tft display burn in brands

TFT LCD image retention we also call it "Burn-in". In CRT displays, this caused the phosphorus to be worn and the patterns to be burnt in to the display. But the term "burn in" is a bit misleading in LCD screen. There is no actual burning or heat involved. When you meet TFT LCD burn in problem, how do you solve it?

Burn in is a noticeable discoloration of ghosting of a previous image on a display. It is caused by the continuons drive of certain pixels more than other pixels. Do you know how does burn in happen?

When driving the TFT LCD display pixels Continously, the slightly unbalanced AC will attract free ions to the pixels internal surface. Those ions act like an addition DC with the AC driving voltage.

Those burn-in fixers, screen fixer software may help. Once the Image Retention happened on a TFT, it may easy to appear again. So we need to take preventive actions to avoid burn in reappearing.

For normal white TFT LCD, white area presenting minimal drive, black area presenting maximum drive. Free ions inside the TFT may are attracted towards the black area (maximum drive area)

When the display content changed to full screen of 128(50%) gray color, all the area are driving at the same level. Those ions are free again after a short time;

:max_bytes(150000):strip_icc()/Emerson-McDonalds_CNN_Burn-In-5692ad0d3df78cafda81df58-5c619daec9e77c0001d92fc1.jpg)

On August 31, 2017, we started a long-term 20/7 burn-in test on 3 TVs (OLED vs VA vs IPS). Our goal was to see how their performance changed over time, especially with static images like network logos, black bars in movies, or video games with a fixed interface.

We already test for temporary image retention, which generally subsides over a few minutes. It"s a temporary annoyance and results in some faint artifacts usually visible in high contrast areas.

Permanent image retention is a more serious issue, but it requires looking at the TV"s performance over months or years. We tested three TVs side-by-side, the OLED LG B6, the VA Samsung KU6300, and the IPS LG UJ6300 in a two-year-long test.

This test ended in 2019, as we feel that we now have a good understanding of what types of content are likely to cause burn-in. However, we still haven"t addressed the issue of longevity in general, and we don"t know if newer OLED panels are still as likely to experience burn-in. To that end, we"ve decided to start a new accelerated longevity test to better understand how long new TVs should last and what are the most common points of failure. Although burn-in isn"t the main goal of this test, we"re hoping to better understand how newer OLED panels compare to the older generation of OLEDs. It"s generally accepted that burn-in isn"t as much of an issue as it used to be, but it"s unclear just how much better the newer OLED TVs are. With new panels, new heatsinks, and even brand-new panel types like QD-OLED, there are a lot of unknowns.

The 20/7 burn-in test ran for about two years, from August 31, 2017, until November 15, 2019. The goal of this test was to see whether burn-in could happen for the three most popular TV types (VA LCD, IPS LCD, and OLED). These are the results of our experiment:

Long periods of static content will cause burn-in on OLED TVs. The red sub-pixel appears to degrade the fastest, followed by green and blue. The effect is cumulative, as even cycled logos do burn-in (but over a longer period). We investigated this further in our Real Life OLED Burn-in Test.

The "Pixel Shift" option on the OLED LG B6 can help spread static content over more pixels (so each pixel displays the same content for less time), but it"s not as effective for our large logo. It may be helpful for very small static areas.

Black letterbox bars were displayed for almost 5,000 hours (equivalent to 208 days of continuous letterboxing). Some letterboxing is starting to become noticeable on full-screen slides, but not in normal content. As a result, we don"t expect letterbox bars to cause any issues for people. It"s due to the uneven aging of the screen. The black portions of the screen haven"t aged as much as the rest, so those dark areas appear brighter in regular content.

Some of the LED backlights of the UJ6300 died, so the image is unwatchable. To keep a constant brightness of 175 nits across these TVs, the UJ6300"s backlight was turned up to maximum, while the other TVs achieved this brightness at a lower backlight/OLED Light setting. It may mean that it has been operating at a higher temperature, contributing to the failure.

The TVs were placed side-by-side in one of our testing rooms, as shown to the right. The TVs stayed on for 20 hours a day, seven days per week, running our test pattern in a loop. They were turned off for 4 hours each day using USB infrared transmitters connected to each TV and controlled by a PC to better represent normal (but still very heavy) usage. On the B6, the "Pixel Shift" option is enabled. A single Android TV Box was used as a source, with an HDMI splitter used to provide the same material to each display.

We used our calibration settings, as shown on the review page below, but with the backlight adjusted to reach 175 nits on our checkerboard pattern and no white balance settings applied.

A 5.5-hour video loop was used as the test pattern. It was designed to mix static content with moving images to represent typical content. The base material is a recording of over-the-air antenna TV with an overlay of RTINGS logos of different opacities and durations and added letterbox black bars. These additional elements are:

Expressly designed and tested for security and surveillance environments, AG Neovo’s patented Anti-Burn-in™ technology tackles the LCD monitor burn-in effect, otherwise known as a ghost image on the screen. Burn-in images result in the polarisation of the liquid crystal material contained within the TFT LCD panel. The Anti-Burn-in technology prolongs the lifetime of all AG Neovo monitors and displays featuring this technology to secure users’ investment.

LCD Burn-In, known as image sticking, image retention, image persistence, or ghost images, is the phenomenon where fixed images displayed on the monitor screen for extended periods cause the polarisation of the liquid crystal material contained within the LCD panel, making the image to be “burnt” on screen.

Burn-in on an LCD screen occurs because pixels permanently cannot return to their relaxed state after a static image is displayed on the screen over a long period of time. When a screen keeps displaying a single image, the crystals at those pixels will get a permanent memory, and thus the image on the screen will be imprinted onto them permanently. Once it causes screen burn-in, there is no recovery in most cases. Because of this, choosing a display or monitor allowing for pixel shift, like AG Neovo’s monitors with Anti-Burn-in, can help prevent LCD computer monitor burn-in.

“Image retention” and “Burn-in” are sometimes used interchangeably, but they are not precisely the same thing. Image retention, in most cases, is temporary and fixable. It appears when an image is temporarily “stuck” on the screen even if the content changes, but reversible by taking particular measures. Burn-in on the LCD screen is a form of image retention but is permanent and virtually impossible to fix. The prolonged use of static images would cause screen burn-in.

AG Neovo’s patented Anti-Burn-in™ technology tackles the LCD monitor burn-in effect, otherwise known as a ghost image on the screen. Burn-in images result in the polarization of the liquid crystal material contained within the TFT LCD panel. This technology prolongs the life of all AG Neovo monitors and displays to secure the user’s investment.

Anti-Burn-in technology is to activate the pixels to move by the designed time interval and protect panels from being seen the vaguely visible “residual image” under the static charge conditions so as to help prolong the lifetime of TFT LCD panels.

The patent on the Anti-Burn-in technology shows that AG Neovo places importance on its display quality to prevent image burn-in. To best fit the requirement of the security environment, Anti-Burn-in Technology is invented with high-level flexibility and effectiveness. There are three types of mode:

Execute faster than the Line and Dot Intervals. Frame Movement is to move the entire video frame horizontally and vertically (right/left/up/down) for a preset time interval.

Slower but more precise than the Frame Movement. Line Movement is to scan the screen starting from top to bottom and left to right with horizontal and vertical moving lines for a preset time interval.

The slowest but the most precise Anti-Burn-in mode. Dot Movement is to scan the screen with a set of “black & white” dots or pixels in left-to-right and top-to-bottom directions.

Unlike conventional displays, AG Neovo’s security and surveillance displays are built-in with Anti-Burn-in function to reduce the possibility of LCD burn-in for continuous security monitoring applications. It is not needed to create any screen saver, playback youtube video, or install additional tools to prevent burn-in effect.

Compared to the traditional LCD screen burn-in reduction tools which may cause evident interruption to the displayed images, AG Neovo’s patented Anti-Burn-in function is almost unnoticeable when applied. The specially designed three modes of Anti-Burn-in selection provide users with flexibility in choosing the optimal approach that best fits with their non-stop security monitoring.

Video surveillance is commonly used for monitoring of selected images to determine if an improper activity is occurring, such as theft, vandalism, and abnormal situations in daily operation, and any intervention is not allowed during the process. To ensure there are not any interruptions to the video monitoring, turning on a screen saver, reducing contrast/brightness or playing white static image for a particular while is not an option. Instead, selecting a security monitor with built-in Anti-Burn-in function is an efficient solution.

Burn-in on the screen is technically hard to fix. Instead, here are some tips on how to remove image persistence on LCD screens and prevent permanent effects:

Enable the “Pixel Shifting” function on your monitor or display. Most of AG Neovo monitors have a built-in Anti-Burn-in, which allows varying pixel usage by activating the pixel to move at regular intervals. If not enabled automatically, you can manually turn it on and try to alleviate any image retention problems.

Reduce screen contrast and brightness. Lower contrast allows even lighting levels across the LCD screen and thus has less strain on a specific area of the screen. Then, try to watch some different contents, and the effect of Image retention might go away on its own.

Turn on white static image for approximately as long as the persistent image was displayed; this is to use a completely white screen to overwrite the burn-in image. Or, create a screen saver that alternates between black and white images. The continuous changing of white/black across your screen can help alleviate the ghost image from the screen. The solid colour background might reset the image burn but is more likely to deal with image retention than image burn-in.

If you"ve ever left your LCD monitor on a single static screen for an extended period, say 24 hours or more, and then changed the on-screen image and seen a "ghost" of the previous screen, you"ve experienced Image Persistence. You can also sometimes see this phenomenon while traveling through an airport and seeing the flight status monitors. The good news is that the persistence is not permanent, unlike previous technologies such as plasma displays or CRTs.

The previous technologies of plasma displays and CRTs are phosphor-based, and extended static images create a "burn-in" that affects the properties of the phosphor material and create permanent damage. The damage is called burn-in, whereas static image "ghosts" on an LCD are Image Persistence. Image Persistence is not permanent damage and is reversible. Modern LCDs include design, driver ICs and chemical improvements that minimize these effects.

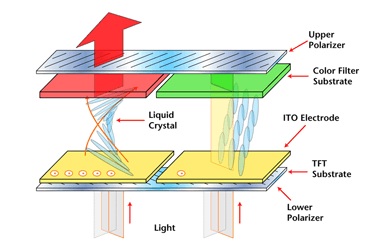

To understand why image persistence happens, we must first understand the basic structure of an LCD TFT. Within the TFT, a voltage is applied to the liquid crystal material to align or twist the crystals in each pixel to allow light to pass through or block light, thus creating the on-screen image. By allowing a static image to remain on screen for an extended duration, the polarity of that voltage on the crystals remains. During this time, ions within the liquid crystal fluid will migrate to either the + or – electrode of the transistor (source or drain). As these ions accumulate on the electrodes, the voltage applied to the crystals to align or twist is no longer sufficient to completely change the image on-screen, resulting in a "ghost effect" from the previous image.

The best method for preventing Image Persistence is to avoid having any static images on the screen for an extended time. If the image changes periodically, the ion flow will never have an opportunity to accumulate on any internal electrode. However, depending upon the use of the display, it is not always possible to avoid static images on the screen. In cases such as these, there are steps that you can do to reduce the chance of persistence.

Switching off the displayduring periods of inactivity (sleeping mode) and arousing at necessary image changes would also be reflected as a positive side effect providing lower power consumption.

Panel manufacturers specifically test for the phenomenon and have designed the TFT cell and improved the purity of the liquid crystal fluid to minimize any effect of image persistence.

If you have a project that is considering taking advantage of any display technology, US Micro Products can provide a solution designed for your application. Send us an email at sales@usmicroproducts.com.

I would just turn down the brightness (for less power consumption and monitor longevity, the backlight has nothing to do with the "burn in") and leave a screen saver on overnight. On my monitor, once the screen is back to normal, it doesn"t come back for a while.

LCD (liquid crystal display) is the most widely used display technology. They are used for automotive, appliance, telecommunication, home appliance, industrial, consumer electronic, military etc. But LCD displays have some drawbacks, such as slow response, narrow viewing angle, lower contrast etc. One annoying phenomenon often complained about by users is image sticking.

If a fixed image remains on a display for a long period of time, the faint outline of that image will persist on the screen for some time before it finally disappears. Normally, it happens to LCD and plasma screens, but for the purpose of our discussion, we will focus on TFT LCD displays. Image sticking is also referred to as “image persistence”, “image retention”, “ghosting” or “burn-in image.”

An LCD screen includes a thin layer of liquid crystal material sandwiched between two electrodes on glass substrates, with two polarizers on each side. A polarizer is an optical filter that lets light waves of a specific polarization pass through while blocking light waves of other polarizations. The electrodes need to be transparent so the most popular material is ITO (indium tin oxide). Since an LCD can’t emit light itself, normally a backlight is placed behind an LCD screen in order to be seen in a dark environment. The light sources used for a backlight can be LED (light emitting diode) or CCFL (cold cathode fluorescent lamps). The LED backlight is the most popular. Of course, if you want a color display, a layer of RGB color filter can be made into an LCD cell. A touch panel can also be added in front of an LCD display.

When an electric field is applied to the liquid crystal molecules, they become untwisted. When the polarized light reaches the layer of liquid crystal molecules, the light passes straight through without being twisted. When it reaches the second polarizer, it will also pass through, meaning the viewer sees the display as bright. Because LCD technology uses electric fields instead of electric current (electron passes through), it has low power consumption.

The cause of LCD image sticking is due to an accumulation of ionic impurities inside the liquid crystal materials. When slight DC voltage occurs, the charged impurities will move the electrodes and build up a reversed voltage field. When the power is removed, the reversed voltage will kick in to make the LCD molecules twisted different from the other part of the LCD, which shows up as the image sticking. The longer the time, the more impurities will migrate, the larger the reversed voltage will be, and the imaging sticking will appear worse.

Using the black/white chess board image shown above: Static image it for 2 hours, then change to 50% gray for 1 min. Use an 8% neutral density filter to check if it is OK.

If a static image must be displayed, try to use block patterns instead of distinct border lines. Try to use medium gray hues and use colors that are symmetric to the middle grey level at the boundary of two different colors. Gradually shift the border lines once in a while.

For LCD manufacturers, try to protect liquid crystal materials exposed to the air by using nitrogen gas or dried air to avoid absorbing moisture that can create a huge amount of impurities in the liquid crystal material, as water is an excellent solvent. Controlling the humidity of the fab is also very important, as is selecting the right liquid crystal materials and their manufacturers. Different liquid crystal materials have different moisture absorbing abilities. Different liquid crystal material factories have different capabilities in terms of controlling impurities. Despite the fact that high purity can mean high in cost, using higher purity liquid crystal materials and designing the circuitry to get rid of DC in LCD display drivers can avoid an image sticking issue.

Unlike the “burn-in” issue common with CRTs, an image sticking issue is not permanent. It will eventually recover after some time. One way to expedite erasing a retained image is to have a screen on in an all-black pattern for 4-6 hours. If you want to make it even faster, the display can be put into an environment with a temperature of around 35 to 50°C for 1-2 hours. As this elevated temperature is within the working temperature range, it will not damage the LCD panels.

If you spend long enough debating the merits of LCD vs. OLED display technologies, eventually, someone will touch upon the subject of the dreaded OLED screen burn in. The point made is that OLED displays will inevitably suffer from horrible-looking artifacts over time, while LCD and new technologies like Mini-LED won’t. But like most of these debates, you’ll probably hear as many overblown anecdotes as you will actual facts about the issue.

You may never have experienced it for yourself, but many consumers are wary about the possibility of burn in when pondering their next smartphone purchase. Particularly as expensive flagship smartphones have universally adopted OLED display technology. Apple, Google, and other manufacturers acknowledge that burn in can be a problem in rare cases. OLED technology has made its way to much more affordable price points in recent years, putting the issue on the radar for even more consumers.

The word “burn in” is a little misleading, as no actual burning or heat problems are involved. Instead, this term describes a display suffering from permanent discoloration across any part of the panel. This may take the form of a text or image outline, fading of colors, or other noticeable patches and patterns on display. The display still works as expected, but a somewhat noticeable ghost image or discoloration persists when the screen is on. To be considered screen burn in, these artifacts have to be permanent and are a defect caused on the display hardware side. Rather than a graphical glitch that may be caused by software, temporary image retention, or a problem with the display driver circuitry.

The term dates back to old CRT monitors, where phosphor compounds that emit light to produce images lost their luminance with time. LCD panels can exhibit similar problems, but these are much rarer due to the nature of LCD’s backlight and color matrix design.

Although not as bad or noticeable as old CRT issues, today’s OLED smartphone displays can eventually suffer from a similar problem. That being said, it’s pretty difficult and rare to notice unless you know what you’re looking for, and it takes hundreds, if not thousands, of hours of screen-on time before any such errors appear. In smartphones, pattern burn in is typically associated with always-on displays, navigation buttons, and the notification bar. The example below demonstrates a textbook case:

Although most smartphones now support gesture navigation controls in the place of the old button design. So this type of burn-in is much less of a problem than it used to be.

The cause of all screen burn in is the varying lifecycle of a display’s light-producing components. As these parts age, their brightness changes, and therefore the panel’s color reproduction gradually shifts with time. Although this can be mitigated somewhat with clever software, all displays experience some color shift as they age. But with burn in, some parts of the screen age faster than others. This can gradually shift the perceivable colors of the screen in one area more than in another, leaving what looks like a ghost image behind.

With modern smartphone and smartwatch technology, screen burn in can manifest due to the different life spans between the red, green, and blue LED subpixels used in OLED panels. As we mentioned before, areas of the display that seldom change, are bright white, or are often black and switched off, such as navigation buttons or the notification bar, are the most likely areas to notice this issue. You may also notice the effect in darkened status bars designed to hide display notches.

This is because these areas are more likely to consistently display one color, a set icon, or text. In contrast, the rest of the display produces a more random selection of colors from various websites, videos, apps, etc., over a long period of use. Therefore the subpixels in these areas see different amounts of use and thus age differently, eventually resulting in a slight variation in color reproduction. Switching to transparent and color-changing bars has the added bonus of evening out the color aging process.

Speaking more technically, the issue is that blue LEDs have significantly lower luminous efficiency than red or green pixels. This means that a blue LED needs to be driven at a higher current for a set sized pixel to achieve the same brightness as red or green. Higher current causes the pixel to degrade faster, shortening its lifespan and eventually tinting the display towards the red and green colors. Therefore an OLED display’s color doesn’t degrade evenly; it will ultimately lean towards a red/green tint.

So, if one part of the panel spends a lot of time displaying a blue or white image, the blue pixels in this area will degrade faster than in other areas. That’s essentially what burn in is. However, display manufacturers do account for this in their panel designs.

If OLED screens have a problem with burn in, why do we continue using them? Burn in is a true downside to OLED displays, but there are plenty of reasons consumers and manufacturers like them. For starters, image quality is much better than in LCDs. OLED panels can reproduce more vibrant colors, more contrast, wider viewing angles, and faster refresh rates. Colors tend to be much more saturated, and blacks are much darker.

OLED displays have a simpler design, allowing thinner, lighter smartphone designs. You can also thank OLED technology for foldable phones and curved displays. If those improvements weren’t enough, you’ll also enjoy lower power consumption with OLED.

Additionally, burn in problems are only common after prolonged periods of use. As you may already know, smartphone manufacturers don’t expect you to keep a smartphone for more than 2-3 years. Recent statistics show that consumers currently keep their phones for an average of 2.75 years.

At this stage, manufacturers are very aware of the potential issues and have already taken some intelligent steps to help avoid burn in. For starters, Samsung has been using its pentile subpixel arrangement in its AMOLED displays since the Galaxy S3. By making the blue subpixel larger, it requires less current to drive in order to provide the necessary light. Driving the LED with less current increases its lifespan, so it takes longer for any noticeable color shift to occur.

This doesn’t directly address the issue of different parts of the screen aging at different rates, but it does mean that it will take significantly longer to notice than with older or cheaper OLED panels. More expensive and modern OLED panels are built with longer-lasting LEDs and well-designed layouts, meaning flagship smartphone displays age slower. These days, it’s cheaper phones packing cheaper displays that are marginally more likely to see issues after heavy use.

There are software solutions too. Android Wear product manufacturers can enable the OS’s “burn protection” option. This mode periodically shifts the screen’s contents by a few pixels, so they spend equal time displaying different colors. Smartphones equipped with Always-On display technology employ a similar tactic. Google also suggests a selection of design guidelines tailored to avoid screen burn-in problems when designing OLED watches. The move towards gesture rather than on-screen navigation controls is also helping to alleviate one of the more noticeable burn in areas.

If your screen is already burnt in, there’s not much that can be done to undo the damage. Some apps on the Play Store claim to reverse the problem. These will end up “burning” the rest of the screen to match the colors, which isn’t a real solution.

Keep your display brightness as low as reasonable. Increased brightness requires more current and therefore shortens LED lifespans. Don’t crank up the brightness unless you have to.

Try to make it so that the screen isn’t displaying the same thing all the time, in the same areas of the screen. For example, if you have a widget that almost always looks the same, chances are it will eventually burn into the image. Move things around now and then, and try to keep the view of your phone dynamic.

All that said, screen burn in isn’t something that should concern many users if they’re looking to buy a new OLED smartphone. Modern panels have much longer lifespans than early OLED smartphones, and even then, burn in was rare. Just don’t leave a static image on the screen 24/7 with the brightness set at max.

The bottom line is that you should be looking at several years’ worth of use out of a modern smartphone display before any screen burn in will be noticeable. But it doesn’t hurt to be aware of what can happen to aging handsets and how to maximize their lifespan.

Screen burn-in, image burn-in, or ghost image, is a permanent discoloration of areas on an electronic display such as a cathode ray tube (CRT) in an old computer monitor or television set. It is caused by cumulative non-uniform use of the screen.

One way to combat screen burn-in was the use of screensavers, which would move an image around to ensure that no one area of the screen remained illuminated for too long.

With phosphor-based electronic displays (for example CRT-type computer monitors, oscilloscope screens or plasma displays), non-uniform use of specific areas, such as prolonged display of non-moving images (text or graphics), repetitive contents in gaming graphics, or certain broadcasts with tickers and flags, can create a permanent ghost-like image of these objects or otherwise degrade image quality. This is because the phosphor compounds which emit light to produce images lose their luminance with use. This wear results in uneven light output over time, and in severe cases can create a ghost image of previous content. Even if ghost images are not recognizable, the effects of screen burn are an immediate and continual degradation of image quality.

The length of time required for noticeable screen burn to develop varies due to many factors, ranging from the quality of the phosphors employed, to the degree of non-uniformity of sub-pixel use. It can take as little as a few weeks for noticeable ghosting to set in, especially if the screen displays a certain image (example: a menu bar at the top or bottom of the screen) constantly and displays it continually over time. In the rare case when horizontal or vertical deflection circuits fail, all output energy is concentrated to a vertical or horizontal line on the display which causes almost instant screen burn.

Screen burn on an amber CRT computer monitor. Note that there are two separate burned-in images: one of a spreadsheet program, and another of an ASCII-art welcome screen.

Phosphor burn-in is particularly prevalent with monochromatic CRT screens, such as the amber or green monochrome monitors common on older computer systems and dumb terminal stations. This is partly because those screens displayed mostly non-moving images, and at one intensity: fully on. Yellow screens are more susceptible than either green or white screens because the yellow phosphor is less efficient and thus requires a higher beam current. Color screens, by contrast, use three separate phosphors (red, green, and blue), mixed in varying intensities to achieve specific colors, and in typical usage patterns such as "traditional" TV viewing (non-gaming, non-converged TV usage, non-Internet browsing, broadcasts without tickers or flags, no prolonged or permanent letterboxing) are used for operations where colors and on-screen object placement approach uniformity.

Modern CRT displays are less susceptible than older CRTs prior to the 1960s because they have a layer of aluminum behind the phosphor which offers some protection. The aluminum layer was provided to reflect more light from the phosphor towards the viewer. As a bonus, the aluminum layer also prevented ion burn of the phosphor and the ion trap, common to older monochrome televisions, was no longer required.

A nearly two-year-old LCD television showing extreme burn-in of CNN"s circa 2008 digital on-screen graphic; this television is in a McDonald"s restaurant where CNN is permanently turned on and displayed throughout the business day.

In the case of LCDs, the physics of burn-in are different than plasma and OLED, which develop burn-in from luminance degradation of the light-emitting pixels. For LCDs, burn-in develops in some cases because pixels permanently lose their ability to return to their relaxed state after a continued static use profile. In most typical usage profiles, this image persistence in LCD is only transient.

Both plasma-type and LCD-type displays exhibit a similar phenomenon called transient image persistence, which is similar to screen burn but is not permanent. In the case of plasma-type displays, transient image persistence is caused by charge build-up in the pixel cells (not cumulative luminance degradation as with burn-in), which can be seen sometimes when a bright image that was set against a dark background is replaced by a dark background only; this image retention is usually released once a typical-brightness image is displayed and does not inhibit the display"s typical viewing image quality.

Screensavers derive their name from their original purpose, which was an active method of attempting to stave off screen burn. By ensuring that no pixel or group of pixels was left displaying a static image for extended periods of time, phosphor luminosity was preserved. Modern screensavers can turn off the screen when not in use.

In many cases, the use of a screensaver is impractical. Most plasma-type display manufacturers include methods for reducing the rate of burn-in by moving the image slightly,Android Wear watches with OLED displays can request that Android Wear enable "burn protection techniques" that periodically shift the contents of the screen by a few pixels.

Other examples: Apple"s iPhone X and Samsung"s Galaxy series both mitigate or delay the onset of burn-in by shifting the pixels every minute or so for the battery, Wi-Fi, location, and service bars. Also, parallax scrolling may be enabled for the home screen to give icons a 3D-like effect, a setting Apple refers to as "perspective zoom". AG Neovo patented Anti-burn-in technology is also using pixel shifting to activate the pixels to move by the designed time interval to prevent burn in effect on LCD monitors.

Google requests that when these techniques are enabled, watch face developers do not use large blocks of pixels so that different pixels are burned in with each shift, reducing the overall wear of the pixels.

Some screensavers move around, such as those on DVD players or those on some television sets that move around paused video after a long period of inactivity.

Depending on the type of screen, it is sometimes possible to remedy screen burn-in through the use of remedial software and remedial devices. In the case of OLED screens on Android phones, burn-in reduction apps can display an inverted image of the navigation and status bars (which are constantly displayed and therefore the most likely elements to be burned in) to burn in opposite pattern, resulting in a screen whose sub-pixels have more even luminosity and therefore less visible burn-in artifacts.

The most prevalent burn-in image on early televisions was said to be that of the RCA Indian-head test pattern, which would often follow the formal television station sign-off. This was due to the viewer leaving the television set on at the end of the day, which was not recommended by the television manufacturers.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

Relies on backlighting to provide brightness rather than producing its own light, hence, they need built-in light emitting diodes (LEDs) in their backlighting structure

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Touch type and accuracy.What type of activities are you planning on using your device for? If it’s for extended outdoor use, then you should go with projected capacitive touch as this is more precise and accurate. Touch accuracy is important for industrial and commercial applications.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

One of the problems with old CRT monitors, over time, was a condition called burn-in. This phenomenon resulted in an imprint of an image onto the display that was permanent, caused by the continuous display of a particular picture on the screen for extended periods. A breakdown in phosphors on the CRT results in the image being burned into the screen, hence the term. Is there such a thing as LCD screen burn-in?

LCD monitors use a different method for producing the image on the screen and are immune to this burn-in effect. Rather than phosphors generating light and color, an LCD uses a white light behind the screen with polarizers and crystals to filter the light to specific colors. While LCDs are not susceptible to burn-in the same way CRT monitors are, LCDs suffer from what manufacturers call image persistence.

Like the burn-in on CRTs, image persistence on LCD monitors is caused by the continuous display of static graphics on the screen for extended periods. Long-term-static images prompt the LCD crystals to develop a memory for their location to generate the colors of that graphic. When a different color appears in that location, the color will be off and will display a faint image of what was previously displayed.

The persistence is the result of how the crystals in the display work. The crystals move from a position allowing all light through to one that doesn"t allow any. It"s almost like a shutter on a window. When the screen displays an image for an extremely long time, the crystals can switch to a particular position. It may shift a bit to alter the color, but not completely, resulting in a display other than the one intended.

This problem is most common for elements of the display that do not change. Items that are likely to generate a persistent image are the taskbar, desktop icons, and background images. These tend to be static in their location and displayed on the screen for an extended period. Once other graphics load over these locations, it might be possible to see a faint outline or image of the previous graphic.

In most cases, no. The crystals have a natural state and could shift depending on the amount of current used to generate the desired color. As long as these colors change periodically, the crystals at that pixel should fluctuate enough, so the image doesn"t imprint into the crystals permanently. However, if the screen is always on the image that doesn"t change, the crystals could obtain a permanent memory.

Set the screen to turn off after a few minutes of idle time. Turning off the monitor display prevents images from appearing for extended periods. Setting the monitor to do this when the computer is idle for 15 to 30 minutes can make a difference. These values appear in the Mac Energy Saver settings or Windows Power Management.

Rotate any background images on the desktop. Background images are a common cause of image persistence. By switching backgrounds every day or every few days, you"ll reduce the risk of persistence.

Using these items can prevent the image persistence problem from cropping up on a monitor. If the monitor displays image persistence problems, here are a few steps that can be used to correct it:

Use a screen saver with a rotating image and run it for an extended period. The rotating color palette should remove the persistent image. Still, it could take a while to remove it.

Manufacturers of plasma and LCD flat panel televisions are continuously introducing technology to help reduce the likelihood of this problem, but there are simple steps you can take to help reduce the chances of experiencing image "burn-in.

For new plasma TVs in particular, be wary of leaving images on the screen for long periods. When phosphors are fresh, they burn more intensely as they are ignited. This means that relatively new plasma TVs are prone to "ghosting", which occurs when on-screen images appear on the screen for an extended time.

If you are using your TV to display a video game from a computer, make sure to utilize screen saver features or power management settings that can change or turn off the display after a period of time.

"Stuck" images can be removed by "exercising" the LCD pixels to bleed off the residual capacitive charge. This can most easily be accomplished by using a random pattern screen saver that changes the screen image repeatedly. You should be able to connect your LCD TV to a computer with TV-out capability. The time required to clear the stuck image can vary widely (minutes, hours, days) depending on the panel technology and the severity of the stuck image.

Turning the LCD monitor off for an extended period of time does not clear the image. The charge must be bled off by charging/discharging the pixels with random images.

When it comes to choosing what to use for your displays, going with the standard can get you farther ahead than thinking outside the box. TFT LCD display gives you an edge for your advertising needs, television screens, or even phone screens.

A thin-film transistor (TFT) is one of the technologies commonly used for building LCDs. With this technology, your LCD is guaranteed a sharp, clear, and full-color display and high-quality performance.

When a signal sent to a pixel also affects the pixels next to it, crosstalk This runs the risk of distorting the quality of your image. With TFT, crosstalk is significantly reduced with the TFT layer integrated into the screen itself. With every pixel corresponding to the signals meant only for them, you are guaranteed the best resolution and image quality.

In the LCD industry, the most popular kinds of displays are manufactured and innovated the most. Unlike other types of LCD technologies, the TFT module is available in different sizes, ranging from cellphone sizes to larger TV sizes, to suit your needs.

All LCD displays have a determined number of hours of use before they become half as bright than when they were turned on for the first time. This is called half-life. Although research is still ongoing regarding half-life, TFT displays are said to have more than 14,000 hours of half-life.

This does not mean, however, that the LCD will burn out after reaching its half-life. It means that its brightness will only be half of when it was new.

Compared to CRTs, TFT LCD modules have lower heat release. Moreover, they emit lower electromagnetic emissions which significantly decrease visual fatigue. This means that TFTs are ideal for devices and displays that require an audience’s prolonged attention, such as cell phones and television screens.

While the TFT’s power consumption is significantly lower than OLEDs in white displays, there are also emerging TFT displays in the market that integrate smart technologies that can save up to 50% energy on battery-operated devices.

One of the notable disadvantages of TFTs, however, is its cost. The characteristics detailed in the previous section, however, must be considered worthy of investment. Moreover, as the number of TFTs floods the LCD display market, the price for TFTs are decreasing by the day.

At Microtips Technology USA, we only provide you with the best among the best of TFT modules. Our TFT LCD displays assure only full RGB brilliance with up to 16.7 million colors, better picture quality with high resolutions and IPS technology, and affordability.

Hi all, I"ve done some research on tft vs IPS screens and it seems tft screens are the worst type around. With that said, all the videos and articles I found were from 5ish years ago. Are tft screens still garbage? If so, why in the world would Motorola put it in their flagship?

Hi all, I"ve done some research on tft vs IPS screens and it seems tft screens are the worst type around. With that said, all the videos and articles I found were from 5ish years ago. Are tft screens still garbage? If so, why in the world would Motorola put it in their flagship?

I have noticed that distributors for small and medium TFT, they consider TFT still a top quality product, it"s enough to see product list of any online distributor like

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey