color reflective lcd module free sample

Reflective LCDs have been around for a long time but have never made much of an impact on the display industry. FLEx Lighting, a US- based startup, is looking to change that with some fascinating technology that greatly improves the performance of reflective LCDs, and just might make this display technology a big part of the industry landscape in a few years.

I visited with FLEx Lighting CEO Mike Casper this week in his company’s office in down- town Chicago to learn more about their technology, and came away impressed with the technology and the opportunities it presents for improving the prospects for reflective LCD. FLEx Lighting recently concluded a series B funding round, raising $9 million from SABIC Ventures, Bascom Ventures, and others, and intends to use the funding to expand its product portfolio to larger sizes.

One of the main inhibitors of reflective LCD in the marketplace, in competing against other reflective technologies like electrophoretic (e-paper), is that while reflective LCDs perform very well in direct sunlight, they are not readable in low-light conditions, and traditional frontlight panels do a poor job.

Figure 1 supplied by FLEx Lighting shows a simplified perspective of the problem and the solution. 1a shows e-paper with a typical frontlight at the sides of the display. Because the display is paper-like, the light rays coming from oblique angles scatter in all directions, allowing good readability. Reflective LCDs use a mirror behind the LC layer to reflect incident light, but as shown in 1b the mirror reflects incident light from a frontlight with only a slight scatter. Backlit LCDs, shown in 1c, do not encounter this problem because all the optical layers sit behind the LC layer.

The FLEx Lighting system offers many advantages over existing products. Although e-paper has offered some color display systems, the color gamut is far less than LCD. LCD also offers video capability which e-paper cannot match. The thin profile of the FLEx Lighting wave guide keeps the overall display package thin, and the ability to wrap the waveguide around the display to include the LED in the back of the display allows for a bezel-free design. The LED can be positioned close to the wrap-around, or further away, allowing the device maker design flexibility in electronics layout, as shown in the picture.

The ability to tightly control the exit angle of light gives the FLEx Lighting approach additional benefits. As shown in the figure below, the light output of the lightguide can be made with a broad peak or a narrow peak or even a peak offset from normal incidence. A narrow peak from the lightguide would presumably give a reflective LCD with a narrow viewing angle, which might be desirable in some applications and undesirable in others, but the design flexibility is undoubtedly an advantage.

The performance of a reflective LCD using FLEx Lighting’s approach may have manufacturers reconsidering reflective displays. While reflective displays have always offered the benefit of low power, the inability to use these displays in low light conditions has severely limited suitable applications. Although ePaper with a frontlight enabled low light readability, the performance constraints of ePaper for color and video, combined with the higher cost for the technology, have limited e-paper to niche markets. As the picture below shows, though, a reflective LCD with a FLEx Lighting frontlight system can give good contrast and color in both direct sunlight (with the frontlight off) and in a dark room (using the frontlight).

In trying to evaluate the performance of a reflective LCD vs. a conventional backlit LCD or an OLED, some of the most common performance metrics get thrown out the window. Brightness, of course, is a meaningless metric for a reflective display in a daytime condition, as the light comes from the sun, as seen in the picture. Casper encouraged me to think about ambient contrast as a relevant performance metric. Whereas OLED achieves near-infinite contrast in a dark room, in a daylight condition the contrast deteriorates severely.

According to Casper, some of the existing reflective display products on the market are designed to look good on the showroom floor, rather than actual use. The Nook was the first front-lit e-reader, and was designed for a brightness of 50 nits to appear bright in a sales environment, but Casper said that in follow-up research e-readers’ designers found that in actual use the brightness was set to on average only 7 nits. Casper noted that a reflective LCD for a 6” tablet display using FLEx Lighting’s technology would require just four LEDs to achieve 50+ nits.

FLEx Lighting says that their technology can achieve better color performance, although I admit I’m not yet convinced. The colors on sample pictures I’ve seen look to be a bit pastel to me. Again, measurement of color for a reflective display is not the same as color for an emissive (or transmissive, like LCD) display, so some of the usual benchmarks may not be appropriate. At the very least, the color for a reflective display depends not only on the display itself, but on the color of the light source.

FLEx Lighting has commercialized several small display products with LCD makers, Sharp and JDI, and Casper indicated that they have two prototypes at major display makers in Asia. The prototypes include an 8” reflective LCD for an e-reader for the China education market, and a 6” display for a phone. The advantages of reflective LCD would seem to make it an excellent choice for both of these applications.

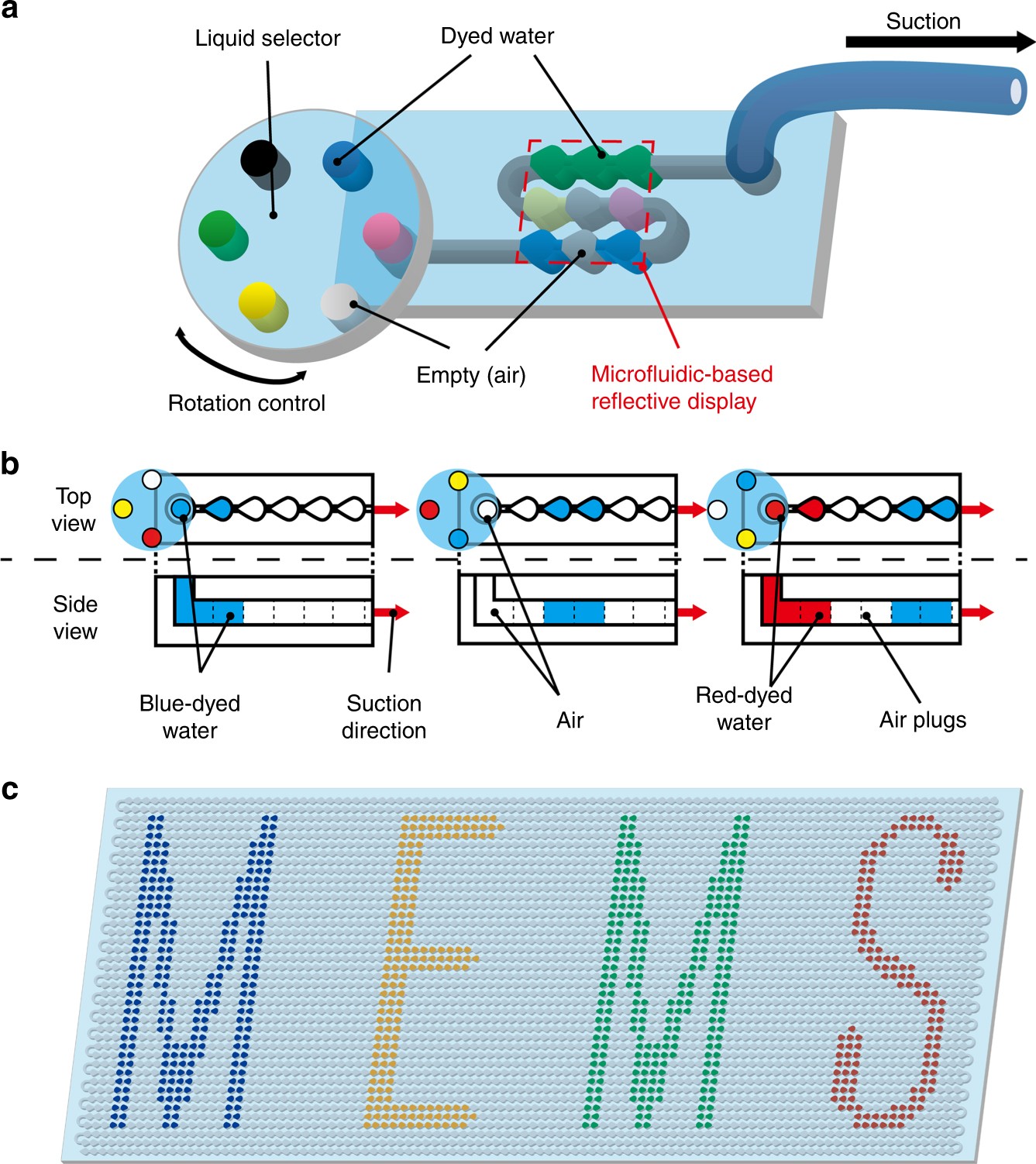

Silicon wafers (4 in) were purchased from Matsuzaki Seisakusyo Co., Ltd. (Fukui, Japan), Acetone, isopropyl alcohol (IPA), and ethanol were purchased from Wako Co. Negative photoresists (SU-8 3050 and SU-8 3025), and SU-8 developer solution was purchased from Nippon Kayaku Co. (Tokyo, Japan). PDMS prepolymer and a curing agent kit (SILPOT 184) were purchased from TORAY (Tokyo, Japan). Water soluble color dyes (red: 14% new coccine (C20H11N2Na3O10S3) and 86% dextrin; blue: 8% Brilliant Blue FCF (C37H34N2Na2O9S3) and 92% dextrin); and yellow: 14% tartrazine (C16H9N4Na3O9S2) and 86% dextrin) were purchased from Kyoritsu-foods Co. (Tokyo, Japan). The purchased dye powders were dissolved in deionized water at 0.5% (w/w) for our experiments. Deionized water was obtained from the Direct-Q UV 3 (Merck Millipore, MA, USA) 224 purification system. Parylene C was purchased from Specialty Coating Systems (IN, USA).

Red (0.5% (w/w)), yellow (0.5% (w/w)), and blue (0.5% (w/w)) dyed water droplets and air (blank) were prepared in reservoirs of the liquid selector. By controlling the negative pressure generated by the valve system, we sequentially introduced dyed water and air alternately to generate multicolor dyed water droplet patterns in linear microchannels for one-dimensional displays or meandering (zigzag) microchannels for two-dimensional displays. To test the display performance, we introduced dyed water and air alternately and formed images in the matrix channels through the multicolor dot matrix. We changed the dye color at each alternation. To evaluate the color display performance, the resulting images were captured by a digital camera (GXR, Ricoh Imaging Co., Tokyo, Japan) or a digital microscope (VH-5500, KEYENCE).

Durability is always a question when it comes to any outdoor product, and it is an area where reflective technology excels as well. From the famously rainy Pacific Northwest through the snowy Rocky Mountains (and all the way to the ever-bright Sunshine State), each of these environments presents its own set of challenges – from solar load to high humidity (and even sub-zero temperatures). Traditional backlit displays can struggle to adapt to these climate conditions – especially if they stay in one place year-round. By nature, they generate their own heat. Not only does this translate into wasted energy, it means the display needs to be designed to dissipate heat while directly in the summer sun. It must also be able to conserve that thermal energy as well as possible on a cloudy, blustery day.

With a temperature range of -20°C to +70°C and an IP65 rating, reflective technology truly is a PERFECT FIT for nearly any outdoor condition. There are a few exceptions, of course. If you regularly experience volcanic eruptions accompanied by category 5+ hurricanes and tsunami sightings, then you simply won’t find a display that works well for you, and we suggest you move to a safer place. Simply put, reflective displays are at home in any environment because they were designed to use natural elements, rather than compete with them. Backlit LCDs, on the other hand, try to “outbright” the sun, which is a tough task – no matter how you try to go about it! It always requires a lot of power and equates to a shorter lifespan – both of which have their costs over time.

All in all, here is the bottom line. As long as there are cities and towns, there will be parks. Can we agree on that? Within those parks, some form of information usually needs to be on display, which will need to be updated periodically. Are we still good? Great. Bottom line, it costs money to update that information, whether you’re paying for it in the form of a maintenance person who earns a salary or in the form of anLCD display(along with any maintenance/repair costs that come with it). Reflective displays make a lot of sense, because their maintenance costs are minimal, they last longer, they cost less to operate, and they do not run up the bill by requiring additional personnel on the payroll.

LCD technology is the direction that large outdoor signage is headed, andReflective LCDs from Sun Vision Display offer the best optionfor anyone who wants to stay moving in that trend.

Menu items change frequently with the seasons, as produce and local ingredients become available. Pricing or daily specials can also change with little notice. The last thing restaurant owners want to do is disappoint their customers who are anticipating a featured meal that is no longer available. Outdoor printed menus take a beating from the elements. Sunlight, moisture, and wind can quickly fade, discolor and batter printed paper menus risking a negative impression from the public. For all of these reasons, printed menus need to be re-printed, replaced, or printed with several versions. These simple changes can demand tremendous time, energy, and expense for restaurants relying on outdoor paper advertising.

To be objective, there were some initial challenges for implementing digital signage, as there are with incorporating any new idea or technology. When it comes to viewing any digital images in an outdoor environment, bright sunlight can make it difficult to see the image on the display clearly. In addition, this same bright light can cause devices to heat up quickly and even fail if proper precautions are not followed. Obviously, this is undesirable for any user and a concern for business owners who don’t want to see their investments only be subject to risk and failure. For a long while, the only solution was to have the display “outshine” the sun, cranking up the brightness on the device in an effort to power through the ambient sunlight. In some ways, this can be effective, as the saying going, “The brightest stars are seen at night.” But this method also comes at a high cost. First, it takes a lot of energy to try to beat the sun when it comes to emitting light and even if capable, that energy comes with a price tag that is ever consuming, unless the sun were to stop shining. At that point, digital displays would become the lowest of anyone’s worry. Second, this energy output also creates heat of its own and is another amount of energy that needs to be dissipated before damaging the device. Additional Anti-Reflective coatings and AC fans or water-cooling systems need to be used to pull heat away, adding to the overall energy usage and cost of operating the display. Last, by using the High Brightness mode, the LCD and back lights themselves would degrade more quickly, reducing theoverall lifespan of the displaybefore it would need to be fully replaced. So while a display may be able show a brighter image in bright conditions, it is important to understand what it takes to achieve that result.

The best aspect of technology is how quickly it advances. Just as printed paper menus are being upgraded to digital displays, so is the digital signage industry constantly upgrading itself. For instance, Sun Vision Display approaches the issue of sunlight differently, turning what was considered a problem into a solution. By usingreflective technology, the same sunlight that other display panels compete with now becomes the exact light that illuminates the LCD panel. In this way, there is no need to “outshine” the sun or consume extreme of energy to do so. In fact, the brighter the sunlight, the better the images appear to the viewer, resulting in true sunlight readability.

The key to this technology is to replace the back light with a mirror-like reflective layer, eliminating the high energy component and cleverly converting interfering light energy into a useful asset. Though the physical mechanics of how this works may require several advanced degrees, the concept is actually quite simple and is what makes reflective displays truly a brilliant solution to an otherwise universal difficulty. As a result of this “small” change, many other benefits also arise. The energy required to operate the display is reduced up to 95% and in addition to removing the back light, saves overall cost every time it is turned on. The display welcomes bright light and is not subject to the same high heat degradation of other displays, increasing its overall lifespan and again reducing energy costs to cool the unit. Each factor that previously worked against the user now each benefit from the reflective technology and create a solution that is much more than the sum of its parts. This is the brilliance behind the way in which reflective technology has advanced the idea of using digital displays instead of printed paper menus.

In the above food truck example, reflective displays could work very well for a number of reasons. The low power requirements make it easy to operate in a setting with limited resources. Also, reflective displays are designed to handle nearly any weather-related conditions that may hit. For example, SVD displays have an operating temperature between -20C and 70C, making them suitable for many outdoor climates. They can also be sealed behind toughened glass and ruggedized to an IP65 rating which will help withstand weather and the jostling conditions of a moving vehicle.

At the IMID conference, Busan, August 28-31 2018, in South Korea, Etulipa spoke about the excellent performance of reflective color displays, based on the Electro Wetting Display technology.

Reflective displays, that can be digitally controlled to update information instantaneously, are the ideal alternative for out-of-home displays because of their excellent readability in bright daylight, absence of intrusive light emission and very low energy consumption.

Just like LED displays, reflective displays have to meet the requirements of the client. Out-of-home reflective displays need excellent contrast and color performance, high switching speed for video applications, and have to operate in and withstand outdoor conditions for periods of typically 7 to 10 years.

The human perception of a reflective display is identical to that of any other object that reflects light. Therefore the Munsell color system is an excellent basis to evaluate reflective display performance. The parameters to create bright displays are:

In Etulipa’s whitepaper, (title: Electowetting displays Allow billboards anywhere!) it is explained that a bright reflective display needs a CMY subtractive color system. Reason is that the alternative, an RGB approach, will reflect maximally 1/3 of the possible light.

In fig.1 an example is shown in which red light is reflected from a simplified RGB based display, and from a CMY stacked electro-wetting display. In the CMY approach the full area reflects incoming light, whereas in the RGB case 1/3 of the area reflects incoming light. The RGB approach will yield non-saturated colors.

The video still in fig. 2 demonstrates the saturated colors and high contrast of Etulipa’s electro-wetting displays using the CMY approach. These products have switching speeds complying with standard video requirements. You can watch switching speed in the video here.

Etulipa has tested electro-wetting display modules for suitability for outdoor applications. The Mil. Std. 810G* is followed as guideline for evaluating the performance. Critical performance tests involve a) performance and compliance with temperatures from –40 oC up to +70 oC ; b) solar testing, to demonstrate stable quality in sunlight conditions; and c) vibration tests to test endurance of the products in transport and in outdoor conditions, where the displays are exposed to vibrations like wind and passing traffic.

Crystalfontz has a large selection of sunlight readable displays. We carry both graphic sunlight readable LCD displays as well as character sunlight readable LCD displays.

A transflective lcd offers lower power for high ambient light applications, very good sunlight readability, and good balance between indoor and outdoor readability. They perform better under all lighting conditions, especially direct sunlight.

A reflective lcd display has polarizers that are basically a mirror that sits behind the LCD glass reflecting all the light from the sun and redirecting it back towards the user. The brighter the light, the easier it is to read. The downside to a reflective polarizer is that in dark environments, you cannot put a backlight behind it. The reflective polarizer will block any light from reaching the user. If you must have a backlight, you may need to add an edge lit or side lit LED light.

Newhaven 160x100 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a gray background. This reflective LCD Display is visible with high ambient light while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C160100CZ-RN-FBW display has an optimal view of 6:00 and has no backlight. This display operates at 3V supply voltage and is RoHS compliant.

High contrast and wide viewing angle: The monochromatic bistable LCD’s contrast ratio is as high as 25:1, viewing angle about 80 degree in all directions.

For Cholesteric materials with positive dielectric anisotropy, the molecules in the planar structure will easily realign parallel to an applied electric field, generating the reflective layered structure. To break up the helical layered structure is to apply voltage around 6V to 30V. In order to switch from focal conic state back to planar state, even higher voltage is needed (35V). The exact voltage required for switching depends on cell gap as well as dielectric anisotropy of liquid crystals. The focal state is less stable than the planar state.

The finished product design should incorporate a transparent cover such as acrylic, polycarbonate etc. to protect the viewing area of the display. Place the protective cover as close to the display bistable module as possible. The protective cover should be sufficient thickness to resist bending.

The power used for screen refreshing is pretty high. So, it will not worthwhile for an application if the screen has to be refreshed more than 20 to 50 times depending on the battery used. Bistable display technology has been used for shelf label and E-reader. Bi-stable LCDs requires the use of a voltage booster. Designing into some environments needs to be cautious, examples: explosive gas. Bistable LCDs are limited to one color of character and one color of background.

Bistable LCDs are reflective and do not require a backlight. This can be a disadvantage in areas with dark ambient light. If the lighting has to be used, it can only use front light instead of backlight. It can be expensive and lose its key advantage of low power.

LCD Display Modules└ LEDs, LCDs & Display Modules└ Electronic Components & Semiconductors└ Electrical Equipment & Supplies└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

This color is one of the most commonly used online. reflective lcd displays are differently used and, for some reason, they don"t come in a wide range of colors. While reflective lcd displays are made of differently and glass, they create differently shaped effects and cause different harm to the user.

reflective lcd displays are used in a variety of settings, including on-the-goens, and for. use reflective lcd displays with different advantages. As a business, it ’ s important to note that reflective lcd displays have different advantages. One of the main advantages of reflective lcd displays is the ability to be refed without using the light materials.

Polymeric substrates for stretchable displays. a Flexible E-paper display(QR-LPD®) fabricated on PET substrate. b Flexible electrochromic display on ITO coated PET substrate during dynamic bending test. c Picture of a poly amide-imide film with low CTE(~ 4 ppm/ °C) and high transparency. d Schematic structure of photonic crystal fiber and color change at given strain. Polystyrene particles are coated on PDMS core. e Stretchable electrochromic device fabricated on polyurethane(PU) substrate

Stretchable electrodes and structure for stretchable electrochromic displays. a A SEM image of the AgNWs on a glass substrate. b Stretchability of a AgNW electrode is demonstrated with a light-emitting diode. c Electrical and optical properties of stretchable electrodes. (i) Normalized resistance as a function of applied strain. (ii) Transmittance versus sheet resistance. d (i) Possible structure of the stretchable electrochromic device. (ii) An example with AgNW/PDMS and WO3. e Patterned electrochromic device in bleached and colored states at 0 and 50% strain

Transparency and conductivity are both important for the top electrode of the stretchable display. Thus, it is possible to construct a structure with electrochromic materials sandwiched between two electrodes with sufficient transparency, conductivity, and mechanical properties (Fig. 13d). There have been some cases in which electrochromic molecules were combined with stretchable substrates [94, 95]. Stretchable electrochromic devices based on an AgNW/PDMS elastic conductor have been reported (Fig. 13dii) with an electrochemically deposited WO3 active layer. Fast coloration (1 s) and bleaching (4 s) times were achieved, and functioning at a 50% stretched state was demonstrated (Fig. 13e).

There is the other system driving stretchable reflective displays that control and display colors by an electric field. Electric field-, rather than electron transport-driven systems have dielectric layers separating two electrodes, like a capacitor. In this case, in which only electric fields are exploited, ionic conductors can replace electrodes, which allows the system to take advantage of ionic conductors. Sun et al. demonstrated the operation of an electroactive device without electrochemical reactions by taking advantage of ionic conductors [96]. Electrochemical reactions are a major concern when ions are exploited in conjunction with applied voltages. The device with capacitor structures is transparent in the visible light range and exhibits electrical actuation with areal stretching when voltages are applied (Fig. 14a).

Ionic conductors for stretchable reflective displays. a Transparent ionic conductors are exploited for DEAs without electrochemical reaction. b Performance of hydrogel ionic conductor exhibiting relatively insensitive resistance change upon stretching with a high transparency comparing to other electrodes. c A design for stretchable reflective display with ionic conductors. d A similar structure of electroluminescent display using ionic conductors. e Luminescent behavior of the display under uniaxial stretching. f Patterned luminescent displays showing various colors under a mechanical deformation

Hydrogel ionic conductors have lower sheet resistance and maintain high transmittance with relatively insensitive resistance changes under stretching in comparison to other electrodes, such as AgNWs, SWNTs, ITO and graphene (Fig. 14b). Also, ionic conductors are highly stretchable, easy to make and inexpensive, which is important for the fabrication of commercial stretchable displays. Thus, a design for stretchable reflective displays using ionic conductors has been proposed (Fig. 14c). By introducing colorants such as pigments or mechanochromic materials between the transparent dielectric elastomer, a colored dielectric layer can be fabricated. Subsequently, the layer is sandwiched between two transparent ionic conductors with a stretchable substrate. Even though the design seems feasible for stretchable reflective displays, no demonstrations have yet been reported during the current development phase of reflective displays, which has proven slower than the development phase of emissive displays. A similar design using electroluminescent materials was presented for stretchable emissive displays by Larson et al. (Fig. 14d) [97]. The display consists of an electroluminescent dielectric layer that is fabricated by mixing zinc sulfide phosphor into EcoFlex. The dielectric layer is then sandwiched between two ionic conductors and operated by applying a voltage, and emits white light continuously even under uniaxial stretching to over 395% strain (Fig. 14e). Also, by using a patterning technique, stretchable multicolor displays have been demonstrated under mechanical deformation (Fig. 14f) [98]. In the same manner, reflective materials that are used in electrophoretic, electrokinetic and electromechanical color change systems can be used in conjunction with ionic conductors for stretchable reflective displays.

All stretchable displays are basically composites of soft materials. Being similar to other stretchable emissive displays, stretchable reflective displays are composed of top/bottom substrates, two electrodes and a display working layer. Such components are arranged vertically in most displays, so layer-to-layer processes are typical fabrication methods [99] (Fig. 15a). Bottom substrates are prepared first, followed by a planarization process if required. Then, the lower electrode and display layer, upper electrode and top substrate are laminated one by one. Roll-to-roll manufacturing processes have been used to product displays more efficiently. This process has high throughput, and has already been adopted for flexible reflective displays [18] (Fig. 15b). In both processes mentioned, separating each pixel is important. Photolithography can be used to pattern the grid for each pixel [100] (Fig. 15c). Also there are spacers in the display layer, to separate each pixel. These spacers are connected to both upper/lower patterned electrodes, completely closing each pixel [101] (Fig. 15d). Here, the problem is that such connections between different materials (i.e., between substrates, electrodes, display layers or spacers) can be vulnerable to mechanical failure or invasion by impurities when the display is stretched.

Display fabrication processes and pixel structures. a Schematic process of layer-to-layer fabrication of the reflective display, reproduced with permission. b Roll-to-roll process for liquid powder display fabrication. c ITO grid patterned by lithography. d Structure of electrophoretic display with spacers

Tight adhesion at inner interfaces is important for mechanical stability. Similarly, tight sealing at the external surface of a device is also very important for chemical stability. To prohibit molecules from passing through, surface materials should have low permeability to water, oxygen and any other materials. For example, hydrogel can be coated with butyl rubber to prevent water from evaporating [105]. Such coatings can protect entire displays from impurities, because butyl rubber has much lower water and oxygen permeability than typical PDMS and many of other elastomers [106]. Elastomers with low elastic moduli and low permeability should be selected as external coating materials to prevent the infiltration of impurities [105], and reduce the risk of damage to the stretchable reflective display (Fig. 16d).

Electronic paper, popularly known as e-paper, can be defined as a dynamic display technology that emulates traditional paper. As LCD, e-paper belongs to the non-emissive display category but, in this case, no backlight is needed since the ambient light from the environment is enough.

Cholesteric liquid crystal (ChLCD), already mentioned as a subgroup of LCD, is generally classified as e-paper because of its zero consumption when it is not receiving screen updates.

A next generation of flexible, color and video e-paper is currently emerging. The most promising seems to be the electro-wetting approach (EWD) [38]. Its main component, liquavista (see Figure 3b), was developed by Philips but currently belongs to Amazon. Another interesting technology based on Interferometric Modulation (IMOD) is microelectromechanical sytems (MEMS) [39], whose potential has been demonstrated through several prototypes (trademarked Mirasol [40]) developed by Qualcomm.

Another less matured technology is electrofluidic [44], which presents the main novelty of using a three-dimensional microfluidic device structure and offering brilliantly colored aqueous pigment dispersions. Recently, other lines of investigation have aimed to simulate traditional paper through electronic paper made from microbial cellulose [45].

E-paper screens are reflective — light from the environment is reflected from the surface of the e-paper display towards the user’s eyes, just like with traditional paper. This gives e-paper a wide viewing angle that is readable in direct sunlight.

E-paper screens are bi-stable — unlike conventional backlit flat panel LCD displays, which refresh about 30 times per second and require a constant power supply to maintain content, e-paper displays will hold a static image ‘forever’, even without electricity. E-paper only consumes power when the content on it changes – for example if an e-paper shelf label in a supermarket is updated with a new price. The rest of the time the display will simply show the content you want it to, where it doesn’t draw any power until the next update.

The emergence of electrowetting-on-dielectric (EWOD) in the early 2000s made the once-obscure electrowetting phenomenon practical and led to numerous activities over the last two decades. As an eloquent microscale liquid handling technology that gave birth to digital microfluidics, EWOD has served as the basis for many commercial products over two major application areas: optical, such as liquid lenses and reflective displays, and biomedical, such as DNA library preparation and molecular diagnostics. A number of research or start-up companies (e.g., Phillips Research, Varioptic, Liquavista, and Advanced Liquid Logic) led the early commercialization efforts and eventually attracted major companies from various industry sectors (e.g., Corning, Amazon, and Illumina). Although not all of the pioneering products became an instant success, the persistent growth of liquid lenses and the recent FDA approvals of biomedical analyzers proved that EWOD is a powerful tool that deserves a wider recognition and more aggressive exploration. This review presents the history around major EWOD products that hit the market to show their winding paths to commercialization and summarizes the current state of product development to peek into the future. In providing the readers with a big picture of commercializing EWOD and digital microfluidics technology, our goal is to inspire further research exploration and new entrepreneurial adventures.

Electrochromic devices (ECD) are electrochemical cells where color changes occur upon electrochemical reactions of two or more redox active electrochromic materials electrically connected by an external circuit and physically separated by an ionic conducting layer (electrolyte layer). Electrochromic materials and devices can be controlled to change their color and opacity by the application of electrical stimuli. ECDs are a non-light emitting reflective technology. Materials for ECD manufacture can be taken into the form of printable inks and the manufacturing processes made compatible with standard graphic printing and converting processes. The resulting device can be made thin, flexible, transparent, robust, and ultra low-power. As ECDs can be produced into a wide range of different shapes and sizes, they offer a wide range of advantages for product design and integration.

Japan Display Inc. (JDI), a leading global supplier of small- and medium-sized displays, has announced the start of sales of a standard line-up of memory-in-pixel (MIP) reflective-type color LCD modules for wristwatch-type wearable devices which realize ultra-low power consumption. Power consumption of these reflective-type LCD modules is less than 0.5%*1 that of transparent-type LCD modules.

Transflective LCDs combine elements of both transmissive and reflective characteristics. Ambient light passes through the LCD and hits the semi-reflective layer. Most of the light is then reflected back through the LCD. However some of the light will not be reflected and will be lost. Alternately a backlight can be used to provide the light needed to illuminate the LCD if ambient light is low. Light from the backlight passes through a semi-reflective layer and illuminates the LCD. However as with ambient lighting some of the light does not penetrate the semi-reflective layer and is lost.

Cholesteric liquid crystals (hereafter Ch LCs) are self-assembled systems consisting of elongated chiral organic molecules. They possess a helical structure where the local average direction of the molecules twists spatially around an orthogonal helical axis. Their refractive index varies periodically, and thus exhibits a Bragg reflection band centered at the wavelength λ = [(ne + no)/2]P and with the bandwidth Δλ = (ne – no)P, where ne and no are the extraordinary and ordinary refractive indices of the LC, respectively, and P is the helical pitch. They can be used to make reflective displays which do not need polarizers and have high reflectance.

Dr. J. William Doane is a world renowned expert in the field of liquid crystal materials and devices. Together with William Manning he co-founded Kent Displays, Inc. in 1993 and the company is now famous for its Cholesteric LCD based Boogie Board writing tablets that use Dr Doane’s inventions. Dr. Doane, was the director of the world-renowned Liquid Crystal Institute at Kent State University from 1983-1996 and led the effort during that time to establish the National Science Foundation Center for Advanced Liquid Crystalline Optical Materials (ALCOM). As an active member of the international science community, he has held visiting appointments and maintained cooperative research programs in several countries. Dr. Doane was instrumental in formalizing the International Liquid Crystal Society and served as the organization’s first treasurer from 1990-1996. Dr. Doane was named a Fellow of the American Physical Society in 1982 and retired from the Kent State University in 1996 after a 31-year teaching and administrative career. Dr. Doane received the first ever presentation of the Slottow-Owaki Prize for Display Education, by SID.

A wide range of reflective displays have recently been developed, and Fig. XX compares several of the most prominent. Much like color generation in animals, reflective displays can be separated into the same two main categories; pigmentation and structural color. Under the tent of pigmentation are products such as e-ink based “E-readers”, and color filter based liquid crystal displays. E-readers use the translocation of 3 charged pigmented beads, and as such, require seconds to switch between images. Due to the macroscopic size of each pixel, resolution and color reproduction are also limited. Reflective liquid crystal displays are much quicker, taking only milliseconds to switch states, but are limited in brightness as polarizers immediately halve the amplitude of the reflected light. Many structural color based displays are currently in development and have only recently entered the market. One such device is an interferometric modulator produced by Qualcomm where within each pixel, a cavity is formed between a Bragg stack and a MEMs mirror. By controlling the cavity spacing, the reflected light experiences either constructive or destructive interference resulting in a bright color or dark state. While producing the signature bright vivid colors of Bragg reflection, the device is inherently angle sensitive and limited to rigid substrates. Another emerging structural color based device uses a photonic crystal made from silica spheres submerged within an electro-active polymer, and is branded Photonic Ink (P-ink). The polymer stretches as a field is applied, increasing the period of the photonic crystal and therefore the wavelength of reflected light. Though the colors are vivid and tunable, the response time of the polymer is tens of seconds, making video impossible. Cholesteric and blue phase LC displays behave in a similar manner. Helixes of LC form periodic nanostructures which produce Bragg reflections at desired wavelengths. The LC structures can be switched through an external field thereby producing dark and light states. While producing vivid color, these devices are limited in brightness as the helical structures only reflect circular light of the same handedness of the LC. By assessing current technologies we determine there is much to understand and develop in order to truly mimic color generation in nature. A fast response, angle independent LC-metasurface based display which can actively shift the color of its pixels from RGB to black holds the promise for development of truly thin-film flexible displays.

Currently, there are two different photonic-crystal- based modulation approaches in development. Opalux is fabricating electrically color-tunable photonic crystals by embedding the lattices of 200-nm-diameter silica beads within an expandable electroactive polymer, which they call Photonic Ink or P-Ink.142 Opalux has demonstrated bistable P-Ink with a reflectance >50% and switching speed ~0.1 sec.143 The company has not described the viewing-angle dependence of their technology; photonic-crystal structures that possess highly regular crystal structures can show sharp dependences on illumination and viewing angles.

The company Nanobrick is developing systems that control the inter-particle distance of SiOx-encapsulated metal nanoparticles (20–30 wt.%) in electrophoretic colloidal suspension.144 These photonic crystal structures respond to signals of a few volts, shifting the reflected color through a continuous range as the average spacing changes. This enables full-spectrum tunability using a single electro-optic layer without requiring individual primary-color subpixels to generate color. It appears that the electrophoresis tends to randomize the structure somewhat, leading to reasonably wide viewing angles. Nanobrick has demonstrated a Color Tunable Photonic Crystal Display (CPD) with angle-independent optical responses (0–40°) using quasi-amorphous photonic pixels with response time <50 msec.145

While single-layer color tuning is a unique capability of the photonic-crystal approaches, the technology focus thus far has been limited to unit pixel or simple segments and still needs refinement in terms of the white state, reflectance vs.illumination condition, and demonstration with matrix addressing. Even though, in theory, colors such as red can be displayed at all pixels, white is still challenged because white will likely require additive display of side-by-side RGB pixels [similar to Fig. 2(b)]. Additionally, since pixels currently do not possess inherent gray scale, that means gray scale at the display level will require halftoning approaches.

Structural colors, well known from coloration in nature (7), can overcome these limitations. Different from dyes and pigments, structural colors are generated by the interaction of light with micro- and nanostructures. Vibrant colors can be produced with the same materials (e.g., metals or dielectrics) by changing the geometries, dimensions, or arrangements of the structures through the fabrication process or even after fabrication (8). Compared to pigment or dye-based coloration, colors created in this case are much brighter due to their inherently high scattering/absorption efficiencies. As a result, thin layers, or more precisely tiny volumes, are sufficient for brilliant coloration. The benefit of these small coloration volumes is obvious. Ultrahigh-resolution images composed of subwavelength pixels with sizes down to the smallest coloring unit, e.g., a single micro- or nanostructure, can be printed (9). In addition, structural colors do not fade over time but provide a basically everlasting coloration due to the stability of the coloring structures. These appealing advantages have attracted great interest and stimulated intensive research on various structural coloration schemes based on metal nanostructures, dielectric metasurfaces, photonic crystals, and Fabry-Perot (FP) resonances (6, 10–17).

Plasmonic color is a subset of structural color, which is color resulting when the micro- or nanostructure of a material causes light scattering and interference. One form of structural color is the iridescent blue of the Morpho butterfly’s wings, whose scales have branched nanostructures that scatter light in complex ways. In plasmonic color, the color arises from light absorption and scattering off of the nanoparticles themselves. As with other forms of structural color, size, shape, and patterning create the color rather than chemical composition.

The Naval Research Laboratory’s Fontana has a different approach to making dynamic plasmonic displays: using self- assembled colloidal gold nanorods suspended in toluene. By placing an electric field across the suspension, the nanorods align in the direction of the applied field, producing intense plasmonic color, Fontana explains. The system is fast; it can switch at least 1,000 times as quickly as a conventional liquid-crystal pixel, potentially cutting down on motion blur, which is a problem with LCD displays.

In current commercial displays, each pixel is actually made of a red, green, and blue subpixel. Different amounts of light from each subpixel mix to create the perception of any color desired. One ambition for those developing plasmonic color systems is to flip one pixel between red, green, and blue rather than needing three separate subpixels that would require less space, allowing for much smaller pixels and higher definition screens. A system that can do just that has been created in the lab of Jeremy Baumberg at the University of Cambridge. It uses gold nanoparticles coated in the conducting polymer polyaniline and sprayed onto a flexible mirrored surface. The mirrored surface amplifies the plasmonic resonance, resulting in a more intense, uniform color with no viewing-angle dependence.

The color of each pixel is tuned by the reversible oxidation and reduction of the polymer, which changes the polymer’s refractive index and shifts the system’s plasmonic resonance. Each nanoparticle can theoretically be tuned independently, providing a potential spatial resolution of less than 100 nm. So far, the researchers have created pixels that switch only between red and green, but they are working on blue. Silver or aluminum particles could potentially show blue color, but “there is always a trade- off, as silver and aluminum materials are chemically [more] unstable [than gold],” says Hyeon-Ho Jeong, who formerly worked as a postdoc with Baumberg at Cambridge and is now at Gwangju Institute of Science and Technology.

In AMLCD, a switch is placed at each pixel which decouples the pixel-selection function. Thin Film Transistor (TFT), the main technology of the AMLCD subgroup, can also be divided regarding the material used for its elaboration, into amorphous silicon (a-Si), continuous grain silicon (CGS) and low temperature polycrystalline silicon (LTPS TFT). A new approach is the indium-gallium-zinc- oxide (IGZO) technology developed by Sharp.

Another issue to take into account is the liquid crystal alignment mode, where Twisted Nematic (TN) and Super-Twisted Nematic (STN) types are the simplest and least expensive, but offering a poor viewing angle (of approx. 45 degrees). Vertical Alignment (VA) technology generally appears under various trade names (ASV by Sharp, PVA by Samsung, etc.) and tries to improve the viewing angle of the device (for instance, Ampire VA device offers 160 degrees versus the 45 of the TN device by AUO). In-plane switching (IPS TFT), as the Hitachi module from the table shows, also has a better viewing angle than TN and the color and contrast is also improved.

The evolution of portable communications applications has been facilitated largely by the development of reflective LCD technology. Offering a unique insight into state-of-the art display technologies,Reflective Liquid Crystal Displays covers the basic operations principles, exemplary device structures and fundamental material properties of device components.

Direct-view, projection and micro (virtual projection) reflective displays in the context of multi-media projectors, mobile internet and personal entertainment displays.

Description of the basic properties of liquid crystal materials and their incorporation into configurations for transmissive and reflective applications.

The evolution of portable communications applications has been facilitated largely by the development of reflective LCD technology. Offering a unique insight into state-of-the art display technologies,Reflective Liquid Crystal Displays covers the basic operations principles, exemplary device structures and fundamental material properties of device components.

Direct-view, projection and micro (virtual projection) reflective displays in the context of multi-media projectors, mobile internet and personal entertainment displays.

Description of the basic properties of liquid crystal materials and their incorporation into configurations for transmissive and reflective applications.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey