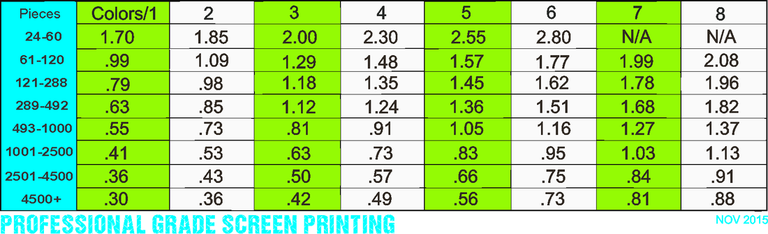

lcd panel printing pricelist

To get started on your custom screen printing t-shirt order, you can submit aQuick Quote, you can start designing in our Design Studio, call us at (800) 757-5646 or email info@brandedscreenprinting.com.

You"re paying to buy t-shirts from wholesalers. This takes times and money, and it"s the first step to printing custom t-shirts. Your garment markup is the first place that you should make profit.

That t-shirt may cost you just $1.50. But there is a real labor cost for procuring, processing, and printing the shirts in your shop. This fixed cost does notdepend on how much you paid for the t-shirt.

You may have to pay to replace spoiled garments, so it"s vital to cover your costs with a higher printing or setup fee. Marking up mid-tier items appropriately is essential.

You should never offer a customer a screen printing quote for a job that you don"t understand. This is why we can"t tell you exactly how much you should charge: there are so many variables that come into play. Each and every shop is unique, and each job is unique on top of that.

There are several common factors related to the screen printing process that we can use to anticipate your printing cost and price jobs appropriately:

If you have more than one print location, it"s like you"re printing 2 shirts.Removing the shirt from the press and replacing it for another print location takes more time and labor.

Novice screen printers may think a 4-color job is more complicated than a simple 1-color print in two locations. But this isn"t true. Printing a 4-color design on the front of a shirt takes less time than printing two separate designs: you have to remove and replace the shirts for that second print location.

Our advice? Price multiple location prints like you"re printing a new garment each time. This could mean charging your print fee two times. You could offer a different price for sleeve prints, neck label prints, and so on. Perhaps the back print is 50% of the original print fee.

Printing one ink color on every job would make the world a more boring place – for your screen printers and for your customers. But you have to charge more money for the increased complexity that colors introduce.

Screen printing pricing is volume-based. Most print shops really want customers to order as many goods as they can: it"s far more efficient to print 300 shirts than three.

Once you cross the threshold into automatic printing, you can begin to distribute price breaks a bit more generously. Until then, be sure to account for the added labor & time constraints that manual printing adds to the process.

In my shop, we add a flat fee on top of our traditional screen printing prices (between $1 to $5 per garment depending on the job). It will add costs to your business (such as bagging-and-tagging) – but it can also boost your revenue and open up new sales opportunities.

Need help getting started with online stores for screen printing? Check out The Ultimate Guide to Online Stores for Print Shops and Screen Printers – with custom sales and marketing materials you can download.

The #1 question screen printers and print shops have is "How do I set my prices?" This is a topic as controversial as it is difficult – every shop we talk to at Printavo has a different strategy for their screen printing pricing.

There are lots of tools, softwares, and methods for developing a pricing model for screen printing shops. We wanted to arm you with something simple that you can use to generate a screen printing pricing matrix.

To use our screen printing pricing matrix generator, there are 7 essential steps. It"s important to understand them all so you can get the most out of the spreadsheet (and modify it for your own purposes). The 7 basic steps are:

Your utilization rate.How much of a working day is spent actually printing? We give you a range of values (from 5% to 50%). Be aware that the typical shop operates at less than 30% utilization!

Tip:calculate the number of impressions for a job, and then time how long printing takes. Do this repeatedly to get an estimate for how many impressions per hour are likely in your shop.

Utilization rate. This is the most important metric in the spreadsheet. Your shop’s utilization rate is the percentage of time your presses are actually printing. We have discussed shop utilization with dozens of shop owners and industry consultants and found that shop utilization tends to be no greater than 40% (and, typically, is much closer to 20-30%).

We"re always tweaking and updating our price matrices at Campus Ink – and Printavo has our back thanks to their simple screen printing management software.

The #1 question screen printers and print shops have is "How do I set my prices?" This is a topic as controversial as it is difficult – every shop we talk to at Printavo has a different strategy for their screen printing pricing.

There are lots of tools, softwares, and methods for developing a pricing model for screen printing shops. We wanted to arm you with something simple that you can use to generate a screen printing pricing matrix.

To use our screen printing pricing matrix generator, there are 7 essential steps. It"s important to understand them all so you can get the most out of the spreadsheet (and modify it for your own purposes). The 7 basic steps are:

Your utilization rate.How much of a working day is spent actually printing? We give you a range of values (from 5% to 50%). Be aware that the typical shop operates at less than 30% utilization!

Tip:calculate the number of impressions for a job, and then time how long printing takes. Do this repeatedly to get an estimate for how many impressions per hour are likely in your shop.

Utilization rate. This is the most important metric in the spreadsheet. Your shop’s utilization rate is the percentage of time your presses are actually printing. We have discussed shop utilization with dozens of shop owners and industry consultants and found that shop utilization tends to be no greater than 40% (and, typically, is much closer to 20-30%).

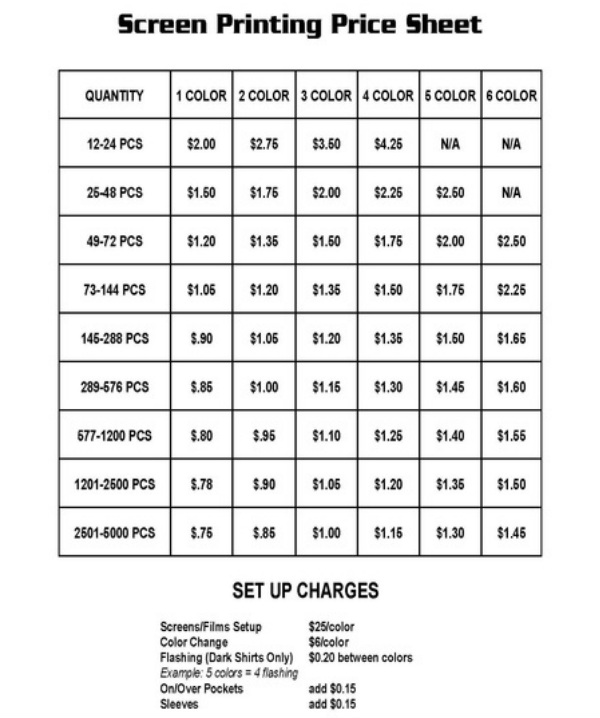

Screen Printing uses one screen for each color in each design being printed. The Service Fee for the First screen is $15 and each additional screen is $10 ea.

I’m hearing from some industry friends that LCD display panel prices are rising – which on the surface likely seems incongruous, given the economic slowdown and widespread indications that a lot of 2020 and 2021 display projects went on hold because of COVID-19.

On the other hand, people are watching a lot more TV, and I saw a guy at Costco the other day with two big-ass LCD TVs on his trolley. And a whole bunch of desktop monitors were in demand in 2020 to facilitate Work From Home. So demand for LCD displays is up outside of commercial purposes.

Continuing strong demand and concerns about a glass shortage resulting from NEG’s power outage have led to a continuing increase in LCD TV panel prices in Q1. Announcements by the Korean panel makers that they will maintain production of LCDs and delay their planned shutdown of LCD lines has not prevented prices from continuing to rise.

Panel prices increased more than 20% for selected TV sizes in Q3 2020 compared to Q2, and by 27% in Q4 2020 compared to Q3, and we now expect that average LCD TV panel prices in Q1 2021 will increase by another 9%.

Prices increased in Q4 for all sizes of TV panels, with massive % increases in sizes from 32” to 55” ranging from 28% to 38%. Prices for 65” and 75” increased at a slower rate, by 19% and 8% respectively, as capacity has continued to increase on those sizes with Gen 10.5 expansions.

Prices for every size of TV panel will increase in Q1 at a slower rate, ranging from 4% for 75” to 13% for 43”. Although we continue to expect that the long-term downward trend will resume in the second quarter of 2021, we no longer expect that panel prices will come close to the all-time lows seen earlier this year. The situation remains dynamic, and the pandemic may continue to affect both supply and demand.

TV panel prices however, continued to rise at an ‘unprecedented’ rate again, far ahead of our expectations, and panel producers do not seem to be hesitant about continuing to push prices further.

Given that TV set demand continues to outstrip production capacity, panel producers are already expecting to raise prices again in 1Q, typically a sequentially weaker quarter. There is a breaking point at which TV set brands will forego requested panel price increases in order to preserve what is left of margins, and with the increasing cost of TV set panel inventory, we expect TV set producers to become unprofitable relatively quickly.

Does that mean they will stop buying and face losing market share to those that are willing to pay higher prices to see unit volume growth? Eventually, but heading into the holidays it doesn’t seem likely this year, so we expect TV panel prices to rise again in December.

LCD TV panel prices have stopped falling after sliding below suppliers" cash-cost levels, according to industry sources. Additionally, aggressive production cuts by panel makers also have helped bring a stop to falling prices.

According to Pan Tai-chi, general manager of the TV Business Center of Innolux, TV panel inventories at most TV vendors and channel operators have bottomed out, and correspondent TV panel prices have risen since the second half of October.

Sales dynamics for TVs and monitors with high CP (cost-performance) ratios have started gaining momentum recently as current panel prices have made high CP display products more affordable, Pan said.

It is worth observing whether the sales of consumer electronics products during the forthcoming year-end shopping season in China, the US and Europe are robust enough to stir up panel demand in the first quarter of 2023, Pan commented.

The price of OLED televisions could soon come tumbling down as display makers race to finalize their Inkjet Printing manufacturing processes, which many experts believe will significantly lower their production costs.

Companies such as LG for example use what’s called a White OLED (WOLED) method that uses repeating arrays of patterned green, red, and blue subpixels placed on a fine metal mask to get an RGB coating of the organic materials. The process works well enough, but it’s also somewhat inefficient in terms of scalability, efficiency, and performance, resulting in higher costs than LCD display manufacturing, for example.

Inkject printing promises to change all that. Inkjet refers to a form of computer printing that’s normally used to recreate a digital image by propelling droplets of ink onto paper, plastic and other substrates. But the process can also be applied to TV displays, and manufacturers from China, Japan and South Korea are reportedly racing to perfect the technique in order to try and drive down production costs.

Now, IHS Markit says they’re getting close. In its newly published Inkjet Printing for AMOLED Technology and Market Report 2019, the analyst firm says the technology is all set to enter mass production next year. Further, it says capacity will increase by up to 12-fold from 2020 to 2024, with an estimated 1.3 million substrates expected to be produced by that year.

Taking an early lead in the race is JOLED Inc., a joint venture firm created by Japan Display, Panasonic and Sony, which has been testing the Inkjet process for some time already and will begin mass production next year, IHS Markit said. The company showed off several Inkjet-printed OLED panels at the Finetech Japan 2018 event in Chiba City last December, including a 4K TV panel sporting a 120Hz refresh rate that’s capable of reproducing full DCI-P3 colour. It also demonstrated various computer screens and smaller displays built using the Inkjet process.

IHS Markit said that Chinese display makers are not far behind JOLED, and several of them should also begin mass production by 2021. It didn’t mention any names, but TCL was previously reported to be experimenting with Inkjet Printing.

Chinese firms are said to have big motivation to accelerate their investments in Inkjet Printing because not only does it fit with Beijing’s long-term national strategies, but it also gives them a way to diversify from the heavily oversupplied LCD market, IHS Markit said.

More important for consumers though is the cost-savings to be had. IHS Markit in its report suggests Inkjet Printing could reduce the cost of manufacturing OLED displays by as much as 15% to 25% compared to the conventional WOLED method used by LG. Inkjet printing also requires less startup costs, and results in less materials wastage, further reducing the overall cost of making the panels.

“In recent years, InkJet Printing has attracted the attention of panel makers due to its strong potential to reduce the cost of OLED production,” Chase Li, a senior analyst at IHS Markit, said in a statement. “Despite years of competition with LCDs in the market for high-end displays of all sizes, OLED market penetration remains limited because of its expensive production costs. However, InkJet printing has the potential to dramatically reduce manufacturing expenses, making OLEDs more cost-competitive with LCDs in products including televisions and displays for computers and tablets.”

Recently, it was announced that the 32-inch and 43-inch panels fell by approximately USD 5 ~ USD 6 in early June, 55-inch panels fell by approximately USD 7, and 65-inch and 75-inch panels are also facing overcapacity pressure, down from USD 12 to USD 14. In order to alleviate pressure caused by price decline and inventory, panel makers are successively planning to initiate more significant production control in 3Q22. According to TrendForce’s latest research, overall LCD TV panel production capacity in 3Q22 will be reduced by 12% compared with the original planning.

As Chinese panel makers account for nearly 66% of TV panel shipments, BOE, CSOT, and HKC are industry leaders. When there is an imbalance in supply and demand, a focus on strategic direction is prioritised. According to TrendForce, TV panel production capacity of the three aforementioned companies in 3Q22 is expected to decrease by 15.8% compared with their original planning, and 2% compared with 2Q22. Taiwanese manufacturers account for nearly 20% of TV panel shipments so, under pressure from falling prices, allocation of production capacity is subject to dynamic adjustment. On the other hand, Korean factories have gradually shifted their focus to high-end products such as OLED, QDOLED, and QLED, and are backed by their own brands. However, in the face of continuing price drops, they too must maintain operations amenable to flexible production capacity adjustments.

TrendForce indicates, that in order to reflect real demand, Chinese panel makers have successively reduced production capacity. However, facing a situation in which terminal demand has not improved, it may be difficult to reverse the decline of panel pricing in June. However, as TV sizes below 55 inches (inclusive) have fallen below their cash cost in May (which is seen as the last line of defense for panel makers) and are even flirting with the cost of materials, coupled with production capacity reduction from panel makers, the price of TV panels has a chance to bottom out at the end of June and be flat in July. However, demand for large sizes above 65 inches (inclusive) originates primarily from Korean brands. Due to weak terminal demand, TV brands revising their shipment targets for this year downward, and purchase volume in 3Q22 being significantly cut down, it is difficult to see a bottom for large-size panel pricing. TrendForce expects that, optimistically, this price decline may begin to dissipate month by month starting in June but supply has yet to reach equilibrium, so the price of large sizes above 65 inches (inclusive) will continue to decline in 3Q22.

TrendForce states, as panel makers plan to reduce production significantly, the price of TV panels below 55 inches (inclusive) is expected to remain flat in 3Q22. However, panel manufacturers cutting production in the traditional peak season also means that a disappointing 2H22 peak season is a foregone conclusion and it will not be easy for panel prices to reverse. However, it cannot be ruled out, as operating pressure grows, the number and scale of manufacturers participating in production reduction will expand further and its timeframe extended, enacting more effective suppression on the supply side, so as to accumulate greater momentum for a rebound in TV panel quotations.

No matter what kind of online printing service you need, you can be sure to find it in our extensive product selection, all of which are customizable.

We offer unmatched professional services and quality products that you can buy online such as custom print, online printing, home signs, outdoor signs, indoor signs, sign templates, custom signs online, posters, logo signage, temporary signage, and permanent signage for large and small businesses.

You can also order personalized prints & signage for your home. Our most popular home signs include styrene printing, yard signs for real estate, cardstock, foam board prints, and gator board prints that are all great for residential use.

We understand that different companies have unique printing service needs. We strive to meet each of our client"s needs by providing custom printing services that match your business operations. Our streamlined process enables us to exceed each customer"s expectations by delivering same-day creative marketing solutions and helping your brand and business grow.

We are adept with the latest printing trends, making it possible to print products that bring ideas to life. Our team of professional designers is committed to bringing your ideas to life.

We offer our clients the best online printing services you will find in any printing business, making us your preferred custom printing shop. Here"s how our services are unique.

We are proud of our services and products because we know we make a difference in the industry. We use the best quality materials and the latest printing technology.

We have a design tool to help make your custom online printing easy. We"ve had hundreds of customers use it, and our support is always available to answer any questions.

Our online printing service can be invaluable to your business if you need a brand identity. Every print product we make is intrinsically curated, from t-shirts and cardstock printing to yard signs. At Foamcore Print, we take all print orders with respect.

Good online printing services such as ours have quick turnaround times, online design tools, top-quality material, value and variety of products and services, and are reliable. Order from Foamcore Print today!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey