG) coating being used. With older S-IPS / H-IPS panels often being criticised for their grainy AG coating, this new lighter coating offers improved picture quality and sharpness.

The term AH-IPS seems to be widely used now in 2014/2015 for modern IPS panels, and with the arrival of other ultra-high res panels we expect it to be used for some time. Performance characteristics remain very similar to older H-IPS and e-IPS panel generations overall. Response times are generally very good nowadays, with quoted specs as low as 5ms G2G common. They aren’t quite as fast as modern TN Film panels still in most cases. Only very recently (2015) have high refresh rate IPS-type panels been introduced, although not by LG.Display (see AHVA section). At the time of writing there is no native support for 120Hz+ refresh rates at this time from LG.Display manufactured IPS-variants. Some Korean manufactured displays featuring IPS panels are capable of being “over-clocked” to 100Hz+ but this is not officially supported by the panel, and can really vary from one screen to another. Furthermore, response times are not adequate to provide optimum gaming experience in most cases, despite the improved refresh rate.

LG.Display’s IPS panels are available in a wide variety of sizes and resolutions, including panels with Ultra HD (3840 x 2160), 4k (4096 x 2160) and even 5k (5120 x 2880) resolutions. A lot of their current focus seems to be on ultra-high DPI screens like this, and they are also investing in ultra-wide 21:9 aspect ratio and curved format displays in various sizes, up to 34″.

PLS was introduced by Samsung at the end of 2010 and designed to compete with LG.Display’s long-established and very popular IPS technology. It is an IPS-type technology and for all intents and purposes can be considered IPS, just being manufactured by another company. Samsung claimed they had reduced production costs compared with IPS by about 15% and so were making a play at the market of IPS panels when it was launched. At the time it was also being dubbed “S-PLS” (Super-PLS) but that name seemed to be dropped quite quickly in favour of just “PLS”. It wasn’t until mid 2011 that the first PLS displays started to appear, fittingly they were manufactured by Samsung themselves. The Samsung S27A850D was the first of its kind and its overall performance certainly reminded users of IPS panels.

Response times are very comparable to IPS matrices, with 5ms G2G being the current lowest spec on paper. There is currently no support for refresh rates above 60Hz from Samsung PLS panels, although there are some Korean manufactured screens which can be over-clocked to 100Hz refresh rates. This is not natively or officially supported though. Contrast ratios are typically around 700 – 900:1 in practice, although can reach up to 1000:1 in some cases as per their spec. Viewing angles are very comparable to IPS as well with wide fields of view and freedom from the off-centre contrast shifts you see from VA panels. From a wide angle dark content has a pale / white glow to it like modern IPS panels, again leading to a fair amount of so-called “PLS-glow” which can be distracting to some users. AG coating is also light, much like the light coating used on modern AH-IPS panels from LG.Display.

All in all, PLS is very comparable in practice to IPS. It should be noted that some display manufacturers market their screens as using an IPS panel, whereas underneath the hood the panel is actually a Samsung PLS matrix. Testament to how close these technologies are really considered although somewhat mis-leading. Samsung have largely moved away from their focus on PVA panels and are concentrating on PLS (and TN Film still) now instead. At the time of writing PLS panels are typically available in sizes between 23 and 27″ with resolutions up to 2560 x 1440. They do also have a 31.5″ panel with Ultra HD 3840 x 2160 available which is currently their largest. They do not currently manufacturer any ultra-wide 21:9 aspect ratio of curved format panels.

In 2012 some PLS based screens started to be marketed using the “AD-PLS” name. It is unclear what is supposed to have changed, if anything, with these recent panel variants. We suspect this is just a marketing name designed to keep up with LG.Display’s change to the “Advanced High-Performance IPS (AH-IPS)” name from the same time. Performance characteristics remain as described in the PLS section above.

Again like Samsung’s PLS technology, AU Optronics have invested in their own IPS-type technology since 2012, dubbed AHVA. This technology is designed by AU Optronics as another alternative to IPS. Confusingly the AHVA name makes it sound like it’s a VA-type panel, which AU Optronics have been manufacturing for many years. It should not be confused with AMVA which is their current “true” VA technology produced. The BenQ BL2710PT was the first display featuring this new technology and gave us some insight into the performance characteristics of AHVA, confirming how closely it resembled an LG.Display IPS panel.

Response time specs reach as low as 4ms G2G on paper but in reality the matrix does not perform any better than the faster IPS or PLS panel versions. Contrast ratios can reach up to the advertised 1000:1 and viewing angles are also very comparable to IPS. There is no off-centre contrast shift like you see on normal VA panels, but a pale glow is visible on dark content from an angle like with IPS/PLS. The AG coating is very light, often semi-glossy.

In very recent times (2015) AU Optronics have been the first to release official high refresh rate (144Hz) IPS-type panels, through their AHVA technology. The first display to use one of these panels was the Acer Predator XB270HU which was impressive when it came to refresh rate support and response times. We expect further panels to emerge at a later date with 120Hz+ refresh rates which can only be a good thing when it comes to gaming. With the addition of this high refresh rate we also saw the first inclusion of a blur reduction backlight (from the NVIDIA ULMB mode) on an IPS-type panel. Again a positive sign when it comes to the gaming future of IPS-type panels.

When we purchase a new smartphone we go through a list of specifications that includes the processor, software, cameras, display type, battery, etc. The display of the smartphone is something which has always been a concern for people. And smartphone technology has advanced so much in the past decade that you get several display technology options to choose from.

Today, a smartphone is not just a means to send and receive calls and texts. It has become a general necessity, so choosing the right technology should be your main priority. Coming back to displays, as we said there are plenty of display types available right now.

Two of the main contenders for display technologies that are widely available are AMOLED and LCD. Here in this article, we will be comprising AMOLED vs LCD and find out which one is better for you.

Starting with the AMOLED first, it is a part of the OLED display technology but with some more advanced features. To completely know about it must understand its all three components. The first one is LED, “Light Emitting Diode”. Then we have “O” which stands for organic and makes the OLED.

The AMOLED display is similar to the OLED in various factors like high brightness and sharpness, better battery life, colour reproduction, etc. AMOLED display also has a thin film transistor, “TFT” that is attached to each LED with a capacitor.

TFT helps to operate all the pixels in an AMOLED display. This display might have a lot of positives but there are a few negatives too let’s point both of them out.

A major issue with these displays is of burning of pixels. After showing a specific image or colour for a longer period of time, the pixel can get burned. And if there is a problem with a single pixel it will affect the entire display.

Low outdoor visibility, usually the AMOLED Displays are quote not bright in direct sunlight and outdoor readability could be a problem for some devices but average screen brightness.

The LCD stands for “Liquid Crystal Display”, and this display produces colours a lot differently than AMOLED. LCD display uses a dedicated backlight for the light source rather than using individual LED components.

The LCD displays function pretty simply, a series of thin films, transparent mirrors, and some white LED lights that distributes lights across the back of the display.

As we have mentioned, an LCD display always requires a backlight and also a colour filter. The backlight must have to pass through a thin film transistor matrix and a polarizer. So, when you see it, the whole screen will be lit and only a fraction of light gets through. This is the key difference comparing AMOLED vs LCD and this is what differentiates these two display technologies.

The LCD displays are cheaper compared to the AMOLED as there is only one source of light which makes it easier to produce. Most budget smartphones also use LCD displays.

LCD displays have bright whites, the backlight emits lots of light through pixels which makes it easy to read in outdoors. It also shows the “Accurate True to Life” colours, which means it has the colours that reflect the objects of the real world more accurately than others.

LCDs also offer the best viewing angle. Although it may depend on the smartphone you have. But most high-quality LCD displays support great viewing angles without any colour distortion or colour shifting.

The LCD displays can never show the deep blacks like AMOLED. Due to the single backlight, it always has to illuminate the screen making it impossible to show the deep blacks.

The LCDs are also thicker than other displays because of the backlight as it needs more volume. So, LCD smartphones are mostly thicker than AMOLED ones.

Both of these display technologies have their own Pros and Cons. Taking them aside everything ends up with the user preferences as people might have different preferences among different colours and contrast profiles. However, a few factors might help you to decide which one fits perfectly for you.

Let’s start with the pricing. Most AMOLED display smartphones always cost more than an LCD smartphone. Although the trend is changing a bit. But still, if you want to get a good quality AMOLED display you have to go for the flagship devices.

The colors are also very sharp and vibrant with the AMOLED displays. And they look much better than any LCD display. The brightness is something where LCDs stood ahead o

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey