lcd panel design pics factory

RM2CX8HJX–An employee of Samsung Electronics explains at the company"s showroom at its main factory in Asan, south of Seoul May 13, 2011. A fall in flat screen prices that has lasted more than a year has finally been arrested and demand growth is set to return as television makers prepare for new product launches ahead of a seasonal pick-up later this year, Samsung Electronics Co, the world"s No.1 LCD flat-screen maker, told Reuters. This in turn has lifted the profit outlook for the battered liquid crystal display (LCD) sector, Chang Wonkie, president of Samsung Electronics" LCD business, said at the R

Compared to Samsung, LG"s LCD factory at Paju felt like a ghost town — despite housing thousands of people on-site. Of course, the sub-zero temperatures at the time probably accounted for that. It was also doubly eerie because the LCD plant is the tallest building visible from North Korea — as it"s so close to the border — and the army base built next door to protect it probably makes it even more of a target!

While televisions of one type or other have been in Australia for over 50 years, they have gone through several changes, with flat panels the latest iteration. LCD TVs have been mainstream products for about four years, but what makes them tick? This year we were fortunate enough to have visited both the Samsung and LG plants in South Korea to get a better understanding of how an LCD TV is made, and what the future holds for the technology.

Samsung is one of the world"s largest manufacturers of LCD panels, and it claims to produce one out of every four in the world. One of Samsung"s largest facilities is in Tangjeong, 80km south of Seoul. Samsung has four different plants on this site, and this is where the joint Sony/Samsung S-LCD plant was first built — and still produces Sony panels to this day. CNET Australia visited Tangjeong recently and while we not only got a squiz at the production lines, we also met with the engineers and designers who helped make them possible.

The Tangjeong factory is a large facility south of Seoul, and produces panels for the five-year-old S-LCD collaboration between Sony and Samsung. As a result of this union, Sony owns part of the production lines on the Tangjeong site — this equates to 50 per cent of the L7-1 line, plus half of the combined L8 (1 and 2) lines. The L8-2 factory has only come online in the last month.

Samsung has begun planning its ninth plant, which will produce its Generation 11 panels (L9), and this will fit in behind the two existing factories. It will be capable of producing much larger panels than the L8 plant with 40, 62 and 72 inches possible.

We got to see one of the L7 (no relation to the LA-based band) lines in operation, after donning the fetching blue shoe covers. Unfortunately, we were unable to take photos inside the LCD factory, as apparently corporate espionage is a big problem. However, we"ll do our best to explain the long corridor with its helpful blue signs and series of LCD panels in various states of undress explaining each part of the process.

There were several different "lines" in each factory — each doing a different sized panel. Apparently it takes three days to convert one line to produce another size, so there is some redundancy built into the system to cover for any downtime.

Information on two types of flat-panel display at the Zürich Hauptbahnhof railway station: an orange LED display (top right) and a LCD screen (bottom)

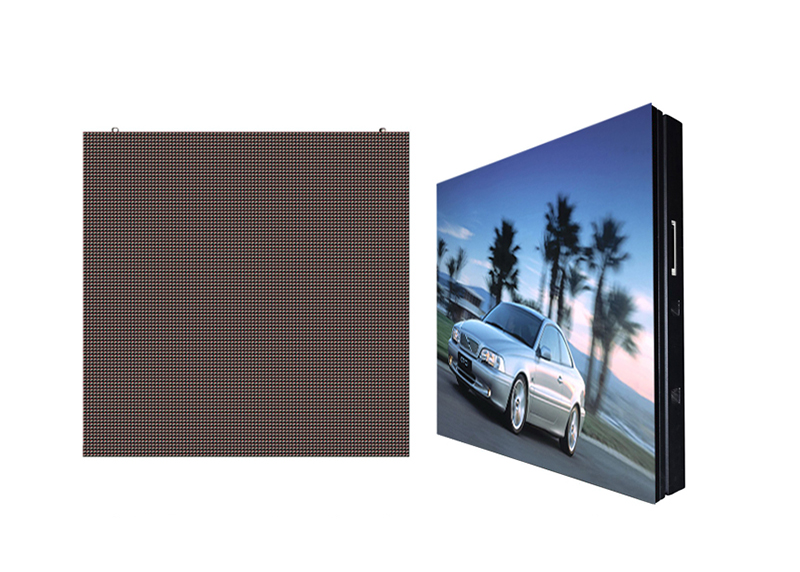

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment.

Flat-panel displays are thin, lightweight, provide better linearity and are capable of higher resolution than typical consumer-grade TVs from earlier eras. They are usually less than 10 centimetres (3.9 in) thick. While the highest resolution for consumer-grade CRT televisions was 1080i, many flat-panel displays in the 2020s are capable of 1080p and 4K resolution.

In the 2010s, portable consumer electronics such as laptops, mobile phones, and portable cameras have used flat-panel displays since they consume less power and are lightweight. As of 2016, flat-panel displays have almost completely replaced CRT displays.

Most 2010s-era flat-panel displays use LCD or light-emitting diode (LED) technologies, sometimes combined. Most LCD screens are back-lit with color filters used to display colors. In many cases, flat-panel displays are combined with touch screen technology, which allows the user to interact with the display in a natural manner. For example, modern smartphone displays often use OLED panels, with capacitive touch screens.

Flat-panel displays can be divided into two display device categories: volatile and static. The former requires that pixels be periodically electronically refreshed to retain their state (e.g. liquid-crystal displays (LCD)), and can only show an image when it has power. On the other hand, static flat-panel displays rely on materials whose color states are bistable, such as displays that make use of e-ink technology, and as such retain content even when power is removed.

The first engineering proposal for a flat-panel TV was by General Electric in 1954 as a result of its work on radar monitors. The publication of their findings gave all the basics of future flat-panel TVs and monitors. But GE did not continue with the R&D required and never built a working flat panel at that time.Aiken tube, developed in the early 1950s and produced in limited numbers in 1958. This saw some use in military systems as a heads up display and as an oscilloscope monitor, but conventional technologies overtook its development. Attempts to commercialize the system for home television use ran into continued problems and the system was never released commercially.

The Philco Predicta featured a relatively flat (for its day) cathode ray tube setup and would be the first commercially released "flat panel" upon its launch in 1958; the Predicta was a commercial failure. The plasma display panel was invented in 1964 at the University of Illinois, according to The History of Plasma Display Panels.

The MOSFET (metal-oxide-semiconductor field-effect transistor, or MOS transistor) was invented by Mohamed M. Atalla and Dawon Kahng at Bell Labs in 1959,Paul K. Weimer at RCA developed the thin-film transistor (TFT) in 1962.Bernard J. Lechner of RCA Laboratories in 1968.dynamic scattering LCD that used standard discrete MOSFETs.

The first active-matrix addressed electroluminescent display (ELD) was made using TFTs by T. Peter Brody"s Thin-Film Devices department at Westinghouse Electric Corporation in 1968.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using TFTs in 1974.

By 1982, pocket LCD TVs based on LCD technology were developed in Japan.Epson ET-10Epson Elf was the first color LCD pocket TV, released in 1984.Sharp research team led by engineer T. Nagayasu demonstrated a 14-inch full-color LCD display,electronics industry that LCD would eventually replace CRTs as the standard television display technology.high-resolution and high-quality electronic visual display devices use TFT-based active-matrix displays.

Ching W. Tang and Steven Van Slyke at Eastman Kodak built the first practical organic LED (OLED) device in 1987.Hynix produced an organic EL driver capable of lighting in 4,096 colors.Sony Qualia 005 was the first LED-backlit LCD display.Sony XEL-1, released in 2007, was the first OLED television.

Field-effect LCDs are lightweight, compact, portable, cheap, more reliable, and easier on the eyes than CRT screens. LCD screens use a thin layer of liquid crystal, a liquid that exhibits crystalline properties. It is sandwiched between two glass plates carrying transparent electrodes. Two polarizing films are placed at each side of the LCD. By generating a controlled electric field between electrodes, various segments or pixels of the liquid crystal can be activated, causing changes in their polarizing properties. These polarizing properties depend on the alignment of the liquid-crystal layer and the specific field-effect used, being either Twisted Nematic (TN), In-Plane Switching (IPS) or Vertical Alignment (VA). Color is produced by applying appropriate color filters (red, green and blue) to the individual subpixels. LCD displays are used in various electronics like watches, calculators, mobile phones, TVs, computer monitors and laptops screens etc.

Most earlier large LCD screens were back-lit using a number of CCFL (cold-cathode fluorescent lamps). However, small pocket size devices almost always used LEDs as their illumination source. With the improvement of LEDs, almost all new displays are now equipped with LED backlight technology. The image is still generated by the LCD layer.

QLED or quantum dot LED is a flat panel display technology introduced by Samsung under this trademark. Other television set manufacturers such as Sony have used the same technology to enhance the backlighting of LCD TVs already in 2013.wavelength such as blue LEDs. This type of LED TV enhances the colour gamut of LCD panels, where the image is still generated by the LCD. In the view of Samsung, quantum dot displays for large-screen TVs are expected to become more popular than the OLED displays in the coming years; Firms like Nanoco and Nanosys compete to provide the QD materials. In the meantime, Samsung Galaxy devices such as smartphones are still equipped with OLED displays manufactured by Samsung as well. Samsung explains on their website that the QLED TV they produce can determine what part of the display needs more or less contrast. Samsung also announced a partnership with Microsoft that will promote the new Samsung QLED TV.

Static flat-panel displays rely on materials whose color states are bistable. This means that the image they hold requires no energy to maintain, but instead requires energy to change. This results in a much more energy-efficient display, but with a tendency toward slow refresh rates which are undesirable in an interactive display. Bistable flat-panel displays are beginning deployment in limited applications (cholesteric liquid-crystal displays, manufactured by Magink, in outdoor advertising; electrophoretic displays in e-book reader devices from Sony and iRex; anlabels; interferometric modulator displays in a smartwatch).

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Morozumi, Shinji; Oguchi, Kouichi (12 October 1982). "Current Status of LCD-TV Development in Japan". Molecular Crystals and Liquid Crystals. 94 (1–2): 43–59. doi:10.1080/00268948308084246. ISSN 0026-8941.

Nagayasu, T.; Oketani, T.; Hirobe, T.; Kato, H.; Mizushima, S.; Take, H.; Yano, K.; Hijikigawa, M.; Washizuka, I. (October 1988). "A 14-in.-diagonal full-color a-Si TFT LCD". Conference Record of the 1988 International Display Research Conference: 56–58. doi:10.1109/DISPL.1988.11274. S2CID 20817375.

Maximize your creative output in magnificent clarity with a 4K UHD (3840 x 2160) resolution panel. With more than eight million pixels on screen – up to 300% greater density than other Full HD monitors – you never need to miss a detail again.

Maximize your creative output in magnificent clarity with a 4K UHD (3840 x 2160) resolution panel. With more than eight million pixels on screen – up to 300% greater density than other Full HD monitors – you never need to miss a detail again.

All work and no play makes Jack a dull boy. Adaptive-Sync not only maintains the smoothness of the screen but also reduces the sense of tearing when the screen rotates quickly. This is a crucial aspect of an immersive gaming experience. And if you are a gamer or game designer, this is a must-have!

While conventional speakers are large and heavy due to components such as the voice coil, cone, and magnet, the Thin Actuator Sound Solution is extremely thin and lightweight thanks to LG Display’s film-type exciter technology. The company’s unique technology allows the device to vibrate off display panels and various materials inside the car body to enable a rich, 3D immersive sound experience.

The Thin Actuator Sound Solution has received the CES® 2023 Innovation Award (‘In-Vehicle Entertainment & Safety’ category) from the Consumer Technology Association in recognition of its space efficiency, design innovation, sound experience innovation, and eco-friendliness. This CES 2023, LG Display is set to showcase the Thin Actuator Sound Solution, which was jointly developed with a global audio company.

"We have transformed the conventionally heavy and bulky speaker into a high-quality "invisible" sound solution by using our cutting-edge technology to elevate space, design, and eco-friendly factors and provide a next-level sound experience like none before." said Yeo Chun-ho, Vice President and Head of the Business Development Division at LG Display.

Unprecedented large-screen LCD panel with 8K4K resolution provides high presence conspicuous and powerful images. Only SDP achieved to develop 120”LCD panel using 10th generation substrate. Two 120-inch displays can be effectively produced from a single substrate.

Leslie is a visual artist whose works encompasses drawings, paintings, and surface design. She explores a range of themes including memory, identity, dreams, and our relationship with the natural world. Leslie studied Painting and Fiber Art at Truman State University and Textile Design at Philadelphia University.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey