gas plasma display screens free sample

A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large (over 32 inches diagonal) flat panel displays to be released to the public.

Until about 2007, plasma displays were commonly used in large televisions (30 inches (76 cm) and larger). By 2013, they had lost nearly all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Manufacturing of plasma displays for the United States retail market ended in 2014,

Plasma displays are bright (1,000 lux or higher for the display module), have a wide color gamut, and can be produced in fairly large sizes—up to 3.8 metres (150 in) diagonally. They had a very low luminance "dark-room" black level compared with the lighter grey of the unilluminated parts of an LCD screen. (As plasma panels are locally lit and do not require a back light, blacks are blacker on plasma and grayer on LCD"s.)LED-backlit LCD televisions have been developed to reduce this distinction. The display panel itself is about 6 cm (2.4 in) thick, generally allowing the device"s total thickness (including electronics) to be less than 10 cm (3.9 in). Power consumption varies greatly with picture content, with bright scenes drawing significantly more power than darker ones – this is also true for CRTs as well as modern LCDs where LED backlight brightness is adjusted dynamically. The plasma that illuminates the screen can reach a temperature of at least 1200 °C (2200 °F). Typical power consumption is 400 watts for a 127 cm (50 in) screen. Most screens are set to "vivid" mode by default in the factory (which maximizes the brightness and raises the contrast so the image on the screen looks good under the extremely bright lights that are common in big box stores), which draws at least twice the power (around 500–700 watts) of a "home" setting of less extreme brightness.

Plasma screens are made out of glass, which may result in glare on the screen from nearby light sources. Plasma display panels cannot be economically manufactured in screen sizes smaller than 82 centimetres (32 in).enhanced-definition televisions (EDTV) this small, even fewer have made 32 inch plasma HDTVs. With the trend toward large-screen television technology, the 32 inch screen size is rapidly disappearing. Though considered bulky and thick compared with their LCD counterparts, some sets such as Panasonic"s Z1 and Samsung"s B860 series are as slim as 2.5 cm (1 in) thick making them comparable to LCDs in this respect.

Wider viewing angles than those of LCD; images do not suffer from degradation at less than straight ahead angles like LCDs. LCDs using IPS technology have the widest angles, but they do not equal the range of plasma primarily due to "IPS glow", a generally whitish haze that appears due to the nature of the IPS pixel design.

Less visible motion blur, thanks in large part to very high refresh rates and a faster response time, contributing to superior performance when displaying content with significant amounts of rapid motion such as auto racing, hockey, baseball, etc.

Earlier generation displays were more susceptible to screen burn-in and image retention. Recent models have a pixel orbiter that moves the entire picture slower than is noticeable to the human eye, which reduces the effect of burn-in but does not prevent it.

Due to the bistable nature of the color and intensity generating method, some people will notice that plasma displays have a shimmering or flickering effect with a number of hues, intensities and dither patterns.

Earlier generation displays (circa 2006 and prior) had phosphors that lost luminosity over time, resulting in gradual decline of absolute image brightness. Newer models have advertised lifespans exceeding 100,000 hours (11 years), far longer than older CRTs.

Uses more electrical power, on average, than an LCD TV using a LED backlight. Older CCFL backlights for LCD panels used quite a bit more power, and older plasma TVs used quite a bit more power than recent models.

Fixed-pixel displays such as plasma TVs scale the video image of each incoming signal to the native resolution of the display panel. The most common native resolutions for plasma display panels are 852×480 (EDTV), 1,366×768 and 1920×1080 (HDTV). As a result, picture quality varies depending on the performance of the video scaling processor and the upscaling and downscaling algorithms used by each display manufacturer.

Early plasma televisions were enhanced-definition (ED) with a native resolution of 840×480 (discontinued) or 852×480 and down-scaled their incoming high-definition video signals to match their native display resolutions.

The following ED resolutions were common prior to the introduction of HD displays, but have long been phased out in favor of HD displays, as well as because the overall pixel count in ED displays is lower than the pixel count on SD PAL displays (852×480 vs 720×576, respectively).

Early high-definition (HD) plasma displays had a resolution of 1024x1024 and were alternate lighting of surfaces (ALiS) panels made by Fujitsu and Hitachi.

Later HDTV plasma televisions usually have a resolution of 1,024×768 found on many 42 inch plasma screens, 1280×768 and 1,366×768 found on 50 in, 60 in, and 65 in plasma screens, or 1920×1080 found on plasma screen sizes from 42 inch to 103 inch. These displays are usually progressive displays, with non-square pixels, and will up-scale and de-interlace their incoming standard-definition signals to match their native display resolutions. 1024×768 resolution requires that 720p content be downscaled in one direction and upscaled in the other.

Ionized gases such as the ones shown here are confined to millions of tiny individual compartments across the face of a plasma display, to collectively form a visual image.

A panel of a plasma display typically comprises millions of tiny compartments in between two panels of glass. These compartments, or "bulbs" or "cells", hold a mixture of noble gases and a minuscule amount of another gas (e.g., mercury vapor). Just as in the fluorescent lamps over an office desk, when a high voltage is applied across the cell, the gas in the cells forms a plasma. With flow of electricity (electrons), some of the electrons strike mercury particles as the electrons move through the plasma, momentarily increasing the energy level of the atom until the excess energy is shed. Mercury sheds the energy as ultraviolet (UV) photons. The UV photons then strike phosphor that is painted on the inside of the cell. When the UV photon strikes a phosphor molecule, it momentarily raises the energy level of an outer orbit electron in the phosphor molecule, moving the electron from a stable to an unstable state; the electron then sheds the excess energy as a photon at a lower energy level than UV light; the lower energy photons are mostly in the infrared range but about 40% are in the visible light range. Thus the input energy is converted to mostly infrared but also as visible light. The screen heats up to between 30 and 41 °C (86 and 106 °F) during operation. Depending on the phosphors used, different colors of visible light can be achieved. Each pixel in a plasma display is made up of three cells comprising the primary colors of visible light. Varying the voltage of the signals to the cells thus allows different perceived colors.

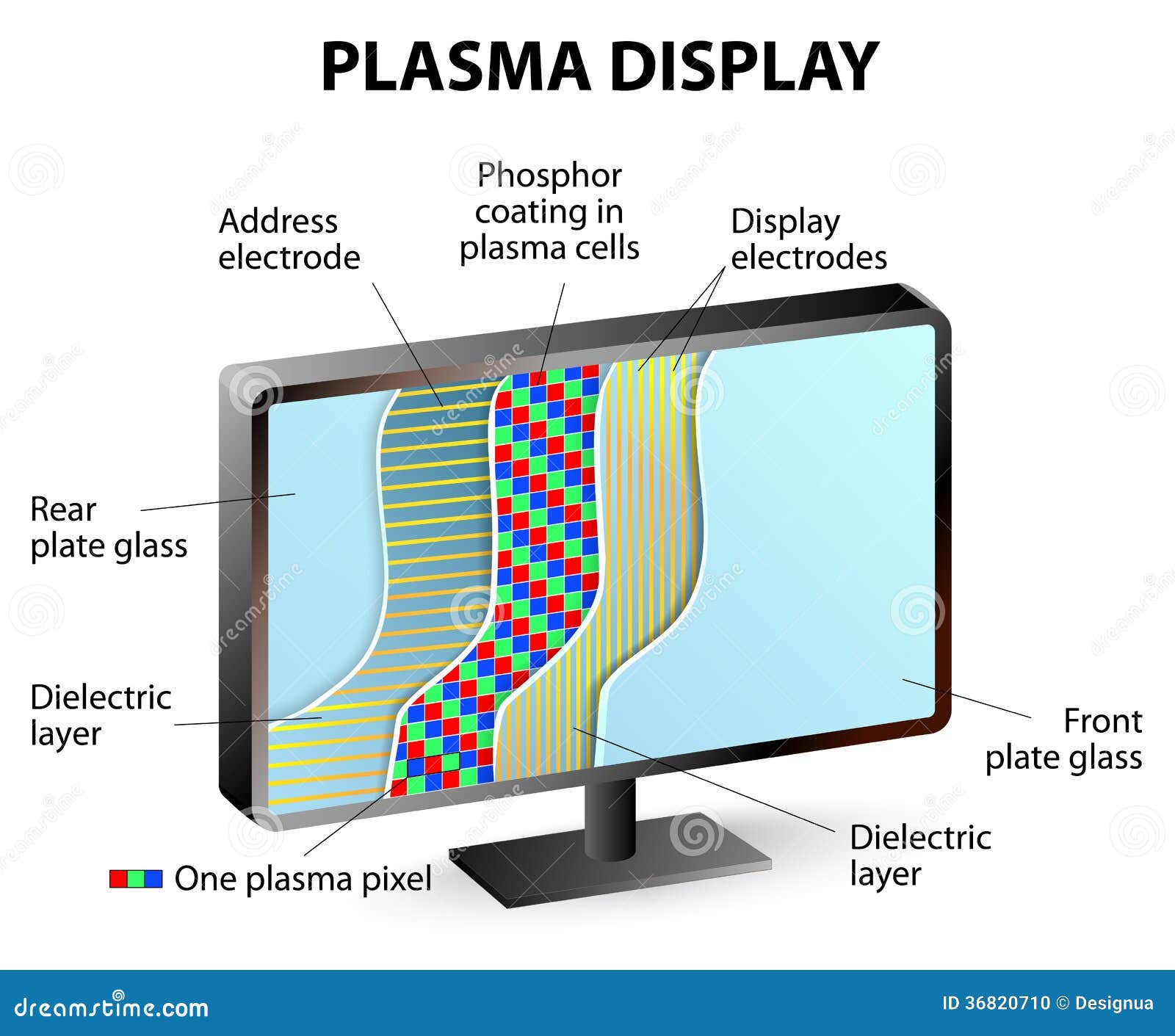

The long electrodes are stripes of electrically conducting material that also lies between the glass plates in front of and behind the cells. The "address electrodes" sit behind the cells, along the rear glass plate, and can be opaque. The transparent display electrodes are mounted in front of the cell, along the front glass plate. As can be seen in the illustration, the electrodes are covered by an insulating protective layer.

Control circuitry charges the electrodes that cross paths at a cell, creating a voltage difference between front and back. Some of the atoms in the gas of a cell then lose electrons and become ionized, which creates an electrically conducting plasma of atoms, free electrons, and ions. The collisions of the flowing electrons in the plasma with the inert gas atoms leads to light emission; such light-emitting plasmas are known as glow discharges.

Relative spectral power of red, green and blue phosphors of a common plasma display. The units of spectral power are simply raw sensor values (with a linear response at specific wavelengths).

In a monochrome plasma panel, the gas is mostly neon, and the color is the characteristic orange of a neon-filled lamp (or sign). Once a glow discharge has been initiated in a cell, it can be maintained by applying a low-level voltage between all the horizontal and vertical electrodes–even after the ionizing voltage is removed. To erase a cell all voltage is removed from a pair of electrodes. This type of panel has inherent memory. A small amount of nitrogen is added to the neon to increase hysteresis.phosphor. The ultraviolet photons emitted by the plasma excite these phosphors, which give off visible light with colors determined by the phosphor materials. This aspect is comparable to fluorescent lamps and to the neon signs that use colored phosphors.

Every pixel is made up of three separate subpixel cells, each with different colored phosphors. One subpixel has a red light phosphor, one subpixel has a green light phosphor and one subpixel has a blue light phosphor. These colors blend together to create the overall color of the pixel, the same as a triad of a shadow mask CRT or color LCD. Plasma panels use pulse-width modulation (PWM) to control brightness: by varying the pulses of current flowing through the different cells thousands of times per second, the control system can increase or decrease the intensity of each subpixel color to create billions of different combinations of red, green and blue. In this way, the control system can produce most of the visible colors. Plasma displays use the same phosphors as CRTs, which accounts for the extremely accurate color reproduction when viewing television or computer video images (which use an RGB color system designed for CRT displays).

Plasma displays are different from liquid crystal displays (LCDs), another lightweight flat-screen display using very different technology. LCDs may use one or two large fluorescent lamps as a backlight source, but the different colors are controlled by LCD units, which in effect behave as gates that allow or block light through red, green, or blue filters on the front of the LCD panel.

To produce light, the cells need to be driven at a relatively high voltage (~300 volts) and the pressure of the gases inside the cell needs to be low (~500 torr).

Contrast ratio is the difference between the brightest and darkest parts of an image, measured in discrete steps, at any given moment. Generally, the higher the contrast ratio, the more realistic the image is (though the "realism" of an image depends on many factors including color accuracy, luminance linearity, and spatial linearity). Contrast ratios for plasma displays are often advertised as high as 5,000,000:1.organic light-emitting diode. Although there are no industry-wide guidelines for reporting contrast ratio, most manufacturers follow either the ANSI standard or perform a full-on-full-off test. The ANSI standard uses a checkered test pattern whereby the darkest blacks and the lightest whites are simultaneously measured, yielding the most accurate "real-world" ratings. In contrast, a full-on-full-off test measures the ratio using a pure black screen and a pure white screen, which gives higher values but does not represent a typical viewing scenario. Some displays, using many different technologies, have some "leakage" of light, through either optical or electronic means, from lit pixels to adjacent pixels so that dark pixels that are near bright ones appear less dark than they do during a full-off display. Manufacturers can further artificially improve the reported contrast ratio by increasing the contrast and brightness settings to achieve the highest test values. However, a contrast ratio generated by this method is misleading, as content would be essentially unwatchable at such settings.

Each cell on a plasma display must be precharged before it is lit, otherwise the cell would not respond quickly enough. Precharging normally increases power consumption, so energy recovery mechanisms may be in place to avoid an increase in power consumption.LED illumination can automatically reduce the backlighting on darker scenes, though this method cannot be used in high-contrast scenes, leaving some light showing from black parts of an image with bright parts, such as (at the extreme) a solid black screen with one fine intense bright line. This is called a "halo" effect which has been minimized on newer LED-backlit LCDs with local dimming. Edgelit models cannot compete with this as the light is reflected via a light guide to distribute the light behind the panel.

Image burn-in occurs on CRTs and plasma panels when the same picture is displayed for long periods. This causes the phosphors to overheat, losing some of their luminosity and producing a "shadow" image that is visible with the power off. Burn-in is especially a problem on plasma panels because they run hotter than CRTs. Early plasma televisions were plagued by burn-in, making it impossible to use video games or anything else that displayed static images.

Plasma displays also exhibit another image retention issue which is sometimes confused with screen burn-in damage. In this mode, when a group of pixels are run at high brightness (when displaying white, for example) for an extended period, a charge build-up in the pixel structure occurs and a ghost image can be seen. However, unlike burn-in, this charge build-up is transient and self-corrects after the image condition that caused the effect has been removed and a long enough period has passed (with the display either off or on).

Plasma manufacturers have tried various ways of reducing burn-in such as using gray pillarboxes, pixel orbiters and image washing routines, but none to date have eliminated the problem and all plasma manufacturers continue to exclude burn-in from their warranties.

The first practical plasma video display was co-invented in 1964 at the University of Illinois at Urbana–Champaign by Donald Bitzer, H. Gene Slottow, and graduate student Robert Willson for the PLATO computer system.Owens-Illinois were very popular in the early 1970s because they were rugged and needed neither memory nor circuitry to refresh the images.CRT displays cheaper than the $2500 USD 512 × 512 PLATO plasma displays.

Burroughs Corporation, a maker of adding machines and computers, developed the Panaplex display in the early 1970s. The Panaplex display, generically referred to as a gas-discharge or gas-plasma display,seven-segment display for use in adding machines. They became popular for their bright orange luminous look and found nearly ubiquitous use throughout the late 1970s and into the 1990s in cash registers, calculators, pinball machines, aircraft avionics such as radios, navigational instruments, and stormscopes; test equipment such as frequency counters and multimeters; and generally anything that previously used nixie tube or numitron displays with a high digit-count. These displays were eventually replaced by LEDs because of their low current-draw and module-flexibility, but are still found in some applications where their high brightness is desired, such as pinball machines and avionics.

In 1983, IBM introduced a 19-inch (48 cm) orange-on-black monochrome display (Model 3290 Information Panel) which was able to show up to four simultaneous IBM 3270 terminal sessions. By the end of the decade, orange monochrome plasma displays were used in a number of high-end AC-powered portable computers, such as the Compaq Portable 386 (1987) and the IBM P75 (1990). Plasma displays had a better contrast ratio, viewability angle, and less motion blur than the LCDs that were available at the time, and were used until the introduction of active-matrix color LCD displays in 1992.

Due to heavy competition from monochrome LCDs used in laptops and the high costs of plasma display technology, in 1987 IBM planned to shut down its factory in Kingston, New York, the largest plasma plant in the world, in favor of manufacturing mainframe computers, which would have left development to Japanese companies.Larry F. Weber, a University of Illinois ECE PhD (in plasma display research) and staff scientist working at CERL (home of the PLATO System), co-founded Plasmaco with Stephen Globus and IBM plant manager James Kehoe, and bought the plant from IBM for US$50,000. Weber stayed in Urbana as CTO until 1990, then moved to upstate New York to work at Plasmaco.

In 1992, Fujitsu introduced the world"s first 21-inch (53 cm) full-color display. It was based on technology created at the University of Illinois at Urbana–Champaign and NHK Science & Technology Research Laboratories.

In 1994, Weber demonstrated a color plasma display at an industry convention in San Jose. Panasonic Corporation began a joint development project with Plasmaco, which led in 1996 to the purchase of Plasmaco, its color AC technology, and its American factory for US$26 million.

In 1995, Fujitsu introduced the first 42-inch (107 cm) plasma display panel;Philips introduced the first large commercially available flat-panel TV, using the Fujitsu panels. It was available at four Sears locations in the US for $14,999, including in-home installation. Pioneer also began selling plasma televisions that year, and other manufacturers followed. By the year 2000 prices had dropped to $10,000.

In the year 2000, the first 60-inch plasma display was developed by Plasmaco. Panasonic was also reported to have developed a process to make plasma displays using ordinary window glass instead of the much more expensive "high strain point" glass.

In late 2006, analysts noted that LCDs had overtaken plasmas, particularly in the 40-inch (100 cm) and above segment where plasma had previously gained market share.

Until the early 2000s, plasma displays were the most popular choice for HDTV flat panel display as they had many benefits over LCDs. Beyond plasma"s deeper blacks, increased contrast, faster response time, greater color spectrum, and wider viewing angle; they were also much bigger than LCDs, and it was believed that LCDs were suited only to smaller sized televisions. However, improvements in VLSI fabrication narrowed the technological gap. The increased size, lower weight, falling prices, and often lower electrical power consumption of LCDs made them competitive with plasma television sets.

Screen sizes have increased since the introduction of plasma displays. The largest plasma video display in the world at the 2008 Consumer Electronics Show in Las Vegas, Nevada, was a 150-inch (380 cm) unit manufactured by Matsushita Electric Industrial (Panasonic) standing 6 ft (180 cm) tall by 11 ft (330 cm) wide.

At the 2010 Consumer Electronics Show in Las Vegas, Panasonic introduced their 152" 2160p 3D plasma. In 2010, Panasonic shipped 19.1 million plasma TV panels.

Panasonic was the biggest plasma display manufacturer until 2013, when it decided to discontinue plasma production. In the following months, Samsung and LG also ceased production of plasma sets. Panasonic, Samsung and LG were the last plasma manufacturers for the U.S. retail market.

The xenon and neon gas in a plasma television is contained in hundreds of thousands of tiny cells positioned between two plates of glass. Long electrodes are also sandwiched between the glass plates, on both sides of the cells. The address electrodes sit behind the cells, along the rear glass plate. The transparent display electrodes, which are surrounded by an insulating dielectric material and covered by a magnesium oxide protective layer, are mounted above the cell, along the front glass plate.

Both sets of electrodes extend across the entire screen. The display electrodes are arranged in horizontal rows along the screen and the address electrodes are arranged in vertical columns. As you can see in the diagram below, the vertical and horizontal electrodes form a basic grid.

To ionize the gas in a particular cell, the plasma display"s computer charges the electrodes that intersect at that cell. It does this thousands of times in a small fraction of a second, charging each cell in turn.

When the intersecting electrodes are charged (with a voltage difference between them), an electric current flows through the gas in the cell. As we saw in the last section, the current creates a rapid flow of charged particles, which stimulates the gas atoms to release ultraviolet photons.

The phosphors in a plasma display give off colored light when they are excited. Every pixel is made up of three separate subpixel cells, each with different colored phosphors. One subpixel has a red light phosphor, one subpixel has a green light phosphor and one subpixel has a blue light phosphor. These colors blend together to create the overall color of the pixel.

The main advantage of plasma display technology is that you can produce a very wide screen using extremely thin materials. And because each pixel is lit individually, the image is very bright and looks good from almost every angle. The image quality isn"t quite up to the standards of the best cathode ray tube sets, but it certainly meets most people"s expectations.

The biggest drawback of this technology has been the price. However, falling prices and advances in technology mean that the plasma display may soon edge out the old CRT sets.

Many of the first plasma displays on the market weren"t technically televisions, because they didn"t have TV tuners. The television tuner is the device that takes a television signal (the one coming from a cable wire, for example) and interprets it to create a video image.

Like LCD monitors, these plasma displays were just monitors that display a standard video signal. To watch television on them, you had to hook them up to a separate unit that has its own television tuner, such as a VCR. Today, most of the plasma-screen devices you can buy at electronics stores are TVs and have digital television tuners.

A plasma computer display is a type of flat panel display that uses tiny cells filled with electrically charged ionized gases to produce images. This display technology is used in computer monitors, televisions, and even digital billboards.The plasma computer screens are generally available in large sizes ranging from 30 inches to 50 inches, but the actual specifications depend on the brand names. This article will tell you more about plasma computer displays, while we also took time to explain other types of monitors, as well.

A plasma monitor uses gas molecules to create images. The display is composed of many cells with pixels, each one filled with plasma. Their number and size determine the resolution and the overall picture quality.

Plasma monitors bring a high level of color detail to users. These characteristics make them ideal for professional users, particularly graphic artists or studio photographers, where accurate colors are important.

Many people are afraid of plasma monitors because they sound more complex than regular monitors, but the actual technology behind them is not that hard to grasp.

A plasma display is made up of millions of cells filled with a gas, or plasma-electrically conductive gas, which contains negatively charged ions and positively charged ions.

The monitor is one of the key components of a computer system. Also known as a display, it is the part of a computer system that produces images and text that can be seen by the user.

The first plasma monitor was invented by Hiram Slottow, Robert Willson, and Donald Bitzer of the University of Illinois, Urbana-Champaign, in the 1960s, for education purposes.

Although this type of monitor was first patented in 1969 by its founders at the University of Illinois, it would take 10 years before the first commercial displays were introduced. Initially called "phosphor-based white displays,” these plasma monitors had slow refresh rates and poor-quality images.

The first commercially plasma monitors were produced in 1981 by SONY and were called the “PS-42”, with a display size of 42 inches. They began to compete commercially with CRT-based monitors and televisions.

Many electronics companies such as Samsung, Panasonic have ended the production of Plasma TVs and monitors. After the introduction of better technologies such as LCDs, LEDs, and OLEDs, plasma monitors and TVs will be a past technology.

The founders of the plasma monitor were Hiram Slottow, Robert Willson, and Donald Bitzer of the University of Illinois, Urbana-Champaign, in the 1960s.

When choosing a plasma screen as a computer monitor, you need to be aware of the different features available on the market. Here are some of the more important features that you should consider when deciding to purchase a plasma monitor.

With the arrival of better monitor technologies, plasma monitors became the least priority, and if you walk into an electronics store these days, there are very few gas plasma display monitors on display.

The reason; many people have shifted to buying LCD, LED, and other flat-panel monitors due to their superior features. The disadvantages of a plasma system monitor are:

Plasma monitor picture quality is great because it has more pixels per inch than in cathode-ray tube or CRT displays. Its higher contrast ratio also translates to great images that are crisp, sharp, and detailed. Unfortunately, Plasmas and CRTs have a common problem with backlight bleeding, simply put, a leakage of light from the edges of the screen.

This is a very common question that people ask when they want to buy a plasma monitor or when they notice their prices are higher than usual. The answer depends on several factors, such as the features they come with, brand, and size. The larger and more features it comes with, the more you should expect to pay.The average price of plasma monitors ranges from $150 to $1000, depending on the brand, size, and features.

Energy consumption of plasma monitors refers to the amount of power consumed by these devices while they are in use, either for viewing a video or presenting graphics.

These types of monitorsconsume more electricity during operation than LEDs, LCDs, according to Energy Use Calculator. Here is a table that supports this. I have included LCD displays for comparison.

Most plasma monitors have a lifespan of 100,000 hours or 11 years of use. When you take great care of them, you can count on your plasma screen to last for years before needing any repairs or replacements.

Before you run right out and buy a plasma monitor, you’ll want to make sure it has the vital capabilities you need. Having done some research online, I consider these plasma monitors to be the best since they come with the right features.

Choosing the right plasma computer monitor for your computer is no easy task. There are so many different models, sizes, brands, etc., to choose from. That"s why I"ve created this section to help you easily find the right monitor.It’s important that you are able to identify these things in order to eliminate the risk of having buyer’s remorse. The following are just a few of the features that should be considered; Screen size, screen resolution, screen aspect ratio, connectivity type, speakers, response time, color depth or picture quality, power consumption or energy efficiency.

The most important feature of a plasma pc monitor is its display resolution. Resolution is the number of pixels in a display and determines image quality.

Screen size is also an important consideration. Think about how and where you"ll be using it—if you want something portable, 15 inches is probably the max. If you plan on using it for gaming or movies, bigger is better.It is worth noting that the majority of plasma pc monitors have big screens. A larger monitor will give you more viewing area and can make editing applications easier to use. It also allows you to see more of your work at the same time, which is nice if you have more than one window open or are reading various documents and texts simultaneously.

A monitor"s refresh rate is measured in Hz, or hertz - indicates the number of times in one second that the display can completely update itself to show new data. If you are planning on purchasing a plasma gaming monitor, I would recommend that you find one with a higher refresh rate, from 75Hz and upwards.

A plasma gaming monitor with a high refresh rate will help create smoother motion on the screen. A low refresh rate will cause distracting motion blur around moving objects or distort the image when playing games.

Most plasma monitors for sale come equipped with a variety of ports and jacks for connecting computer accessories to the monitor. Make sure that the display you choose comes with the ports that you need or will require.

Installing your Dell or Hitachi plasma display monitor should not be difficult. Just gather the tools needed and follow these steps, and your new pc monitor will be up and running in no time.

Step 2: Determine the area of the wall that you want to install your plasma monitor. Make sure the area that you have chosen does not have any water pipes or electrical wires in it.

Clearing a gas plasma monitor off dust, fingerprints and other contaminations is an important maintenance routine for your computer monitor.Cleaning your monitorat least once a month will help maintain clear visibility while using your computer.

If you have a plasma monitor that is no longer in use, one solution is to turn it into a TV. It would make a good TV since many of them have large screens. To achieve this, you would need a video cable such as an HDMI or DisplayPort and a cable TV box.

DisplayPort- it looks similar to HDMI but transmits more signals, or you can achieve higher bandwidth with it. It carries both digital and analog signals, supports high resolutions, sound and video.

Do you own a plasma emission monitor? You should know about common problems you might encounter with it, including flickers or stutters, dead or stuck pixels. I will also include their solutions in this section.

Screen burn-in is a discoloration on some areas of your plasma computer monitor. It shows the remnants of images displayed for an extended period. There are many factors that can cause screen burn-in, including the use of a static image on a monitor for a long period of time.

The image is burned into the monitor, which reduces the life expectancy of the monitor. Screen burn-in can only be prevented by not leaving the display showing the same image for extended periods.

Yes, plasma monitors are suitable for gaming. They have one of the highest contrast ratios, are available with high refresh rates, have large screens and wide viewing angles too.

These great specs have gamers who want to invest in plasma monitors. They also produce better quality images which are great for entertainment like watching sports, movies, and gaming. The best plasma screens support high resolutions such as 1680 x 1050 and 1920 x 1080, which provide sharp details of things.

Businesses are becoming busier and busier, and as such, they are beginning to look for certain products to make life easier. One of the main products that businesses require is a plasma monitor for use in business meetings.

LCD (liquid crystal display) monitors use liquid crystals to produce images on the screen, while plasma monitors use gas-filled cells to produce images.

Plasma screens, on the other hand, use tiny cells with gas that gets excited when electricity is passed through them. This, in turn, produces light which lights up the color pixels.

PLATO. This is one of Bitzer"s own illustrations of his invention from his original patent, which was filed in 1966 and eventually granted in 1971. Like my illustration above, you can see that the screen consists of multiple, gas-filled display "minicells" (the orange blobs in the central blue section). In front and behind this are two sets of electrodes, one running horizontally and the other vertically. Each gas minicell ("blob") in the screen can be fired by energizing the appropriate pair of electrodes either side. Since each minicell can only be either on or off, this screen can display monochrome pictures but not color ones.

Artwork: Bitzer"s original plasma display. From US Patent 3,559,190: Gaseous display and memory apparatus by Donald Bitzer et al, University of Illinois, courtesy of US Patent and Trademark Office.

in 2014 when first Panasonic and then Samsung (which, between them, made about three quarters of all plasma sets) abandoned the technology and better-funded, more-innovative rival technologies (LCDs and OLEDs (organic LEDs)) took over.

Here are 20 examples of plasma. Plasma is the most abundant state of matter in the universe. Unlike solids, liquids, and gases, plasma consists of free electrons or ions that aren’t bound to an atomic nucleus.

Plasma displays properties that distinguish it from other states of matter.Because it consists of charged particles, plasma has innate electrical conductivity.

Overall, most plasma is electrically neutral. That is, it contains the same amount of positive and negative charges. However, there can be regions of current density that form filaments (visible in a plasma ball or aurora) or magnetic ropes. Also, there is non-neutral plasma that consists entirely of a single charge (e.g., particle beams or the electrons in a Penning trap).

In biology, plasma has a different meaning than in physics. Plasma is the liquid portion of blood. It is 92% water and accounts of 55% of blood volume.

Sturrock, Peter A. (1994). Plasma Physics: An Introduction to the Theory of Astrophysical, Geophysical & Laboratory Plasmas. Cambridge University Press. ISBN 978-0-521-44810-9.

![]()

The first plasma displays that were available were technically televisions because they did not have TV tuners. The television tuner is the device that converts a television signal from a cable wire or any other means into a video image. Since the plasma displays lacked tuners, they were used as simple monitors that display a standard video signal. Recent developments have made inbuilt digital television tuners. Plasma Display Panel is an emissive display which means that the panel itself is the light source. In comparison to a transmissive display, where the light source is separate and light is passed through the panel to create an image, PDPs are extremely bright and light-tolerant flat panel display technology that utilizes a gas discharge principle thus also known as gas discharge display.

Plasma gives a big display screen length which degrees normally from 42” to 63”. It works properly in dimly lit rooms tremendous for looking movies, gives excessive assessment ratios, gorgeously saturated shades, and permits for extensive viewing angles each seat inside the residence is a tremendous one.

Plasma Panel DisplayPlasma Display Panel is composed of two parallel sheets of glass that enclose a mixture of discharge gases composed of helium, neon, and xenon.

Advantages of Plasma Display Panel :Plasma Display Panel are thin lightweight and take up less space than other displays which makes them easy to install anywhere.

Earlier generation Plasma Display Panel were more susceptible to screen burn-in and image retention, recent models have a pixel orbiter that moves the entire picture faster than is noticeable to the human eye, which reduces the effect of burn-in but does not prevent it.

Due to the strong infrared emissions inherent in the technology standard Infrared repeater systems cannot be used in the viewing room. A more expensive “plasma compatible” sensor needs are used.

Plasma is the state of a matter where atoms are ionized by adding energy. In the context of plasma display technology, a plasma display is a computer video display in which each pixel on the screen is illuminated by a tiny bit of plasma or charged gas, very similar to the way that a fluorescent or neon light works.

The plasma display technology demonstrates inherent engineering advantages over conventional CRTs (Cathode Ray Tubes) and LCD (Liquid Crystal Display) panels. Plasma displays are thinner than a CRT and brighter than LCD panel. They also offer a very wide viewing angle that is free from distortion at the edges of the screen.

Plasma TV production ended in 2015. However, they are still being used and sold in the secondary market. As a result, it"s helpful to understand how a Plasma TV works and how it compares to an LCD TV.

Within each cell, a narrow gap that contains an insulating layer, address electrode, and display electrode, separates two glass panels. In this process, neon-xenon gas is injected and sealed in plasma form during the manufacturing process.

When a Plasma TV is in use, the gas is electrically charged at specific intervals. The charged gas then strikes red, green, and blue phosphors, creating an image on the screen.

Each group of red, green, and blue phosphors is called a pixel (picture element — the individual red, green, and blue phosphors are called sub-pixels). Since Plasma TV pixels generate their light, they are referred to as "emissive" displays.

Plasma TVs can be made thin. However, even though the need for the bulky picture tube and electron beam scanning of those older CRT TVs is not required, Plasma TVs still employ burning phosphors to generate an image. As a result, Plasma TVs suffer from some of the drawbacks of CRT TVs, such as heat generation and possible screen burn-in of static images.

Unlike a Plasma TV, since there are no phosphors that light up, less power is needed for operation, and the light source in an LCD TV generates less heat than a Plasma TV. There is no radiation emitted from the screen.

Plasma TVs are more vulnerable to burn-in of static images. However, this problem diminished over the years due to "pixel orbiting" and related technologies.

Potentially shorter display lifespan. Early models had 30,000 hours or 8 hours of viewing a day for nine years, which was less than LCD. However, screen lifespan improved and 60,000-hour lifespan rating became the standard, with some sets rated as high as 100,000 hours, due to technology improvements.

Narrower effective side-to-side viewing angle than Plasma. On LCD TVs, it is common to notice color fading or color shifting as you move your viewing position further to either side of the center point.

An LCD TV was typically more expensive than an equivalent-sized (and equivalent featured) Plasma TV. However, that is no longer a factor, since companies have ceased manufacturing Plasma TVs.

Although it was possible to incorporate 4K resolution display capability into a Plasma TV, it was prohibitively expensive. When the sales of Plasma TVs started declining, TV makers decided against bringing consumer-based 4K Ultra HD Plasma TVs to market, which was another factor in their demise. The only 4K Ultra HD Plasma TVs manufactured were for commercial application use.

Plasma and OLED are two types of visual displays. You normally see these terms when comparing plasma TVs and OLED TVs. OLED, which stands for organic light-emitting diode, is a more common display type that"s an improvement on the older LCD technology. The lesser-used plasma display panels use plasma. We compared plasma and OLED technology to help you decide which technology is best for your video viewing.

Compared to the differences between OLED and LCD, and plasma and LCD, plasma and OLED are more similar. In other words, OLED and plasma are more like each other than are either with LCD.

The practical result is that most peoplecould view either and not notice much of a difference beyond the price tag. Plasma screens have some slight advantages over OLEDs, particularly in terms of longevity. Their colors are less likely to fade over time.

OLEDs display darker blacks and aren"t vulnerable to radio interference from other devices that are operating nearby. They"re also easier to find since most manufacturers have stopped producing plasma screens.

Both technologies better portray blacks than older tech, both are available in high resolution and large screen sizes, and both can be used for years without suffering color degradation or screen burns. The refresh rate on plasmas and OLEDs is also relatively high compared to older screen technologies, so screen flicker is usually not a problem with either.

Where OLED uses organic material to light up the screen, plasma uses ionized gases. The color of an OLED screen fades over time, so it won"t last as long as a plasma screen. However, because plasma relies on gases inside the screen to light up the images, you can"t use a plasma screen at high altitudes or the pressure difference between the environment and the inside gases damages the set.

Plasma TVs are more susceptible to interference, given the ionized gases. OLED doesn"t suffer from this problem, so you can listen to AM radio around an OLED TV without any radio-frequency interference.

OLED technology turns off pixels representing black, so the blacks on an OLED screen are 100% black. Plasma screens don"t have that level of precision, so blacks aren"t as black on a plasma screen as they are on an OLED screen.

Plasma screens are heavier than OLEDs because they are covered in glass, which also makes them more susceptible to breaking. OLEDs use a thinner protection that makes them more flexible.

If you have small kids or want a lighter set, and breakage is a concern, go with the OLED. At the very least, it will be easier to get into your house than a plasma screen with its thicker glass display.

Television manufacturers stopped making new plasma units years ago, so your best bet to find one is probably secondhand through services like eBay and Craigslist. OLED TVs, however, are available at major retailers from a variety of companies.

If you have a favorite (or at least preferred) TV maker, you"ll have more options with OLEDs than plasmas because of the greater number available. With plasma screens, you have limits based on availability from local sellers.

Plasma TVs have all but disappeared as OLED and other technologies such as Super-AMOLED have taken over the scene. In 2014, because of production costs and because the demand for other screen technologies grew, Panasonic, LG, and Samsung stopped producing plasma TVs.

OLEDs have advantages over plasmas, however, including lighter weight, less fragile construction, and resistance to environmental interference. You"re better off going with OLEDs instead of the antiquated and somewhat temperamental plasma technology.

We"ve already learned about that funky fourth state of matter: plasma. The word plasma itself has entered our vocabulary with much more frequency thanks to the invention of plasma TVs. Do plasma TVs have anything to do with plasma the state of matter? Yep.

The basic idea of a plasma television is to illuminate tiny colored fluorescent lights to form an image. Each display is made up of millions (sometimes even billions) of pixels, which are just tiny dots on the display. In reality, these pixels are made up of three fluorescent lights: a red light, a green light, and a blue light (RGB for short). By combining these colors in different proportions and intensities, the television screen can produce the entire color spectrum and form our spit the latest reality show or made for TV movie.

The plasma display might seem like a newer technology, but it was actually invented way back in 1964 by professors Donald Bitzer and Gene Slottow at the University of Illinois.11Their first display could only emit green or orange light, but by 1992 the world"s first full-color plasma display was ready for its world debut.

One of the main components of a plasma display is plasma. Shocking. We learned earlier that plasma is similar to the gas phase, but the electrons are free to move around positively charge ions of the nucleus. Basically, plasma is a gas with electrons that bounce all over the place.

The inventors of the plasma display realized that under normal conditions a gas is made up of mainly uncharged particles. The individual gas atoms include equal numbers of protons and electrons, making the net charge zero. By tossing in an electrical current (and therefore a bunch of electrons), they could turn a normal gas into a plasma. This explains so much, like why you have to plug in a TV in order for it to work. Eureka.

How do the electrons convert an otherwise normal gas into this weird fourth state of matter? The extra electrons collide with the atoms. This knocks other electrons off of the atom orbitals, further altering the charge balance. The sample of gas has now become a sea of cations and crazy fast electrons. Having charges flying around means we have a plasma.

Xenon and neon atoms are the elements used in most plasma displays. They release light photons when electrons a knocked off of their orbitals. To make a display, hundreds of thousands of tiny cells containing these gases are positioned between two glass plates along with long electrodes on both sides of the cells in a crisscross construction. The entire set-up is insulated with a dielectric material and covered by a magnesium oxide layer which gives an added layer of protection.

When an electric current flows through the gas in the cell it releases ultraviolet light particles (called "photons") that interact with the material coated on the inside of the cell which in turn gives off visible light photons. Voilà, we have a picture on a screen that we can see. Magical, right?

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

Before flat-screens and crystal displays, most TVs and monitors featured CRT (Cathode Ray Tube) technology. In CRTs, individual pixels comprise a red, blue, and green phosphor component. Depending on the intensity of each phosphor component, the pixel appears to the human eye as a unique color.

Plasma displays use plasma, a gaseous substance containing free-flowing ions. When the plasma is not in use, the particles in the plasma are uncharged and display nothing. With the introduction of an electric current, the ions become charged and begin colliding, releasing photons of light.

This is a very simplified version of how a plasma screen works. However, the main thing to understand is that plasma screens use phosphor material (like CRTs) to turn those photons into images.

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

First, let"s tackle plasma screen burn-in. Remember why CRTs experience image burn? When a still image remains on the screen for too long, the phosphor components in each pixel wear out at different rates. The uneven burn rates leave behind a ghost image, forever etched into the screen.

Plasma screens also suffer from phosphor deterioration. Plasma burning occurs when pixels on the screen are damaged through long exposure. The phosphor loses its intensity and only shows the light it was fed repeatedly. In this case, the still image, which causes the burn.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

The other thing to consider is that LED and OLED image burn-in, when it happens, is irreversible. That"s because of how LED and OLED screens work. Individual pixels within an LED display decay when they emit light.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

My personal rule of thumb is to turn off the display if I plan on being away for more than 15 minutes. That way, it is difficult to get caught out, plus you save yourself money on electricity costs and monitor or TV wear and tear.

Another prevention method is to reduce screen contrast as much as you can. Unfortunately, most screens aren"t calibrated correctly, often pushing the contrast and brightness settings too high.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

Other modern screens feature built-in screen refresh functions that the manufacturer will advise using to remove image retention and image burn issues.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

If you have television burn-in, you can attach a laptop to your TV using an HDMI cable, extend your desktop to the television, and share the white screensaver. Hopefully, that will shift your television burn-in.

The structure of PDPs consist of multiple layers of various materials, as seen in figure. The inner most layer consists of a series of 3 cell compartments which make up a single pixel of the projected image. Each cell contains a gas mixture of noble gases, usually neon with 10-15% xenon, and is responsible for producing one of the three primary colors, red, blue, or green. Outside of these cells is the layer of dielectric material and electrodes that provides energy to each of the 3-cell chambers. The dielectric layer allows for more charge to gather between the electrodes and the cells. On the projection side of the display, the electrodes are vertical and transparent. These electrodes are known as the transparent display electrodes and are coated in magnesium oxide, while the back electrodes are known the address electrodes. The outer most part of the plasma display are the glass layers, one of which the image is shown on.

The way plasma displays work is similar to how a florescent light bulb works, gas is used to excited phosphors which produce visible light. In plasma displays a voltage is given to the gas within the cells and the gas becomes ionized, creating plasma. The plasma itself does not provide the light energy itself, rather it produces ultraviolet, UV, light that excites the phosphors that are coated on to each cell. The color that is produced (either red, green, or blue) is dependent on the phosphor. Red light is produced by phosphors such as (Y,Gd)BO3:Eu, YBO3:Eu, and Y2O3:Eu. Blue light is produced by phosphor such as (Y,Gd)(V,P)O4and BaMgAl14O23:Eu. Green light is produced with phosphor such as Zn2SiO4:Mn, BaAl12O19:Mn, and SrAl12O19:Mn.By varying the intensity of the red, green, and blue cells, all colors in the spectrum can be achieved.

In order to start this process, a control box within the display gives power to both electrodes at the specific intersection that a pixel is needed to be illuminated. The electrode then provides a voltage that adds electrons to the gas mixture. The addition of electrons causes collisions between the added electrons and the neutral atoms of the gas. These atoms lose some of their electrons which causes them to ionize and have a net charge, creating plasma. As current from the electrodes goes through the cells, the now positive ions and electrons move to the respective side of the current, positive ions move to the negative side and electrons move to the positive side. During this movement more collisions occur between the electrons and ions. This creates energy and causes the electrons that are in the ion to get to an excited state briefly. When these electrons come down to the lower orbital of less energy, they release the excess energy in the form of an UV photon. The energy from the UV photons cause the phosphors in the cell to be excited and emit light in the visible spectrum, a seen in figure 2. The combination of numerous cells emitting varying degrees of light and color creates the digital image that occurs, and the constant turning off and on of electrodes allows for these images to move.

Plasma display module is a flat panel module mostly used in televisions. A plasma display module contains a plasma that consists of electronically charged ionized gases. Plasma display modules have a wide colour gamut and very low luminance. A plasma display module produces deeper black, which enables a superior contrast ratio. The colour reproduction of a plasma display module is very similar to CRTs as it uses similar phosphors.

Moreover, plasma display modules do not suffer image degradation like LCDs. Plasma display modules have a wider viewing angle as compared to LCDs. Plasma display modules provide improved display performance, have faster response time, high refresh rates and superior uniformity. Plasma module displays are tailor made to stimulate low-temperature plasma systems and sources. Plasma display modules perform in all the space dimension, which include 1D, 2D and 3D.

Plasma display modules are a set of parallel conductors placed at right angles to each other and are deposited on a glass plate with a very small space between plates that are filled with gas. Each intersection of the two-placed conductor defines a single cell. These single cells are energised to produce a gas discharge, thus forming a dot-matrix display. Plasma display modules are filled with tiny lined cells with ionised phosphor gas. One pixel of a plasma display module comprises three cells. These cells sandwiched between x and y axis panel are selected by charging x and y electrodes. The charge enables the gas to emit ultraviolet light, which causes phosphor to generate colour. The amount of charge and combination of three colours, i.e. red, blue and green, determines the colour displayed on the plasma display module. Plasma display modules are of high quality and for large video formats. Plasma display modules are mostly used for high-definition DVDs. Several developments in plasma display modules with reference to technology, the steady growth of the market, along with recent developments & innovations are among factors expected to drive the global plasma display market during the forecast period.

Features, such as enhanced video quality, improved performance and faster response time, have increased the adoption of plasma display modules and are significantly contributing to the growth of the global plasma display module market. The increasing adoption of large screen TVs and laptops is significantly contributing to the growth of the global plasma display module market.

Challenges associated with the plasma display module market are flickering issues, heavy weight as compared to LED displays and loss in the luminosity of phosphorus over the time. These are some of the critical issues adversely affecting the growth of the global plasma display module market during the forecast period. However, vendors are continuously focused on improving plasma display modules and are expected to overcome these challenges during the forecast period.

The plasma display module market is segmented into North America, Latin America, Europe, CIS & Russia, Japan, APEJ and Middle East & Africa. Presently, APEJ holds the largest share of the plasma display module market due to an increase in disposable income in emerging countries.

The research report presents a comprehensive assessment of the plasma module market and contains thoughtful insights, facts, historical data and statistically supported and industry-validated plasma display module market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to plasma display module market segments such as geographies, application and end-user.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey