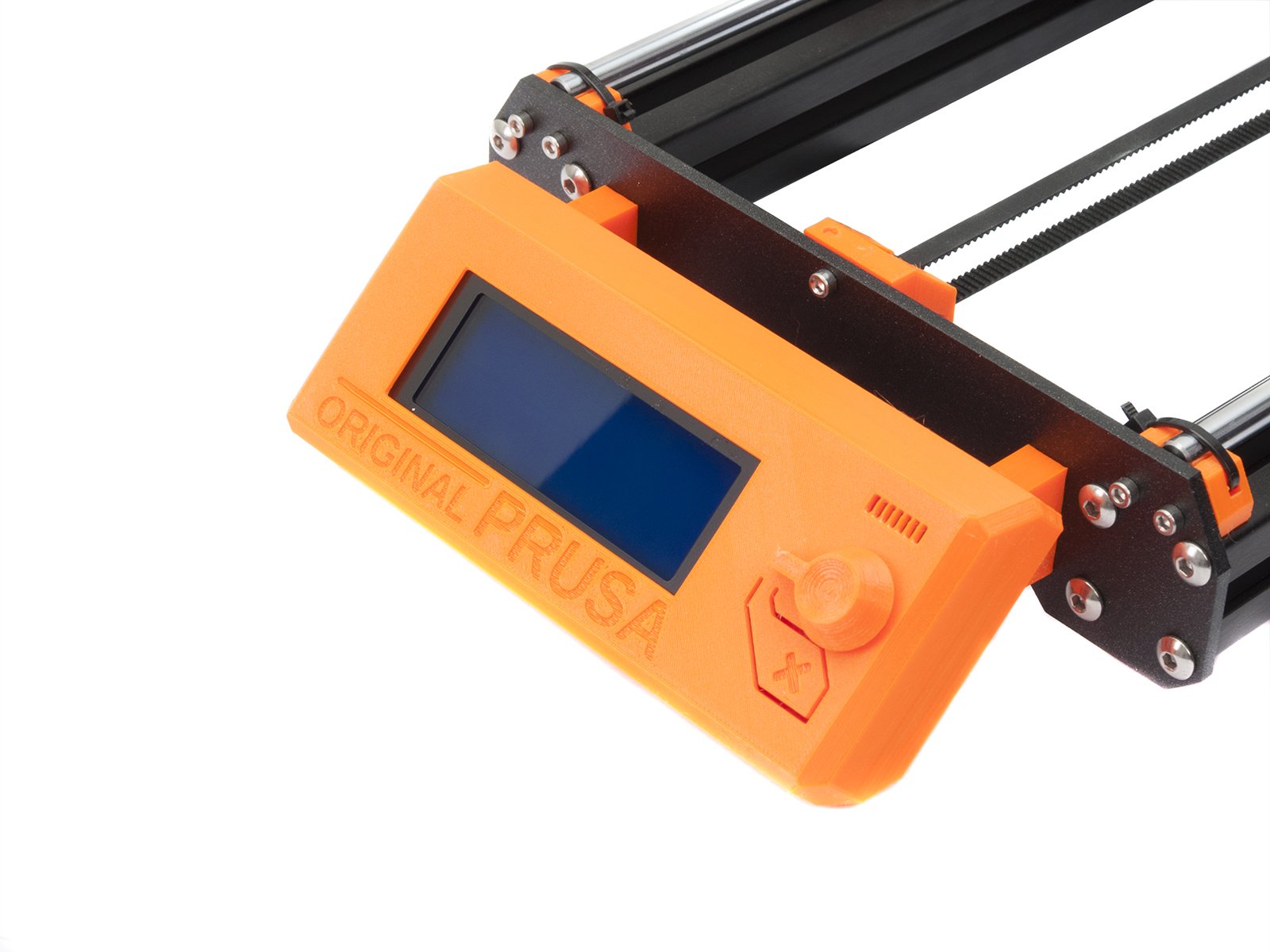

prusa i3 mk3 lcd screen quotation

This LCD display works and fits like original PRUSA MK3 display. The price point for this unit was below anything I could find elsewhere. It’s a perfect match for the PRUSA MK2 and MK3. No complaints.

This LCD unit supports the screen brightness adjustment feature.Brightness function requirements: MK3, MK3S, Einsy board revision 1.1a (or newer), Firmware 3.9.0 (or newer)...

I have a concern regarding the Prusa i3. When i connect the printer to my computer via USB the LCD panel on the printer works absolutely fine but as soon as i turn the power supply on for the printer, the LCD panel starts showing all squares. All the text is gone but when i cut off the power supply the LCD panel is back to normal, i can see the text correctly.

That sucks. I assume this just "happened" as you powered on the printer or some such? If you are adept with a soldering iron the first thing I"d recommend is just a quick "re-flow" of all of the solder joints on the LCD assembly. Sometimes a cold solder joint can manifest like this. If that doesn"t fix the problem you can probably recover by just replacing the 4x20 LCD module itself as this problem looks like one of the row or column drivers on the LCD module has gone out to lunch.

You should get one without the serial interface adapter board as I am reasonably certain that the Prusa panel does not use the serial interface to communicate directly with the LCD panel and that module is unlikely to have failed anyway if they are using it. Unsoldering the existing LCD will be a little irritating because of all of the pins but it is otherwise straighforward and you can hopefully have a fully functional panel again for about $8.00.

I used to have the same issue with noise from the power supply getting onto the screen and even sometimes resetting my printer mid-print. I found that if I had my USB programming cable plugged in I never experienced the issue. I found that the issue was the noise from the power supply wasn"t not being drained to earth ground, and it was actually tripping the reset on the micro-controller. Part of that comes from the micro-controller and screen having to share their power, which is regulated down to 5v from the incoming 12v. The trick is to supply the micro controller with its own 5v while printing and drain the incoming noise off to earth ground. I modified the typical USB A-B cable to resolve this. As long as you still use the SD card to load the gcode you can occupy the programming port with this cable to supply the 5v.

The Prusa i3 is one of the most successful 3D printer designs in history. Because it’s an open-source design, dozens of manufacturers have sold their own versions. Sometimes those are exact clones, and sometimes they have small tweaks. But genuine Prusa i3 3D printers are consistently rated as the most reliable consumer printers on the market. That said, they have a pretty basic monochrome LCD screen.Dr. Scott M. Baker decided to swap that out for something a little more interesting, and chose a vintage VFD.

This mod was tested with the Prusa i3 Mk33D printer, but should work with earlier iterations and many clones. It essentially just replaces the boring monochrome LCD with a cyberpunk-style VFD (vacuum fluorescent display). VFDs used to be common in consumer electronics, because they produced clear, bright graphics. But they’ve fallen out of favor in recent years as LCD, LED, and OLED displays have become more affordable. There is no denying how cool they look though, which is why Dr. Baker performed this modification.

TheVFDitself is made by Noritake, and — very surprisingly — is almost an exact drop-in match for the LCD that comes with the Prusa i3 Mk3. The display is a little expensive at around $90, but it’s hard to beat the convenience. All you have to do is take apart your control panel and pull the PCB out. Then either desolder the original LCD or order a new PCB (available atprintedsolid.com). Next, just solder in the Noritake VFD and put the control panel back together. That’s it! It should just work. You can even use filters if you want to change the color of the VFD.

Though these 3D printers are similar in features and print quality, the Prusa MK3S+ comes at a substantially higher price tag than the Creality Ender 3 S1 Pro. While cost isn’t everything, it is definitely an important factor to consider when purchasing. The Ender 3 S1 Pro is priced in the $500-550 price range (Check the current price on Amazon), and includes free shipping from Amazon (or most other vendors). The Prusa$ MK3S+ starts at the $800-850 price point for the unassembled kit, and is over $1000 for the assembled version (Check prices on prusa3d.com). Shipping is not free, and will add $50-100 to the price tag depending on whether you purchase the kit or the fully assembled version.

Creality 3D printers are manufactured in China, while Prusa Research is located in the Czech Republic. Due to lower costs of labor and easier access to other manufactured parts, 3D printers manufactured in China cost less to produce and can support a lower price point. In addition, the Prusa MK3S+ uses 3D printed parts in the construction of the printer. This has a number of advantages for Prusa, such as the ability to iterate quickly on part updates, and is a way for Prusa to extensively test their printers when manufacturing these parts. However, 3D printing at scale is more expensive than traditional manufacturing methods such as injection molding.

For parts that they do not 3D print, Prusa focuses primarily on part quality with cost as a secondary consideration. For example, Prusa uses premium parts for the linear rail system and name-brand Bondtech and E3D components for the extruder and hot end. Creality takes a more balanced approach with the Ender 3 S1 Pro, and reduces cost by producing parts themselves, such as the CR-touch leveling sensor and a Creality branded power supply. Creality has historically focused on cost first, but we have seen that the higher-end printers like the Ender 3 S1 Pro do strike a good balance between quality and cost savings.

It is clear from the moment you open the MK3S+ that Prusa puts a lot of effort into testing and quality control. For our assembled unit, a checklist and test results sheet were included which showed all of the testing that they performed before shipping the unit. Additionally, the printer shipped with a completed test print on the bed, indicating that they run an actual print test on each unit they produce. Creality printers do not go through as rigorous of testing, and in some cases there will be small issues that require adjustment. In our experience of purchasing over 30 Creality printers at retail, we have noticed small QC issues on 10-15% of the printers.

Improved quality control is not free, and is likely a contributing factor in Prusa’s higher price point. The bottom line is that if you prefer to pay more to get a machine that will almost certainly work out of the box without any defects, the Prusa MK3S+ is more geared toward you.

In a similar vein, Prusa provides a much better support experience than Creality. After purchasing a printer, it is easy to get in touch with Prusa’s dedicated support team through their site, since you are buying directly from the manufacturer. With Creality, getting support is more difficult since you will be purchasing through a 3rd party like Amazon. If there are major defects with the printer, Amazon is very good about providing replacement units, however you will not be able to get assistance in repairing issues, and needing to do a full replacement can be a frustrating experience.

There are few 3D printers with as many industry accolades as the Prusa i3 MK3S+, and after spending some time with this printer, it’s easy to see why it’s one of the best 3D printers currently on the market. With a price tag of $999 for an assembled machine or $750 for a DIY kit, the price point of the MK3S+ is towards the high end for an open format consumer 3D printer, but the features of this machine and the ecosystem created by Prusa (they make their own hardware, software, filament, and more) have made the MK3S+ a formidable machine for anyone interested in taking their 3D printing game to the next level.

The features of the MK3S+ (silent stepper drivers, power-panic, etc.), noteworthy when originally launched, have largely become standard on lower-cost machines and may not seem particularly impressive on a spec sheet. However, clever software implementation and well-written documentation have created a machine that provides a best-in-class printing experience. For instance, the auto-leveling SuperPINDA probe of the MK3S+ maps the build platform for surface distortions, but the printer firmware is capable of storing multiple Z-offsets so you can switch build platforms without having to recalibrate every time.

The MK3S+ is a visually distinct machine; and the Prusa team has kept their black and orange color scheme for their smaller printer, the Prusa Mini+. The bright orange printed parts on the MK3S+ have created instant brand-recognition for the Prusa line of printers, and Prusa has doubled down on this by reinforcing their branding across their machine. In fact, you can find the word ‘Prusa’ printed, engraved, or etched into the MK3S+ in 25 places, 29 if you’re using a spool of their Prusa Polymers Prusament PLA material.

The fully assembled Prusa MK3S+ ships with all of the accessories required to make your first print, and also includes enough spare parts to replace almost every fastener on the machine. The fully assembled MK3S+ also includes a bag of Haribo Goldbears, a signature addition from the Prusa team.

The Prusa MK3S+ includes a full spool of silver PLA material, screwdriver, a metal part scraper, a glue stick (for adhesion), an isopropyl alcohol wipe, lubricant for the linear rails, power and USB cables, a sheet of stickers, a printed handbook, and a diagnostic printout that confirms the functionality of the mechanical and electrical systems.

The usefulness of the handbook is hard to overstate. When you’re starting out with your first 3D printer, it can be difficult to pinpoint the cause of problems such as loss-of-extrusion, poor layer adhesion, or a clogged extruder. The included handbook is full of detailed photographs, troubleshooting workflows, and solutions to common problems. This is an invaluable resource for beginners, amateurs, and experts alike, and it’s clear to me that Prusa has set the standard for technical documentation.

You might be surprised to find that the Prusa MK3S+ is based on the RepRap i3 (third iteration) frame, originally released in September of 2012. Despite this nearly decade-old release date, the MK3S+ is full of modern advancements and enough innovative features to still be a top contender in the prosumer 3D printer market.

At the heart of the MK3S+ is the 8-bit Einsy RAMBo board, housed in a 3D printed enclosure mounted to the frame of the machine. This board is equipped with Trinamic 2130 silent stepper drivers, user-replaceable fuses, and the cable management is clean and professional.

The attention to detail on the Prusa MK3S+ is clear, and a perfect example of this is the wire management across the machine. Current-carrying wires are attached to the extruder module with zip ties that act as a strain-relief to prevent the wires from fatiguing and separating. The wires from the power supply are tucked neatly under the frame of the machine, out of sight and reach from users to prevent accidentally unplugging them during printing.

The 24V heated bed is able to reliably hit 100C, which is more than enough to allow high temperature materials like PETG and ASA to adhere to the build platform without delaminating. The magnetic build platform is firmly held in place without any clips or latches and can easily be removed once it cools to room temperature. PETG in particular is easy to remove from the textured surface of the textured spring steel sheet, and the MK3S+ build platform is best-in-class for high-temperature adhesion.

The MK3S+ is equipped with a genuine E3D hot end, and it has the holographic sticker to prove it (seriously). E3D manufactures every component in the hot end from the nozzle to the heatbreak which means you are very unlikely to run into the type of manufacturing defects that occasionally pop up on less expensive printers (incorrectly drilled nozzles, degraded PTFE tube liner, etc.) In addition, this nozzle is rated for a max temperature of 300C (572F), which is easily hot enough to extrude most common thermoplastics and even some higher-temperature engineering-grade materials like Nylon and Polycarbonate.

The printed parts on the MK3S+ are a perfect example of a company applying its in-depth knowledge of a subject to its product. The printed brackets found on the MK3S+ have been printed in PETG, and the outward-facing textured surface shows the level of quality you can expect from using a textured sheet.

Compared to the manual bed leveling process of a printer like the Creality Ender 3 Pro, the MK3S+ is faster, easier to use, and requires less trial and error. PrusaSlicer includes a “G80” command in the start G-code (the instructions the printer reads when making a part), and this command performs a ‘Mesh Bed Leveling’ which probes the bed in a 3x3 grid to create a mesh surface that is used for calibration. This mesh surface causes the Z-axis motors to undulate over uneven areas while the print head remains perpendicular in the X/Y axis. During my testing, I didn’t need to run a single non-print calibration on the printer after the initial mesh bed leveling.

Prusa also offers a textured steel build platform for the MK3S+ that has a gritty surface which can give printed parts a more uniform appearance. In fact, the signature textured look of the printed parts on the MK3S+ come from this build platform.

The sample prints on the included SD card with the Prusa MK3S+ are a refreshing change from the sample parts that are typically included with low-cost 3D printers. The MK3S+ includes 16 pre-sliced parts that have been prepared for PLA with the total print time included in the file name. The sample prints vary in time from 23 minutes (a simple block with the word PRUSA on it) to almost 14 hours (a castle printed at .1mm layer height), and have all been prepared using sensible settings for the machine and highlight various features (variable layer height, multicolor printing, and fine .1mm layer resolution).

The current version of PrusaSlicer (2.3.3) includes profiles for printers by Prusa, Creality, Lulzbot, and more, and also includes a library of material profiles. In addition to these profiles, PrusaSlicer also includes multiple print setting profiles, which range from ultra-high detail at 0.05mm layer height to a draft mode which offers .3mm layers fast print speed at the expense of reduced quality.

PrusaSlicer is a feature-rich program with a simplified interface that is accessible to beginners, experts, and everyone in between. I’ve spent a lot of time in the PrusaSlicer settings, and I appreciate how much work Prusa has put into making almost every parameter of the printing process addressable without creating an overwhelming interface.

There are few prints that are better at testing out a printer than the 3DBenchy, so I used the included spool of silver Prusa PLA to print this model out using the default .2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

The Benchy boat model is designed to highlight various features of a printer (such as the ability to print steep overhangs, small features, etc.), and a quick examination of the model shows that the MK3S+ performed very well and didn’t have any of the common defects typically seen on this model.

The Prusament Galaxy Purple is a favorite color of mine due to the glitter additive in the filament. This additive creates layer lines that are evenly blended and have a textured appearance. Combining this material with the Spiral Vase mode produces parts that look almost conventionally manufactured, with layer lines that are difficult to see. This model printed in just over 3 hours in Spiral Vase mode, as opposed to over 13 hours if it had been printed using conventional settings.

PETG is a material that offers increased mechanical toughness, heat resistance, and flexibility when compared with parts printed with PLA. Prusa has taken advantage of these material properties by printing many of the components on the MK3S+ with PETG, which creates a rigid part that is able to withstand mechanical stress. PETG is also notoriously difficult to print with due to the high level of stringing that can occur when printing multiple parts simultaneously, but I didn’t have any issues when printing with the Prusament PETG material on the MK3S+.

I used the default settings in PrusaSlicer to print the clamp model provided by Prusa that was designed specifically for PETG. This model features a functional thread, a flexible ball-and-socket joint, and can be tensioned without snapping the body of the clamp. The part printed in multiple pieces without stringing, and I was able to easily assemble it and verify functionality without damaging the clamp. If printed in a more brittle material (like PLA), I would expect the clamp to crack at a transition point on the body, but the PETG was able to hold tension without deforming or breaking.

PrusaPrinters (the online file repository created and maintained by Prusa) offers the unique ability to share 3D printable files that have been pre-sliced and prepared for the MK3S+ with detailed print statistics available from the site. A perfect example of this is the Bag Clip by Andrei; a cam-driven bag clip that highlights the type of design freedom offered by a 3D printer.

At a price-point of $999 for an assembled printer (or $749 for a kit), the Prusa MK3S+ is a machine that doesn’t compromise on user experience and is absolutely one of the best 3D printers currently on the market. The MK3S+ has a professional and neat appearance, but the 8-bit monochrome LCD user interface might be a challenge for some users to get past, given the steep price. Interface aside, the prosumer features of the MK3S+ make it a stand-out machine for anyone who is looking for a reliable machine to produce functional parts without worrying about spending a lot of time tinkering.

If you are looking for a less expensive machine outside of the Prusa ecosystem, the Elegoo Neptune 2 (currently on Amazon for $180) offers similar printing size and features (with the notable exception of automatic bed leveling) at a fraction of the price but without the same level of robust support and documentation provided by the MK3S+ or any of the name-brand components like the E3D hotend. If you want the Prusa experience but are looking to spend a little less money, the Prusa Mini+ (available from Prusa for $399 assembled, $349 for a kit) is an excellent place to start.

The Prusa i3 MK2 is an excellent 3D printer for people who want to start with 3D printing. It is most suited towards beginners as it is very user-friendly, but at the same time offers some advanced features as well. All in all, the Prusa i3 MK2 is an excellent choice for anyone looking to get into 3D printing. Yes, it has a higher upfront cost than some other 3D printers, but the time it will save you during setup and before printing is incalculable. Plus, with such a vast array of supported materials, you have unlimited potential for growth.

Today, we’re going to review a 3D printer that’s often imitated yet never surpassed. We’re talking, of course, about the Prusa i3 MK2. Now, before we begin, you should be aware that Prusa’s website is the only legitimate vendor of this product so don’t buy it from any other marketplace.

Simply, the i3 MK2 takes the hassle out of setting up a print. It comes with a heated bed and cold corner compensation, but what does this mean? Basically, filament tends to stick to cold surfaces and this feature ensures the bed remains at a constant temperature all over. That’s not bad, but there’s more.

The Prusa i3 MK2 features a built-in LCD display and SD card, controller. An 8GB SD card is also included to get you started but if you’re a heavy user, you’ll likely want to upgrade this in the future. It also uses cutting edge modern technology to stay as quiet as possible during the printing process – usually around 50dB, which is comparable to the noise from moderate rainfall.

We’ve all seen them: instructions that look like they’ve been translated into Chinese and back. They’re almost useless and unfortunately, all too common. In contrast, Prusa provides a thick instruction booklet with illustrated, concise directions on how to set up and configure your new 3D printer.

All in all, the Prusa i3 MK2 is an excellent choice for anyone looking to get into 3D printing. Yes, it has a higher upfront cost than some other 3D printers, but the time it will save you during setup and before printing is incalculable. Plus, with such a vast array of supported materials, you have unlimited potential for growth.

Although there are tons of 3D printer manufacturers, Prusa remains one of the best-known 3D printing businesses. And its 3D printers are hands-down among the top 3D printers on the planet. When comparing filament-based, or FDM printers, the Prusa i3 MK3S and Prusa Mini both offer similar features with some notable differences. Wondering which 3D printer is best for you? Compare the Prusa Mini+ vs. Prusa i3 MK3S!

The Prusa i3 fused deposition modeling (FDM), or filament printer, was developed by the Czech-based company Prusa Research. It"s an open-source printer that was engineered by Josef Prusa and began with the Prusa Mendal. The third model Josef Prusa developed was the i3 model which became a popular and lasting design. Since then, the Prusa i3 line has undergone a few different iterations including the Prusa i3 MK2 in 2016, i3 MK3 in 2017, and i3 MK3S in 2019. But Prusa Research didn"t stop at the i3. Rather, Prusa developed the Prusa Mini FDM printer as well as its Prusa SL1 SLA printer.

The Original Prusa i3 MK3S follows up the incredibly popular Prusa i3 MK2 3D printer. You"ll find a number of different features such as a revamped extruder, tons of onboard sensors, plus a premium magnetic MK52 heatbed with a replaceable PEI spring steel print sheet. New for the i3 MK3S is a filament sensor that utilizes an optical sensor triggered by a basic mechanical lever. It"s virtually immune to mechanical wear and tear. Additionally, you"ll find an overhauled extruder. As such, swapping the PTFE tube or nozzle is simple. Furthermore, the extruder motor and nozzle are closer to the X-axis therefore reducing resonance while improving print quality.

A high-quality aluminum extension on the Y-axis lends additional stability to the frame. 10mm of Z height has been added for a total of 210mm. The MK3S sports a Trinamic2130 driver and Noctua fan which combine for fast yet ultra-silent printing. A nifty feature is its power panic capability which can resume printing in the event of a power outage. There"s a large 25 x 21 x 21 cm or 9.84 x 8.3 x 8.3 in bed, and automatic mesh leveling. The Prusa i3 MK3S supports a wide array of printed materials including PLA, ABS, PET, HIPS, flex PP, ninjaflex, laywood, laybrick, nylon, bamboofill, bronzefill, ASA, T-Glass, carbon-fibers enhanced filaments, and polycarbonates.

You can pick up the Prusa i3 MK3S as a do-it-yourself 3D printer kit, or as a pre-built unit. The included instructions for the DIY Prusa kit are clear and easy to follow. Putting the entire MK3S together shouldn"t take more than an hour, even for beginners. But whether you"re just starting out and intimidated by building a 3D printer yourself or just want to save a bit of time, there"s an already completed i3 MK3S available.

Of course, opting for the build-your-own printer will save you quite a bit of cash. The Prusa i3 MK3S clocks in at $750 USD for the self-assembly kit, versus $1,000 for the fully assembled and tested Prusa printer. That"s a hefty savings, although the time and troubleshooting you"ll save by skipping set up makes the pre-built totally worth it.

As its name suggests, the Original Prusa Mini+ is a shrunk-down version of the MK3S. Despite its small stature, the Prusa Mini manages to pack in a hefty feature set as well as deliver stellar quality. Although the Prusa Mini is smaller than its MK3S older sibling, the build volume clocks in at a respectable 7 x 7 x 7 inches, or 18 x 18 x 18 CM. It"s somewhat limiting for larger prints, but still more than capable of tackling small, medium, and moderately-sized print jobs. There"s sensorless homing and automatic mesh bed calibration. And while it may be tiny, the Prusa Mini touts excellent customization options. Its nozzle is fully-replaceable. Onboard network connectivity allows for Octoprint support, and there"s USB printing for a hardwired connection. While an Ethernet RJ45 port is standard, you can add an optional ESP Wi-Fi module.

Using the built-in 2.8-inch 240x320 LCD screen, you can preview prints, stop and start prints, and change the settings. The magnetic heatbed complete with removable spring steel sheets makes finished print removal a breeze. Its 32-bit Buddy motherboard and Trinamic 2209 drivers are incredibly capable, even up to the task of print farm management. What"s more, you"ll find a geared extruder which makes for a decreased extruder weight. Originally, Prusa offered the Mini which received an upgrade to the Mini+ that included a SuperPINDA replacement for the M.I.N.D.A. The SuperPINDA offers temperature-independence and a high-quality sensor all while not requiring a thermistor.

Like the Prusa i3 MK3S which is available as a completely assembled printer ready to use out-of-the-box or a DIY 3D printer kit, the Prusa Mini+ may be had as a pre-assembled kit or a DIY option. The pre-built unit isn"t totally put together, but requires a simplified 3-piece assembly which is easier than cobbling the printer together from the ground up. It"s $350 for the Prusa Mini+ kit and $400 for the pre-built version.

There are a few main differences in the Prusa i3 MK3S and Prusa Mini. Most obviously, the printers are physically distinct. The Prusa Mini comes in a compact form factor with a 38×38×33 cm (15×15×13 in) stance and a 18 x 18 x 18 cm (7 x 7 x 7 in) build volume. Compare that to the Original i3 MK3S and its 25 x 21 x 21 cm (9.84 x 8.3 x 8.3 in) build volume and 55 × 40 × 50 cm (21.6 x 15.7 x 19.6 in) dimensions.

Aside from size, price differs. The Prusa Mini slides in at a cool $350 USD. Even springing for both steel sheets, the smooth PEI version and textured powder-coated sheet as well as the optional filament sensor, you"re looking at $400. You can effectively get two Prusa Mini printers for the cost of one Prusa i3 MK3S DIY kit. The Original Prusa i3 MK3S retails for $750, or $789 with both steel sheets.

Unlike the i3 MK3S, the Mini only comes as a do-it-yourself 3D printer kit. On the other hand, the MK3S may be had as a self-assembly or pre-built and tested unit that"s ready to use out-of-the-box. However, the i3 MK3S isn"t merely larger, pricier, and available as both a DIY kit and pre-built 3D printer. Rather, it"s compatible with more printing materials. The list of MK3S support materials includes standards like PLA, ABS, and PET as well as HIPS, Flex PP, Ninjaflex, Laywood, Laybrick, Nylon, Bamboofill, Bronzefill, ASA, T-Glase, Carbon-fibers enhanced filaments, and polycarbonates. Like its size, the Prusa Mini"s supported materials list is condensed at PLA, PETG, ASA, ABS, and Flex.

While the Prusa Mini and i3 MK3S have their fair share of unique features, both printers rock a number of similarities. Both 3D printers are easily upgradable, and feature ready-to-print settings using slicers like the PrusaSlicer, Cura, and Simplify3D. With either the Mini or i3 MK3S you"ll benefit from automatic bed leveling and a choice of removable magnetic heatbed sheets. Plus, there"s great support both first- and third-party.

The Original Prusa i3 MK3S is best for power users. Whether you"ve never touched a 3D printer before or you"ve logged weeks, months, and years printing the i3 MK3S remains a top pick. It"s easy to use, at least as 3D printers go, comes with a stellar spec sheet, and print quality is almost unrivaled. The larger print bed means the MK3S can handle pretty much any print job you throw at it. And you can easily make upgrades.

But the price tag makes the Prusa i3 MK3S tough to justify as an impulse purchase. For a minimum of $750, the MK3S is a premium printer through and through, from build quality to print quality. Its performance totally justifies its cost. Still, it"s suitable for makers planning to print regularly rather than a curious newcomer or occasional printer.

Although it"s smaller, the Prusa Mini is a versatile 3D printer. Its modest price tag makes it perfect for hardcore makers setting up a print farm, fresh hobbyists looking for a first printer or an upgrade, and everyone in between. The outright cost is fairly low at under $500. Assembly is fairly easy and painless with just a few fiddly moments, a commonality amongst all 3D printer kits. What"s more, the simplified assembly version is super easy for beginners. For those with limited space such as apartment-dwellers, the Prusa Mini offers great bang for your buck, maintaining a small footprint without sacrificing features or much of the build area.

Overall, the Prusa Mini and Prusa i3 MK3S are both superb purchases. With either printer, you"ll appreciate solid build quality, lovely print quality, and top-notch support. Additionally, a slew of premium features arrive standard on the Mini and MK3S like mesh bed leveling. Despite its smaller form factor and print bed, the Mini maintains a reasonably-sized build platform that"s not as limited as its name, the Mini, might suggest. It"s a wonderful beginner-friendly printer that"s perfect for seasoned 3D printers and 3D print farms. The main difference, aside from size and cost, is printing material. The average user will stick to common materials such as ABS and PLA, but advanced 3D printing aficionados might the wide range of i3 MK3S compatible printing materials. While the Prusa Mini and its i3 MK3S sibling are two of the best 3D printers money can buy, there are plenty of other 3D printer options on the market.

Direct from LDO drop in replacement screen for your Prusa MK2/s, MK2.5/s or MK3/s. Includes LCD screen and two long cables. This is the screen that allows for software-based dimming control on the latest MK3S firmware. Model LDO-RRLCD-A005

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey