lcd display with push buttons free sample

Combining pushbuttons with LCDs can go a long way when making Arduino projects. Take a vending machine for example. A vending machine works by making a payment to receive the appropriate product. Usually, it is self-service and you only need to interact with buttons and an LCD for instructions and feedback. Another device that uses LCD and buttons to work properly and efficiently is the printer. You can set options by pressing the appropriate buttons with instructions displayed on the LCD.

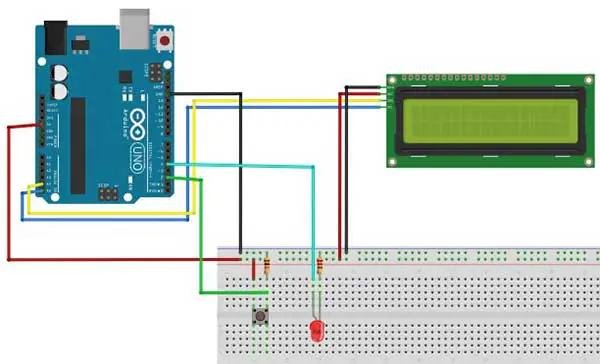

This is Project 51 of the Arduino Intro app. This is an example of how to select modes or settings using a pushbutton and displaying the choice entered by the user on the LCD.

This project uses the I2C LCD. For more details on how to use this LCD, you may read this article: Displaying Characters Using the I2C Liquid Crystal Display (LCD)

We will be using the variable valto store the current value of the pushbutton. Every time the button is pressed, its value becomes 1, otherwise, its value is 0. However, in some cases, this might be reversed. When the button is pressed, its value becomes 0, otherwise, it is 1. You may change this later on in the code. You can use the serial monitor to check the value or you may use a simple trial and error. The led_num keeps track of how many times the button is pressed and this corresponds to the current mode selected.

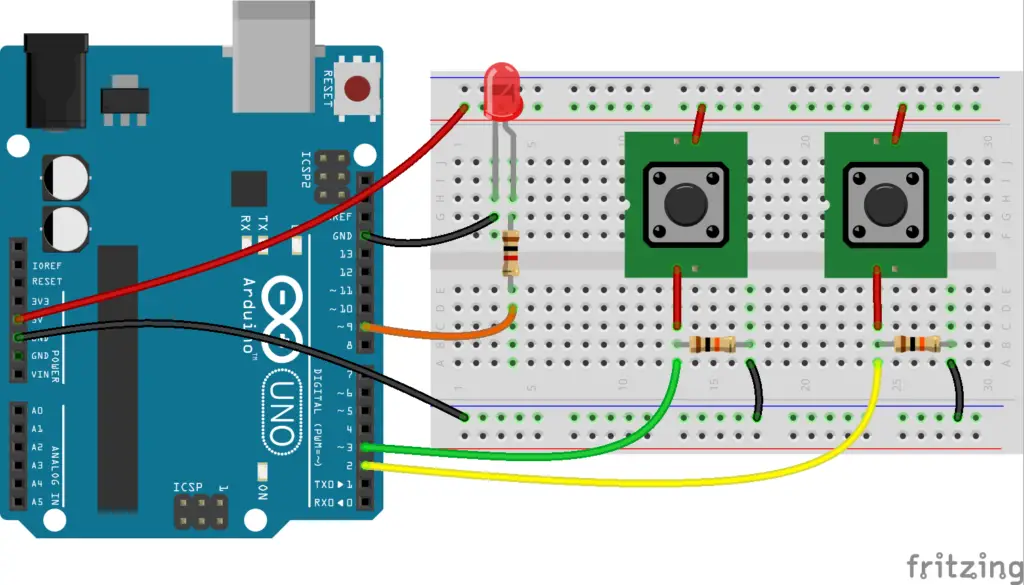

This is Project 52 of the Arduino Intro app. It displays the status of the LED, whether it is turned on or off. A single pushbutton will turn on/off the LED.

This sketch uses the "Sticky" pushbutton effect. What happens here is that when the button is pressed, the LED turns ON and it STAYS ON even when you release the button. The next time you press it, the LED turns OFF and it STAYS OFF until the next press of the button. This is explained further in this article: Using Simple Pushbutton Switches to Light Up LEDs

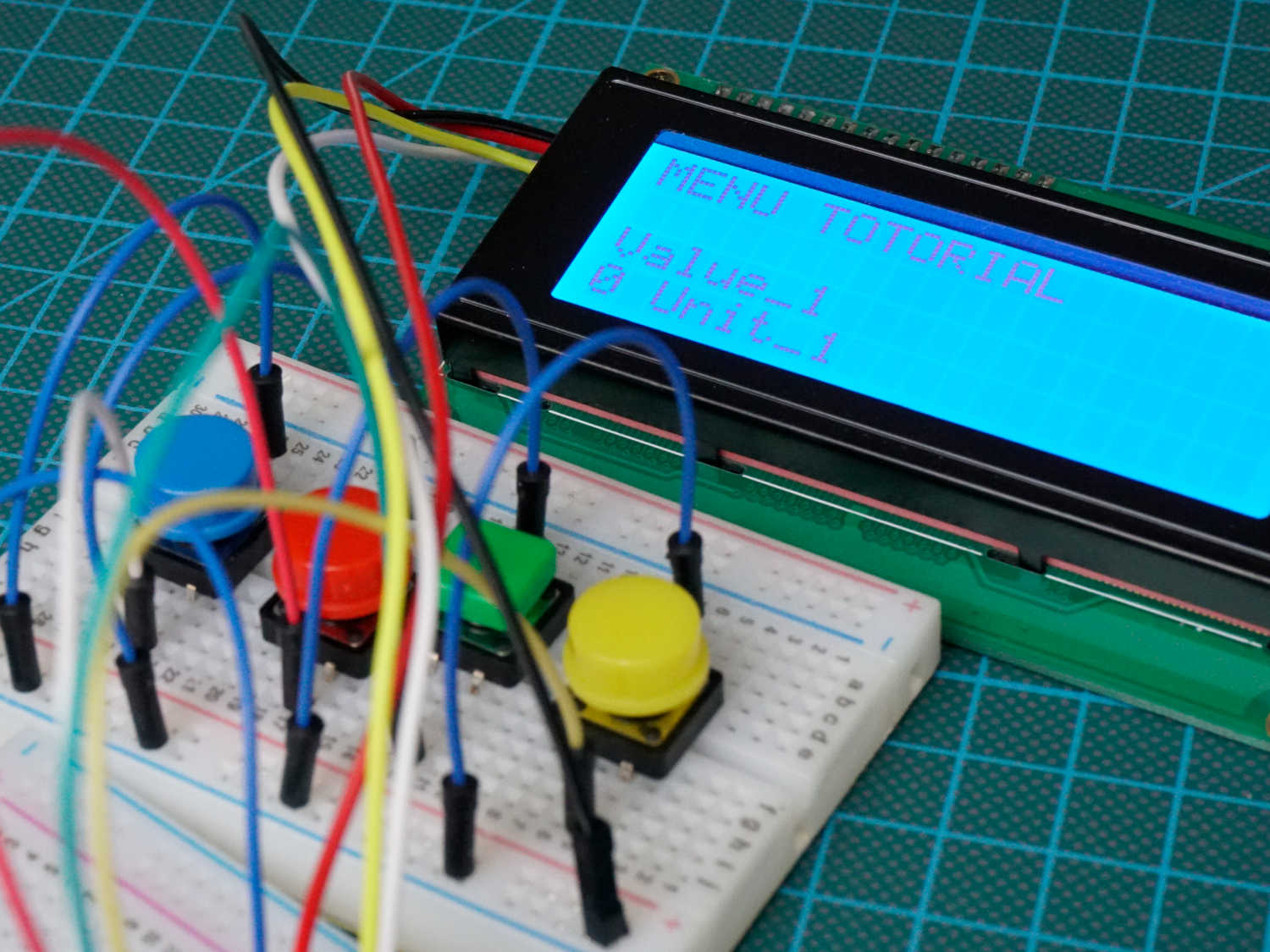

You may have used an electronic device with a small Liquid Crystal Display (LCD) which has a textual hierarchical menu system for setting device configuration parameters. If you have tried writing menu code for your Arduino projects, you will recognise the challenge in developing a generic menu system for an open prototyping platform. This is because there are many input and display devices available, and a generic menu system must be independent of whichever input and display devices you wish to use. With our Arduino menu library, this independence is achieved by having the menu manager code use callback methods for handling user input and rendering the menu display.

To keep things simple, all coding examples have been targeted to work with an R3 Arduino Uno/Leonardo/Mega2560, and an LCD keypad shield similar to one illustrated above. There are numerous manufacturers of LCD keypad shields that have the same or similar pin connections, and you must ensure that the sample menu code uses the pin connections that are right for your shield. If the keypad buttons of your shield give different analog readings, you’ll need to make changes to file LcdKeypad.h. Bear in mind that the analog readings are not always consistent, which can lead to the occasional misreporting of a button press. Once you become familiar with the menu library, adapting it for use with other input and display devices should be straight-forward.

With numerous menu libraries readily available, why use this Arduino menu library? We think it is easier to use thanks to our online code generator, and has better memory efficiency with its use of PROGMEM. Watch the short video clip below and see for yourself.

You can use the downloaded sample Arduino project as a starting point for your own coding requirements. You will need to write your own code in the body of method processMenuCommand(byte cmdId) to determine what must be done when a menu item is selected. The cmdId parameter is the Id you associate with a menu item in your menu Xml file. Callback method getNavAction() handles user input, and callback method refreshMenuDisplay(byte refreshMode) renders the menu. To work with other input and display devices you’ll need to re-write the code in these methods. Some LCD keypad shields are not suited for hardware PWM backlight control, and as such the coding example uses a soft PWM alternative.

The Select button on the LCD shield starts/stops a timer, with a long press resetting the timer. A long press of Up enters the menu. Up/Down/Right buttons are for navigating the menu, and Select for choosing a menu item. When an item is selected, Up/Down are used for changing values. When the Reset menu item is displayed, a long press of Select loads default configuration values. Digital pin 2 is used for activating a beeper for the alarm. Examining the source should give you good insight for using the menu system in your own projects. If you find this Arduino menu library guide useful, please share it.

All our hackatronics projects are free for personal use, and there are many more in the pipeline. If you find our projects helpful or useful, please consider making a small donation to our hackatronics fund using the donate buttons on our web pages. Thank you.

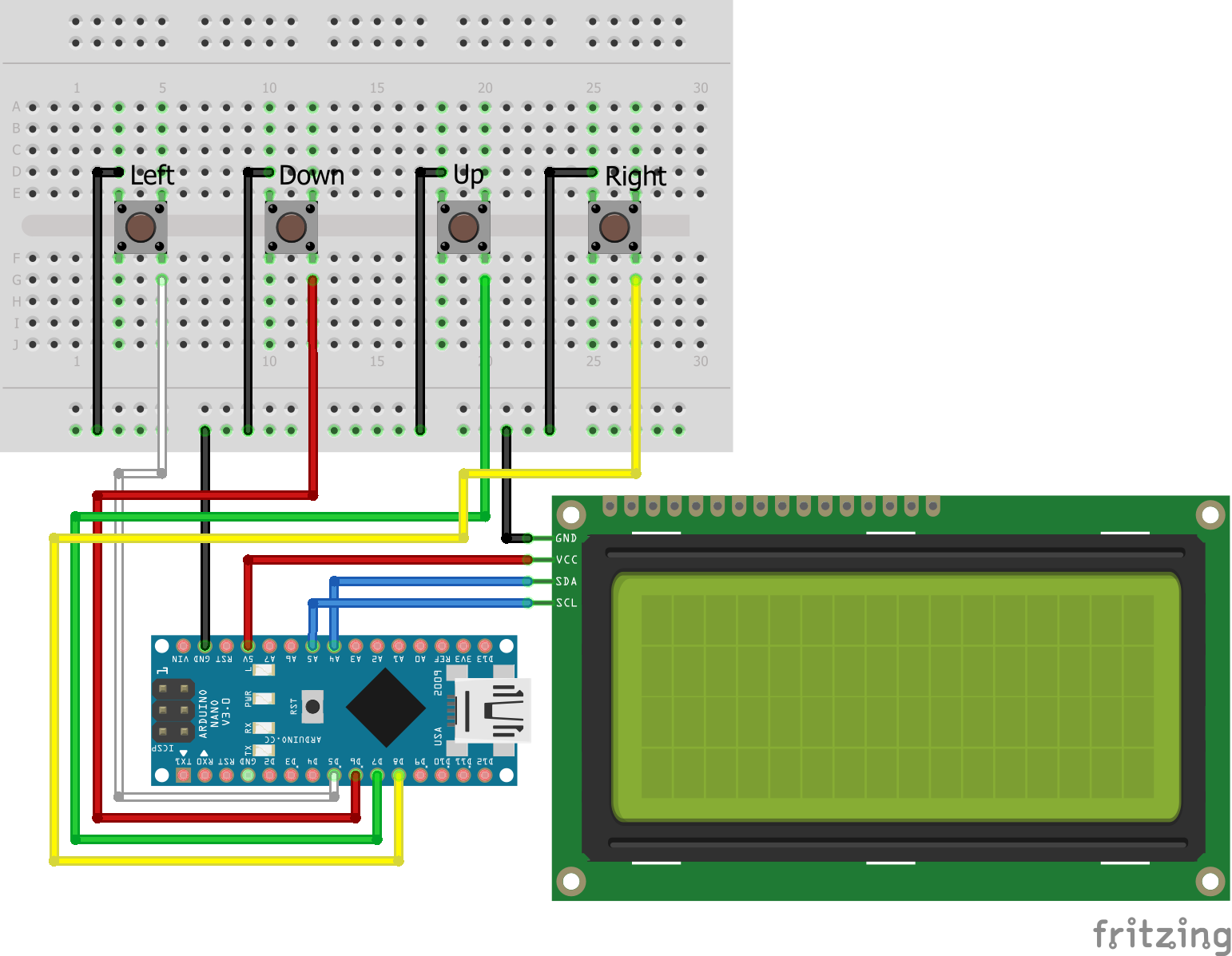

After all variables are defined we take care about the setup function which will only run once at the start of the microcontroller. First we define the baud rate to 9600 which means that we can see values in the serial monitor with a data rate of 9600 bits per second. The baud rate defined in the setup function and in the serial monitor has so be synchronous.

Then we initialize the 4 buttons with their pins and we enable the internal pull-up resistor so that we do not need an additional resistor for our circuit.

For the setup function we want to write a short text to the displays. First we clear the complete display and set the cursor in the second line on digit number 4. Here we print the first part of the text. Then we place the cursor in the next line and because the second part of the test is longer we set the cursor to the 3 digit number and print the second part of the text. The text is shown 5 seconds and after that time the display is cleared.

Now we enter the whole loop function which is of course processed over and over. The first 4 lines of the loop function are to read the current state of the buttons. If a button is pressed, the variable buttonState is LOW and we react in the following with the reaction depending on what button was pressed and then run the printScreen function which will be explained in the following section of this menu tutorial.

First we discuss the buttonStateLeft and buttonStateRight statement. We enter the first if query if the button is pressed and clear the screen to display the new screen without the old information. For the left button we decrease the pointer to show the screen before but when the pointer is already on the first screen (currentScreen == 0) we want to display the last screen to get a never ending rotation which you know from your mobile phone. For the right button we want to display the next screen. That is why we increase the variable currentScreen. If we reach the last screen we show the first screen also to get the functionality of a never ending loop in screens.

Now we want to discuss what happen if we push the button up or down. We first clear the screen too and then either increase or decrease the value of the current screen. The corresponding array which we defined earlier stores the changes values. For each screen we can therefore change the value.

The printScreen function has a lot of rows but is pretty easy and straight forward. First we check if we are in the last screen number 3. If so we want to display every number and unit line per line. Therefore we set the cursor in the first line and print the number name, number and unit. We do this line by line by changing the cursor.

If we are not in the last screen we want to display the title “MENU TOTORIAL” in the first line and use the last two lines to display the number name, number and unit.

Explore the sample circuit embedded here by starting the simulation and testing the pushbutton. Remember that the breadboard rows are connected inside, so you can plug in components and wires to make quick temporary

Drag a pushbutton from the components panel to the center of your breadboard, and place it across the center column break so that its legs are plugged into four different breadboard rows.

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

All of the code below uses the LiquidCrystal library that comes pre-installed with the Arduino IDE. A library is a set of functions that can be easily added to a program in an abbreviated format.

In order to use a library, it needs be included in the program. Line 1 in the code below does this with the command #include

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

This function takes a string of text and scrolls it from right to left in increments of the character count of the string. For example, if you have a string of text that is 3 characters long, it will shift the text 3 spaces to the left with each step:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

If you found this article useful, subscribe via email to get notified when we publish of new posts! And as always, if you are having trouble with anything, just leave a comment and I’ll try to help you out.

Scottsdale, Ariz. – January 6, 2017 – NKK Switches, the world’s leading designer and manufacturer of innovative electromechanical switches, announces significant product improvements to its line of SmartDisplay LCD 36 x 24 programmable switches and displays. The changes to the LCD 36 x 24 Switches and Displays allow for interface to low voltage applications and increases the maximum clock frequency. The low voltage SmartDisplay LCD 36 x 24 product will go into production in February 2017. Prototype quantities are currently available.

The new low voltage SmartDisplay LCD 36 x 24 will have a logic voltage range of 3V to 5.5V, allowing for interface to low voltage applications. Additionally, the maximum clock frequency for the 36 x 24 LCD SmartDisplay has increased from 6 MHZ to 8 MHZ. There will be no part number or changes in pricing because of the improvement.

NKK’s SmartDisplay LCD programmable pushbuttons and displays are the smallest LCD devices available off-the-shelf and have single, bi-color or RGB LED backlighting. Real-time sequencing simplifies multi-decision operations, saving time and space while providing a brilliant solution for user interface. Using the backlight as mode of operation allows operators to quickly see changes in any critical environment.

Suited for a wide range of applications requiring a graphical user interface or real-time sequencing, NKK’s unique SmartDisplay product line streamlines and improves complex multi-decision operations. Applications include audio-video broadcast workstations, industrial control panels, medical equipment, communications systems and ground transportation.

NKK’s complete SmartDisplay product line consists of a variety of programmable LCD and OLED Pushbuttons, Compact Pushbuttons, and Displays. Visit www.nkkswitches.com/smartdisplay for more information.

NKK’s switches turn on millions of products around the world every day by offering more than 3.5 million different toggle, rocker, pushbutton, slide, rotary and keylock switches to illuminated, process-sealed, miniature, specialty, surface-mount and programmable switch devices. For more information, visit www.nkkswitches.com.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

The processors that power the Arduino development boards aren"t your granddad"s microcontrollers - they"ve got serious processing power and can be used to monitor and control many types of physical hardware and sensors simultaneously. The XOD graphical programming IDE for Arduino can simplify the task of rapid-prototyping hardware designs, but as a system grows in complexity there"s the issue of user control and information management - how to arrange information about the process being controlled for display and let the user control it in a logical manner. Dedicated buttons and switches work for simple projects but one soon runs out logical ways to arrange them (or places to put them on an enclosure.) Many designs use a display of some type to give this kind of feedback, even a microwave oven usually has a small screen that allows editing settings and entering cook times, and while too much "menu diving" to access obscure settings can compromise user experience, menu-driven interfaces are a fact of life for projects of all kinds.

Software frameworks for developing menu-based interfaces in C or C++ for microcontrollers often have a steep learning curve and can be difficult to make rapid design changes in, as often everything interacts with everything else. The goal of this project was to use the XOD graphical programming environment to provide the ability to rapidly prototype menu-driven interfaces for Arduino-compatible microcontroller projects using a drag-and-drop/WYSIWYG style of interface. The output and input parameters of the generated menu structure are modular and generic and should be able to be used with a wide variety of input sources (switches, buttons, encoders) and produces a sequence of plain text outputs which can be fed to a wide variety of XOD-supported display types, including multi-line text LCD modules as used in this example.

At the right of the patch editing screen in XOD are four nodes connected up in a descending fashion. From top to bottom there"s first an analog input-type node, which is selected to be connected to one the Arduino"s analog input ports. In my tests I"ve been using an Arduino Uno with an ATMega328 8 bit processor, with a 16x2 LCD/keypad shield connected on top of it. The keypad on the shield is connected via the shield pins to the Arduino"s "A0" analog input, and the hardware generates voltages of differing levels to signal to the Arduino which buttons on the pad are depressed.

Other than the "reset" button on the keypad which doesn"t interface to the Arduino sketch directly, this type of display shield provides four directional buttons - up, down, left, and right, a "select" button. The second node down fed by the analog input node contains code which reads the differing voltage levels and outputs pulse-type triggers depending on which button is pressed. A "timeout" input is provided so an XOD developer can adjust the debounce timeout of the LCD shield keypad to avoid false triggering, adjusted to a particular application"s button or switch type.

As currently implemented it accepts a single Number-type input which can be any parameter the user can change from an external control, say a potentiometer or dial on a control panel which represents some parameter that can be changed. When a given leaf-type menu is selected by the menu-controller receiving a pulse to its "Invoke" input, over in the menu tree to the left the node of the screen the user is currently looking at will output a pulse on its own output, and also send out a parameter change. There are also two String inputs which can be used to generate a splash screen on the display when the Arduino powers up.

Following that node is a stock 16x2 LCD controller module from the XOD environment standard library, but any type of display that a module is available for can be used to display the output text here.

At the top of the sketch screenshot is a tree-like structure which, when compiled and the final output "root" of the tree is routed to the menu-controller input that accepts it, will automatically generate a navigable menu just as pictured in the graphical designer. Currently implemented are three types of menu tree nodes, a "leaf"-type menu - a final sub menu, with no orange-colored input ports - this represents some action or parameter the user can control, a "branch"-type menu with both an input and output, where the user can select among several child sub-menus, and a "concat"-type menu where sub-menus are grouped together and fed into the input of a branch-type menu, to make a group of options. It should hopefully be somewhat self-explanatory from the diagram how to wire up this set of nodes.

Selecting "invoke" when a "branch"-type menu is displayed descends into its associated sub menu group, rather than generating an output as a leaf-type menu does. Sub-sub menus, sub-sub-sub menus, etc. are possible! Complex structures can be implemented, limited primarily by the available RAM and Flash memory resources of a particular Arduino model"s processor.

This set of nodes has been tested and should work OK with the Arduino Uno as-is, but a few issues remain that weren"t resolved by this project"s deadline. Currently there must be a branch-type menu in the tree somewhere for a sketch to compile, though most projects would probably want to have at least one. The "top" menu input to the menu-controller, intended to return all the way back to the title screen of the interface, isn"t currently implemented but should be an easy feature for the next revision.

Four-line displays are supported by the menu controller node but the leaf-type menu interface with four lines of text input hasn"t been written, yet. A good amount of effort has been put into reducing the memory overhead of this utility but the way the XOD transpiler currently stores constant strings isn"t optimal for very low RAM overhead, and menu-based interfaces tend to have a lot of text. For this project a work-around was developed and a set of flash-string type nodes added in the patch to ensure longer strings did not consume precious program RAM.

Using the flash-string type nodes isn"t too painful but does require duplicating the patch and code for each new string stored in program memory, and clicking into the C++ code contained within the node itself to edit the output string:

The "ID" input of leaf and branch nodes doesn"t have a function, yet. The thought is it would be good for each set of sub-menus to have associated ID numbers arranged in order so the user can keep track of their position in a set of displays but it will require some more thought on how to code this in C++ to happen automatically.

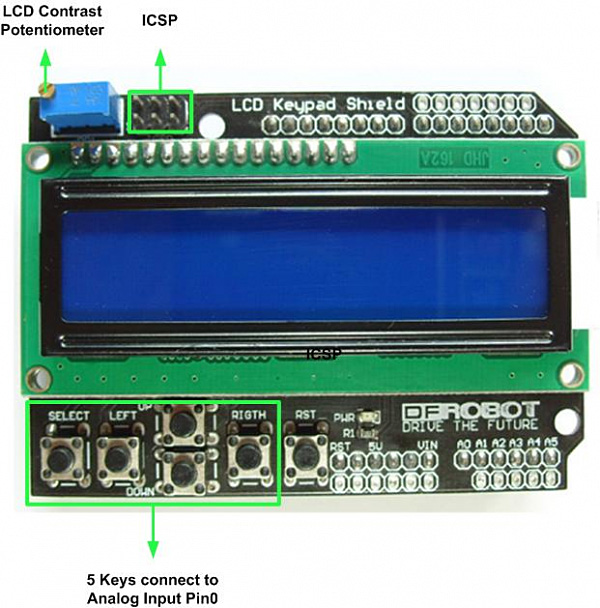

This is a very popular LCD Keypad shield for Arduino and other variants. It includes a 2x16 LCD display and 6 momentary push buttons. Pins 4, 5, 6, 7, 8, 9 and 10 are used to interface with the LCD. Just one Analog Pin 0 is used to read the five pushbuttons. The LCD shield supports contrast adjustment and back-lit on/off functions. It also exposes five analog pins with DFRobot color code for easy analog sensor plugging and display. The on board LED indicates power on.

This lcd arduino shield has 5 keys — select, up, right, down and left which allow you move through menus and make selections straight from one board attached to yourArduino project without requiring a massive tower of shields.

This design allows you keep connecting sensors to the rest of the pins, and use it for monitoring or menu selection with the push buttons even for gaming. Project applications require testing or debugging. Displaying information right away help on most occasions when a computer is not at reach. If you are planning to build something not attached to a computer and you need to check what is going on when you place it on position, this addition will prove very valuable to make sure the program is running well.

The used LCD pins are not exposed on top side of the board leaving only the unused ones. This way, conflict with LCD pins on top of the board will not happen anymore. This design includes a APC / Bluetooth v3 socket to enable you data transmission with your robot.

Explore the sample circuit embedded here by starting the simulation and testing the pushbutton. Remember that the breadboard rows are connected inside, so you can plug in components and wires to make quick temporary

Drag a pushbutton from the components panel to the center of your breadboard, and place it across the center column break so that its legs are plugged into four different breadboard rows.

All I had to do here was add in the three digitalRead() calls, and make sure I accounted for the fact that if all buttons were low, we should reset the timer (lastDebounceTime = currentTime) and set all previous states to low. I also store millis() in currentTime.

Liquid Crystal displays or LCDs have been used in electronics equipment since the late 1970s. LCD displays have the advantage of consuming very little current And they are ideal for your Arduino projects.

In this article and in the accompanying video I’ll show you how easy it is to add an LCD display to your next Arduino design. I’ll also show you a very popular Arduino Shield that has a keypad which you can use in your projects as well.

Today LCD displays are used in a variety of items from test equipment to televisions. They’re inexpensive and versatile, this makes them ideal for all sorts of designs.

LCD displays do not emit light. Instead they block the passage of light, like little windows which open and shut the let light through. The liquid crystals used inside LCD displays are sandwiched between two layers of polarized material. By changing the orientation of the liquid crystals they allow light to pass or they block the light entirely.

Because transmissive LCD displays (the type we will be using) work by blocking light they require a backlight. Several methods have been used to create back lights including electroluminescent panels and fluorescent tubes. these days the most common form of backlight is an LED, in fact so-called LED televisions are usually just LCD screens with an LED backlight system.

Another type of LCD display, the passive-matrix display, does not require a backlight, it works using reflected light. This type of display is often found in digital watches.

The principles of liquid crystals were discovered in the late 1880s but work on Modern LCD displays did not begin until the mid-1960s. a number of patents were filed in the early 1970s and in 1973 the Sharp Corporation introduced LCD displays for calculators.

The first color LCD displays were developed in the early 1980s but production units were not commonly available until the mid-1990s. By the late 1990s LCD displays were quite common.

A number of LCD displays are available for experimenters. These low-cost monochrome displays are ideal for use with microcontrollers like the Arduino and micro computers like the Raspberry Pi.

These displays are available in a number of different configurations. The part number for the display generally relates to the number of rows and columns in the display.

Common display configurations include 16 x 2, 16 x 4 and 20 x 4. All of these displays are used in a virtually identical fashion the only difference being the number of columns and rows they have.

The LCD1602 display module is a very popular and inexpensive LCD display. It is available in a number of different colors such as blue yellow and green and can easily be connected to an Arduino or Raspberry Pi.

In operation data is sent down the parallel data lines for the display. There are two types of data that can be sent to the display. The first type of data are the ASCII characters which are to be displayed on the display. The other type of data are the control characters that are used to activate the various display functions.

Brightness– This is the input for the brightness control voltage, which varies between 0 and 5 volts to control the display brightness. On some modules this pin is labeled V0.

Because the LCD module uses a parallel data input it requires 8 connections to the host microcontroller for the data alone. Add that to the other control pins and it consumes a lot of connections. On an Arduino Uno half of the I/O pins would be taken up by the display, which can be problematic if you want to use the I/O pins for other input or output devices.

We will begin our experiments by hooking up the LCD1602 to an Arduino Uno and running a few of the example sketches included with the Arduino IDE. This will allow you to get familiar with the display without needing to write any code.

We need to hookup our LCD display to our Arduino. The display can use any of the Arduino digital I/O pins as it has no special requirements, but if you hook it up as I’ve illustrated here you can run the example sketches without needing to make any modifications.

In addition to the LCD1602 display ands the Arduino Uno you will need a 10K trimpot ot potentiometer, this is used a s a brightness control for the display. You’ll also need a 220 ohm resistor to drop the voltage for the displays LED backlight.

The sketch starts with a number of credits and a description of the required hardware hookup. You’ll note that this is the same hookup you just performed on your Arduino and LCD module.

We then initialize an object that we call “lcd” using the pinouts of the LCD display. If you decide to hook up your display to different pins then you’ll need to modify this section.

In the beginning of the loop we set our cursor to the first position in the second row. Note that the row numbers start with zero so the second row is row 1.

Load the sketch up to your Arduino and observe your display. If you don’t see anything try adjusting the brightness control that you wired to the display.

The second example we will try isthe Scroll sketch. Scrolling is a useful technique when you can’t get your text to fit on one line of the LCD display.

In the loop the code demonstrates the use of thescrollDisplayLeftandscrollDisplayRightfunctions. As their names imply they move the text in a left or right direction.

Finally the last counter moves the text 16 positions to the left again, which will restore it back to the center of the display. The loop then repeats itself.

Custom characters are useful when you want to display a character that is not part of the standard 127-character ASCII character set. Thi scan be useful for creating custom displays for your project.

A character on the display is formed in a 5 x 8 matrix of blocks so you need to define your custom character within that matrix. To define the character you’ll use thecreateCharfunctionof the LiquidCrystal library. You are limited to defining a maximum of eight characters.

To usecreateCharyou first set up an array of bytes with 8 elements. Each element in the array defines one row of the character in the 5 x 8 matrix. You then use createCharto assign a number from 0 to 7 to that array.

As with the previous sketches we examined this one starts by loading theLiquidCrystallibrary and defining an object calledlcdwith the connection information for the display. It then moves on to define the custom characters.

Each character is defined as an array with 8 elements, the zeros and ones in the array indicate which elements in the character should be on and which ones should be off. Five arrays are defined, although the sketch actually only used four of them.

The last two arrays,amsUpandarmsDowndefine the shape of a little “stickman”, or “stickperson” if you want to be politically correct! This is done to show how we can animate a character on the display.

Finally the setup routine ends by printing a line to the first row of the LCD display. The line makes use of two of the custom characters, the “heart” and the “smiley”.

One thing you may have noticed about using the LCD display module with the Arduino is that it consumes a lot of connections. Even in 4-wire mode there are still a total of seven connections made to the Arduino digital I/O pins. As an Arduino Uno has only 14 digital I/O pins that’s half of them used up for the display.

But there is another solution. Use the I2C bus adapter for the LCD display and connect using I2C. This only consumes two I/O pins and they aren’t even part of the set of digital I/O pins.

The Master transmits the clock signal which determines how fast the data on the bus is transferred. There are several clock speeds used with the I2C bus. The original design used 100 KHz and 400 KHz clocks. Faster rates of 3.4 MHz and higher are available on some I2C configurations.

Every device on the I2C bus has a unique address. When the Master wants to communicate with a Slave device it calls the Slaves address to initiate communications.

The I2C Adapter for the LCD display is a tiny circuit board with 16 male header pins soldered to it. These pins are meant to be connected directly to the 16-pin connection on the LCD1602 display (or onto other displays that use the same connection scheme).

The device also has a 4-pin connector for connection to the I2C bus. In addition there is a small trimpot on the board, this is the LCD display brightness control.

Most of these devices have three jumpers or solder pads to set the I2C address. This may need to be changed if you are using multiple devices on the same I2C bus or if the device conflicts with another I2C device.

Nick has written a simple I2C scanner sketch that he’s put into the public domain. It scans your I2C bus and gives you back the address of every I2C device it finds. I’ve repeated Nick’s sketch here, it’s also in the ZIP file that you can download with all of the code for this article.

Load this sketch into your Arduino then open your serial monitor. You’ll see the I2C address of your I2C LCD display adapter. You can then make note of this address and use it in the sketches we’ll be looking at now.

In order to run the subsequent sketches you’ll need to install another library. This is theNewLiquidCrystallibrarywhich, as its name implies, is an improved version of the LiquidCrystal library packaged with your Arduino IDE.

On the next line we define the connections to the LCD display module from the I2C Adapter,. Note that these are NOT the connections from the Arduino, they are the connections used by the chip on the adapter itself.

In setup we set the size of the display and then print “Hello world!” on the first line in the first position. After a short delay we print “How are you?” on the second line.

We need to make a minor wiring adjustment to the hookup with our I2C adapter, specifically we will need to add a DHT22 temperature and humidity sensor into the circuit. The wiring is shown here:

As you can see the DHT22 is connected with its output tied to pin 7 of the Arduino. The other two connections are 5 volts and ground. Note that pin 3 of the DHT22 is not used.

This sketch also makes use of theDHTlibrary from Adafruit. We used this library in a previous article, “Using the HC-SR04 Ultrasonic Distance Sensor with Arduino” so you may want to take a look at that one in order to get it installed.

The sketch is similar to our demo sketch in that it creates an “lcd” object with the I2C and display connection information. It also defines a couple of parameters for the DHT22 sensor, as well as some floating variables to hold the temperature and humidity values.

Note that this displays the temperature in Celsius. If you want to change this to Fahrenheit its a simple matter of using some math. The formula( temp * 1.8 ) + 32will convert the results to Fahrenheit.

So far we have used the LCD1602 display module for all of our experiments. For our final demonstration we’ll switch to a popular Arduino shield that contains a LCD1602 along with some push buttons.

The LCD Keypad Shield is available from several different manufacturers. The device fits onto an Arduino Uno or an Arduino Mega and simplifies adding an LCD display to your project.

The other five push buttons can really be used for anything you’d like to use them for. And the way they are hooked up is very interesting, at least it is to me!

Instead the buttons are connected to a resistor array that acts as a voltage divider. The entire array is connected to the Arduino’s analog A0 pin. One pin for five push buttons.

Note that the LCD is being used in 4-wire mode. The LCD itself is the same one used on the LCD1602 module, so all of the code for that module will work with the LCD Keypad Shield as well.

Now that you know how the LCD Keypad module works and which Arduino pins it uses all that remains is to install it onto your Arduino and load the demo sketch.

Use a shield that exposes the pins for prototyping before you install the LCD Keypad shield. In the video associated with this article I use a “Screw Shield” that brings all of the Arduino I/O pins out to a series of screw connectors. There are other similar shields. Using one of these shields is the easiest way to work with the LCD Keypad shield, as well as other Arduino shields.

The sketch begins by including theLiquidCrystallibrary. You can use the original one or the one includes with theNewLiquidCrystallibrary. We then set up an object with the LCD connections, note that these are just hard-coded as they won’t change.

Next we define a number of constants, one for each of the push buttons. Note that nothing is defined for the Reset button as it simply mimics the Arduino Reset button, however a constant is defined for the “none” condition.

We then define two variables. The first one holds the value of the selected pushbutton, the second holds the analog reading from port A0 where the push button input is detected.

After that we define a function calledread_LCD_buttons(). This function reads the value on analog port A0 and returns an integer corresponding to the button integers we defined earlier. Note that the function adds approximately 50 to each of the manufacturers specified values to account for intolerances in the resistors in the voltage divider.

We start the loop by placing the cursor 9 spaces over on the second line. We then use themillisfunction to display a counter that counts the time since the Arduino was reset. This is to test the Reset button.

We then call ourread_LCD_buttons()function and use it to display the value of the push button, right before the counter. Then we end the loop and do it again.

Load the code onto the Arduino and run it. You should see the value of each button as you press it, along with a counter that increments each second. If you press Reset the counter should reset itself back to zero.

As you can see LCD displays are pretty simple to use thanks to the availability of some excellent libraries for the Arduino. As these displays are also very inexpensive they will make an ideal addition to many of your Arduino projects.

And finally the LCD Keypad Shield is a convenient method of adding both a display and a simple keypad to your project, no wiring or soldering required.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey