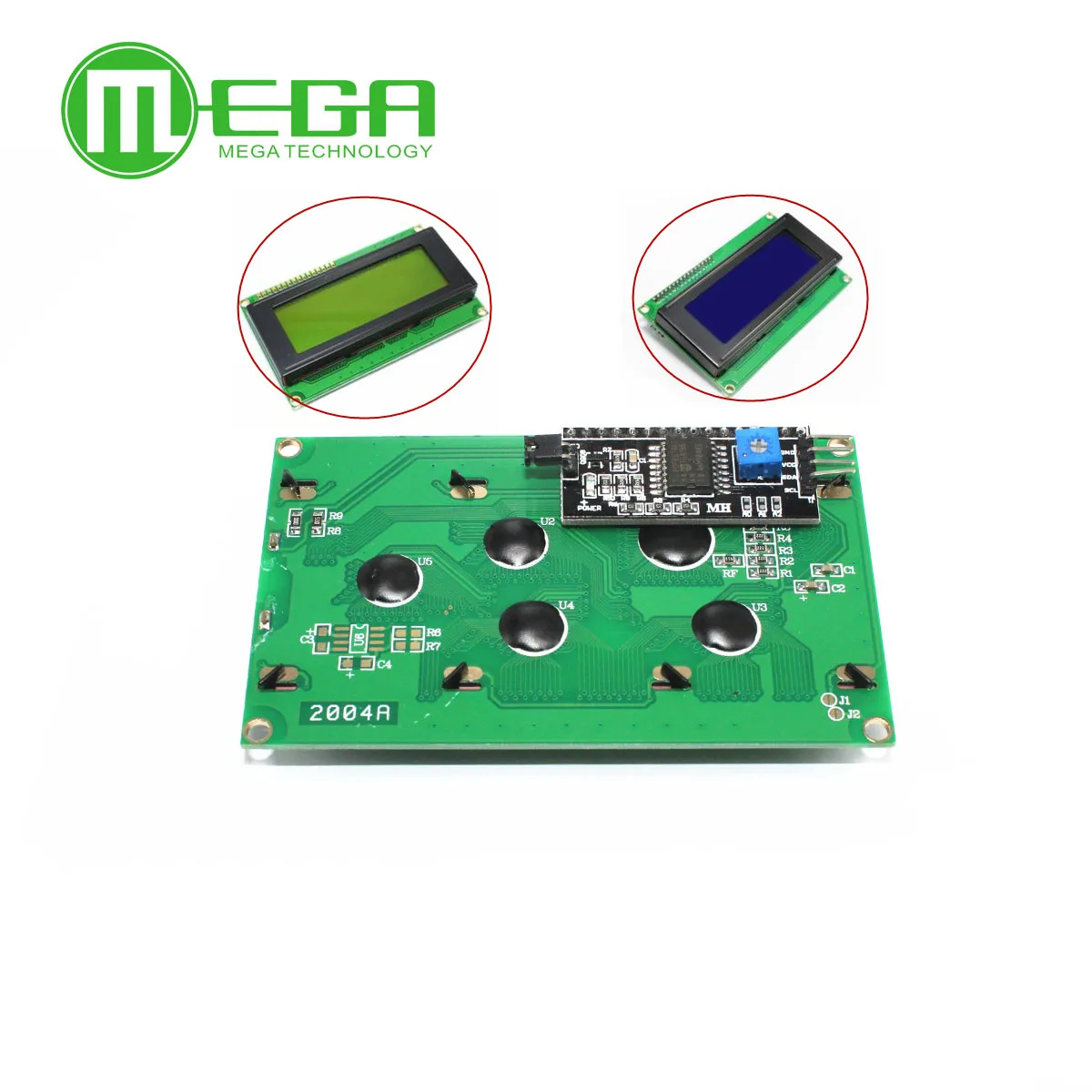

iic i2c interface 2004 lcd module display free sample

In this article I am going to interface a 16x2 I2C LCD with Arduino Uno. In my previous article is discuss aboutinterfacing of 16x2 LCD with Arduino Uno. The difference is in number of wires. There we need more than 12 wires. But here only use just 4 wires. How ?!!!!!! Before I use parallel communication method for interfacing LCD with Arduino. But now I am using I2C Communication.

Here I use the same 16X2 LCD in my previous article. But additionally attach a I2C Module to the 16x2 LCD. It work as an inter mediator between the LCD and MCU (here Arduino).

I2C is short for Inter-IC. And it is a type of BUS. This is designed by Philips semiconductors. I2C is a synchronous, multi slave, multi master packet switched, single-ended serial bus. ie. multiple chips can be connect to the same bus.I2C uses only two bidirectional open collector or open drain lines, Serial Data Line (SDA) and Serial Clock Line (SCL), pulled up with resistors. Typical voltages used are +5 V or +3.3 V, although systems with other voltages are permitted. For more about I2C protocol clickhere.

It is also known as I2C Module. It has total of 20 male pins. 16 pins are faced to rear side and 4 pins faced towards front side. The 16 pins for connect to 16x2 LCD and the 2 pins out of 4 pins are SDA and SCL. SDA is the serial data pin and SCL is the clock pin. The rest 2 pins for power supply (Vcc and ground).There is a POT on the I2C Module. We can control the contrast of the LCD display by rotating this POT. And there is a jumber fixed on the module. When we remove the jumber, the backlight of the LCD display will go OFF.

Before starting we need to know about addressing of I2C devices. Every device which can attached to MCU have an address. We need to know this address for communicate with that particular device.

You can see three solder pads on the I2C module. which is labeled as A0, A1 and A2. This is Address selectors. ie, each solder pads have one upper potion and a one lower potion. if, there is a connection between upper potion with lower connection it is called "Connected" otherwise it is called "Not connected". When A0, A1, A2 are in "Not Connected" condition ( A0 = 0, A1 = 0, A2 = 0) the address would be 0x27. In default the A0, A1, A2 are in "Not connected" condition. And some time default address is 0x3F. There is no need to change the address of the I2C module when we use only one LCD. But when we use more than one LCD, need to change the address. Because two or more different device can"t communicate with the same address. For more address see the table given below.

In some cases A0, A1, A2 are "Not connected" state, but the address is not 0x27. We can"t communicate with this address. So we need to find the original address of that device. For that we need to run the Arduino with "I2C Scanner" code.

I2C Scanner code is used for find the number of I2C devices and address of I2C devices. First add the header file for include "Wire.h" library. Then in setup part, begin the "Wire" library by "Wire.begin()". Then begin the serial monitor as the baud rate of 9600 by "Serial.begin()". Next in loop part, define two variables with the datatype "byte" named "error" and "address". Then define another variable with the "Integer ( int)" datatype named as "Devices". And set initial value as 0. Next start a for loop with minimum value of 1 and maximum of 127. "address" used as loop variable. Next input the address to wire with the function "Wire.beginTransmission()". The i2c_scanner uses the return value of the "Write.endTransmisstion()" to see if a device did acknowledge to the address. This return value store the value to the variable "error". The return value become 0, if a device acknowledge to the address. Otherwise, the return value become 4. Next use a if. And the condition is "error==0". Then print the particular address to the serial monitor only if the address<16. Here we print the address in Hexadecimal. The printing instruction is "Serial.print(address, HEX)". And count the Device.The complete I2C Scanner code is given below#include

Next open Serial monitor from the icon on top right corner of Arduino IDE. And set the baud rate as 9600. Please ensure the correct port. Then you can see the address of LCD in serial monitor like shown below

Before that need to add a library to Arduino IDE. Go to thelinkand download the library Arduino-LiquidCrystal-I2C-library. Then open Arduino IDE and go toSketch>Include Library> Add.ZIP Library. Next select the downloaded ZIP file and clickopen.

Next create a sketch. First I include the header "Wire.h". This library help to communicate with I2C device. Then include "LiquidCrystal_I2C.h" for better communication with display.#include

Next set the address, number of column and number of rows using the function "LiquidCrystal_I2C lcd(). The address is 0x27 (discovered using the I2C Scanner Code). Number of columns is 16 and number of rows is 2. After this, we can call the display using "lcd". You can also use multiple I2C LCDs with Arduino Uno. But set different addresses and variable for each display.LiquidCrystal_I2C lcd(0x27, 16, 2);

Now the LCD is ready to print. The cursor is at 4th column(count from 0), and 0th row(count from 0). Then print the Message "Hackster" by the function "lcd.print()".lcd.print("Hackster");

The programming is completed. Upload the sketch to Arduino and see the message on LCD.The complete code is given in the Code section of this article.Please don"t copy-paste my code. Try to understand the code line by line and create your own sketch.

Hello friends welcome back to Techno-E-solution, In previous video we see how to interface LCD 16×2 to Arduino Uno, but there are very complicated circuits, so in this tutorial, I"ll show you how to reduce circuitry by using I2C module which is very compact & easy to connection. Simply connect I2C module with LCD parallel & connect I2C modules 4 pins to Arduino. I2C module has 4 output pins which contains VCC, GND, SDA, SCL where 5V supply gives to I2C module through VCC & GND to GND of Arduino. SDA is a data pin & SCL is clock pin of I2C module. To interface LCD and I2C with Arduino we need Liquid Crystal I2C Library in Arduino IDE software.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

The LiquidCrystal_I2C is available from GitHub. When visiting the GitHub page, select the Code button and from the drop-down menu, choose Download ZIP option to save the file to a convenient location on your workstation.

Before installing LiquidCrystal_I2C, remove any other libraries that may reside in the Arduino IDE with the same LiquidCrystal_I2C name. Doing this will ensure that only the known good library is in use. LiquidCrystal_I2C works in combination with the preinstalled Wire.h library in the Arduino editor.

To install the LiquidCrystal_I2C library, use the SketchSketch > Include Library > Add .ZIP Library…from the Arduino IDE (see example). Point to the LiquidCrystal_I2C-master.zip which you previously downloaded and the Library will be installed and set up for use.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

Similar to the cursor() function, this will create a block-style cursor. Displayed at the position of the next character to be printed and displays as a blinking rectangle.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

A custom character allows you to display any pattern of dots on a 5×8 matrix which makes up each character. You have full control of the design to be displayed.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

As we all know, though LCD and some other displays greatly enrich the man-machine interaction, they share a common weakness. When they are connected to a controller, multiple IOs will be occupied of the controller which has no so many outer ports. Also it restricts other functions of the controller. Therefore, LCD1602 with an I2C bus is developed to solve the problem.

I2C bus is a type of serial bus invented by PHLIPS. It is a high performance serial bus which has bus ruling and high or low speed device synchronization function required by multiple-host system. The blue potentiometer on the I2C LCD1602 (see the figure below) is used to adjust the backlight for better display. I²C uses only two bidirectional open-drain lines, Serial Data Line (SDA) and Serial Clock Line (SCL), pulled up with resistors. Typical voltages used are +5 V or +3.3 V although systems with other voltages are permitted.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

In this simple sketch we show you the most useful and important functions from the LiquidCrystal_I2C library. So, let’s take a quick look at how the code works.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1 and A2) are placed at the end of the 7-bit I2C address register.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1 and A2) are also placed at the end of the 7-bit I2C address register. But the other bits in the address register are different.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

Filter your search by typing ‘liquidcrystal‘. There should be some entries. Look for the LiquidCrystal I2C library by Frank de Brabander. Click on that entry, and then select Install.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

In this Arduino LCD I2C tutorial, we will learn how to connect an LCD I2C (Liquid Crystal Display) to the Arduino board. LCDs are very popular and widely used in electronics projects for displaying information. There are many types of LCD. This tutorial takes LCD 16x2 (16 columns and 2 rows) as an example. The other LCDs are similar.

In the previous tutorial, we had learned how to use the normal LCD. However, wiring between Arduino and the normal LCD is complicated. Therefore, LCD I2C has been created to simplify the wiring. Actually, LCD I2C is composed of a normal LCD, an I2C module and a potentiometer.

lcd.print() function supports only ASCII characters. If you want to display a special character or symbol (e.g. heart, angry bird), you need to use the below character generator.

Depending on manufacturers, the I2C address of LCD may be different. Usually, the default I2C address of LCD is 0x27 or 0x3F. Try these values one by one. If you still failed, run the below code to find the I2C address.

I2C (Inter-Integrated Circuit, eye-squared-C), alternatively known as I2C or IIC, is a synchronous, multi-controller/multi-target (master/slave), packet switched, single-ended, serial communication bus invented in 1982 by Philips Semiconductors. It is widely used for attaching lower-speed peripheral ICs to processors and microcontrollers in short-distance, intra-board communication.

Several competitors, such as Siemens, NEC, Texas Instruments, STMicroelectronics, Motorola,Nordic Semiconductor and Intersil, have introduced compatible I2C products to the market since the mid-1990s.

System Management Bus (SMBus), defined by Intel in 1995, is a subset of I2C, defining a stricter usage. One purpose of SMBus is to promote robustness and interoperability. Accordingly, modern I2C systems incorporate some policies and rules from SMBus, sometimes supporting both I2C and SMBus, requiring only minimal reconfiguration either by commanding or output pin use.

Describing connectable devices via small ROM configuration tables to enable plug and play operation, such as in serial presence detect (SPD) EEPROMs on dual in-line memory modules (DIMMs), and Extended Display Identification Data (EDID) for monitors via VGA, DVI and HDMI connectors.

A particular strength of I2C is the capability of a microcontroller to control a network of device chips with just two general-purpose I/O pins and software. Many other bus technologies used in similar applications, such as Serial Peripheral Interface Bus (SPI), require more pins and signals to connect multiple devices.

The I2C reference design has a 7-bit address space, with a rarely used 10-bit extension.2C bus speeds are the 100 kbit/s standard mode and the 400 kbit/s fast mode. There is also a 10 kbit/s low-speed mode, but arbitrarily low clock frequencies are also allowed. Later revisions of I2C can host more nodes and run at faster speeds (400 kbit/s fast mode, 1 Mbit/s fast mode plus, 3.4 Mbit/s high-speed mode, and 5 Mbit/s ultra-fast mode). These speeds are more widely used on embedded systems than on PCs.

The number of nodes which can exist on a given I2C bus is limited by the address space and also by the total bus capacitance of 400 pF, which restricts practical communication distances to a few meters. The relatively high impedance and low noise immunity requires a common ground potential, which again restricts practical use to communication within the same PC board or small system of boards.

In addition to 0 and 1 data bits, the I2C bus allows special START and STOP signals which act as message delimiters and are distinct from the data bits. (This is in contrast to the start bits and stop bits used in asynchronous serial communication, which are distinguished from data bits only by their timing.)

An I2C transaction may consist of multiple messages. The controller terminates a message with a STOP condition if this is the end of the transaction or it may send another START condition to retain control of the bus for another message (a "combined format" transaction).

Pure I2C systems support arbitrary message structures. SMBus is restricted to nine of those structures, such as read word N and write word N, involving a single target. PMBus extends SMBus with a Group protocol, allowing multiple such SMBus transactions to be sent in one combined message. The terminating STOP indicates when those grouped actions should take effect. For example, one PMBus operation might reconfigure three power supplies (using three different I2C target addresses), and their new configurations would take effect at the same time: when they receive that STOP.

With only a few exceptions, neither I2C nor SMBus define message semantics, such as the meaning of data bytes in messages. Message semantics are otherwise product-specific. Those exceptions include messages addressed to the I2C general call address (0x00) or to the SMBus Alert Response Address; and messages involved in the SMBus Address Resolution Protocol (ARP) for dynamic address allocation and management.

One specific example is the 24C32 type EEPROM, which uses two request bytes that are called Address High and Address Low. (Accordingly, these EEPROMs are not usable by pure SMBus hosts, which support only single-byte commands or addresses.) These bytes are used for addressing bytes within the 32 kbit (or 4 kB) EEPROM address space. The same two-byte addressing is also used by larger EEPROMs, like the 24C512 which stores 512 kbits (or 64 kB). Writing data to and reading from these EEPROMs uses a simple protocol: the address is written, and then data is transferred until the end of the message. The data transfer part of the protocol can cause trouble on the SMBus, since the data bytes are not preceded by a count, and more than 32 bytes can be transferred at once. I2C EEPROMs smaller than 32 kbit, like the 2 kbit 24C02, are often used on the SMBus with inefficient single-byte data transfers to overcome this problem.

A single message writes to the EEPROM. After the START, the controller sends the chip"s bus address with the direction bit clear (write), then sends the two-byte address of data within the EEPROM and then sends data bytes to be written starting at that address, followed by a STOP. When writing multiple bytes, all the bytes must be in the same 32-byte page. While it is busy saving those bytes to memory, the EEPROM will not respond to further I2C requests. (That is another incompatibility with SMBus: SMBus devices must always respond to their bus addresses.)

Once SCL is high, the controller waits a minimum time (4 μs for standard-speed I2C) to ensure that the receiver has seen the bit, then pulls it low again. This completes transmission of one bit.

One of the more significant features of the I2C protocol is clock stretching. An addressed target device may hold the clock line (SCL) low after receiving (or sending) a byte, indicating that it is not yet ready to process more data. The controller that is communicating with the target may not finish the transmission of the current bit, but must wait until the clock line actually goes high. If the target is clock-stretching, the clock line will still be low (because the connections are open-drain). The same is true if a second, slower, controller tries to drive the clock at the same time. (If there is more than one controller, all but one of them will normally lose arbitration.)

The controller must wait until it observes the clock line going high, and an additional minimal time (4 μs for standard 100 kbit/s I2C) before pulling the clock low again.

Although the controller may also hold the SCL line low for as long as it desires (this is not allowed since Rev. 6 of the protocol – subsection 3.1.1), the term "clock stretching" is normally used only when targets do it. Although in theory any clock pulse may be stretched, generally it is the intervals before or after the acknowledgment bit which are used. For example, if the target is a microcontroller, its I2C interface could stretch the clock after each byte, until the software decides whether to send a positive acknowledgment or a NACK.

Clock stretching is the only time in I2C where the target drives SCL. Many targets do not need to clock stretch and thus treat SCL as strictly an input with no circuitry to drive it. Some controllers, such as those found inside custom ASICs may not support clock stretching; often these devices will be labeled as a "two-wire interface" and not I2C.

To ensure a minimal bus throughput, SMBus places limits on how far clocks may be stretched. Hosts and targets adhering to those limits cannot block access to the bus for more than a short time, which is not a guarantee made by pure I2C systems.

Every controller monitors the bus for start and stop bits and does not start a message while another controller is keeping the bus busy. However, two controllers may start transmission at about the same time; in this case, arbitration occurs. Target transmit mode can also be arbitrated, when a controller addresses multiple targets, but this is less common. In contrast to protocols (such as Ethernet) that use random back-off delays before issuing a retry, I2C has a deterministic arbitration policy. Each transmitter checks the level of the data line (SDA) and compares it with the levels it expects; if they do not match, that transmitter has lost arbitration and drops out of this protocol interaction.

One case which must be handled carefully in multi-controller I2C implementations is that of the controllers talking to each other. One controller may lose arbitration to an incoming message, and must change its role from controller to target in time to acknowledge its own address.

While I2C only arbitrates between controllers, SMBus uses arbitration in three additional contexts, where multiple targets respond to the controller, and one gets its message through.

There are several possible operating modes for I2C communication. All are compatible in that the 100 kbit/s standard mode may always be used, but combining devices of different capabilities on the same bus can cause issues, as follows:

Fast mode is highly compatible and simply tightens several of the timing parameters to achieve 400 kbit/s speed. Fast mode is widely supported by I2C target devices, so a controller may use it as long as it knows that the bus capacitance and pull-up strength allow it.

High speed mode (3.4 Mbit/s) is compatible with normal I2C devices on the same bus, but requires the controller have an active pull-up on the clock line which is enabled during high speed transfers. The first data bit is transferred with a normal open-drain rising clock edge, which may be stretched. For the remaining seven data bits, and the ACK, the controller drives the clock high at the appropriate time and the target may not stretch it. All high-speed transfers are preceded by a single-byte "controller code" at fast or standard speed. This code serves three purposes:

Ultra-Fast mode is essentially a write-only I2C subset, which is incompatible with other modes except in that it is easy to add support for it to an existing I2C interface hardware design. Only one controller is permitted, and it actively drives data lines at all times to achieve a 5 Mbit/s transfer rate. Clock stretching, arbitration, read transfers, and acknowledgements are all omitted. It is mainly intended for animated LED displays where a transmission error would only cause an inconsequential brief visual glitch. The resemblance to other I2C bus modes is limited to:

I2C is popular for interfacing peripheral circuits to prototyping systems, such as the Arduino and Raspberry Pi. I2C does not employ a standardized connector, however, board designers have created various wiring schemes for I2C interconnections. To minimize the possible damage due to plugging 0.1-inch headers in backwards, some developers have suggested using alternating signal and power connections of the following wiring schemes: (GND, SCL, VCC, SDA) or (VCC, SDA, GND, SCL).

The vast majority of applications use I2C in the way it was originally designed—peripheral ICs directly wired to a processor on the same printed circuit board, and therefore over relatively short distances of less than 1 foot (30 cm), without a connector. However using a differential driver, an alternate version of I2C can communicate up to 20 meters (possibly over 100 meters) over CAT5 or other cable.

the 10-pin iPack connector carries I2C;6P6C Lego Mindstorms NXT connector carries I2C;Ethernet physical layer to instead carry differential-encoded I2C signals2C signals;HDMI and most DVI and VGA connectors carry DDC2 data over I2C.

When there are many I2C devices in a system, there can be a need to include bus buffers or multiplexers to split large bus segments into smaller ones. This can be necessary to keep the capacitance of a bus segment below the allowable value or to allow multiple devices with the same address to be separated by a multiplexer. Many types of multiplexers and buffers exist and all must take into account the fact that I2C lines are specified to be bidirectional. Multiplexers can be implemented with analog switches, which can tie one segment to another. Analog switches maintain the bidirectional nature of the lines but do not isolate the capacitance of one segment from another or provide buffering capability.

Buffers can be used to isolate capacitance on one segment from another and/or allow I2C to be sent over longer cables or traces. Buffers for bi-directional lines such as I2C must use one of several schemes for preventing latch-up. I2C is open-drain, so buffers must drive a low on one side when they see a low on the other. One method for preventing latch-up is for a buffer to have carefully selected input and output levels such that the output level of its driver is higher than its input threshold, preventing it from triggering itself. For example, a buffer may have an input threshold of 0.4 V for detecting a low, but an output low level of 0.5 V. This method requires that all other devices on the bus have thresholds which are compatible and often means that multiple buffers implementing this scheme cannot be put in series with one another.

Alternatively, other types of buffers exist that implement current amplifiers or keep track of the state (i.e. which side drove the bus low) to prevent latch-up. The state method typically means that an unintended pulse is created during a hand-off when one side is driving the bus low, then the other drives it low, then the first side releases (this is common during an I2C acknowledgement).

Although MSB 1111 is reserved for Device ID and 10-bit target (slave) addressing, it is also used by VESA DDC display dependent devices such as pointing devices.

An I2C transaction consists of one or more messages. Each message begins with a start symbol, and the transaction ends with a stop symbol. Start symbols after the first, which begin a message but not a transaction, are referred to as repeated start symbols.

Many I2C devices do not distinguish between a combined transaction and the same messages sent as separate transactions, but not all. The device ID protocol requires a single transaction; targets are forbidden from responding if they observe a stop symbol. Configuration, calibration or self-test modes which cause the target to respond unusually are also often automatically terminated at the end of a transaction.

In order to avoid false marker detection, there is a minimum delay between the SCL falling edge and changing SDA, and between changing SDA and the SCL rising edge. Note that an I2C message containing n data bits (including acknowledges) contains n + 1 clock pulses.

I2C lends itself to a "bus driver" software design. Software for attached devices is written to call a "bus driver" that handles the actual low-level I2C hardware. This permits the driver code for attached devices to port easily to other hardware, including a bit-banging design.

Below is an example of bit-banging the I2C protocol as an I2C controller (master). The example is written in pseudo C. It illustrates all of the I2C features described before (clock stretching, arbitration, start/stop bit, ack/nack).

Since OpenBSD 3.9 (released 1 May 2006; 16 years ago(2006-05-01)), a central i2c_scan subsystem probes all possible sensor chips at once during boot, using an ad hoc weighting scheme and a local caching function for reading register values from the I2C targets;general-purpose off-the-shelf i386/amd64 hardware during boot without any configuration by the user nor a noticeable probing delay; the matching procedures of the individual drivers then only has to rely on a string-based "friendly-name" for matching;2C sensor drivers are automatically enabled by default in applicable architectures without ill effects on stability; individual sensors, both I2C and otherwise, are exported to the userland through the sysctl hw.sensors framework. As of March 20192C that export some kind of a sensor through the hw.sensors framework, and the majority of these drivers are fully enabled by default in i386/amd64 GENERIC kernels of OpenBSD.

In NetBSD, over two dozen I2C target devices exist that feature hardware monitoring sensors, which are accessible through the sysmon envsys framework as property lists. On general-purpose hardware, each driver has to do its own probing, hence all drivers for the I2C targets are disabled by default in NetBSD in GENERIC i386/amd64 builds.

In Linux, I2C is handled with a device driver for the specific device, and another for the I2C (or SMBus) adapter to which it is connected. Hundreds of such drivers are part of current Linux kernel releases.

In Mac OS X, there are about two dozen I2C kernel extensions that communicate with sensors for reading voltage, current, temperature, motion, and other physical status.

In Microsoft Windows, I2C is implemented by the respective device drivers of much of the industry"s available hardware. For HID embedded/SoC devices, Windows 8 and later have an integrated I²C bus driver.

There are a number of I2C host adapter hardware solutions for making a I2C controller or target connection to host computers, running Linux, Mac or Windows. Most options are USB-to-I2C adapters. Not all of them require proprietary drivers or APIs.

I2C protocol analyzers are tools that sample an I2C bus and decode the electrical signals to provide a higher-level view of the data being transmitted on the bus.

When developing and/or troubleshooting the I2C bus, examination of hardware signals can be very important. Logic analyzers are tools that collect, analyze, decode, and store signals, so people can view the high-speed waveforms at their leisure. Logic analyzers display time stamps of each signal level change, which can help find protocol problems. Most logic analyzers have the capability to decode bus signals into high-level protocol data and show ASCII data.

The assignment of target addresses is a weakness of I2C. Seven bits is too few to prevent address collisions between the many thousands of available devices. What alleviates the issue of address collisions between different vendors and also allows to connect to several identical devices is that manufacturers dedicate pins that can be used to set the target address to one of a few address options per device. Two or three pins is typical, and with many devices, there are three or more wiring options per address pin.

Automatic bus configuration is a related issue. A given address may be used by a number of different protocol-incompatible devices in various systems, and hardly any device types can be detected at runtime. For example, 0x51 may be used by a 24LC02 or 24C32 EEPROM, with incompatible addressing; or by a PCF8563 RTC, which cannot reliably be distinguished from either (without changing device state, which might not be allowed). The only reliable configuration mechanisms available to hosts involve out-of-band mechanisms such as tables provided by system firmware, which list the available devices. Again, this issue can partially be addressed by ARP in SMBus systems, especially when vendor and product identifiers are used; but that has not really caught on. The Rev. 3 version of the I2C specification adds a device ID mechanism.

I2C supports a limited range of speeds. Hosts supporting the multi-megabit speeds are rare. Support for the Fm+ 1 Mbit/s speed is more widespread, since its electronics are simple variants of what is used at lower speeds. Many devices do not support the 400 kbit/s speed (in part because SMBus does not yet support it). I2C nodes implemented in software (instead of dedicated hardware) may not even support the 100 kbit/s speed; so the whole range defined in the specification is rarely usable. All devices must at least partially support the highest speed used or they may spuriously detect their device address.

Because I2C is a shared bus, there is the potential for any device to have a fault and hang the entire bus. For example, if any device holds the SDA or SCL line low, it prevents the controller from sending START or STOP commands to reset the bus. Thus it is common for designs to include a reset signal that provides an external method of resetting the bus devices. However many devices do not have a dedicated reset pin, forcing the designer to put in circuitry to allow devices to be power-cycled if they need to be reset.

Because of these limits (address management, bus configuration, potential faults, speed), few I2C bus segments have even a dozen devices. It is common for systems to have several such segments. One might be dedicated to use with high-speed devices, for low-latency power management. Another might be used to control a few devices where latency and throughput are not important issues; yet another segment might be used only to read EEPROM chips describing add-on cards (such as the SPD standard used with DRAM sticks).

I2C is the basis for the ACCESS.bus, the VESA Display Data Channel (DDC) interface, the System Management Bus (SMBus), Power Management Bus (PMBus) and the Intelligent Platform Management Bus (IPMB, one of the protocols of IPMI). These variants have differences in voltage and clock frequency ranges, and may have interrupt lines.

High-availability systems (AdvancedTCA, MicroTCA) use 2-way redundant I2C for shelf management. Multi-controller I2C capability is a requirement in these systems.

TWI (Two-Wire Interface) or TWSI (Two-Wire Serial Interface) is essentially the same bus implemented on various system-on-chip processors from Atmel and other vendors.2C is not a registered trademark as of 2014-11-07.2C have now lapsed.Microchip Technology, TWI and I2C have a few differences. One of them is that TWI does not support START byte.

In some cases, use of the term "two-wire interface" indicates incomplete implementation of the I2C specification. Not supporting arbitration or clock stretching is one common limitation, which is still useful for a single controller communicating with simple targets that never stretch the clock.

"8-Kbit serial I2C bus EEPROM (PDF)" (PDF). STMicroelectronics. October 2017. Archived (PDF) from the original on 2019-10-18. Retrieved 19 November 2019.

Using The ZONE_READ And ZONE_WRITE Protocols (PDF) (Application Note). Revision 1.0.1. System Management Interface Forum. 2016-01-07. AN001. Archived (PDF) from the original on 2017-09-22.

Gasperi, Michael; Hurbain, Philippe (2010), "Chapter 13: I2C Bus Communication", Extreme NXT: Extending the LEGO MINDSTORMS NXT to the Next Level, ISBN 9781430224549

"I2C Address Allocation Table" (PDF) (Selection Guide). Philips Semiconductors. 1999-08-24. Archived from the original (PDF) on 2017-10-16. Retrieved 2017-10-01.

"System Management Bus (SMBus) Specification" (PDF). Version 3.0. System Management Interface Forum. 2014-12-20. pp. 81–82. Archived (PDF) from the original on 2016-01-29. Retrieved 2017-12-01.

"VESA Display Data Channel Command Interface (DDC/CI) Standard" (PDF). Version 1.1. VESA. 2004-10-29. pp. 15–16. Archived (PDF) from the original on 2016-09-09. Retrieved 2017-12-01.

"Intelligent Platform Management Interface Specification Second Generation V2.0" (PDF). Document Revision 1.1. Intel, NEC, Hewlett-Packard & Dell. 2013-10-01. p. 563. Archived (PDF) from the original on 2016-03-27. Retrieved 2017-12-01. The 7-bit portion of the slave address for the BMC is 0010_000b

Theo de Raadt (2015-05-29). "/sys/dev/i2c/i2c_scan.c#probe_val". Super User"s BSD Cross Reference. OpenBSD. Retrieved 2019-03-04. static u_int8_t probe_val[256];

Constantine A. Murenin (2010-05-21). "5.2. I2C bus scan through i2c_scan.c". OpenBSD Hardware Sensors — Environmental Monitoring and Fan Control (MMath thesis). University of Waterloo: UWSpace. hdl:10012/5234. Document ID: ab71498b6b1a60ff817b29d56997a418.

Delvare, Jean (2005-08-16). "Re: [PATCH 4/5] add i2c_probe_device and i2c_remove_device". linux-kernel (Mailing list). Archived from the original on 2016-08-17.

The library allows to control I2C displays with functions extremely similar to LiquidCrystal library. THIS LIBRARY MIGHT NOT BE COMPATIBLE WITH EXISTING SKETCHES.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey