tft lcd application note factory

Super Mobile HR TFT LCDs provide brilliant, vivid images outdoors where it is bright, but their visibility is poor indoors, where ambient light levels are lower.

Thus, though the display panel is transflective, it provides high transmittance and excellent image quality on a par with conventional transmissive TFT-LCDs.

The High Transmission Advanced TFT-LCD is suitable for applications where indoor use is of primary importance but outdoor use is occasionally necessary.

The parallel interface typically controls the LCD via 8 data pins and 3 control lines. The control lines used are Enable (E), Register Select (RS), and Read/Write (R/W). RS tells the LCD module if the information being sent is an Instruction or Data. The Enable tells the LCD module that the data or instruction in the register is ready to be interpreted by the LCD Module. Some controllers may have more than one Enable Control Line. The Read/Write tells the module whether to write data or read data from the register.

Serial LCD controllers typically have one Serial Data Line that writes data and cannot read. Normally, a Register Select Line(Sometimes designated A0) is used to tell the controller whether the incoming data is display information or a controller command

SPI, or Serial Peripheral Interface bus, is a synchronous (data is synchronized to the clock) serial data link standard that operates in full duplex mode, which means that devices that can communicate with one another simultaneously. To do this, two data lines are required. With this standard, devices communicate in a master/slave mode, where the master device (host processor) initiates the data and the clock. The LCD module is the (or one of the) peripheral slave device(s) attached to the data bus. Multiple peripherals (display modules and other devices) are addressed on the same serial data bus. However, the LCD module will only listen to the data it sees when the Chip Select line is active (usually low). If the Chip Select line is inactive (usually High), the LCD module listens to the data on the bus, but ignores it. The SDO line is not active when this state occurs. The SPI bus is comprised of four logic signals, two control lines and two data lines and is commonly referred to as SPI (4 wire).

With CS (Chip-Select) the corresponding peripheral device is selected by the LCD Controller. This pin is mostly active-low. In the unselected state the SDO lines are hi-impedance and therefore inactive. The clock line SCL is brought to the device whether it is selected or not. The clock serves as synchronization of the data communication.

The chip select signal CS is optional for a single device system, because you could tie the CS input at the LCD Module low, if the other lines are dedicated to SPI use. This is sometimes called a 3 Wire SPI Interface.

SPI Data transmissions usually involve two shift registers. Most display module applications normally use 8-bit words. However, different size words, such as 12 bit, are also used. By convention, the most significant bit is shifted out of one shift register while the least significant bit is shifted in. The word is then written into memory if the CS (chip-select) is low (active). If not, the data is ignored.

LVDS (Low Voltage Differential Signaling) technology provides a port with low voltage difference and differential signals. Developed by NS Technology Co., the American company uses digital video signal to resolve the excess amount of resource consumed and reducing EMI (Electromagnetic Interference) while transferring high bit rate data using TTL (Transistor-Transistor Logic). LVDS ports are able to perform differential data transfer between PCB traces or balanced cables with a relatively low output voltage swing (350mV), allowing a transfer speed up to several hundred megabit per second with low voltage difference. As a result, low voltage swing and low current drive applications have led to dramatic reduction in resource consumption and noise.

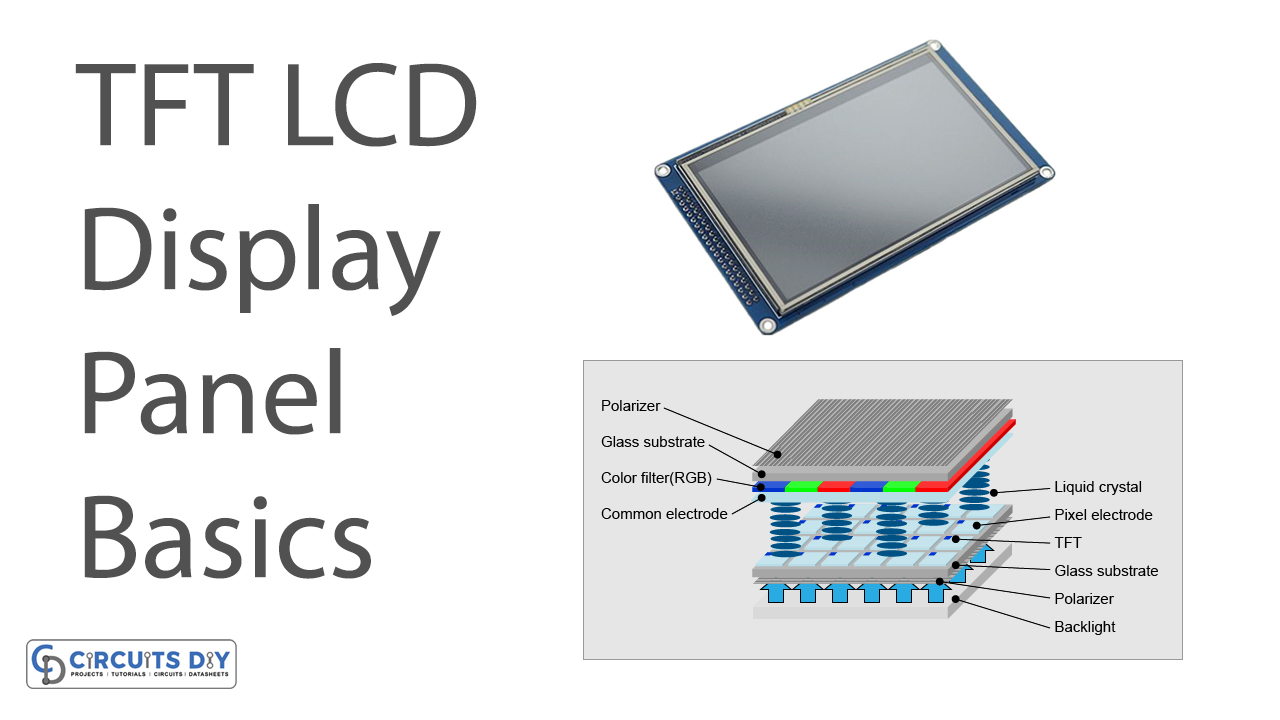

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Established in 2007, Raystar has built its reputation by offering advanced products in PMOLED display and modules as well as in FSTN / STN LCD Display Module, COG LCD, TFT LCD Display.

Low-temperature polysilicon (LTPS) technology has drawn the attention of many display manufacturers because it has several potential advantages over amorphous thin-film-transistor liquid crystal display TFT LCD). The mapping operation matches one TFT and one color-filter (CF) glass plate together to form one LCD plate. Each plate contains a certain number of cells that are independent devices. The matched LCD cell is good only when the TFT and CF cell match is good. When only a TFT or CF cell is good, there is a yield loss. The sorter is a robot used in LCD manufacturing systems to achieve higher yield in matching TFT and CF plates. This sorter contains several ports that can transfer CF glasses from CF cassettes to match TFT glasses. This is an important determinant for post-mapping yield. This study first proposes a linear programming formulation to optimize the plates-matching problem for the various ports. Next, we propose an algorithm to reduce the number of ways for choosing different matched objects when the number of matched cassettes is large. This algorithm avoids computer overload and provides an excellent solution. The empirical results illustrate the efficiency and effectiveness of the proposed approaches. Note to Practitioners - Yield is an important competitiveness determinant for thin-film-transistor liquid crystal display (TFT LCD) factories. TFT-LCD contains three major manufacturing sectors: the array, cell and module assembly processes. The yield loss from the cell process is one of the most critical steps. This study first formulates a linear programming for the TFT color-filter plates-matching problem in the cell process and a reduction algorithm then is developed to reduce the computational efforts. Our proposed approach is workable and it does not require a significant investment to produce yield improvement by applying the proposed matching algorithm.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey