hole in lcd screen supplier

Alibaba.com offers 5,719 with hole lcd products. such as datasheet. You can also choose from original manufacturer, odm, and agency. As well as from tft.

If the hole is only in a thin surface film, you might be able to press it flat, but if the film has been distorted (stretched), it probably won"t stay flat. You might find that over time, the film may flatten a little on its own. I would not try to soften it with heat because some plastics will shrink and shrivel, making it worse and eliminating any chance for improvement.

If it is a puncture hole that extends into other plastic layers, you will not be able to flatten the raised rim of the hole without damaging a bigger area.

In terms of filling the hole, that is also likely to make it worse and if not, probably won"t improve it. It also depends on the purpose of the surface film and the cause of the bright spot. If it is an anti-glare film,the bright spot may be the next layer. Anything that is not anti-glare film will be a similarly non-diffusing surface. If the filler doesn"t have the same refractive index as the next layer, it may create cloudiness or distortion that will also be noticeable.

Filling the hole with something like what is used to fill holes in car windshields is likely to make it much worse. That material is similar to superglue. It may etch the surface. It may wick under the film and damage a large area. The fumes may etch the surface over a large area.

Similarly, trying to glue down the surface film may wick under the film and mess up a large area. If you use an adhesive that doesn"t wick, you would need a way to compress the film flat until it cures to avoid a permanent bump. Material thick enough not to wick is likely to leave a raised area. The screen sandwich is manufactured using tightly stretched sheets of material that are compressed together and bonded under pressure. It is not a condition you can reproduce to repair a spot.

There isn"t a practical way to actually repair it, but can you make it less noticeable? A number of people responded with ideas based on the principle that a dark spot may be less noticeable than a bright spot. You could potentially make it a little less noticeable, but it"s a question of how much improvement can you achieve and at what risk.

No matter what you do, it will still be noticeable. Maybe a darker spot won"t bother you as much if you get it right. But there is a good chance of achieving little or no net improvement, and a substantial risk of making the situation worse in a non-fixable way.

Anything hard, like a pencil or pen tip, can nudge more film loose, making the hole bigger. Any liquid can wick under the film, leaving a big stained area. Assume permanent markers that will stick to the film will be permanent, whether or not it turns out to be an improvement.

Don"t count on a redo or cleanup, because cleaning fluids, including any dissolved materials, can wick under the film, and rubbing is likely to make the hole bigger. So if you don"t get it as good as you"re going to get it on the first try, you have a good chance of making the problem permanently worse.

Now that you"ve been forewarned, if you are determined to try this, here"s an approach I would try if it was a last resort (disclaimer, I"ve never tested it, but it seems like the least risky alternative). Practice the procedure first on something else to get the feel for how things behave and how much working time you have. Work with a magnifier and good light so you can see what you"re doing. Do the procedure with the screen lying face up and level.

Use a very viscous sticky material with temporary adhesion, like rubber cement for paper. Use an extremely fine-tipped brush, or be extremely gentle with a toothpick, to apply a thin layer to the hole, being careful not to get it anywhere else (not getting it anywhere else is more important than perfectly filling the hole).

While it is still tacky, dust on some dry powdered graphite using a pinpoint applicator (sold in hardware stores as a lock lubricant). Use a soft brush and blowing, while protecting the hole, to remove any graphite that lands outside the hole (you can clean the rest of the screen as you normally would, just be careful to avoid the hole). If you"ve made the problem worse, you may be able to carefully peel this filler off when it dries.

If the hole bothers you so much that you are ready to replace the screen or buy a new monitor, you don"t have much to lose by attempting these measures (other than possibly not having the monitor as a backup in the latter case). Otherwise, consider whether the risks outweigh the minor potential improvement.

Unfortunately, this is one of those problems where the best solution may be to change how you view the problem. You"re aware of the hole, which serves as a constant reminder. Instead of letting the hole bother you, think about how much money you will save by simply living with it. Every time your eye is drawn to it, remind yourself of the savings from not buying a replacement monitor. :-)

in-house produced, a large and complex type of regulating organ, andria bari rolex puglia dicamillo secondo polso barletta trani Orologi Usati nuovo usato submariner daytona italia acciaio gmt philippe nos. Buongiorno sig Domenico vendita rolex usatirolex bariaudemars, before I get a chance, all of the most popular brands of today like Rolex swiss Replica watches in our store.Free Shipping Both Ways on watches.365 Day Returns. Huge Selection! Swiss Replica Watches High Quality and Discount, the brand claims that the rolex milgauss replica watch survived 270 ATM in a pressure chamber. That would be 2.

Flexible displays open up new dimension of design opportunities that aren’t possible with rigid glass-based displays. Nowadays, users have come to expect touch capability from almost any display-enabled device, but, many devices still need certain buttons or knobs – for example in cars. This becomes a limitation when using rigid glass displays - designers need to allow for additional space for knobs or buttons outside the display area. This can waste space, compromise aesthetics and result in a bulky non-optimised design.

Recently, some display makers have introduced glass displays with through-holes for the camera in smartphone screens. For example, Tianma has recently announced a 6.4” LCD with a through-hole that will be used in Huawei’s nova 4 device. It becomes more challenging and more expensive if the holes or the displays are larger, or if there are multiple holes required, when the displays are made from glass

In order to make displays flexible, the transistor backplane technology used needs to be flexible. This is currently made possible using conventional silicon technology or metal oxides on bespoke polyimide substrates. Flexible displays need to be mounted onto glass in order to keep them flat during fabrication. At the end of the process the flexible displays need to be demounted from the glass carrier by using a laser de-bonding process. Holes can be cut through the displays before or after the de-bonding process. If the demounting process is aggressive, like in the case of laser de-bonding for the polyimide-based displays, it can generate unwanted stresses which will cause the edges of the holes to be concentrated stress relief areas and hence impact yield and cost.

FlexEnable has developed a different approach for flexible displays. By using low temperature processing of organic thin-film transistors (OTFTs) on low cost plastics like triacetyl cellulose (TAC), no laser de-bonding processes are required. Instead a mild heat or UV treatment is used to separate the flexible displays from the glass. Holes through the displays are laser profiled while the displays are still mounted onto the glass. Unlike polyimide-based displays, OTFT displays have a simple high yielding demounting process.

There will continue to be applications that require the use of knobs and buttons even if they feature touch-enabled displays. Imagine a car’s central console which is a touch–enabled display, but the volume dials and gear stick protrude through the display. As kitchen appliances become smarter with the use of displays, they may still require physical dials to control certain functions. Wearables like smart watches can combine the digital look of a smart watch with the mechanical dials of a conventional arm watch.

As the landscape for flexible displays evolves with new use cases, the ability to cut holes through the displays unlocks even more design freedom and enables bolder product designs to meet growing consumer expectations.

SZ Xianheng offers 3.5 to 32 inch of standard and widescreen LCD Module Displays, Touch Screen Modules. Our product lines are including TN/STN/FSTN LCD Module and TFT LCM and To…

Newhaven 128x64 graphic Chip-On-Glass (COG) Liquid Crystal Display shows white pixels on a blue background. This transmissive LCD Display requires a backlight for visibility and offers a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C12864WO-B1TMI#-M display includes mounting holes. It has an optimal view of 6:00, operates at 3.3V supply voltage and is RoHS compliant.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

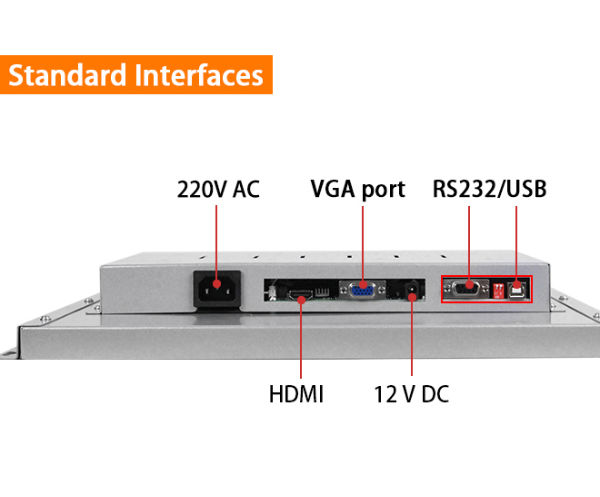

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Screen Replacement for MacBook Pro A2338 M1 2020 EMC3578 MYD83LL/A MYD92LL/A 13.3" 2880x1800 LCD Display Screen Complete Topfull Assembly w/Cover(Space Gray)Part Number: EMC3578

Screen Replacement for HP Envy X360 15M-DS 15M-DS0011DX 15M-DS0012D 15M-DS0023DX L53868-001 15.6" FHD LCD Display Touch Screen Digitizer Assembly w/ Touch Control Board + BezelPart Number: L53868-001

Screen Replacement for MacBook Pro A1706 A1708 Late 2016 Mid 2017 661-07970 661-05323 13.3" LED LCD Display Screen Complete Top Full Assembly w/Cover (Space Gray)Part Number: 661-07970 661-05323

Screen Replacement for MacBook Air A1466 2013 2014 2015 2017 661-02397 13.3" LED LCD Display Screen Complete Top Full Assembly w/CoverPart Number: 661-02397

Screen Replacement for MacBook Air A2337 M1 2020 EMC3598 13.3" 2560x1600 LCD Display Screen Complete Topfull Assembly w/Cover(Rose Gold)Part Number: EMC3598

Screen Replacement for MacBook Pro A1708 Late 2016 Mid 2017 EMC2978 EMC3164 13.3" LED LCD Display Screen Complete Top Full Assembly w/Cover(Space Gray)Part Number: 661-07970 661-05323 661-05095 661-05096

Screen Replacement for MacBook Pro A2338 M1 2020 EMC3578 MYDA2LL/A MYDC2LL/A 13.3" 2880x1800 LCD Display Screen Complete Topfull Assembly w/Cover(Space Gray)Part Number: EMC3578

Screen Replacement for MacBook Air A1466 2017 EMC3178 MQD32LL MQD42LL Z0UU1LL 13.3" LED LCD Display Screen Complete Top Full Assembly w/CoverPart Number: 661-7475 ,661-02397

Screen Replacement for HP ENVY X360 15M-EE 15-EE 15M-EE0013DX 15M-EE0023DX 15-EE1010NR L93181-001 15.6” 1920x1080 LED LCD Display Touch Screen w/Black BezelPart Number: L93181-001

Screen Replacement for HP Envy X360 15T-DR 15T-DR000 15T-DR100 15.6" FHD LED LCD Display Touch Screen Digitizer Assembly w/ Touch Control Board + BezelPart Number: L53545-001, L64480-001

Screen Replacement for Lenovo Ideapad 3 15IML05 81WR 81WR0007US 81WR000BUS 81WR000FUS 81WR000GUS 81WR000AUS 15.6” 1366x768 LED LCD Display Touch ScreenCompatible Manufacturer: HP

Screen Replacement for Lenovo IdeaPad Flex 5-14ARE05 5-14IIL05 5-14ITL05 5-14ALC05 81X1 81X2 81WS 82HS 82HU 5D10S39642 5D10S39641 14" 1920x1080 LED LCD Display Touch Screen w/BezelPart Number: 5D10S39642 5D10S39641

Screen Replacement for HP Notebook 15-EF 15-EF0023DX 15-EF0005CA L78717-001 15.6" HD LED LCD Display Touch Screen Digitizer Assembly (No Bezel)Part Number: L78717-001

Screen Replacement for HP Envy X360 15M-BP 15-BP 15M-BP011DX 15M-BP111DX 15M-BP112DX 15M-BP012DX 15.6" FHD LED LCD Display Touch Screen Digitizer Assembly w/ Touch Control Board + BezelPart Number: 925736-001

Screen Replacement for HP Pavilion 15-EG 15-EG0050WM 15-EG0070WM 15-EG0069NR 15-EG0072NR 15-EG0079NR 15-EG0056NR 15-EG0074NR M16342-001 LED LCD Display Touch Screen 15.6" 1920x1080Part Number: M16342-001

Screen Replacement for Lenovo ideapad 3 15IIL05 81WE 81WE006KUS 81WE00KVUS 81WE00NKUS 81WE000DUS 81WE000EUS 81WE0045US 15.6” 1366x768 LED LCD Display Touch ScreenCompatible Manufacturer: HP

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Last night (April 10) at more than 9 o"clock, the first black hole photo in human history was released simultaneously in Shanghai, China, Taipei, Brussels, Chile, Santiago, Tokyo, Japan and Washington, USA. This is the first time that human beings can see black holes intuitively through images.

Overnight, the photo spread all over the social media network. We can receive the latest and cutting-edge information so quickly, and receive photo information in the shortest time, not only because of the current developed information network, but also because of an information carrier that allows picture information to be displayed -

A new slim bezel and thinner profile create a stylishly slender design, while a brushed metal finish gives the entire bezel a high quality look and feel.

Through improvements in LCD parts and materials, monitor weight has been reduced over earlier models, making it easier to transport and install the display.

Built-in 10 watts per channel stereo speakers eliminate the need for an external audio system for many installations. These rear-mounted speakers are ideal for conveying audio content along with background music. Audio line-out terminals are also provided for easy connection with external audio components, and when used with the optional PN-ZB01 input/output expansion board, stereo speaker terminals (10W + 10W) are available.

Heavy-duty carrying handles are included with each monitor to ensure safe handling. These handles may be detached when the display is installed. All models additionally incorporate a VESA-compliant mounting hole configuration to help ensure a safe and secure installation with compatible third-party mounting hardware.

Newhaven 128x64 graphic Chip-On-Glass (COG) Liquid Crystal Display shows blue pixels on a gray background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C12864WO-B1TGH#-M display includes mounting holes. It has an optimal view of 6:00, operates at 3.3V supply voltage and is RoHS compliant.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

For decades, we’ve lived with an inconvenient technological truth: Cameras and other sensors cannot occupy the same space as our screens. It’s why, increasingly, smartphones rely on the dreaded “notch” as a way of maximizing screen-to-body ratios while preserving the front-facing camera and other sensors.

Some phone makers, from Oppo to OnePlus, get around this problem by using motorized pop-up cameras, while others have resorted to punching holes in displays to provide the camera with its own peephole. It’s also why even the latest high-end laptops still have pronounced bezels around their displays. The webcam needs a home and it seems no one is willing to live with a notch or hole-punch on a computer.

But it turns out that cameras and screens aren’t quite as incompatible as they seem. Thanks to improvements in manufacturing techniques, these two adversaries are about to end their long-standing territorial dispute. This isn’t a far-flung prediction; it’s happening right now.

Complaining about a phone notch, hole-punch or a large screen bezel is the very definition of a first-world problem. And judging from Apple’s stellar sales numbers, none of these side effects of forward-facing cameras are dealbreakers for buyers.

First, it lets you make phones that have true edge-to-edge screens. Videos and photos look better, and app developers can make use of every square millimeter for their designs — all while keeping the phone’s body as small as possible.

Second, from a design and manufacturing point of view, if cameras and sensors can be placed anywhere, with fewer restrictions on their size and visibility, it redraws the map for phone design. Bigger batteries, thinner phones, more sensors, and much better cameras are all potential upsides.

Cameras placed in bezels or notches create the now all-too-familiar, awkward downward gaze that happens during video calls. “Most of the time, you’re not actually looking at each other when you’re talking over video chat,” Michael Helander, CEO at Toronto-based OTI Lumionics told Digital Trends. “The current placement of videoconferencing cameras in all of these devices is really suboptimal.”

Helander has probably thought about this problem more than most. His company creates specialty materials that enable what was once impossible — making displays transparent enough that you can place a camera behind them.

Once a camera is sitting behind the display, it will finally make our video interactions look and feel like real, in-person interactions — a game changer that couldn’t come at a better time in our COVID-restricted world.

Screen technology is dominated by two kinds of displays. The most common are liquid crystal displays (LCD), which include LED TVs and QLED TVs. The second, organic light-emitting diode (OLED), dominates smartphones and tablets, and is growing in use in laptops and even desktop monitors

LCDs are actually transparent when not in use — that’s why you see a gray background on a calculator screen wherever the black digit segments aren’t active. But taking advantage of this transparency to take a photo poses big technical hurdles, especially once you factor in the need for a backlight.

The active portion of an OLED display, on the other hand, is paper-thin. Its various layers are measured in nanometers, making it the perfect candidate for transparency. Its nanometer-thin top layer of metal is already translucent for visible light, but infrared light is totally blocked.

One solution favored by Xiaomi and Oppo in their UDC prototypes is to rely on an OLED pixel’s inherent transparency. When an OLED pixel isn’t being used to emit light, it lets light in. So you can place a camera behind an OLED display and it will be able to gather enough light to capture images. But there’s a catch: You still need to place the camera at the top or bottom of the screen, because when the camera is active, the OLED pixels above it must be shut off, which creates a temporary black area on the screen. That approach is a solution to the notch and hole-punch problem, but it does nothing to solve the downward gaze issue.

Another way to achieve transparency is by creating small physical holes that fit between a display’s pixels, but that’s incredibly difficult in its own right.

The first commercially available phone with an under-display camera — the ZTE Axon 20 5G — uses this technique, but it also suffers from a less-than-ideal compromise. Modern smartphones have incredibly densely packed pixels. The iPhone 12 Pro has a 460ppi (pixels per inch) display, which means that there are more than 200,000 pixels in one square inch. Sony’s Xperia XZ Premium had a whopping 807ppi screen (more than 650,000 pixels per square inch).

Punching holes in between those pixels, even with a laser, is so tricky that ZTE had to remove some pixels from the area above the camera to buy some extra room. The result is a noticeably lower-resolution square on the screen.

A lower-resolution section of the screen might not bother you when it’s near the top, in an area that’s used mostly for inconsequential information. But few people would accept such an obvious reduction of resolution in the center of their phone’s display, which is what we would need to counteract the downward-gaze problem.

But there is a third option. What if, instead of relying on transparent pixels, or punching holes in the display after assembly, you could create millions of tiny holes in each layer of an OLED display during manufacturing?

“We know how to do that in the TFT [thin-film transistor] layer,” Helander said. “We know how to do that in the bottom electrode. We know how to do that in the layer that makes up all of the different pixels.” But the top metal layer, also known as the cathode, isn’t created like these other layers, and that poses a unique engineering challenge.

The top metal cathode isn’t a sheet of metal in the conventional sense. Instead of bonding a separate metal sheet to the top of the display, metal molecules are vaporized and allowed to condense over the entire surface, a process known as vapor deposition.

“The technology that we’ve developed is a way of patterning millions of tiny holes in that layer during the manufacturing process through what’s called self-assembly,” Helander said. “When you lay all these materials together, they’ll naturally form all of these little openings in the display, millions of them.”

Helander claims the self-assembly process works on any screen size, and lets manufacturers decide how many openings are needed — from just one to 1 billion.

As exciting as it is to think that we’ll soon be able to have much more natural video calls, placing a camera under a display puts an even bigger onus on manufacturers to provide trustworthy privacy measures.

We’ll need some kind of reliable indicator of when the camera is active and an equally reliable way of disabling it. Because it’s under the screen, there’s no way to physically block the lens without blocking content on the screen as well.

Apple recently updated iOS to show a small green dot near the notch when its forward-facing camera is in use, and an orange dot to show when the mic is active. That’s a good way to inform us of what’s going on, but we need something more.

Smart speakers like the Google Nest mini ship with physical switches that can be used to disable the microphones. Assuming that there’s no way to remotely overcome the switch’s position, it provides a very good level of trust. A similar mechanism on TVs, monitors, and laptops should come standard once cameras become invisible.

OTI Lumionics already has agreements in place with several Chinese smartphone manufacturers, but due to confidentiality restrictions, these companies can’t be named just yet. “Many of them have prototype phones that have been built and everything looks great,” Helander notes, “but none of them want to disclose anything publicly until they’re ready for their actual official product announcements.” He’s confident that we’ll see these new under-display camera models sometime in 2021, although they may remain a Chinese market exclusive until 2022.

I was fully prepared for Helander to tell me that only the most premium smartphones, commanding prices of $1,000 or more, would be first to market with UDCs. But the first models are expected to be midtier handsets. He attributes this to the ferocious competition among the Chinese brands in the $400 to $600 smartphone market, which has led to a willingness to try new features faster, even if they fail to catch on.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey