how to clean lcd display made in china

Remember when your LCD or OLED display had that brand-new, fresh-out-of-the-box shine, feel and look? You are in the right place if your display is now due for deep cleaning.

Things to consider before cleaning or handling an electronic displayAvoid static by grounding your body and following proper ESD-safe handling techniques.

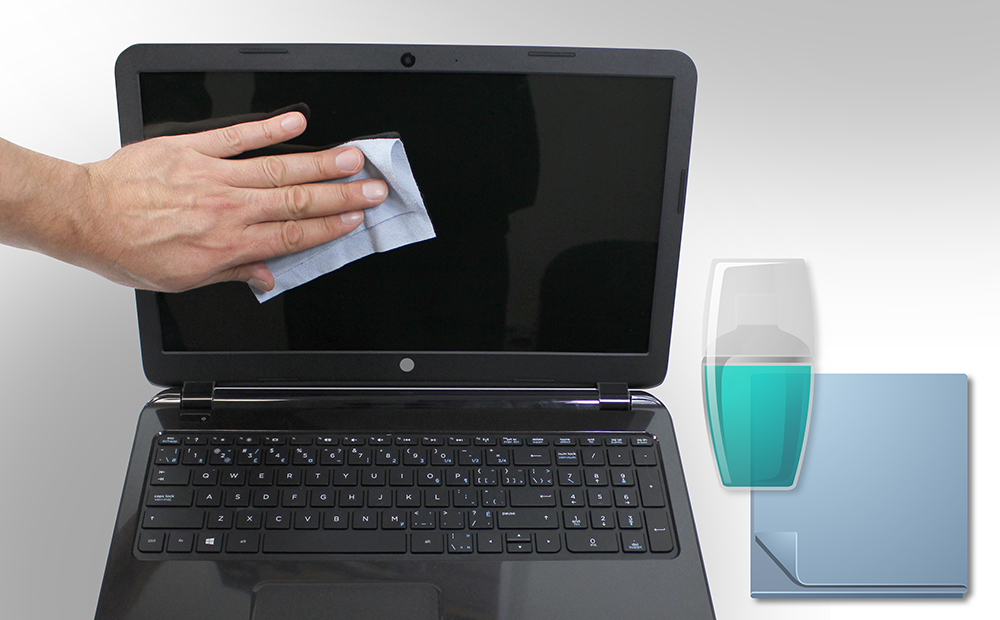

A microfiber cloth and distilled water is recommended for cleaning the display glass. Use Qtips and Isopropyl alcohol for cleaning the printed circuit board.

Although distilled water is recommended for wiping the display glass, you can use a cleanser developed explicitly for cleaning displays. However, do not spray it directly onto the display. Spray a tiny amount of the cleaner onto a microfiber cloth first to avoid getting any cleaning solution inside the display.Never spray any liquids directly onto the display.A spray is too hard to control and confine. The fluids can seep into the other display layers or surrounding components and cause irreversible liquid damage.

Only use a microfiber cloth and don"t use chemicals to clean a resistive touchscreen.Disconnect the display from the power supply and remove any screen protectors or liners.

Isopropyl alcohol (IPA) is widely used to clean printed circuit boards (PCBs). Use a Q-tip or soft small bristle brush for scrubbing a PCB, and never use a paintbrush.Gently rub a Q-tip in Isopropyl alcohol.

Cleaning soldering residue on LCD with Isopropyl alcohol and a Q-Tip.Cleaning residue around soldering elements is not necessary if Newhaven Display performed the soldering.

Cleaning your electronic display is a simple task. However, it is essential to consider these steps to handle and clean it properly. You should now have a better understanding of what cleaning products are safe to use, how to clean the display screen glass, how to clean touchscreens and how to clean soldering residue.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

What can be better after a long day’s work than lying down on a sofa watching TV? The television can become our best friend to relieve the pressure from work, relationships, and annoying relatives. LCD TV displays as added “member” of the family also need to be taken care of. For this reason, it is recommended to regularly clean the LCD screen as dust and dirt may affect its performance. What we are trying to say is that if the television is too dirty, you won’t be enjoying your favorite program. Trust me! you do not want that…

How can we clean the LCD Display? This is a concern for many people. Before we find out the answer, we need to know what to avoid. Here, please do not take out your t-shirt and wipe the screen from those beer stains, calm down, and hear me out. Many people would easily make mistakes in solving this problem even without consciousness. So let’s take a look at some wrong cleaning methods first: Wiping the LCD Screen directly with the palm or fingers

You should know that LCD should not be touched. When rubbing with the palm or fingers, it is difficult to use the right amount of force. If the force is too strong, it may cause permanent damage to the liquid crystal molecules, which translate into watching at a multicolor liquid stain on your TV instead of your favorite show. Wipe the LCD screen with a rough towel

Someone may directly clean the LCD display with the towel used to wipe the table at home. However, this is a wrong behavior as you can scratch the surface or get the screen even dirtier. Do not also use paper towels, toilet paper, or old T-shirts. These materials are abrasive and leave a lot of residues.

Now that we know what we should not do, let us move with the proper cleaning methods. First of all, let us briefly explain the LCD TV display structure. The LCD panel is mainly composed of two sodium-free glass sandwiched by a polarizer, a liquid crystal layer, and a color filter. Feeling confused? check here our article about LCD TVdisplays.

Moving on to the cleaning. Well, the first thing you should do is to turn off your television. I know it seems obvious to say, but many people do not follow this step. After that, you have two main choices: standard or creative method:

The first being the standard option, is the most formal and troublesome. Stand up and go out buying the special LCD cleaner and microfiber cloth to clean the LCD screen. If you are too lazy, you can order it online. Although this method is effective, it implies that you need to buy the cleaning agent and my friend, depending on how regularly you clean, it can be expensive. Once bought the products, apply the cleaning agent to the cloth and gently wipe the entire surface of the LCD TV display, removing any visible traces of dirt and dust.

If you thought it was too easy after hearing the standard option, or those nasty stains are still there, we have the solution for you. Here we share the “creative” method.

Prepare a liquid solution using equal amounts of vinegar and water. Vinegar is a natural and safe detergent and is much cheaper than the products on the market, specially designed for cleaning televisions.

Dampen the microfiber cloth in the vinegar and water solution and then wipe your TV screen softly. If necessary, apply gentle pressure and a circular motion to the spots where you notice stubborn stains. Keep in mind not to spray the vinegar solution directly on the TV screen, as you could damage it irreparably.

Following, use a second microfiber cloth to dry the TV screen. Pay attention not to allow the screen to air dry. Otherwise, annoying halos may remain and influence image quality.

Finally, wash the plastic frame of the TV. If the frame also requires a more intensive cleaning, use some paper towels after wetting it in the vinegar and water solution. Use paper towels to dry it completely.

To better enjoy your LCD TV display, you need to take good care of it. Our team at Aiwa is devoted to developing innovative solutions for visual entertainment with LCD TV, LCD monitors, and other electronic devices. Our product offers a longer life-span and longevity.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

If your screen is still dirty, apply a small amount of 70~75% isopropyl alcohol (IPA) solution to your cloth and gently wipe down the exterior of your screen. Alternatively, you can also use a 70~75% IPA wipe.

Repair guides can be hard to find. I"ve only seen guides for iMac but the general idea is the same. Remove the LCD assembly from the housing, remove the fixture tapes and side frames from the assembly, lift the panel and clean it. It seems that soft cloth is enough to clean the panels. Be aware of additional dust when wiping the panels and wipe gently, you may scarch the panel in the process if not careful enough. Make sure you seal the assembly well to prevent further dust.

It IS a very difficult repair, the assembly is very heavy, maybe more than 2/3 of the unit"s total weight, and it is a fragile piece of art. Several cables and sensors attach to the back side of the panel. You can easily damage them when lifting the LCD. There are many clips locking the frame. Quite tricky to remove. And at last the LCD driver board is connected to the panel by several ribbon cables. You must not tear any one of them or the entire unit is totaled. In conclusion, very challenging to do so.

The injection of ITO glass — glass CLEANING and drying — PR COAT — PREBREAK — DEVELOP MAIN CURE — ETCHING — STRIP CLEAN — TOP COAT — UV CURE — curing — MANICURE) – cleaning (CLEAN) – applied orientation agent (PI) PRINT – CURING (MAIN CURE), cleaning (CLEAN), silk screen printing (SEAL/SHORT PRINTING) – baking (CUPPING FURNACE), SPRAY packing material (SPACER SPRAY) – para pressing (ASSEMBLY) – CURING (SEAL MAIN CURING)

A.The input of ITO glass: According to the requirements of the product, appropriate ITO glass is selected and put into the transfer basket. Specifications and models of ITO glass are required to meet the requirements of the product. Remember that the ITO layer must be inserted into the basket upward.

B. Cleaning and drying of glass: Clean ITO glass with the cleaning agent and deionized water (DI water), wash impurities and oil stains on the ITO surface with physical or chemical methods and then remove and dry the water to ensure the processing quality of the next process.

C.Photoresist coating: Evenly coat a layer of photoresist on the conductive surface of ITO glass. The glass coated with photoresist must be pretreated at a certain temperature: (as shown in the figure below)

D.Pre-drying: The glass coated with a photoresist is baked for a period of time at a certain temperature to volatilize the solvent in the photoresist and increase its adhesion to the glass surface.

E.Exposure: Ultraviolet light (UV) is used to illuminate the surface of the photoresist through the pre-made electrode pattern mask, which causes the reaction of the photoresist layer. The photoresist is selectively exposed under an ultraviolet lamp by covering the photoresist on the glass coated with the photoresist (as shown in the figure).

F.Development: the surface of the glass is treated with developer solution, the photoresist layer decomposed by light is removed, the photoresist layer of the unexposed part is retained, the photoresist of the part exposed by UV light is dissolved in the developer solution by chemical method, the developed glass has to undergo a certain temperature hardening film treatment.

H.Etching: With appropriate acid etching solution, the ITO film without photoresist covering is etched off. Thus, the required ITO electrode pattern is obtained.

Note:is conductive glass (In2O3 and SnO2), which is easy to react with acid and is used to etch off the excess ITO to obtain the corresponding wire electrode.

I.Film removal: the high concentration of alkali solution (NaOH solution) is used as the film removal solution to peel off the remaining photoresist on the glass, thus forming ITO graphics exactly consistent with the lithography mask on the ITO glass.

General TN and the STN product does not require this step, the TOP film coating process is after the photolithography process making SiO2 coating, once again to the etching area and the etching area between the grooved bridge and the electrode covering, this can have the effect of the insulation layer, and can effectively eliminate the display state of the bottom electrode, also help to improve the perspective characteristics and so on, so most of the high-grade product requires TOP coating.

This process involves coating an oriented layer on the etched ITO glass surface and treating the restricted layer in a specific way so that the liquid crystal molecules can be oriented (arranged) in a specific direction on the surface of the oriented layer. This step is unique to the production of liquid crystal displays.

Organic polymer-oriented material is coated on the surface of the glass, that is, a uniform orientation layer is applied to the appropriate position of ITO glass by a selective coating method, and the orientation layer is cured at the same time. (Usually in the display area)

Flannelette material is used to rub the surface of the oriented layer in a specific direction so that the liquid crystal molecules can be arranged along the friction direction of the oriented layer in the future. For example, TN type friction orientation: 45 degrees

In this process, two conductive glasses are stacked on top of each other, and sealed together, and cured to make a glass box with a specific thickness of clearance. The technology of box-making is one of the key technologies in LCD manufacturing. (Spacing of LIQUID crystal boxes must be strictly controlled)

Evenly distribute the supporting material over the lower glass. A certain size of the liner (usually a few microns) is evenly distributed over the surface of the glass. These materials are used to ensure that the spacing between the glasses is the thickness of the box.

press the upper and lower glass against each other on the counterpoint mark, and then glue the corresponding two pieces of glass face to face with sealing material.

Curing the sealing material at high temperatures. When curing, the pressure is applied to the upper and lower glass to make the spacing of the liquid crystal boxes (thickness remains uniform).

SCRIBING — BREAK OFF — LC INJECTION — END seal — BREAK OFF — sharpen — VISUAL inspection — ELECTRICAL test — secondary cleaning special procedure (POLYGON) — BACK PRINTING — dry ink — POLARIZER ASSEMBLY — Thermal pressure — Inspection appearance test (FQC) — BIT PIN — FINAL test — PACKING — IN STOCK.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrialcontrol equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

Next, a photoresist is applied to the glass on which ITO film is deposited, and a uniform photoresist layer is formed on the ITO glass. After baking for a period of time, the solvent of the photoresist was partially volatilized to increase the adhesion of the photoresist material to the ITO glass.

Ultraviolet light (UV) is used to illuminate the surface of the photoresist through a pre-made electrode pattern mask, which causes the photoresist layer to react. The photoresist is selectively exposed under ultraviolet light by covering the photoresist on the glass coated with the photoresist.

The exposed part of the photoresist is then washed away with the developer, leaving only the unexposed part, and the dissolved photoresist is then washed away with deionized water.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Then, the organic polymer directional material is coated on the surface of the glass, that is, a uniform directional layer is applied to the appropriate position of ITO glass by the method of selective coating. Meanwhile, the directional layer is cured.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

A polarizer is an optical plate that allows only light from a certain direction to pass through. It is an optical element that converts natural light into straight polarized light. The mechanism of action is to make the vertical direction light pass through the straight incident light after passing through the vertical polarizer, and the other horizontal direction light is absorbed, or use reflection and scattering and other effects to make its shade.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

In order to get more orders and give our clients more convenice, we accept small order. Can you do OEM for me9 We accept all OEM orders,just cantact us and give me your design. If you are very urgent to get the quotation, please call us or tell us in your mail, so that we could regart your inquiry priority.

Dell recommends ensuring that the device drivers and BIOS are up to date using the SupportAssist application for optimal video performance and to help resolve common video-related issues.

NOTE: When SupportAssist does not show up in the search results, go to the SupportAssist for PCs and tablets page for information about downloading and installing SupportAssist.

To learn how to manually download and install a device driver such as Chipset, Video card (GPU), and Monitor driver (if required, most monitor drivers are delivered automatically through Windows Update) on your Dell computer, see the Dell knowledge base article How to Download and Install Dell Drivers.

We must verify whether the problem is the display screen of the laptop, video card (GPU), or video settings on the computer. A straightforward way to identify this is to connect the laptop to an external monitor or TV.

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

If you notice a physical damage, contact Dell Technical Support to learn more about repair options that are available in your region. If there is no damage, go to the next step.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Windows Safe Mode does not load any drivers, startup applications, third-party services. This will help us identify if the issue is related to the operating system, video settings, device drivers, or third-party software. To learn how to boot your computer into Safe Mode, see the Dell knowledge base article below based on the operating system that is installed on the computer:

Windows updates can support your Windows operating system in many ways. Windows updates can solve specific problems, provide security patches and protection from malicious attacks, or even add new features to the operating system.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

NOTE: Depending on the model of the Dell laptop, the shortcut keys to adjust or change the brightness may differ. See the User Guide or User Manual of your Dell laptop for model-specific information.

If you find that the Dell laptop is unresponsive to touch, touch stops working entirely, or other touch-related issues, you can try some common troubleshooting steps to help fix the touch-related issue.

System Restore is an integrated Windows tool that is designed to protect and repair the operating system. When something goes wrong with your computer, System Restore must be used before you try to restore the operating system to factory default settings.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

WARNING: Restoring or resetting the computer to factory default settings will erase all personal data on the computer. Back up all important data like documents, images, music files, spreadsheets, videos to an external hard drive or a cloud-based backup like Microsoft OneDrive.

Dell computers are built with a small amount of hard disk space that is reserved for reinstalling the operating system. This method is the easiest way to restore the computer to factory condition. The restoration process deletes all user data from the computer, so be sure to back up all your files before starting this process.

Don"t make the mistake of thinking that LCD screens work like your nifty new iPad. In general, touching should be off limits because pressing too hard on the screen can actually break or crack pixels. So the first rule to cleaning an LCD screen is don"t do it unless you have to (i.e. unless it"s actually dirty).

Many retailers offer special cleaning solutions for LCD screens, but the truth is that most of these are made up primarily of water. So, if you don"t want to take the time to go buy a cleaner or you want to save the money (maybe to put toward that "What Not to Wear" dress), you can just make your own LCD cleaner by mixing water with some vinegar or isopropyl alcohol -- the solution should be no more than 50/50.

You could even start with plain water and see if you need the vinegar or alcohol, which will come in handy when you"re trying to wipe away greasy fingerprints. Some people recommend only using distilled water, but regular water works fine, according to Dave Chipman from Sharp.

Unless you want to end up with a melted, discolored, hazy or scratched LCD screen, steer clear of all spray cleaners. In particular, don"t use any solvent cleaners that include acetone, ethyl alcohol, ethyl acid, ammonia or methyl chloride. You also want to avoid using any materials that could potentially scratch the screen"s delicate surface. Opt for a soft, clean, cotton cloth instead of wood-based products like paper towels and tissues. Chipman suggests using a microfiber cloth for best results.

If you"re lucky enough to have a service come in and do your cleaning for you, make sure they don"t inadvertently ruin your television or monitor by trying to clean it with something like glass cleaner. You should either take the time to explain -- and maybe even demonstrate -- how you want your LCD screen cleaned or just ask your cleaner to leave this particular job for you.

TOKYO -- China is expanding its presence in the field of key components for the electronics industry, such as liquid crystal display panels and semiconductors. In China, seven state-of-the-art LCD panel factories will come onstream over the next three years, and there has emerged a plan to construct one of the world"s largest memory chip plants.

Backed by the Chinese government"s funding power, the country seems to be trying to control the global digital industry through aggressive, massive investment despite the risk of excess facilities.

A light-emitting diode (LED) is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons.

This question is important. Outdoor panels are usually seen from further distance, thus resolution will be lower. Outdoor led panels will likely be brighter because they are used in sunlight. Also outdoor panels will be more durable as they need to withstand weather conditions, dust, moisture and dirt. Indoor panels offer superior color, smaller pixels and a more refined picture. For the same pitch, indoor screens are cheaper. For all these reasons, we recommend indoor panels, unless you actually need to use an outdoor screen.

1) Ground Support Installation: This method system is a combination of a base-unit, connection bar and ladder truss that creates a very stable system to support your LED screens in various configurations and offers flexibility in height as well as width.

2) Flown Method (rigging): There are certain requirements that need to be in place in order to fly a screen. Most importantly, there needs to be ample structural support in the ceiling to hold the total weight of the screen. When someone says they want to “Fly” an LED screen, that means the screen will be rigged to either an overhead truss system, a ceiling grid, a crane, or some other support structure from above.

3) Wall Mounted: Some panels can be drilled and mounted into the wall. This is a great option if you’re looking for an aesthetically clean look with easy maintenance features, but it will add cost to the panels.

We offer high refresh rate panels. If you broadcast online, you’ll want to ensure your panels have a refresh rate no less than 3840 hz. Low refresh rate panels will result in wavy lines that will distract your audience.

Most LED Panels are rated for 60,000 to 100,000 hours. You’ll have these panels for a long time and will get a lot of life out of them. In case something malfunctions, you can get in contact with us and we will give you all the information to properly service and maintain your panels.

It can be really frustrating to find several fingerprints on the display of your smartphone. Unfortunately, most smartphones today do not support fingerprint resistance. Thus, there is a continuous need to always wipe our smartphone screens to make them look cleaner. While many people are comfortable with a simple wipe using any clean cloth, some are not. Some users believe that they need some sort of disinfectant to make the smartphone screen clean. During the pandemic, various alcohol-containing disinfectants and cleaners have become common household items. We hold mobile phones in our hands every day and they can easily get contaminated with various pathogens. Since various alcohol-containing cleaners can not only clean oil stains but can also kill germs, wouldn’t it be appropriate to use them to wipe the smartphone screen? Well, don’t be too sure about how appropriate alcohol is for cleaning a smartphone screen.

While you may be tempted to use alcohol-based disinfectant to wipe your smartphone screen, please don’t. This is because if you do it incorrectly, it is likely to damage your phone or other electronic devices. Because using alcohol to wipe the smartphone screen is likely to cause irreversible serious damage to the screen. This is particularly true for LCD screens. So, why does alcohol have a strong erosive effect on LCD screens?

However, modern LCD screens, especially various touch screens, are not so fragile. Because we will also set a glass cover on the top layer of the screen, this cover mainly prevents scratches from damaging the screen. Furthermore, this later can naturally block various moisture and solvents from the outside from directly interacting with the structure below. But even so, wiping the screen with alcohol-based cleaners is a dangerous practice for two main reasons.

First, the surface of the glass cover is actually coated with a special organic film, such as an oleophobic film. This can reduce oil adsorption and ease fingerprints from dirtying the screen. Most of these coatings contain various organic compounds, and their resistance to alcohol is very weak. If they are wiped with alcohol from externally, the coatings are more likely to fall off. This will cause the display to become blurry. Of course, if the screen of the mobile phone is covered with film, then there is no need to worry too much about this problem.

Second, although the top layer of the LCD screen, that is, its surface is not so squeamish, its sides are still very fragile. Most of the LCD screens damaged by alcohol are actually because the alcohol penetrated into the gaps on the side of the screen. This means that as the user wipes with alcohol, the alcohol, finds its way into the sides of the display. It manoeuvres from the glass panel and drills directly into the lower structure. The surface tension of alcohol is weak and the capillary effect is strong. Once it finds its way into the side of the display, it will quickly penetrate into it. As we will all expect, the consequences are naturally very irritating.

If somehow, a small amount of alcohol enters the inside of the screen, you can immediately turn off the device to dry naturally. Alternatively, you can use a hairdryer to dry it carefully and this will not affect subsequent use.

From time to time, there is usually a need to clean the display of our smartphones. We also need to clean the screen of our tablet or computer. When we have such a need, all we have to do is spray some special LCD screen cleaner and wipe it with a soft cloth. This will make the screen clean and appear brand new. The LCD screen cleaner has a very good removal effect on fingerprints and oil films, and many wet wipes also have similar functions.

The active ingredients contained in these cleaning products are mainly surfactants. They have a good cleaning effect on oil stains and will not damage various organic coatings. If there is no similar cleaning agent, the LCD screen can also be cleaned with a damp cloth dipped in a very small amount of pure water. However, be very careful not to let water flow into the gaps around the screen.

To sum up, if it is just for cleaning, it is not safe to use alcohol. If there is a need for disinfection, then you should be cautious. Some mobile phone products will be sterilized with alcohol. It is recommended to read the instructions before disinfection. In addition, when disinfecting a mobile phone with alcohol, it is also recommended to first dip the alcohol on a soft cloth, and then gently wipe it with the soft cloth. Do not spray or pour alcohol directly on the screen, so as to prevent the alcohol from flowing everywhere and increase the risk of eroding the original screen and damaging the mobile phone.

There are multiple types of LCD screen cleaners that users can purchase off the shelf. If you feel that a simple cloth wipe is not enough, then try and purchase any of the LCD screen wipes on the market. As much as you can, try to avoid the use of alcohol or alcohol-based disinfectant to clean your smartphone. The adverse effect of this could be worth much more than the need to clean or disinfect the device.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey