lcd panel light 405nm manufacturer

Advancements in 3D printing, along with product complexity and different types of available processes have made it challenging to select the right 3D printer for high-volume manufacturing. Digital Light Processing (DLP) and LCD are two commonly implemented resin-based 3D printing technologies. The following compares DLP vs. LCD 3D printers, their unique features, and the subtle differences.

Resin-based 3D printing technologies (also known as vat-polymerization) such as stereolithography or SLA, DLP, and LCD involve curing a photosensitive resin using a light source that helps solidify the resin and create the printed product layer-by-layer. The post-processing steps include cleaning the excess uncured resin and exposure to UV light for final curing. However, the major difference lies in using different light sources for curing the resin.

Next-generation DLP and LCD 3D printing platforms built on LuxCreo’s LEAP™platform are delivering new capabilities that simplify manufacturing and enable high-volume production. LuxCreo’s LEAP™platform outperforms current DLP, LCD, and SLA printers by developing and tuning software, hardware, and resin to deliver new capabilities: high throughput, maximum batch size, and DigitalPolishing™.

DigitalPolishing™ eliminates 90% of the post-processing polishing labor allowing manufacturers to print clear, transparent parts with no polishing required, eliminating the Achilles heel of SLA, DLP, and LCD vat-polymerization systems.

How it works:In DLP 3D printers, a digital projector screen is used to flash an impression of a layer across the platform. The light is reflected on a Digital Micromirror Device (DMD) — a semiconductor chip consisting of microscopic-sized mirrors/ lenses that direct the light towards the bottom of the tank containing the resin. The light defines the coordinate of the voxel (three-dimensional pixel) that is cured within the given layer.

Print Quality:As lenses are used to modify the size of the image, coming from a smaller DMD source to fit a wider print area, there are chances of producing distorted voxels at the edges of the build area. Cheaper DLP printers have issues with uniformity, such as the “flashlight effect,” resulting in higher light intensity in the middle but lesser on the sides. Such issues lead to layers not adhering and poor surface finishes due to under-curing or over-curing.

Speed:The higher intensity of light facilitates faster printing. By utilizing a wavelength of 405 nm with light intensity as high as 20-30 mW/cm2, DLP 3D printers can cure an entire layer at once and require less time to print more parts in a batch. Lower DLP wavelengths, including 385nm, are used to improve clear part accuracy and open up other traditional SLA resins for use on DLP. However, there are advantages and disadvantages to selecting 405nm or 385nm depending on if speed, precision, and/or longevity are the priority.

Pricing:DLP 3D printers traditionally are higher-priced printers vs. LCD printers. For this higher price, industrial Smart Factory DLP 3D printers are designed for volume manufacturing with consistent batch-to-batch and machine-to-machine production. Smart Factory DLP 3D printers provide higher speed, larger build volumes, longer life, and higher precision across large build areas versus LCD printers.

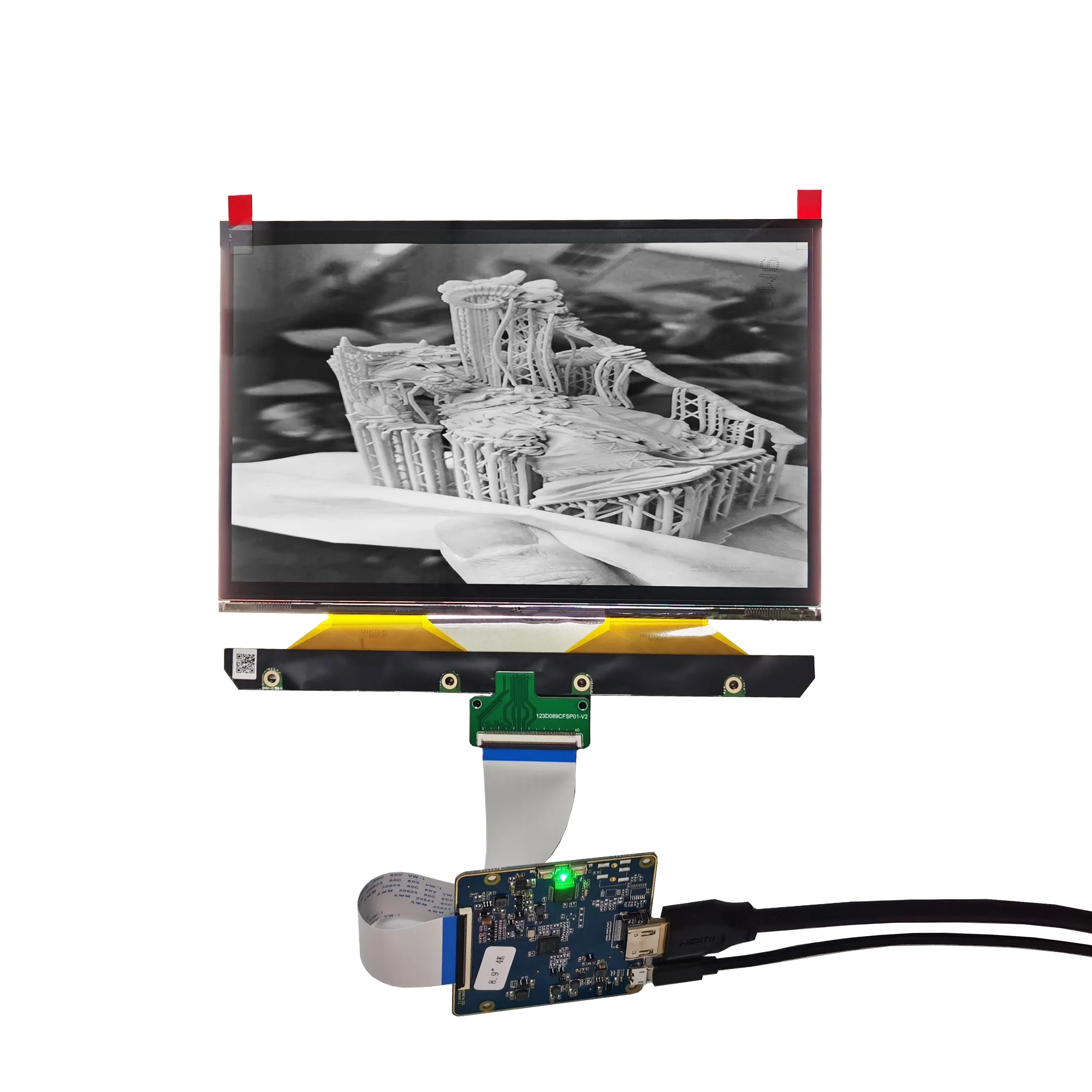

How it works:Unlike a DLP printer which is used as a projector, an LCD printer does not use a projector and deploys an array of UV LEDs as the light source and an LCD to mask (block) UV light allowing only select areas to be cured in the layer. Inexpensive LCD printers utilize cheap light sources that have low uniformity and produce light that is not columnated (aligned with the print area). This results in pixel distortion. LCDs also have a much shorter life versus DLP light engines requiring owners to frequently replace LCD screens, increasing consumable cost versus DLP printers.

Print Quality:Higher quality LCD can produce high-quality prints; however, as LCDs become larger, they have limits on uniformity, and batch to batch, machine to machine variability becomes an issue. Less expensive LCD 3D printers have challenges controlling distortion caused by a lack of LED array uniformity and alignment. If these technical challenges are not addressed, the print quality can be and be worse than in DLP printers.

Applications:Compared to FDM 3D printers, LCD printers offer better printing quality for the same price and are therefore popular for chairside dental or desktop applications. The lower cost barrier makes these printers popular for adopting 3D printing across dental, jewelry, engineering, hobbyists, and other industries.

Speed:Compared to DLP 3D printers, LCD printers are slower and are low in intensity in the range of 3-5 mW/cm2. Conventional LCD 3D printers can not print with high viscosity.

Pricing: LCD printers are created as an affordable alternative to their advanced 3D printing counterparts. With an easily replaceable LCD panel, these printers are customized for small spaces and are desktop-sized for ease of use.

When deciding between DLP vs. LCD 3D printers, a popular perception is that the DLP printers are better than the LCD. However, on a budget, next-generation LCD 3D printers can be the right first step into resin 3D printing, depending on the application-specific applications.

Next-generation DLP and LCD 3D printing platforms built on LuxCreo’s LEAP™platform are delivering new capabilities that simplify manufacturing and provide on-demand access to Smart Factory volume production. LuxCreo’s LEAP™platform outperforms current DLP, LCD, and SLA printers by developing and tuning software, hardware, and resin to deliver new capabilities: high throughput, maximum batch size, and DigitalPolishing™.

LuxCreo’s Smart Factory DLP and LCD 3D printer solve the above problems with traditional DLP and LCD 3D printers supporting repeatable high throughput production of high-performance and high-viscosity materials. LuxCreo’s Smart Factory DLP and LCD 3D printers open up a new category of 3D printers that deliver the fastest, most economical path to volume production.

To improve the performance of DLP or LCD 3D printers, it is necessary to get control over design, software, printer, and resins. LuxCreo’s integrated Smart Factory 3D printing solutions facilitate clear, transparent, faster, and accurate printing with both DLP and LCD printers while also providing the fastest, most economical path to volume production. Our advanced range of Smart Factory DLP 3D printers enables in-house production and provides contract 3D printing services through cloud-connected smart factories.

Luxcreo’s integrated suite of high-performance 3D printing materials, 3D printers, and software help manufacturers simplify high-viscosity 3D printing with Smart Factory DLP and LCD 3D printers. Our intuitive software tuned to our materials and our DLP and LCD 3D printers ensure uniformity, consistency, and accuracy in high-throughput and high-yield manufacturing batch to batch and machine to machine to achieve the highest, most economical production throughput.

All categories3D Hologram Fan LED DisplayAddressable LED StripsAll-in-one Conference LED Display SystemAll-in-One Video Conference SystemAnti-coronavirus Protective DevicesAsynchronous Controller/CardCatalogs of LED LightingComplete LED Strip KitsDecorative LED Light Strings & LanternsFlexible LED StripsFoldable LED DisplayFree Product - U.S. StockGift CardsHealth&Home&OutdoorsHigh Brightness LCD Display for Store WindowHigh CRI 90 LED StripsHigh Powered LEDs and COB LEDsIndoor Fixed LED ScreenIndoor Flexible LED Modules (P1.8-P8)Indoor LED Modules (P2-P10)Indoor Transparent LED ScreenIndustrial LED Grow LightsInground Path & Garden LED LightsIR (InfraRed) LED StripsLCD Digital SignageLCD Video WallLED Aluminum ChannelLED Car LightsLED Ceiling Downlights & SpotlightsLED Controller & DimmerLED Deck & Step LightsLED downlightsLED FloodlightsLED Grow Light BulbsLED Grow Light StripsLED Grow Tube LightsLED High Bay LightsLED Light BulbsLED Module StringsLED Neon Light HousingLED Neon Light StripsLED Night LightLED Novelty LightingLED Panel Lights & Troffer LightsLED Poster DisplayLED Power SuppliesLED Puck LightLED Receiving CardLED Street LightsLED Strip Connectors & CablesLED Tube Lights & FixturesLED Video ProcessorLED WallWashersLED_DownlightsLightweight HKN Series Outdoor LED DisplayMagic Cubic LED DisplayMulti-Color Changeable LED StripsMulti-role HK Pro Indoor LED DisplayNovelty LED DisplayOthersOutdoor Fixed LED ScreenOutdoor Flexible LED Modules (P2-P8)Outdoor LED FloodlightOutdoor LED Modules (P3-P10)Outdoor Transparent LED MeshPromotion!Red Light TherapyRental LED ScreenRigid LED StripsSHOPSTORM_HIDDEN_PRODUCTSmall Pixel Pitch LED DisplaySmall Pixel Pitch LED Modules (P1.25-P2)Smart Transparent Digital PosterSphere LED DisplaySupermarket Shelf Screen LCDSurface Mount (SMD) LEDsSynchronous Controller / CardThrough Hole and Pre-wired LEDsTransparent LED Digital Signage DisplayUltra High CRI 95+ LED StripsUnder Cabinet LED LightingUnderWater LED LightsUV (Ultraviolet) LED StripsXR Virtual LED Display Screen Solution

The Antarctic Bear learned that On October 20, 2021, Shenzhen International Touch and Display and Shenzhen Electronic Components Exhibition, Pengji Company held the autumn new product conference, and launched a variety of large-size, high-precision 3D printed LCD Mono displays.The biggest highlight of this conference was the industrial-grade 13.6 inch 7K mono screen with an area of 298.08 * 165.60mm,accuracy of 40um, purple light transmittance up to 10%, contrast ratio of 500, and operating temperature of -20 to +80°C. It means that consumer LCD light-curing desktop-level 3D printers are moving towards industrial-grade professional applications and it will make a rapidly development of LCD light-curing professional applications, and open a new era of LCD light-curing technology into industrial-grade machines....

The market for desktop resin 3D printers is booming — more and more manufacturers are offering compact devices for every taste. Earlier, this niche was firmly occupied by machines based on SLA and DLP technologies. Nowadays, however, there is a significant development of expensive 3D printing technologies, one of them is LCD, meaning printers with a liquid-crystal matrix. This is the technology that was used by the company that successfully received funding on Kickstarter twice — a Taiwanese manufacturer Phrozen, which is the main focus of this article.

Phrozen, founded by a group of Taiwanese engineers, has been around since 2013. In 2017, the company launched its first prototype — a 3D printer, which used an LCD matrix to create an image on a layer of photopolymer resin. Phrozen was able to raise more than $375,000 on the Kickstarter crowdfunding platform, with a stated goal of $30,000. In 2019, the company repeated its success, raising more than $519,000, with the same modest goal of thirty thousand. In both cases, the sponsors were interested in getting a printer with unique characteristics at a reasonable price.

The LCD printing process is almost identical to the DLP technology. In DLP, the three-dimensional product is created by curing layer after layer of resin with UV light. The main difference is that LCD-based 3D printers use a bank of UV LEDs to project light through a mask of the layer on an LCD panel. In DLP 3D printers however, a set of micro mirrors is used to selectively project UV light to create an image on the resin layer.

What makes Phrozen 3D printers stand out from other manufacturers? The main distinguishing features are the ability to quickly print out several units simultaneously, a great variety of brand resins, and compatibility with third-party materials. In addition to that, other features such as easy maintenance of the resin vat with FEP film, a high-resolution LCD matrix that allows printing with an accuracy of 0.047 mm, and low cost are worth mentioning.

Another remarkable feature is the Phrozen’s signature UV engine — paraLED, which provides a perpendicular and uniform light flow in relation to the LCD matrix.The construction is made up of an array of LEDs with a system of concave glass forms. The printing platform moves along the Z-axis on linear bearings on two rigid rails, which helps to avoid the usual printing errors for 3D printers of the same price category.

The Phrozen Sonic 4K 2022 is a desktop 3D printer that is considered to be the best entry-level solution for dental application.The machine uses the so-called mono-LCD technology, which allows it to use a more transparent LCD screen compared to standard ones.

Greater transparency in the UV range makes it possible to increase the intensity of light exposure, which allows to print a single layer of resin in just two seconds. Additionally, Phrozen claims that the new panel is four times more wear-resistant and durable than the usual, and promises a lifetime of 2000 hours.

The Phrozen Sonic Mini is a professional high-speed MSLA 3D printer introduced as the compact version of the Phrozen Sonic. It features the same proprietary mono-LCD technology allowing for great curing speed and high quality of resulting 3D models.

The machine boasts lightweight and portable design, stable kinematics, and high level of printing detail. The CHITUBOX software comes with a user-friendly interface and simple 3D printing experience. Apart from its outstanding technical characteristics, the Sonic Mini model attracts with its price as the best budget 3D printer of Spring 2020 (according to All3DP).

The Sonic Mini 4K operates with the utmost degree of reliability and precision. A long-life monochrome LCD screen guarantees at least 2000 hours of productive work. A solid frame with increased stability and a decent build volume make the Sonic Mini 4K ideal for both entry-level and experienced makers.

The model is considered to be one of the best cost-effective solutions among LCD 3D printers to date. It can be successfully used by small businesses and printing enthusiasts for a range of various applications.

The Phrozen Sonic Mini 8K features the highest resolution of 22 microns and 1152 PPI, which outperforms all consumer electronics on the market. Moreover, the machine boasts the 7.1" LCD screen with larger printing space and 18 cm Z-axis. Due to the frosted laser cut building plate, printed models attach firmly onto the build plate. In combination with the stable dual linear rails, it makes for smooth and impeccable printing of extremely detailed miniatures, bust sculpts, etc.

The Phrozen Sonic Mighty 4K is a resin 3D printer that is equipped with a monochrome LCD screen with a 4K resolution and 9.3" diagonal, which is 1.5 times larger compared to its counterpart, the Sonic Mini 4K. The massive build volume allows creating large scale models, while the proprietary ParaLED matrix and dual Z-axis guides provide the stability and high precision of printing.

Another feature inherited from the Mini model is an outstanding print speed due to the high intensity of UV light. Similar to other company’s products, the device boasts quality build and user-friendly controls. Thanks to its highlights, the Sonic Mighty 4K is a perfect tool for both personal and professional applications, such as jewelry, dental models, prototypes, tabletop miniatures, and much more.

The Phrozen Sonic Mega 8K is an industrial-grade mono-LCD 3D printer with a long-life monochrome LCD screen and ultra-high 8K definition. This professional machine is able to create remarkably detailed models. Due to its massive build volume, the printer allows producing multiple batches of 3D parts at really short times.

The Phrozen Cure V2 is an easy-to-use desktop UV curing machine designed to give your resin 3D prints a more refined and smooth outlook as well as certain durability. With an outstanding inner capacity and powerful UV lights, the post processing becomes really fast and efficient.

The machine is equipped with an UV lamp (405nm) that provides about 40,000 hours of continuous operation. The 360° rotating platform ensures uniform light distribution. With the Phrozen Cure Luna, the curing process is rapid and fully automated.

The Phrozen Cure XL is designed with great capacity and effective mechanism. It uses 365nm, 385nm, and 405nm UV-LEDs to cure different layers of printouts. The process is fully automated, fast, and even thanks to the 360° rotating platform.

The company offers special materials for their 4K and 8K machines. The unique formula guarantees top quality for high resolution models with fine details. The light color will serve as a perfect base for figurines.

With the slicer, one can easily build supports, hollow models, modify dimensions of various 3D files as well as slice them. Among other functions, there is a direct upload via WiFi, XY dimensions optimization, adding floor structures and light masks, etc.

However, he highlights several design flaws affecting print quality. For example, Eddito recommends removing the original tape gasket around the screen and using a regular tape instead to get more detailed outputs.

About storage:Store at room temperature (15-35℃); away from light; keep dry and good ventilation. Do not put it under the sun or under strong light. Keep it out of the reach of children.

Unlike many more expensive machines, Our printers allow the end user to choose what type and brand resin they want to use. Our printers use the industry standard 405nm UV Light curing materials. From any manufacturer.

In SLA system, light intensity, wavelength, and optical path highly influences printing quality and efficiency. Conventional LCD 3D printer tends to use thumb-size COB LED with Fresnel film. It is still not good enough for overall uniformity, especially for large area & edge area. Their major target is to reduce the cost. To further improve it, Phrozen"s ParaLED Optical Engine uses LED array matrix with the size same as LCD panel. Moreover, we narrow down the LED emission angle to make it as parallel as possible. That way, we can increase the efficiency that light pass through LCD and, therefore, greatly improve printing speed and quality.

Looking on the market, you will see Z-axis of many 3D printers are not fixed on top (or just simply put a cap on it). Overall Z-axis design is based on simple optical axis and rail shaft. These will cause severe wobbling during 3D printing process, especially for large & high models. That"s why Phrozen team uses Twin Linear Rail, Ball Screw, and Ball Bearing with Aluminum-CNC part to on our Z-axis. That can assure linearity and minimize impact of loaded force during the printing process. This concept has been widely verified in our previous model Phrozen Make XL, 8.9 inch LCD 3D Printer. Now we adopt same design again on our Phrozen Shuffle XL.

Phoseon’s unique UV-LED curing provides a consistent and reliable process to assemble touchscreen displays, whether it be to bond a cover glass to a liquid crystal display (LCD) or an organic light emitting diode (OLED) screen, or curing adhesives on a smartphone’s ultra-thin border to prevent light leaking out through the edges. Phoseon’s solution also cures the encapsulation layer of the OLED display, which is an essential element to prevent the damage of organic elements from oxygen and moisture over its life time.

“Phoseon’s UV-LED technology is used to cure the UV adhesive, typically an acrylic formula, creating a strong and uniform bond between each touchscreen display layer,” said Rui Zhou, technical marketing engineer at Phoseon Technology. “The benefits of UV-LED curing include excellent optical properties such as better light transmission, vivid color display and reduced glare.”

Phoseon’s technology, which has been used commercially for more than 12 years, is a photopolymerization process that uses UV-LED light to rapidly change or “set” a liquid to a solid, usually within seconds, without the use of heat or solvents.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey