lcd display schematic manufacturer

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

Interface Devises Business includes Display and Senor, Sensor, and Application Solutions. As a leading company in the global semiconductor display industry, BOE has made the Chinese display industry develop from scratch to maturity and prosperity. Now, more than one-quarter of the global display panels are made by BOE, with its UHD, flexible display, microdisplay, and other solutions broadly applied to well-known worldwide brands.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

LG Display now operates back-end assembly plants in South Korea, China, and Vietnam. In addition, LG Display operates a sales subsidiary with a global network to effectively serve overseas markets.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

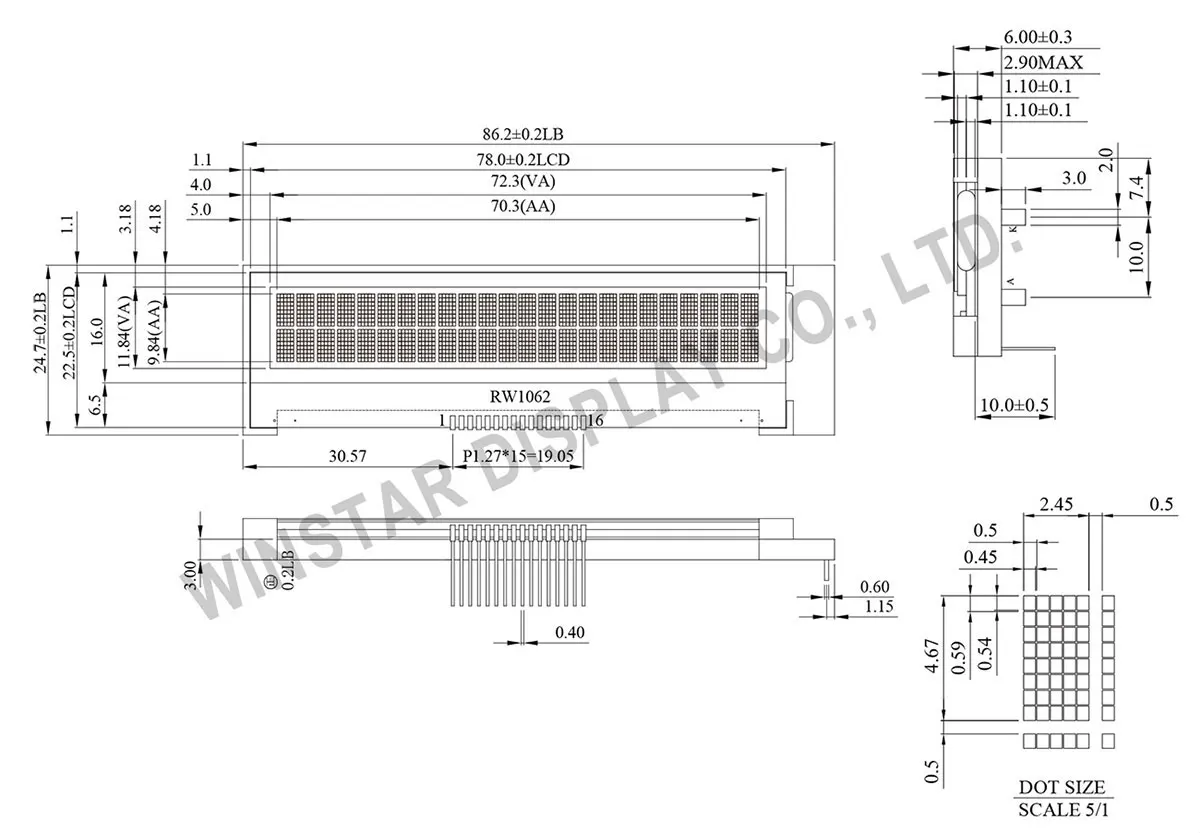

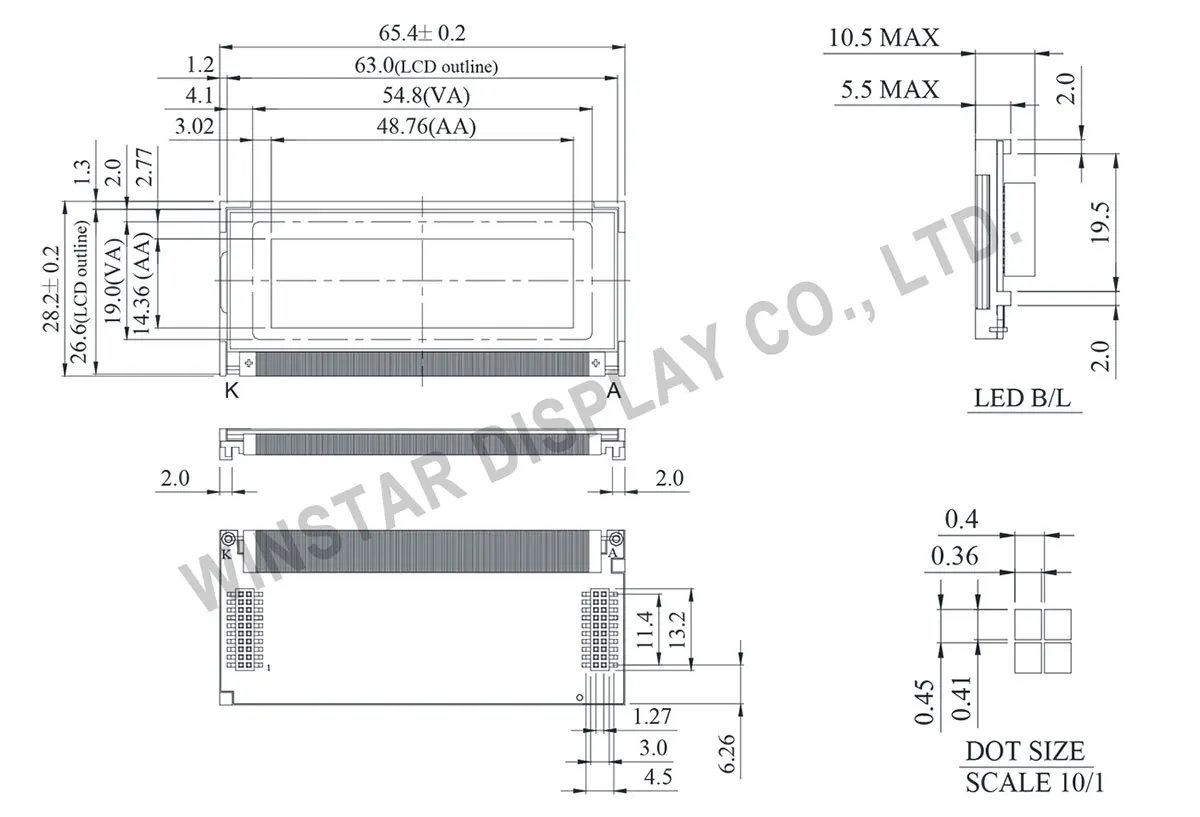

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

In addition to custom LCD displays, we provide custom PCB assemblies and turnkey solutions for products that feature a Displaytech LCD. As a display manufacturer, our engineering and production staff are experienced in handling the design and manufacturing of printed circuit board assemblies for front panels, rack mount equipment, handheld devices and many other products.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

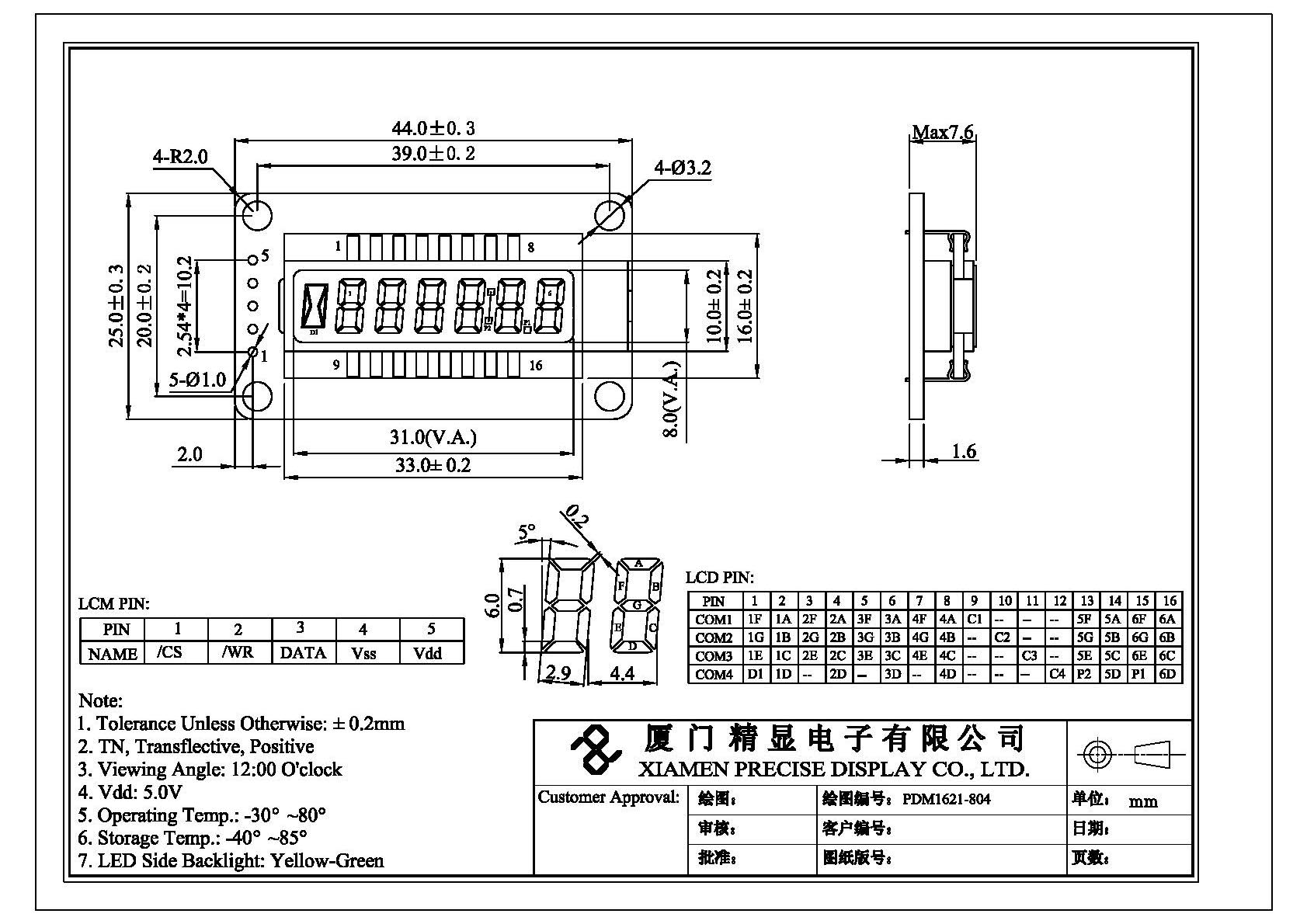

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

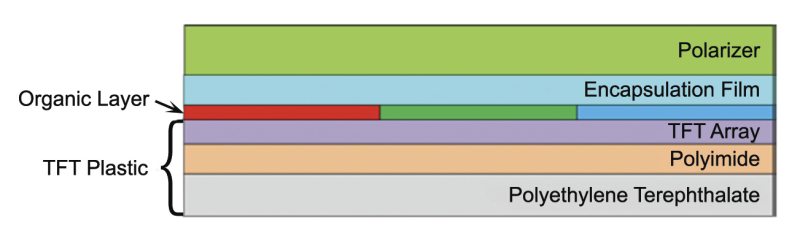

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Are you bogged down by unreliable PCB manufacturers, who are cheap but not dependable? Then stop right there! Switch to PCBMay, because we have the right options for all your LCD PCB needs.Count on our strict and safe PCB manufacturing process

We are a company that values honest communication Anytime, 24/7, you can contact us if you have questions about your circuit board. We have people on hand to answer inquiries about your LCD PCB.

Rest assured that we strictly follow international rules on environment management. We also execute professionalism by upholding IS0 9000:2015 guidelines. As a result, you are treated to comprehensive customer care and customer relationship building. We don’t just see to your LCD PCB needs, we will take care of our partnership.

For large orders, we can provide a free sample as well as a soldering sample. We want to make you feel sure that we got your LCD PCB specs precisely right.

Are you looking to manufacture LCD monitors? Then you need LCD PCBs to power and control your LCDs, because circuit boards are essential in your electronic device.

Before beginning the manufacture of LCD PCBs, you need to know a lot of facts about the LCD PCBs boards. Info about the manufacturing process, material selections, types of boards, and manufacturer are key factors you need to know.

We will discuss and answer several questions about LCD PCBs in this FAQ article. Go through the entire article to get basic facts about LCD PCB monitor PCB boards.

LCD is an abbreviation for Liquid Crystal Display. Pictures are produced when various electrical voltages are applied to a display device. A display device is an electronic display device that creates images.

The LCD is usually thought of as a collection of diodes. The pictures are produced by the diodes using small cells and ionized gasses. Aside from that, the LCD is based on the light modulation characteristic, which is a mechanism for transmitting and receiving signals via light.

So a PCB that is utilized for controlling LCD screens is referred to as the LCD PCB. LCD PCBs are made of different materials such as FR4, Polyamide, and Teflon among others.

To make an LCD PCB, you need to follow specific design procedures. There are a lot of things to consider. For starters, the LCD PCB design begins with drawing the schematic. Here is a further step-by-step design procedure of LCD PCB production.

The first step to designing an LCD PCB is to start with a schematic. First, you need to draw a schematic of your LCD PCB. You can say the schematic is your circuit’s blueprint.

The schematic will show the components you will use for your PCB. Also, it directs how you will connect the components and the relationship between the group of components.

After creating the schematic, you have to create a blank LCD PCB layout on your computer design tool. Now, import the schematic of the LCD PCB to the blank layout by schematic capture tool.

Determine the stack-up of your LCD PCB with multilayers. You can set any number for the PCB layers you want. You can use the layer stack-up manager to define and design the layers.

After finalizing the PCB layout and layers, you must print the PCB layout on the PCB board. For printing the layout of your LCD PCB, you can use 3D or laser printing. Etch the conductive traces to ensure the electric current flows to the components.

After finishing the successful printing of your LCD PCB, it is time to assemble the PCB. You can use an automated process or manually arrange and place them on your PCB board.

There are CRT monitors, which stand for Cathode Ray Tubes. The majority of its early usage came in the form of TV monitors. CRT displays employ high-energy electrons to create images on a fluorescent screen.

LED stands for Light-Emitting Diode. It is one of the latest display technologies in the market. LED monitors are kind of flat panels or slightly curved. LED panels create high contrast images with less negative impact tone.

OLED stands for Organic Light-Emitting Diode. This is another technological development in the display sector. OLED produces high-quality pictures. It is brighter, thinner, and powers a better refresh rate. AMOLED monitors are a sub-type of OLED.

The most popular of application is the LCD TV PCB board. These are used for high contrast television monitors. LCD is a cheaper alternative to plasma monitors.

When soldering the base metal of LCD PCB boards together, you may find that the solder does not adhere properly. When the melted solder fails to form a connection, this is referred to as a non-wetting defect of the printed circuit boards.

You may follow the following steps to fix the non-wetting defects on your LCD PCBs:Take proper action to prevent oxidation. Oxidation is one of the biggest causes of non-wetting defects.

Polyamide, commonly known as polyimide, is a PCB board material used to fabricate flexible printed circuit boards. Polyamide is made from a variety of materials, including silk and wool. It is widely utilized in the mass fabrication of LCD PCBs.

The following are some significant advantages that polyamide has:The most common reason to use polyamide is its suberb flexibility. It is mainly used to produce flexible, rigid-flex LCD PCBs.

The LCD controller board is the board that regulates the LCD’s functions. The controller board creates video signals and connects them to various video sources. Then the board creates the visibility of the videos on the LCD when they are connected.

The following are some excellent features of LCD controller boards:The LCD controller boards are capable of displaying images in ultra-high resolution. The resolution may be as high as 3840 x 2160 pixels per point.

Impedance in LCD PCBs measures opposition to electrical flow, which is something measured in ohms. This measurement is vital for the operation of the circuits in high frequency.

The PCB layer stack-up is the process of placing the copper layers and insulating layers one on top of the other. This facilitates you to design and implement many conductive layers of the LCD PCBs in a single PCB.

Testing is among the most essential steps in manufacturing PCBs. Employ proper testing to ensure the required design facts for your LCD PCBs. The following are the most robust testing methods you can use for testing LCD PCBs.

In AOI, you have to use two 3D or one 2D camera to take photos of every board detail. Then, you need to compare the photos to the schematic of the LCD PCB. The PCB is okay if the comparison verifies that the board and the schematic are the same.

You cannot expect that your LCD PCB will last forever. But, that does not mean you cannot extend the lifespan of your PCBs. If you follow the following tips, you can extend the life cycle of your PCB significantly.

Temperature is a vital fact in electronics. High heat or excessive heat can harm your LCD PCBs in many ways. You need to monitor your LCD PCBs’ temperature else, the following harm can occur to your PCB:

Finding a reliable manufacturer for LCD PCBs is crucial. A highly skilled and experienced manufacturer can provide you with the best quality products. To find out the best PCB manufacturer, you should check the following criteria:The manufacturer should have intensive experience in the PCB industry.

As An LCD PCB enthusiast, you need proper knowledge about this type of PCB. We hope that this guide reconciled you with the type of information you need. Already, you might sense that a highly experienced manufacturer can help you produce high-quality PCBs for your business.

You may choose us, PCBMay, as your PCB manufacturer. We are a highly professional LCD PCB manufacturer in China. We have been successfully manufacturing all sorts of high-end PCBs for an extended period. You can contact us today to get the best quote for your LCD PCBs.

PCBMay is your authentic and original Display PCB manufacturer and supplier from China. We have quality Display PCBs that can fully support your requirements. Upgrade your PCB business by partnering with us!

Our Display Printed Circuit Board is made initially by our in-house professional team. We have reliable and professional Display PCB technicians who merit your trust. We also have several hundred excellent support teams with a lot of experience in manufacturing PCB products.

PCBMay has a group of certified engineers for making Display Printed Circuit Boards. We supply different kinds of Display PCB according to customers and clients’ applications. At PCBMay, you can be assured that all of our PCB products are perfect.

Furthermore, PCBMay’s support services cooperate with you to produce the best quality PCB. We will provide a wide range of Display circuit boards upon your request. We can make any color, shape and sizes according to your wishes.

PCBMay’s Display PCB guarantees the quality of raw materials. We only make Display PCBs from unique and original elements. We can help you provide fully functional Display PCB with no defects. PCBMay is continuously improving the quality of each product to suit your application.

PCBMay is happy to help you customize the best Display board you need. We can customize your ideal Display PCB uniquely for you. Provide us a sample to quote and copy or let us know your main idea. We can give you a tailor-fit solution.

Are you are looking for the best Display PCB? PCBMay is your best choice. Besides Display circuit boards, We also offer all other types of PCBs. We are always here to provide for your Display PCB demands.

A Display PCB improves the overall performance of electronic device displays. This product is a leading solution used in the digital era. Its tremendous functionality makes it a dependable circuit for numerous display technologies.

PCBMay manufacturers display PCBs reliably. In this FAQ article, we will inform you of the ins and outs of this type of PCB. We hope you will achieve expert knowledge of PCB manufacturing through this guide. Let’s make a move.

A Display PCB is a highly functional circuit board used in electronic displays. It controls different features of display modules like brightness, pixel rate, response time, etc. A Display PCB should have effective thermal performance and signal transmission to ensure great display quality.

Display circuit boards are compatible with LED, LCD, and OLED displays. These LED items are composed of useful materials that promote the reliability of display circuits. Their designs are effective in facilitating low noise in signal transmission.

There are a lot of varieties of Display PCBs. We can categorize them according to size, colors, shapes, etc. But the most significant types of these circuit boards are:Graphic card display PCB

Also, there are numerous Display circuit board types based on applications. Examples of these are Metal Detector Display PCBs, Audio Power Amplifier Display circuit board, Refrigerator Display PCB, and etc. All of these types are widely bought and sold for use in electronic projects.

LED display PCBs operate by applying LED (Light-Emitting Diode) technology. In this case, Surface Mount Technology (SMT) is used when placing a LED display on the PCB surface. Then, components are mounted on the other side of the circuit board.

LED transmits light to the display. The PCB controls different features like colour contrast, brightness, pixel rate, response time, etc. LED technology is highly efficient for saving electrical energy.

LED display circuit boards control the functionality of three types of backlight configurations of LED TV. These functionalities are: direct-lit, full array, and edge-lit. Different LED mechanisms are applicable in numerous display circuit boards. For example:QLED (Quantum Dot LED)

LED display PCB boards enrich your experience while viewing different contents on display devices. The effective operating principle is to promote display quality without causing damage to your vision. Watch this video to know about LED display PCB making:

Display PCBs are dependable used inside numerous display devices. These devices encompass smartphones, laptops, and gaming devices, among others. Major benefits for using the Display PCB are:

Ease of processing and maintenance are significantly better compared to other types of circuit boards. The Display PCB is highly durable and that’s why you don’t need to replace or repair it frequently. If needed, replacement is not so complicated.

Display PCBs show impressive performance in noise reduction. The design inhibits EMI effects. So, this type of circuit board can provide outstanding signal quality while displaying video content on monitors.

Display circuit boards are supremely reliable due to their long-lasting consistent performance. Its operating life is long enough to fulfill the consumer’s demand. Besides, it remains functional in high temperatures. So, its practical usage is beyond question.

The Display PCB provides considerable functionality in high-speed signal transmission systems. This product optimizes the pixel rate, aspect ratio, and brightness of the device display. That’s why the Display PCB has become the widest circuit board in the present time.

Display PCBs are constructed by using high functioning materials. Usually, it is assembled utilizing FR4, Aluminum, FPC, and high TG materials. These materials are useful in maintaining the essential electrical and thermal properties of the PCB.

These aforementioned dielectric materials ensure proper insulation in the circuit board. That’s why the Display PCB can handle heavier current loads without overheating.

PCBMay supplies Display circuit boards of superior quality. We also take care of testing and design aspects. Contact us now to enjoy cost-effective PCB display modules.

A trustworthy manufacturer can render high-quality service in the shortest possible time. You need to consider the following factors when choosing a dependable Display PCB manufacturer in China.

Display circuit board manufacturing is a little bit expensive. That is why China-made PCBs are a good option. You have to find a manufacturer that provides PCB products at a competitive rate compared to the market price. If quality assurance can be assured at a lower price, you should consider this manufacturer as a viable option.

The above factors are the major considerations before choosing your PCB supplier. PCBMay manufactures and supplies high-quality PCB-mounted display modules at affordable rates. Inquire from us immediately!

Refrigerator Display PCB connection wires have notable effects on the freezer activity. Wrong wire connections cause flickering in refrigerator displays. Misaligned connections make the circuit board and refrigerator defective while operating at high temperatures.

That’s why you should use reliable connecting wires and to establish secure connections. If these wires get damaged, replace them as soon as possible. Proper wire connection improves the activities and longevity of the refrigerator display circuit.

Seven Segment Display PCB is an electronic circuit board that acts to display decimal numbers and characters. It operates through LED technology in mostly, and LCD technology in some applications.

This type of circuit board is highly applicable in calculators, washing machines, and digital clocks, as well as other similar electronic appliances. The 7 segment display PCB design is compatible with advanced display modules. It is easy to make this circuit board.

You just need to follow some instructions to achieve a perfect 7 Segment Display PCB. Here are the required steps to make a 7 Segment Display PCB for your convenience.

Surface Mount Technology is common for placing LEDs on the circuit board. Since the display needs to be seen from a remote place, the LED opening angle should be wide. White color LEDs are the most effective kind compared to other colors.

Now, create a design layout through design software. Seven Segment Display PCB Package Proteus is reputable software for designing this PCB. You should follow the instruction manual to operate this software. Annotate the PCB components and run Proteus to detect errors of the schematic.

After completing the design and component connection, it is time to create a Gerber file. You have to click on “File>Plot” option and plot all design files. Then, send it to the Display PCB manufacturer so that they know about your design requirements.

Dot Matrix LCD Display PCB is a satisfactory option to use with graphic and text displays. This type of PCB operates through LCD or OLED technology. The PCB transfers signals, arranging the pixels in specific rows and columns.

With this PCB, the graphic displays are compatible with both built-in or non-built-in character sets. But the text displays contain integrated character sets. This circuit board supports SMT (Surface Mount Technology) during assembly.

You only need to connect a few connecting wires for the Dot Matrix LCD Circuit. Its design and processing are very effective for display modules. Watch this video about the working principle of dot matrix display:

LED and QLED technologies are suitable for display devices. When you are dealing with a display PCB, both of these have some positive points. Such as:LED-based displays offer a higher contrast ratio than QLED.

LED display circuits have Rigid-flex features. So LED displays are compatible with different device shapes and sizes. But, QLED technology is not supportive of both rigid and flexible applications simultaneously.

Display Aspect Ratio (DAR) indicates the proportion of the display width and height. This is a vital factor for displays used in computers, mobiles, and so on. Display PCB is an impressive product in terms of this feature.

Display devices require a fixed aspect ratio. Otherwise, signals get distorted. Display PCBs control the signal transmission rate to maintain a consistent aspect ratio for different displays.

For instance, the ideal aspect ratio of an LED TV is 16:9. LED display circuit boards to regulate the operation of drivers to ensure a fixed aspect ratio. That’s why the Display PCB provides outstanding display in several applications.

Yes, Display PCBs have Rigid-flex features. Rigid-flex PCBs are inside components of smartphones, laptops, and home appliances. Rigid-flex PCBs renders a firm, inelastic quality to display modules.

Materials like FR4 and composite epoxy are used in constructing display circuits. FR4 and similar materials can handle high thermal pressures and external forces the devices need to stand up to.

However, you can also use the Rigid-flex PCBs in bendable displays which don’t contain flat surfaces. That’s why these PCBs are compatible with both robust and flexible display designs. Moreover, display boards having rigid-flex features require minimum fuss. You can easily handle such reliable circuit boards in your electronic projects.

LCD (Liquid Crystal Display) and AMOLED (Active Matrix Organic Light Emitting Diode) are two reliable display technologies. These are mostly used in mobile displays. There are some distinguishable properties between the circuit boards used in these two display mechanisms.

AMOLED PCB enables the display to deliver realistic colours. These circuit boards also superbly control the aspect ratio and contrast. The AMOLED PCB allows displays to be dark.

In contrast, LCD circuit boards are capable of displaying true life colours. They can’t achieve a completely black display. LCD makes it easier to enjoy viewing in bright conditions.

AMOLED displays are more energy-efficient than LCD boards in a way. AMOLED displays can separate light pixels. That’s why AMOLED can achieve standard energy efficiency in most mobile displays.

LCD circuits provide a higher viewing angle in electronic display appliances. Its highest angle of view is around 180⁰. But, AMOLED can’t deliver such a wide-angle of view.

AMOLED displays are more expensive compared to LCD circuit boards. The manufacturing process is easier in the case of LCD PCBs since LCD technology was established first.

AMOLED displays contain flexible, stretchable, and adaptable features. In contrast to this, LCD technology does not support Flex Display PCB, for example, LCD is not used in foldable smartphones.

USB LCD display PCBs have some useful features. These features make the use of LCD-based devices attractive. Notable among these:Compatibility with lead-free technology.

Quality control is a vital factor for optimum display PCB manufacturing. You can maintain the top quality of this circuit board by following some measures. Here we show you the factors related to the quality maintenance of display modules. Let’s have a look.

You need to use durable and excellent components to construct display circuits. Otherwise, it is difficult to maintain higher standards of display in electronic appliances. You must check different features like current ratings, power dissipation, and thermal conduction capabilities before choosing PCB components.

This is another crucial factor in controlling standard display quality. Effective dielectric materials promote the functionality and operating time of display circuits.

This is another major part of PCB quality control. You can conduct manual and automated tests to detect faults. The following tests are reliable for display PCB performance checking.Flying probe test

It is important to perform preventive maintenance for display devices. You need to proactively check for temperature changes, moisture, contamination, and etc. while handling Display PCBs.

Temperature affects PCB performance in various ways. You should control the operating temperature of the Display PCB to achieve maximum output. Improper temperature change is harmful in the maintenance of thermal, electrical, and mechanical properties of PCB materials.

That’s why you need to consider changes in temperature during the design phase. Frequent and unplanned change of thermal states creates serious complications in signal transmission systems of display circuits. Such as:Improper temperature rise increases current conduction through the circuit board. It causes overheating that significantly reduces the operating life of display modules.

Excessive heat makes the high-frequency signals vulnerable to electromagnetic interference. Signal quality falls when there is such an interference, then the display will be affected functionally.

LED display PCBs can suffer from some technical problems. When this happens, you need to repair the PCB. If the damage goes beyond repair, you should replace them to maintain the integrity of the device.

To repair a LED display circuit board, you have to first determine its problem. A short circuit is a common issue. You need to detect resistance, voltage, and circuit connections through a multimeter.

After that, restore the through-holes of the Display circuit board. The remaining task is to place a new component in place, then and solder properly. If you face any difficulty, contact a skilled technician to deal with this issue.

This FAQ guide tried to cover every aspect of Display PCBs. Modern display technologies are based on this PCB. That’s why the proper assembly of this piece impacts the overall performance of digital merchandise.

PCBMay is the most trustworthy display PCB manufacturer in China. We supply high-quality Display PCBs for advanced electronic projects. Contact us to enjoy the PCBMay difference.

NHD-12864WG-BTGH-T#N | Monochrome Graphic Module | 128x64 Pixels | Transflective LCD | Side White Backlight | STN (+) Positive Gray Display | Built-in Temperature Compensation Circuit | Negative Voltage

Newhaven 128x64 graphic Liquid Crystal Display module shows blue pixels on a gray background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-12864WG-BTGH-T#N display has a built-in temperature compensation circuit and negative voltage. It has an optimal view of 6:00, operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

GuaranteeThe Sunny Health & Fitness Treadmill features 9 built-in workout programs, handrail controls, and phone/table holder that will add comfort and accessibility during any workout routine. This well designed treadmill features an easy folding mechanism and soft drop system. The soft drop system will assist you when opening the treadmill, avoiding a big slam or damage to your wood/carpet floor. It features an LCD screen that tracks your speed, time, distance, pulse and calories which makes it easier to track your fitness goals. The Sunny Health & Fitness Treadmill is expertly designed for maximum performance, optimal comfort and ultimate efficiency, with a maximum user weight capacity of 220 lb.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey