how to fix lcd display supplier

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

With an array of different timing profiles and the use of a video-signal generator, full testing is available on most display models we can offer support for.

CRT Monitors: given the nature of the CRT displays, repairing them is often not a viable option. To a large extent this depends on the severity of the damage. When something fails within a CRT display, it often triggers deterioration of other components at the same time. This sometimes leads to a repaired CRT monitor fail again and again, even after a thorough repair.

When a CRT monitor is damaged beyond repair, we have a wide range of different retrofit options available to help get that machine back up and running with an even brighter and clearer image compared to the original monitor.

How to repair LCD displays? Three visual inspection methods can help you solve problems, including external inspection, internal inspection and electrical inspection.

(1) External inspection: LCD display inspection should start from the outside, according to the working mode of the machine to check whether the buttons and switches on the operation panel are normal, whether the power connection is good, whether the video signal line is normal, etc.

(2) Internal inspection: LCD display in the external inspection did not find any abnormalities, open the display shell, check the internal circuit. Observe whether the solder joints and connecting wires of components are virtual soldering, de-soldering, whether the pins are mildewed or not, whether the plug-ins are loose, whether the circuit lines of printed circuit boards are broken, whether the components are burnt, burst or leakage, etc.

(3) Electricity check: LCD display is connected to the power switch to observe whether the power indicator light is on, whether there is fire, fever, burning odor and smoking in the machine.

People often ask how to repair the LCD display. In fact, this is a very professional problem, because precision instruments can not be explained in one word or two, so today I will tell you

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

The main control buttons may be faulty. Clean them with a metal cleaner, or jostle to attach a loose connection. If necessary, locate the circuit board they are attached to and re-solder any broken connections.

Check input cables for damage, or try other cables of the same type. If necessary, inspect the circuit board they are attached to and re-solder damaged connections.

3. #If all the above is OK, measure the LVDS voltage value. Under normal conditions, the LVDS signal’s RX+/ RX-voltage value is about 1.2v, and RX+/ RX-difference value is about 200mV. At the same time, the resistance of the LVDS signal to ground and the resistance between the LVDS signal pairs can be measured (100 ohms). If there is an exception to these values, try replacing the ASIC.

2. #Confirm whether the VAA is normal (normally about 17V). If abnormal, disconnect the RP32 to confirm whether it is caused by DC/DC loop or X-side COF: disconnect RP32, if the VAA is normal, the COF is bad, CO must be changed; COF can be Disconnect one by one to determine which NG disconnects RP32, VAA NG, try to change UP1; at the same time, confirm whether the continuity of the surrounding triode is OK.

1. #Measure GM1~GM14, the values are arranged from large to small. In general, a certain gamma value will be abnormal in the case of NG, then try to replace gamma-IC;

3. #Confirm whether the RSDS value is correct, normal RSDS is about 1.2v, and the signal difference is about 200mV; At the same time, we can confirm the resistance between RSDS signal (normal 100 or 50 ohms) and RSDS resistance to ground. If the voltage is NG, check if the ASIC and X-COF are hot.

Polarizer / CELL damaged To change the polarizer, a polarizer attaching machine is required The degree of whitening of the picture changes with different viewing angles

1. #Adjust the VR knob to see whether it can be adjusted and whether the screen performance changes. At the same time, confirm the VCOM value (about 7v), if NG, replace the VR knob.

2. #Confirm VGH/VGL voltage (about 30V VGH and -6v VGL), and confirm whether it is DC/DC loop NG or COF IC NG; The corresponding resistance of disconnected VGH and VGL can determine whether it is a DC/DC problem or a COF-IC problem. If it is DC/DC NG, try to replace UP1 or confirm whether the corresponding transistor is OK.

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

B. Confirm VAA resistance to ground at VAA test point of R plate (A short circuit usually occurs), disconnect the corresponding capacitance of the following 3 COF, and confirm VAA resistance to the ground again. If OK, replace the capacitor, if NG, replace COF. If VAA is still NG, confirm DC/DC loop as all models.

6. #Disconnect RP32 to confirm VAA, if NG, try to change the PWM IC (in general, it will be good), if still NG, try to change the gamma-ic or corresponding to the VAA several large capacitances (in general, it is rare, this situation is generally accompanied by VAA to the ground short circuit).

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

The production mode of medium and large size module factories (15.6 inches or more) and small and medium size module factories (0.X~10.1 inches) are different.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

Neoti certified technicians will repair or replace diodes, modules, shaders, receiving cards, hub boards, power supplies, and more. We approach each LED display screen repair with industry knowledge, skill, and experience. Our passionate, dedicated team commits their time and energy to solve any display problem that arises. We diagnose and develop the right course of action to restore your screen.

We also know that a damaged screen can impact your visitors’ experience or even delay an upcoming event. To help you move forward, we execute LED panel repairs quickly and efficiently. We complete repairs for various industries, such as broadcast, education, stadiums, and corporate organizations.

Five simple words that can equate to significant LCD display challenges for you. Here’s how you can successfully address and resolve these 5 LCD display challenges:

Missed deliveries are a killer. With even just one component missing, an assembly line goes down, affecting operations, missing revenue goals and failing customers. Components often have long and variable lead times which can lead to production and subsequent delivery problems if they’re not managed quickly and effectively.

Proactively address this challenge with the LCD display provider and within your company. Internally, assure suppliers’ lead-times are accurate in your MRP. Additionally, maintain a 2-4-week buffer stock or more depending on lead-times and component scarcity.

The LCD display supplier can also carry a buffer stock for your application. Reactively, the LCD display supplier should offer expedited options. Effective display provider can pressure the upstream supply chain, adjust production schedules, ship partial quantities and accelerate shipments. Applying these solutions eliminates most delivery problems and handles unplanned customer demand (a good thing!).

Find a display provider that is prepared for and addresses obsolescence when it rears its ugly head. Display providers who are manufacturing more customized systems are more likely to work with your needs than high-volume suppliers. Understand what would cause an LCD display to become obsolete. Your ideal design partner(s) will design for obsolescence mitigation. Then, by giving a long end-of-life (EOL) notice period, the LCD display provider can react by creating safety stock, sourcing alternates and re-engineering your display around a readily available replacement. Additionally, they should plan development of a compatible replacement so your product development doesn"t need to change. Obsolescence management safeguards your product line and down the road - your bottom line.

Quality issues generally arise in a few ways. First, the LCD display"s failure to meet the performance specification as intended. This involves defining what"s required to satisfy the product"s intent and customers" needs. Next, there are the optical and mechanical aspects of LCD display manufacturing. This includes meeting dimensional tolerances and maximum defect limitations.

A supplier that manufactures to your specific needs will minimize quality issues due to their ability to bring flexibility and expertise by modifying the LCD display for your specific product, and then actively supporting ongoing product improvements.

Defining “performance” begins with the application. Who is the target market or end user and how will they interact with the LCD display? In what environment will it be used? How is it being sold or demonstrated to customers? What data does the LCD display need to convey? Must it be readable by the visually impaired?

When performance is fully understood, we can define the idealdisplay type, size, pixel density, contrast, temperature range, brightness, color gamut response time, etc. Over-specifying any of these factors adds unnecessary cost, while under-specifying will detract from the end product"s usability. Ensure performance is optimized in order for your application to be successful. It is key to find an LCD display provider who is willing to adjust and customize these particular variables and explain them to you in terms of the end user experience.

Determining the right price to pay depends on three factors. What does the display need to do? What does the display NOT need to do? And lastly, what quantity is needed? In most cases the ideal option is a custom or semi-custom display perfectly designed for its application. Despite what many think, this is often the most cost-effective solution.

With greater volume, you expect a lower price point, which goes hand in hand with provider selection. Oversimplifying this, imagine three categories; low-volume - standard product distributors; mid-volume - built-to-order custom and semi-custom suppliers; and high-volume - consumer market suppliers. As you can imagine, you will never get to the optimal volume pricing with a low volume stocking distributor for a high-volume consumer product. Identify where you fit and then work with the right provider who serves that particular category.

Another cost challenge is system-level manufacturability. This is where display integration improvements can reduce product complexity, improve manufacturing time, and reduce system level manufacturing defects. For the most seamless LCD display integration, there are additional components such as buttons, LEDs, PCB boards, and connectors that are more efficiently integrated on the display rather than a separately assembled component. Clearly in this case, the LCD display cost will go up, but when done right, the system level cost is reduced to result in a net gain.

Lastly, you need to know system-level costs. If you’re giving up customer valued performance or functions, you"re trading market share and profitability for display savings and the net result may be decreased profit. The opposite also holds true; adding performance that is not necessary (these are attributes that the customer does not value) simply adds additional product costs.

Choosing the right supplier, based on your volume and quality needs is essential. Then implement the optimal LCD display solution with the optimal features and performance.

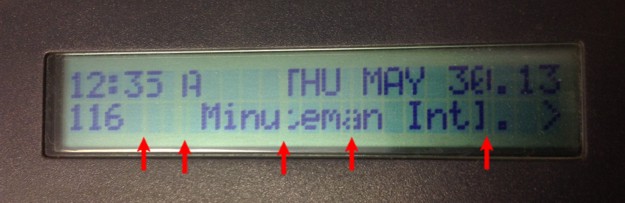

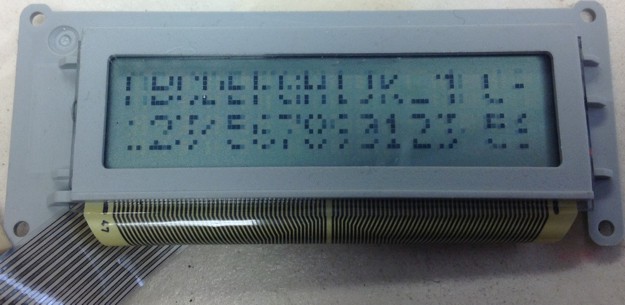

I have a TASCAM DR-05 audio recorder that has a monochrome orange LCD whose display has partially been damaged. Only the bottom half can be read while the top half is blank. I would like to attempt to change out the LCD by finding a replacement. I need help in finding a source for a replacement LCD. I’ve included a picture of the LCD on the PC Board just in case it might help. Would you please be able to point me in the right direction? Thanks in advance for your time and help.

P.S. I am aware it is not worth the effort to repair and it would definitely be more prudent to just buy another DR-05. That’s not the point. It’s a personal challenge to see if I can fix it. This is purely for fun, therefore no need to be tempted to let me know that I should just buy another DR-05. It’s not what I want to do. Thanks.

Over the years, LCD modules and LCD displays have grown in popularity. Companies in many different industries, including but not limited to the medical, automotive, consumer, food services, industrial, and technology sectors rely on at least one TFT LCD module or TFT LCD display on a daily basis. Although touchscreens are very durable and designed to withstand the hands of time, older modules and displays sometimes need to be repaired. When weighing the cost of having your displays repaired, you should take the time to consider your options.

After doing some research on the cost of repairs, many business owners find that it makes more sense to have their TFT LCDs replaced. Although units may cost less to repair initially, the cost of having to repair your older displays over and over again can add up. This is because older units may need to be repaired more than once. Even if multiple repairs will not cost any additional money, repairs lead to downtime and can have a tremendous impact on your business.

Older units in need of repair can have a long-term impact on a company’s bottom line. This is because outdated displays do not perform as well as new and improved displays. As many business owners have come to discover, new and improved touchscreen technology can increase efficiency, boost productivity, and improve customer satisfaction. This a top reason why so many companies decide to have a TFT LCD display or module replaced.

If you are thinking about having your older touchscreens repaired, then you should consider how having newer technology in place will help your business grow. Focusing strictly on the cost of replacing your displays can have a long-term impact on your business in more ways than one. For better results, you should consider all of the benefits of having new custom touchscreens specifically manufactured for your business. Ultimately, having new and improved displays in place for your employees and customers to use will be a business decision that pays for itself over time.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Use our “Get an Estimate” tool to review potential costs if you get service directly from Apple. If you go to another service provider, they can set their own fees, so ask them for an estimate. For service covered by AppleCare+, your fee per incident will be the same regardless of which service provider you choose. We"ll inspect your product when we receive it. If additional damage is found, you could pay an additional fee.

The Apple Limited Warranty covers your Apple Display and the Apple-branded accessories that come in the box with your product against manufacturing issues for one year from the date you bought them. Apple-branded accessories purchased separately are covered by the Apple Limited Warranty for Accessories. This includes adapters and spare cables.

If your situation isn’t covered, you’ll pay a fee. If the issue with your Apple Display is ineligible for service, you might pay the full replacement value.

We guarantee our service, including replacement parts, for 90 days or the remaining term of your Apple warranty or AppleCare plan, whichever is longer. This is in addition to your rights provided by consumer law.

Vicpas provide lcd display screen of worldwide brand, such as Hitach, Mitsubishi, sharp, NEC, Kyocera, BOE, ALPS. there also have many special lcd screen display for siemens, lcd display for AB Allen bradlay, lcd display for B&R powerpanel, lcd display for Beckhoff, lcd display for proface, lcd display for Schneider, lcd display for Kuka, lcd display for ABB, lcd display for KEBA, lcd display for YASKAWA, lcd display for KAWASAKI, lcd display for FUJI Hakko, lcd display for Beijer, lcd display for Bosch, lcd display for Cutler-Hammar, lcd display for Delta, lcd display for Hitech, lcd display for eview, weinview, weintech, lcd display for Eaton Microinnovation, lcd display for ESA, lcd display for Uniop, lcd display for EZ automation, lcd display for Fujistu, lcd display for keyence, lcd display for lenze, lcd display for lauer, lcd display for IDEC, lcd display for KOYO, lcd display for Omron, lcd display for Panasonic, lcd display for Parker, lcd display for Red lion.

The industry is flooded with manufacturers of varying capabilities, resources, commitment to quality and pre/post sales support. Some of these manufacturers will produce average quality displays without the needed enhancements that your customers expect today.

E3 Displays is all about making the manufacturing of your perfect display simple. We’ll guide you through an easy process to help you built your product so you never have to worry about low quality, inferior technology, unnecessary enhancements, and post sales continued support. Let’s make your business thrive.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey