is lcd screen repairable made in china

Mandy, ETS is obviously a company that you are connected to and this could easily be taken for spam. I think we can make an exception at this time since you are asking a good market research question that may be useful to many.

Having checked out your video, I personally will not use the aftermarket screen as a replacement for my X. It just doesn"t have what I expect for a $1000 USD phone. I recognize that $300 USD for a replacement is hefty but the aftermarket screen does not appear to have the quality that I would expect for my phone.

Alibaba.com offers 91,318 lcd screen repair products. such as machinery repair shops, manufacturing plant, and retail. You can also choose from 1 year, 6 months, and 2 years. As well as from provided. And whether lcd screen repair is gray, white, or black.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

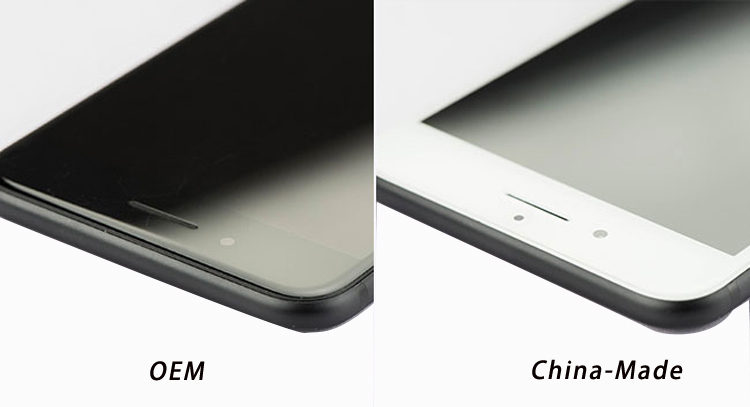

Since the iPhone 7/7 Plus has been released for quite a long time, finally the China made iPhone 7/7 Plus screen replacementscame out in the market. we’ve got some iPhone 7 series LCD screen replacements samples and done some tests on them, now let’s take a closer look at these new iPhone 7 series LCD screen replacements!(TianmaandLGsources for testing)

After installing all the sample screens to the iPhone 7/7 Plus rear housing assembly, we found that all the China made iPhone 7 series screen replacements are fitting well just like the original ones - the home button fits well, the screen assembly and the rear housing also fits well.

From the picture below, we can see that there is no difference between the China made iPhone 7 series display and the original ones, however, back to the rear side, we can easily figure out which one is which, cause the original one has Apple logo on it while the China made screen has none.

By comparing these two iPhone 7 screens, we can find that the screen flex cables are much different, there are extra IC on the China-Made iPhone 7 screen while the original one has none. And the original iPhone 7 series screen flex cable is integrated together while on the China-Made iPhone 7 series screen the touch function flex cable is soldered to the display and 3D touch flex cable.

Another difference between the original and China made iPhone 7 screen replacements is the exposed IC on the after-market iPhone screen, just like other China-Made iPhone 5 or 6 series screen replacement, which has more potential risk of electrostatic damage and more likely to get damaged and this problem needs to be improved.

During our test, we found that the display color between our after-market iPhone 7 screen and original screen seems a little different although they are not effecting the touch function. And to be honest, there may have some black dots on the screen because of impurities within the screen module when laminating the LCD and backlight together, without any doubt, this can be solved with technical improvement.

The screen touch sensitivity is another big concern for all of us, luckily, during our test, almost all home button and touch functionality on both iPhone 7 and 7 Plus works well, except one piece of iPhone 7, the 3D touch function is not acting so well on the central part of the screen.

The China-Made iPhone 7 series LCD screen assembly replacement still remains to be improved in quality and performance compared to the original ones, the exposed IC, heavier screen flex cable ribbon, and the screen color difference, the touch function stability, although the price is attractive. However, the China made iPhone 7 series screen replacement is under the improvement, and sooner or later their quality and performance can be quite close to original ones and acceptable, if you"re going to stock up some non-original iPhone 7 series LCD screen replacement, pay more attention and we’ll keep you updated with further information about after-market iPhone 7 series screen replacement!

With the lack stock of the original iPhone 5 & 6 series LCD screen, the China made LCD screens becomes more and more popular among the repair shops. As the originaliPhone 6 Plus LCD screenprices are still high and not likely to fall down, plus more and more repair shops are tending to accept the China made LCD screens replacement instead, therefore, China made iPhone 6 Plus LCD screen appeared on the market naturally.

Recently we have got some samples of the China Made 6 Plus LCD screen, which have been called ‘LG 1:1 version’ on the market. We did some tests with these samples and found some differences compared to other China made LCD screens.

After tests, we found some differences in LCD frame height, glass screen thickness and the home button location among these 5 samples. You may wonder why these differences exist while they are sourcing from the same manufacturer?

Thus we need to learn the production process of the China made LCD screens, which was assembled by the 3rd party manufacturers, who purchased the China made LCD,LCD frame,glass lens,metal shields, screen foam and digitizer from different manufacturers, which could be original or high copied ones. Since there are some differences among theseglass lenses, LCD frames and so on, even though they shared the same LCD, there will still be some difference.

There is no doubt that significant differences existed between these 2 kinds of LCDs whether in display effect or working stability. In pursuit of greater profits, there is no strict requirements and standards for China made LCDs production process as long as the LCDs can achieve the basic using requirements. Therefore there is quite a gap in color difference, viewing angle and working stability compared to original ones, as the LCDs which are designed for the other brand cellphones, after replacing the IC and flex cable, have been inspected strictly before flowing to the market. (Such as the Samsung GalaxyS3 LCD screen assemblywhich are transformed from the GiONEE phones. Due to the few original stock in availability, most of the S3 LCD screen assemblies are produced by Samsung through transforming GiONEE LCDs.

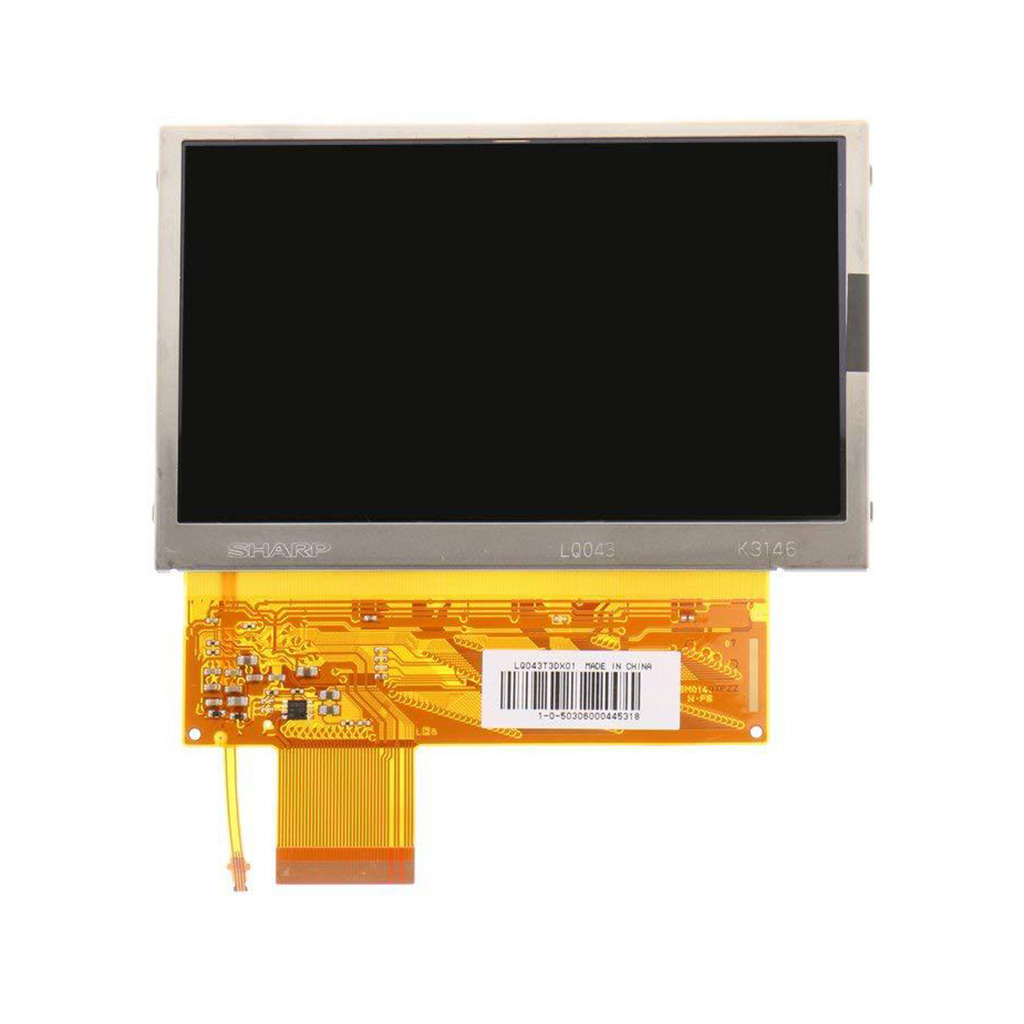

It is said that these China made iPhone 6 Plus LCD screens are transformed from the MeiZu Meilan Note LCDs (Also features 5.5 inches) which are produced by Sharp and AUO, the overall performances of these LCD screens are better than LT/TM/JDF’s. And what’s big different from the other LCD screens is that there is one more LCD drive IC on the screen flex cable.

Because of the big production MOQ and long R & D cycle, the customized China made LCD screens had some difficulties intechnologyimprovementwith the changes of the marketing demands, while the original LCD features higher quality and reliability.

For these China made iPhone 6 Plus LCD screens, theLCD frametending to pop off and LCD screens are thicker. But in display effects, China made iPhone 6 plus LCD screens are better than5 series. Those customers who cared more about the prices will have one more choice once the improvements of the China made iPhone 6 Plus have been implemented. And we also will continue to focus on the China made iPhone 6 Plus LCD screen assembly.

China, we’re told, can make anything. If you need some PCBs in a few weeks, there are a few factories in China that will do it. If you need a nuclear reactor, yep, there’s probably a factory in China that’ll do it because nuclear reactors are listed as one of the items facing new tariffs when imported into the United States. No, I am not kidding. What about LCDs? What about old-school character LCDs? Is it possible to find a factory in China that will make you the LCD you want? That’s what [Robert Baruch] will find out, because he’s repairing an old computer with new parts.

The object of this repair and restomod is a TRS-80 Pocket Computer (PC-1), otherwise known as the Sharp PC-1211. It looks like a calculator, but no, it’s a legitimate computer you can program in BASIC. [Robert] bought this computer for a bit more than $5 on eBay ‘for repair’, which means the zinc-air battery was dead, and unfortunately, the LCD was shot. The LCD technically works, but it just doesn’t look good. Sometime in the last thirty years, moisture got in between the layers of glass, polarizing film, and liquid crystal. This is not unique to [Robert]’s unit — a lot of these PC-1s have the same problem, many of these broken seals rendering the computers themselves useless.

This is an ancient computer, and replacements for this LCD are impossible to find, but because the Sharp PC-1211 is well documented, it is possible to find the datasheet for the original display. With that, it’s just a question of finding an LCD manufacturer that will do it. So far, the costs look good — $800 USD ($300 for tooling and 10 samples, $500 for another 200 LCDs) is what it’ll take to get a few units. [Robert] already has a few people interested in repairing their own Pocket Computers. You can follow the eevblog thread here, or check out the video below.

The rumor that the China made iPhone LCDs can’t survive the upcoming iOS updates existed for quite a long time which aroused panic among repair shops. Many repair shops who want to use/have already used these screens to compete with authorized repair are wondering, will Apple brick these iPhone to kill the third party repair? We ETrade Supply don’t think so and here is why:

Do you still remember that users sued Apple for bricked iPhone due to "error 53"? The situation is almost the same except only few people have let their home button be replaced by third party repair shops. How many China made iPhone LCDs have been sold? We don’t have the exact number. However, from what we know, the number should be over 1 million pieces at least. Will Apple brick millions of iPhones just to kill third party repairs?

Same rumors for the 4/4S screen before. The OEM LCDs for 4/4s died out for quite a long time, all screens supplied were China copy one since 2 years ago. Not a case of bricked phone/unusable have showed for the updating to the new iOS system.

The most possible reason that this rumor has been created—is just to cut the price of the China copy iPhone LCD and more possibly-- the demand for it.

A week before the Apple event in March 2016, the rumor was “China made iPhone LCDs can’t survive in the coming iOS 9.3 updates”, the price of these LCDs dropped significantly and everyone was holding their orders, waiting to see the result. Within one week, the price has dropped around $10/pc. After people found out that they did survive, the price increased again and here came the rumor “the China made iPhone LCDs won’t survive the iOS 10 updates”.

Since last June, more and more repair shops have accepted the China made iPhone LCDs because less OEM screens are supplied. A large certain amount of demand of OEM iPhone screens has been moved the China made ones. The rumor that “the China made iPhone LCDs won’t survive the newest iOS updates” will sure bring some demand back to those crappy OEM screen which have been used for quite a long time/ refurbished for multiple times.

The rumor is “ALL the China made iPhone LCDs won’t survive the iOS 10 updates”, not only for 5 series. As we all know, there are already China Made 6 screens in the market. Those who stocked large amount OEM 6 screens will be happy to see people still paying high price for the OEM 6 screens for quite a long time.

The supply chain of cell phone replacement parts is sophisticated, unclear and without any standards, which make it look more like gambling. Find a reliable long-term relationship partner who can grow with you is the key to success for repair shops. If you have any questions regarding the China made LCDs, please leave your comment below!

All the test procedures were analyzed in detail with opinions proposed. Now, let’s take a close look to the first China madeiPhone 7 Plus LCD Screen sample with professional testing report below.

To analyze inside layers of the iPhone screen, we tear it down layer by layer .The sample China made screen applies G + G layer structure, there is a glass base touch layer,

The quality and performance is quite close to OEM and acceptable, and sure it will come with impressive lower price offer. The display panel is China made with G + G layer structure, and the screen is assembled with a third-party driver IC solution.

Unfortunately, in most cases, you cannot fix a broken TV screen. TV manufacturers do not sell screen replacements, and there is no secondary market for used screens. That’s because the screen is the most expensive part of the TV, by far. Replacing it would cost more than buying a new TV!

In many cases, your local electronics or TV repair shop won’t even consider working on your broken TV screen. They know that it’s just not worth their time.

The BOE factory, where most US TV screens are made today, is almost a mile long and cost about 7 BILLION dollars to build! Sony, Samsung, LG, Vizio, etc. all buy their TV screens from BOE.

“Liquid Crystal display screens are made by putting two thin sheets of glass together. On one of the sheets transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through. That’s how you can get electrical signals to the middle of a screen.

Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts. This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen. Each step has to be precisely aligned to the previous one within a few microns. Remember, the average human hair is 40 microns in diameter.”

This is the number one reason your TV screen is so costly – they are incredibly challenging to build, and as a result there are only a few companies in the world that make them.

I’ve also heard that only 1 out of every 3 TV screens pass testing at the END of the manufacturing process. That means 2 out of every 3 screens made are worthless!

The screens are made in China and then have to be shipped across the world to be sold in the US. The cost to ship them is high, and a lot of damage can happen during the journey.

So the complexity, and shipping both contribute to the high cost of TV screens. It’s why no one sells the screen separately, it just doesn’t make financial sense.

If your TV screen has an imperfection, discoloration, lines, streaks, spots, etc., then there is a good chance that your warranty will cover it (if it’s within the allotted time period). Most TV warranties are in place for the first year, and they cover these types of manufacturer defects.

And the even better news here is thatthe majority of issues you’re likely to encounter with your TV will happen within the first year (when you’re covered by the manufacturer).

You can always try selling it. Your broken TV isn’t worth much, but to the right person, it’s worth something. Someone who knows what they are doing will take your TV apart, and sell off each individual piece.

Technically, you could do this yourself, but it’s time consuming and you risk damaging the parts. I wouldn’t bother. Instead, try listing the whole TV for sale. Getting something for a broken TV it is better than nothing.

If it turns out no one is willing to buy it, you can try listing it on those same marketplaces for free!Tons of people usually respond when they can get something for no cost, even if it’s broken.

Local electronics stores typically recycle products that they sell. A great example of this is Best Buy. They have a nationwide recycling program. But keep in mind, they will charge you a small fee!

Your town likely collects e-waste. Check out your town/cities trash website and see what their policies are for electronic waste. Some towns have special pick up days, others have drop off locations. I would just call your city’s public works department and ask for a place to recycle or dispose of old electronics.

Buy a TV screen protector. You can buy a screen that covers your TV and protects it against damage, and many are waterproof! These provide great added protection from possible bumps and contact with liquids from pets and children.

Mount your TV on the wall.This way your television is up off the ground, and out of reach. It won’t stop your kids from throwing a toy at it, but at least they can’t bump into it, or accidentally knock something, or someone into it.

Don’t allow video games. This might sound harsh (especially for the kids), but I’ve heard too many stories of Nintendo Wii controllers being accidentally thrown at the TV. If you don’t hook up a video game console to your TV, this can’t happen.

Most TV repair shops won’t even bother trying to fix a broken screen. In the end, between a screen replacement and the repair costs, you’d spend the same amount for a brand new TV!

If your TV is cracked or damage because of something you did, your warranty is unlikely to cover it. In that case, consider selling your broken TV or disposing of it.

“Original” screens are those containing LCDs manufactured for Apple. “Copy” screens are compatible replacements entirely designed and manufactured by third-party companies not associated with Apple.

LCD display panel can have poorer resolution (i.e. looks “coarser”), worse brightness, contrast and vibrancy and reduced refresh rate amongst other problems.

Changes in specification from original can result in battery and performance issues. Certain badly-engineered screens could even damage the backlight circuitry.

Customers who bring their iPhones to us for a screen repair are offered two choices of replacement- an original or a “copy” screen. The most common response is “Is there a difference- and which one would you recommend?”

Originals are those screens containing LCDs that were manufactured for Apple. So-called “copy” screens are compatible replacements, but designed and manufactured entirely independently by third-party companies, typically in China.

Our answer is simple- the original screen is the one we’d go for ourselves, every time. Some people think we make more money on them, but this isn’t the case. We recommend originals because they’re far higher quality and the price difference is fairly small.

We’d rather only fit original screens. The only reason we don’t is that many people will shop around and choose purely on price. As such, we need to offer the cheaper copy screens to remain competitive and avoid losing these customers. In some cases, they didn’t even know there was a difference in the first place- especially since it’s not in some shops’ interest to draw people’s attention to the issue!

This may well be the worst copy screen we’ve ever come across. As a result, the unfortunate customer has ended up paying twice to have their screen replaced- we’re sure that had they been properly informed, they would have chosen an original in the first place.

While the difference in price between copies and originals can vary across devices, it’s generally around £10 – £14 extra to have an original screen fitted. This really isn’t a lot considering the improved quality and reliability.

We compare our prices to our competitors- and we know that we come out of it favourably. While we have to offer copy screens to remain competitive, we always advise customers to go for the original.

When you’ve spent- directly or indirectly- several hundred pounds for an iPhone with a Retina display, it doesn’t make sense to replace it with a lower-quality screen that can make a £400 phone look like a £40 one! Not only that, but you’re likely to have fewer issues, and a longer-lasting screen.

There’s nothing stopping any random person without training or experience opening up a smartphone repair shop. As a result, the industry is full of companies with little skill or experience who are only interested in getting hold of your money and installing the cheapest parts they can find.

Many- if not most- don’t even acknowledge the existence of copy screens, let alone explain the difference to the customer. Hardly in their interest to do so if they only fit cheap, low-quality copies. Some of them can hardly be blamed- they know so little, they’re not even clear on the differences between OEM, non-OEM and copy displays themselves! Others can be more deliberately misleading… and some outright lie.

Generally, these shops are looking for the cheapest price on replacement screens.. When offered a copy at a half or a third of a price of the original, they’re going to go for that. That might be fine if they offered the customer a cheaper price- what we disagree with is selling “supermarket beans” (i.e. the copy screens) at “Heinz beans” prices!

Heading towards the “blatantly fraudulent”, we’re aware of companies that shamelessly fit copy screens while claiming them to be original. Worse, they’ll take your broken original screen and sell that to a recycler for more than they paid for your copy!

Apple tightened up their supply chain around 2015, which reduced the number of screens available for repairs and increased their price dramatically. A lot of companies went bankrupt, and Chinese manufacturers responded by making their own “copy” screens from scratch. At first, these weren’t much cheaper than the Apple ones, but the price soon fell.

We should be clear that- despite the name- “copy” screens aren’t direct copies of the Apple originals. Rather, they’re compatible replacements that have been designed from scratch and- as a result- vary in some respects that have an effect on usability and quality.

One of the most important differences between an original and a “copy” screen is how the digitizer (touch sensor) is designed. Apple has it manufactured as part of the LCD itself, whereas the copies have it on the glass.

Although there are only a small number of manufacturers of the bare LCDs themselves, these are then bought by countless other companies who add the remaining components needed to turn these into a complete working screen. As a result, you could easily end up with an LCD from the best “copy” manufacturer, but the digitizer/touch (as part of the separately-manufactured glass) from the worst.

There are countless digitizers out there, and you can only take the supplier’s word that the quality is good. Many ship good ones at first, then switch to cheaper parts to make more profit. This is particularly bad with the iPhone 6S and 6S+, since Apple moved the chips responsible for touch processing onto the LCD itself. As a result, you’re not just getting a copy screen- you’re getting copy chips too.

The performance specification (power drain, etc.) of most copy screens isn’t identical to the originals. As a result, they can drain the battery more quickly and mislead the operating system which was optimised for the original screen design.

It’s even possible that this mismatch could damage your backlight. We do a lot of subcontracted repairs for less-experienced shops, and get backlight repairs in almost every day. We’ve had cases where we fixed the circuit, fitted the new copy screen to test it, and had it break the circuit again!

Copy screens can disrupt the touch ID fingerprint reader. With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. Frequently the home button flexes on aftermarket designs don’t work properly and stop the touch ID working- annoying if you use it to unlock the phone or log in to your bank.

We’ve seen many lift away from the frame that holds them in place. This usually results in the flex cable getting torn, and the screen needing replacing. You don’t even need to have dropped the phone- this often happens through general everyday wear and tear.

That brings us to another major issue with the copies. When you drop an Apple original, the glass often breaks, but if the LCD itself is intact, you can continue to use it until it’s fixed. With the copies, the touch/digitizer is on the glass and stops working when that’s broken. Even worse, the LCD itself is more likely to break due to the thinner and more fragile glass.

We’re not convinced this will happen, since Apple recently changed their repair policy to accept iPhones with third-party screens. However, it is possible that copy screens could be stopped from working via an iOS update, since those make a number of security checks.

What exactly is short in the market? Your iPhone’s screen is one solid unit made up of several elements that are fused together with OCA (optically clear adhesive). The exterior glass, the digitizer panel (touch sensor), the polarizer and LCD panel. The LCD panel is the key component that is in short supply. Originally Apple had 3 manufacturers to produce LCD panels (LG, Sharp and Toshiba). Apple’s authorized manufacturers have the exclusive technology to produce LCD panels. Other Chinese manufacturers can copy the glass, digitizer, polarizers, OCA, flex cables, backlights, frames and everything except for the main component of the LCD assembly.

How were we getting these parts before? A big leak in Apple’s supply chain. The iPhone 5, 5S and 5C all share most of the same raw components including the LCD panel, the only difference is the flex cable and plastic frame. Independent factories in China can produce these components and can manufacture any 5 series assembly from an LCD panel. Shown on the left is a pulse pressing machine, used to connect the flex cable to the LCD. We use one of these to repair LCDs with damaged flex cables.

So what’s happening?A few things, first Apple has cut off LG and Toshiba, making Sharp their exclusive supplier for iPhone LCD panels and implemented very tight security. Secondly, they have had Foxconn destroy stockpiles of series 5 LCD panels to reduce the parts and material leakage to factories that re-engineer them for the independent repair industry. Along with this strategy, Apple has instructed Foxconn to reduce series 6 materials leakage from their manufacturing centers. Lastly, Apple is working aggressively with US Customs to seize inbound parts.

How long is this shortage going to last? In short,we have no idea. At the time of this writing, LCD prices have been steadily rising for 6 months and replacement iPhone 6S LCDs cost twice what Apple charges for their repair service. Apple does not intend to compete with independent repair shops, instead they are squeezing the profit out of the industry. LCD refurbishing may help shops cut cost but without new LCD panels entering the system it won’t last long.

What does this mean for the independent repair community?Apple is the only repair operation that is immune. Even the Chinese LCD refurbishing plants used by the large chain repair companies are running out of LCDs. Continually rising costs may push out the big chains but with lower overhead and clever problem-solving, the owner-operated shops stand a fighting chance.

If your phone has image display issues, an unresponsive touch screen or physical cracks or scratches on the glass, this LCD and touch screen assembly is what you need

This is not an easy job for someone who has no technical skills with Disassembling or Assembling Cellphones/mobile phones, so only purchase this item if you know how to install it

AboutGuangzhou Youyue Electronic Technology Co.,Ltdis a high-tech enterprise specializing in the mobile phone spare parts and tablet parts with high quality and competitive price, prompt delivery and courteous manner of our .

was established in 2012 which dedicated in mobile phone, tablet pc, laptop replacement parts. We are specialty providing large stock for spare parts, various kinds of parts and different quality for you and your business.

Smart Part, alibaba assessed 2 years gold supplier. Tightened inspection, rigorous test, attentive services, that is we do for you. Quality, Reliability, Integrity! We are looking forward to be friend and long term cooperation strategic partners.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey