lcd panel driver board burnt factory

I have a Fujitsu e8410 that I have given up to repair. It was reballed twice. So it was broken down to harvest the usable parts. The step by step guide of breaking down a laptop is available. The crown of the harvest was the magnesium alloy encased 15.4 LCD panel, capable of a resoultion at1280x800 WXGA , and with Crystal View. It will be such a shame to put the useful parts into landfill!!

This project serves those who are looking forward to have an external or secondary LCD monitor that is HDMI capable, USB photo frame or media player, without breaking the bank.

The LCD controller A.VST29.01 I ordered arrived early last week. I can even find a data sheet for it on the Internet prior to purchase. With proper documentations, gone are the days we have to make some educated guesswork on unknown PCB. The price is USD29.9 without the AC adapter (12V, 4A); I got it for USD 51 for the complete set.

The vendor is found from aliexpress; they mentioned the model of the LCD LTN154P3-L02 harvested from the laptop is not tested before with this LCD controller, but it worked for other similar samsung make. So I run a chance of making a failed weekend project.

First, uncover all hidden screws on the LCD front panel, unscrew and lift the plastic front panel. Extra precautions needed to ensure the plastic snaps are not broken.

A couple years ago, I managed to extend the life of my LCD TV using a very basic trick. I thought the main board was fried, but ironically, baking it fixed it :-D.

Anyway, now the mainboard is fried for good (after being baked 4 times), and I want to find a universal board, but I have no idea how to find one that matches my LCD panel. The panel model is LC420WUH (SC)(M1). Back then @oldturkey03 had kindly helped and found the specs sheet for the panel: LC420WUH-SCM1-LG.pdf .

When looking for generic boards online, most of them need to be connected to a T-CON board, but this particular TV doesn’t have a T-CON. It seems to be embedded in the main board.

So my question is quite simple: how do I go about finding a generic board that matches the LCD panel? I’ve spent hours looking for it using search engines, online shops (from big ones to small ones) and other resources, but no luck so far.

Here is a Toshiba C655D-S5200 that had a broken case. It had severe water damage and the case was broken at the hinges. I salvaged as many parts as possible and wanted to use the LCD panel for a project. Over the last few years that I have been a member of iFixit, we had a couple of questions about what to do with spare panels. So, I figured I"d spend $32 and purchase a LCD controller board and investigate how difficult it would be. The trickiest part was to find a controller board that matches the panel.The LCD panel in this Toshiba is a LTN156AT05-U09. I contacted a couple of vendors on Ebay and found one that was very responsive and accommodating. I ordered the controller board and it arrived in 2 weeks from China.

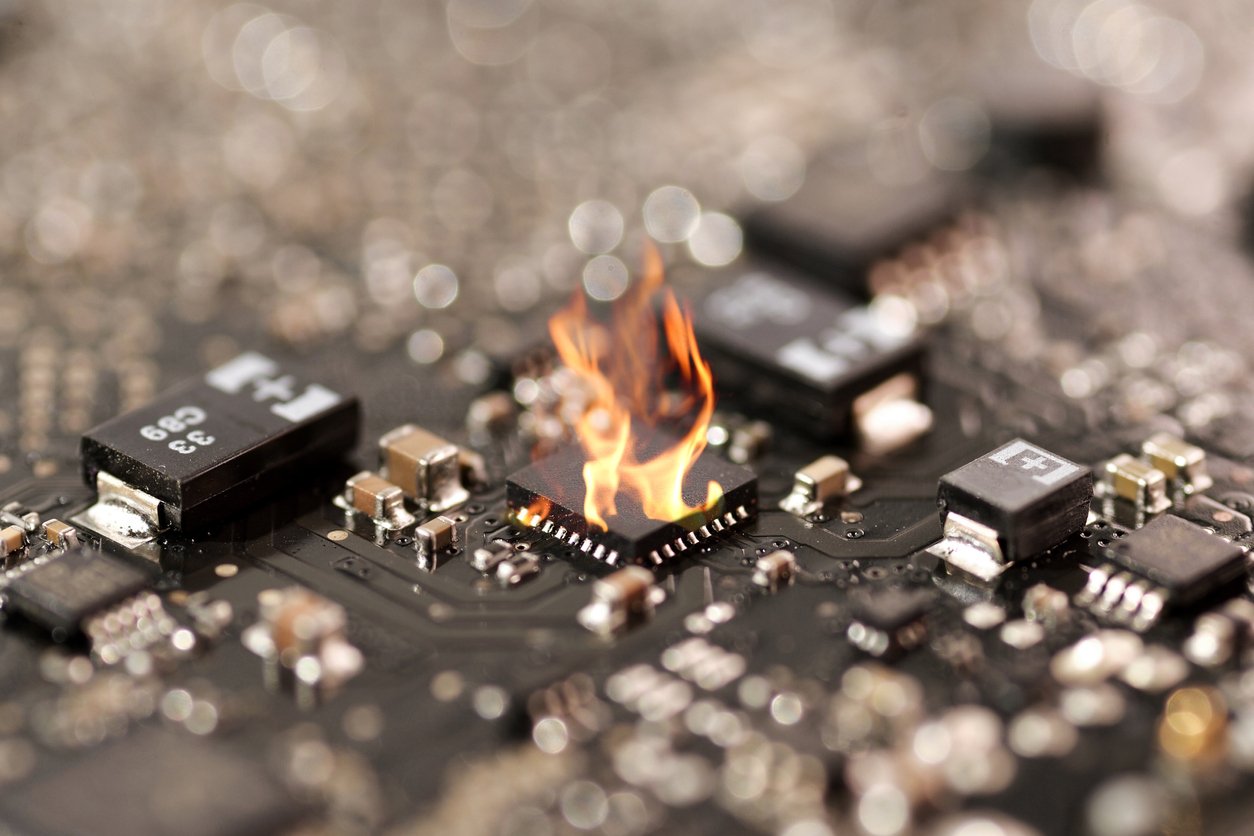

While there are many common printed circuit board defects, one of the most notorious is burnt components. It"s also, unfortunately, one of the most damaging defects, as it can be difficult to repair and challenging to diagnose where the issue stemmed from.

Before we get into PCB failure analysis techniques, let"s first take a look at some of the reasons why a printed circuit board may burn. Burnt circuit boards aren’t necessarily a defect by themselves, and they are frequently caused by other inconsistencies or defects on the PCB.

But, accidents can happen. If a machine overheats or the board is exposed directly to flame, then that might not be the best situation for your components.

In other words, you want to avoid overstuffing the board. Not only will this reduce costs and accelerate production, but it can also help you avoid any costly mistakes that could come to bite you later down the road.

The most important part of manufacturing a PCB is the design phase, so if something is not quite right in the design phase, there will likely be consequences down the road. That being said, checking to make sure the right diodes and capacitors are specced out for the board will decrease the likelihood of component-failure related burning.

Boards might burn because of poor protections. The lack of properly sized fuse protection should be number one priority. A high voltage protection diode protects the board from burning in the event of a lightning strike or other voltage surges.

Other reasons for board burning are related to technician error. If the board connections are hooked up incorrectly or attached to the wrong type of power supply, leading to eventual burn out. In addition, if installation documents are confusing or nonexistent, a field technician might hook up the board improperly.

Conducting a PCB failure analysis is key to improving the product and preventing future defects from occurring. Here"s a look at some questions that we suggest asking that can likely help you resolve burnt component defects:

Always make sure to send your design to your board house for review before manufacturing -- think of it as a second pair of eyes on an email before you send. They may catch a mistake you missed.

Circuit board overcrowding isn"t just more likely to lead to burning, but to manufacturing challenges as well. Sometimes, preventing defects can be as simple as ensuring more adequate spacing on the PCB. Better spacing for high voltage and higher current traces can also decrease the risk of burning out a PCB.

PCB defects like burnt components can be a real pain, but partnering with an electronic contract manufacturer who has experience with PCB assembly can make all the difference.

The LCD screen is vital for operating the printer. Should you encounter any kind of trouble, such as a dead screen, corrupted text, or other issues, please refer to the guide below.

First of all, unscrew the LCD screen from the printer frame, remove both M3x10 screw holding it the LCD board in the plastic casing, and remove it from the casing. See if the problem still appears when the LCD is not pressed by the casing.

Firmware updates are necessary to keep your printer up to date. However, the installation of incorrect firmware can lead to letter corruption on the LCD screen. There"s an easy fix, though:

There is a small chance the printer"s LCD screen can glitch out by electrostatic discharge when inserting the SD card. Try to turn the printer off and on again.

This problem usually appears only on user-assembled printers. If your printer"s LCD screen remains blank or displays corrupted symbols after you turn on the printer, there is a chance it is caused by incorrect wiring. Follow these steps to fix the issue.

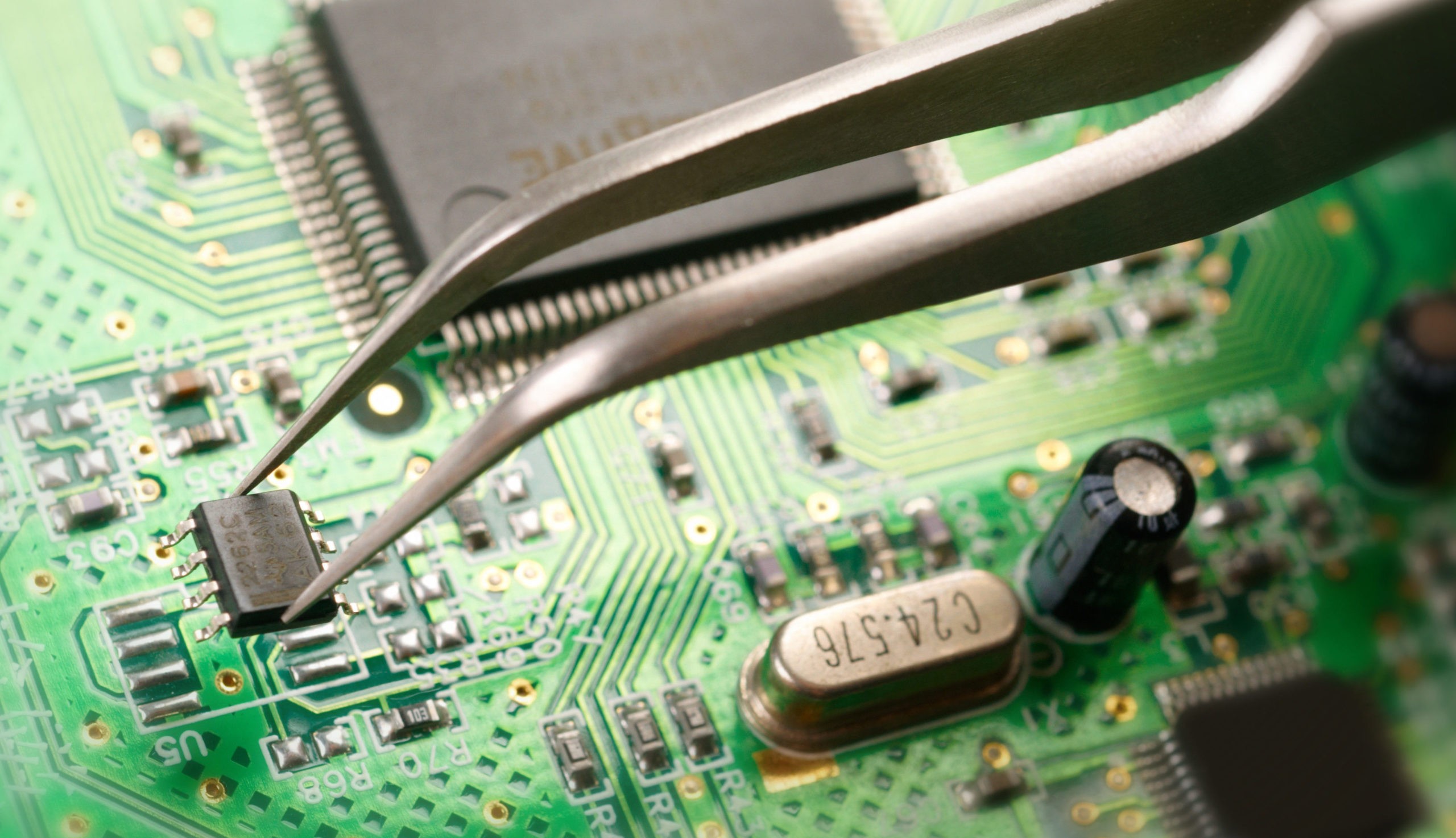

If you suspect that the LCD ribbon cables connectors are not firmly seated in the slots, disconnect the LCD ribbon cables and check the slots for any bent pins. If there are bent pins, you can use tweezers to fix them. However, be very careful not to break the pin(s) completely.

TV repair costs between $60 and $350 with most spending $207 on average for LCD, LED, plasma, and 4K TVs; costs are higher if repairing older DLP, projection, and HD TVs. TV problems like display issues, powering-on problems, or sound issues can be fixed. Pickup and delivery fees may apply.

For example, the price of a new Samsung 40-inch LED TV is about $400, yet the cost of a replacement display panel for this model is about $380. This price is only for the replacement part and does not cover diagnostic costs, labor costs, or travel or shipping fees.

Unless you are trying to fix a TV from the ’80s or earlier, cracked TV screen repair is not feasible; the entire display panel must be replaced instead. The cost of a replacement TV display panel is more than the cost of buying a new TV, and that’s before labor and other service costs.

TV manufacturers do keep replacement TV screen panels on hand to support products under warranty in case the screen malfunctions, due to manufacturer defect.

If you still want to replace a damaged or malfunctioning TV screen, your best option is to find a used replacement panel or a broken TV of the same model on which the screen is still functional. You might find one on eBay, and you can hire a technician to change out the panel.

The cost of a used replacement TV panel ranges from $50 to $350 or more, excluding shipping, depending on the brand and size. Note that the chances of finding exactly the part you need in excellent condition are slim, and the cost excludes the cost of installation by a repair shop.

Whether your TV is LCD, LED, plasma screen, or 4K (Ultra HD), the cost to fix common problems ranges from $60 to $350, depending on the repair type and the brand of TV being repaired.

TV motherboard replacement costs between $200 and $350, including parts and labor, or about $275 on average. Motherboard replacement parts range from $35 to $199and labor costs from $60 to $125.

A TV inverter repair costs $104 to $171, including parts and labor, with an average cost of $138 for a TV with one inverter board or $178 for two. Parts range from $7 to $74, and the average labor cost for TV inverter repair is $97 per hour.

The function of an inverter board in a TV is to power the backlight of the screen. The inverter board requires a few hundred volts of power. If the inverter board goes bad, this would cause the TV to power on and have sound but no picture.

When an inverter component goes bad, it is usually replaced rather than repaired. In some cases, the capacitors on a converter board fail, and a technician can fix it by replacing the capacitors rather than replacing the entire inverter component. However, if an entire inverter board replacement is not available for the model of TV being repaired, replacing the capacitors may be the only option for TV inverter repair.

If an older model LCD TV or projection TV powers on and has sound but no picture, this may be due to lamp burnout, which is both common and expected. In this case, replacing the bulb will fix the problem. An experienced technician should be able to replace the bulb quickly and easily.

Repairing a TV power supply board costs $23 to $234 for parts alone. Completely replacing the power supply board costs $250 for parts and labor. If one capacitor has failed, the cost for replacement capacitors is low. However, it’s more cost-effective for the technician to replace the entire board rather than spend time trying to diagnose and replace faulty capacitors one by one.

The cost to fix an HDMI port on a TV is $93 to $302. In some cases, the input circuit board that the HDMI port connects to may be damaged and need to be replaced. The cost for replacing this input circuit board, including labor, ranges from $200 to $350.

Flat screen replacement glass is not available. The only option for flat-screen TV glass repair is to try optical glass glue, which costs $1.70 for a 5-ml. tube. This may be an option for TV glass repair if the crack is only a few inches or less. TV panels are built as one unit at the factory, with the glass adhered to the display panel.

LCD flat-panel repair is not considered cost-effective. If the glass is cracked or the display is physically damaged, it is cheaper to replace the entire TV than to repair or replace the display panel.

The cost of flat-screen TV repair ranges from $42 to $359. You cannot fix a broken screen, but the price of a new flat-panel TV starts from around $249 for a 1080-mp (non-4K) LED TV from LG to as much as $14,999 for an 85-inch 8K LED TV from Samsung. A TV referred to as a “flat TV” or “flat-screen” TV might be any of the following:

LCD TV repair typically costs $60 to $85 for diagnostics testing, and $200 to $300 to perform repairs. LCD TVs use backlighting, which may fail. Newer LCD TVs use LED strips for backlighting. Older ones might use CCFL. If CCFL backlighting fails, a technician can replace it with LED backlighting.

An LED TV is just an LCD TV that uses LED backlighting, which all newer models do (older models use CCFL backlighting). The cost to replace one LED backlighting strip ranges from $100 to $122, including parts and labor.

The cost to replace the motherboard, inverter, or LED"s in a 4K TV ranges from $100 to $275 or more depending on the brand and model. The cost for screen repair for a 4K TV is irrelevant because it cannot be fixed or replaced at a cost that is lower than the cost of a new 4K TV.

Circuit breaker - Check the circuit breaker for the power outlet that the TV plugs into. You can check the breakers by opening the door to your breaker panel and looking for circuit breakers that are in the OFF position.

Lamp burnout -In a projection TV or older LCD TV, no picture may be caused by lamp burnout. In this case, a technician can replace the bulb quickly and easily.

If the picture is displaying but there are problems such as vertical lines, a double picture, or a white display, this could indicate a faulty motherboard or mainboard.

In most cases, a flat-screen TV can be fixed. The exception is a physically damaged display panel or screen. Most other issues including failing speakers, backlights, or power supply. Burned out fuses and damaged input ports can also be repaired.

ER-TFTV050-3 is 800x480 dots 5" color tft lcd module display with vga,video,av signal driver board,optional 4-wire resistive touch panel with USB driver board and cable, optional capacitive touch panel with USB controller board and cable, optional remote control,superior display quality,super wide view angle.It can be used in any embedded systems,car,industrial device,security and hand-held equipment which requires display in high quality and colorful video.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey