why does lcd module need sla in stock

Laser, LCD, and DLP are three distinct methods of exposing a light-sensitive resin in layers to cause a cross-linking of liquid polymers, curing the liquid into a solid object. All of these are used within SLA printers, a term used to refer to the stereolithography process. There has been a disturbing trend to refer to LCD printers are “DLP” printer that started when lower price-point manufactures began to use the already-taken “DLP” term for marketing purposes and claiming it was ok because their LCD does light processing using digital signals. Doing so, however, is like calling a gasoline-engine car an electric vehicle – something that it is not – just to confuse consumers into thinking that they are getting something often seen as more desirable but at a lower price.

Laser, (originally L.A.S.E.R as an acronym for Light Amplification by Stimulated Emission of Radiation) uses galvanometer scanners to direct a light beam via vector and raster scanning. The process is fast for smaller object, but get progressively slower when it must draw out more objects. The advantage is a smooth surface finish and compatibility with resins high in polymer content for the strongest resulting parts. An example of desktop laser-based SLAs are the Peopoly Moai and the Formlabs Form-2 printer.

LCD is a variation of SLA that uses a Liquid Crystal Diode display, the same as in most laptops and mobile phones, as a mask. It is also known as MSLA, or masked SLA. A light source is placed on one side, and the resin on the other. Because the entire layer can be exposed at the same time, they are generally faster for printing more or larger objects. Example of LCD-based SLA printers are the Anycubic Photon, Wanhao Duplicator 7, and the EPAX-3D 1X. One reason why LCD still remains on the low end, because the fact that they can simply be manufactured for less cost, is that there is a limited amount of light that can pass through the LCD panel before it overheats and self-destructs. This limits the speed at which printing can take place. To help make up for this lower amount of light exposure, the resin makers increase the monomers and photo-sensitive initiators, with a resulting increase in potential for shrinkage and weaker parts. In reality though, due to advances in resin such as Siraya Labs Blu (the strongest LCD resin I have tested) and eSun Bioresin (the strongest solid-color LCD resin I have tested), some very strong parts can be made – just as strong, if not stronger, than PLA and ABS parts on FDM printers.

DLP uses a digital micro-mirror device in which light is reflected through a projector lens and onto a tank of resin. Because this matrix of mirrors can be well cooled, a lot more light can be directed than with LCD, thus making it the choice of larger, faster, and more expensive printers that can still make use of less sensitive and stronger resins normally reserved for laser. The downside being a higher price point, taller printer size, and sometimes lower resolution because DLP chips tend to max out at 1080P.

But you may ask – why is it not ok to refer to my LCD-based printer as “DLP” when the manufacturer says it has light processing and is digital? The answer is because the term DLP was already taken for a digital micro-mirror projector device, and there would be no distinction between the technologies, both of which are used in resin printers, if you used the same term for both.

There are a wide variety of 3D printers on the market right now. LCD, DLP, and SLA 3D printers all use resin as a way to create prints. But which one is best suited for your needs?

LCD 3D Printers use an LCD display module to project a certain light pattern which is then used to cure resin in the resin vat. LED light is used as the light source while the LCD screen controls the light pattern. Light is emitted from the LED lamp. It then passes through an LCD screen and is absorbed by the resin. An image of each layer is generated on the LCD screen while an entire layer is hardened at once.

SLA 3D printing, or stereolithography, uses lasers as a light source to print out 3D prints. As the laser traces each point in a single layer, the liquid resin hardens in the process.

In each LCD screen, you can calculate the pixel size by dividing the length of the LCD by the number of pixels on the length of the LCD screen. Let’s take Phrozen Sonic Mini 4K as an example, its X resolution (pixel size) is 134.4 mm / 3840 pixels = 0.035 mm.

DLP 3D printers use the same concept as LCD 3D printers; you can calculate the pixel size by dividing the length of the tiny mirrors by the number of pixels present on the DMD.

SLA 3D Printers:For SLA 3D printers, the XY resolution will depend on the average spot size of the laser beam and the increments at which the laser beam is controlled.

LCD 3D Printers:As there are a wide variety of LCD 3D printers on the market, companies are now rushing to create LCD 3D printers that are much more precise and accurate than previously possible. This means that LCD 3D printers are getting close to the accuracy and precision provided by traditional SLA 3D printers with proper calibration components.

SLA 3D Printers:As lasers are used in SLA printing, 3D models printed using this technique tend to be accurate and precise. SLA 3D printers print out models with an even and smooth surface as the laser moves through a continuous path while slowly drawing out each layer.

Though SLA 3D printers can print out smooth models, the price of purchasing such a device could be 3-5 times higher than LCD 3D printers. It also takes much longer to print with an SLA 3D printer as we will explain next. For those looking to print resin miniatures and other similar models at home, it would be more worthwhile to purchase an LCD 3D printer for speed and cost purposes.

LCD 3D Printers:LCD 3D printers are similar to DLP 3D printers in that an entire layer of resin can be cured at once, meaning that it also can print much faster than SLA 3D printers and print out a collection of 3D models in one go.

This is because monochrome LCD screens are designed for the purpose of allowing higher light transmission and higher thermal resistance. This way, 3D printers that use Mono-LCD screens can cure resin at a shorter layer exposure time and have a longer lifetime than Color LCD screens.

DLP 3D Printers:As an entire layer of resin is cured with UV light at once, this means that you can print a large number of tiny models at once while using a DLP printer. The process will be much faster than an SLA 3D printer and even some LCD 3D printers.

SLA 3D Printers:As SLA 3D printers use lasers to trace out the pattern of a single layer before moving onto the next layer, it takes a much longer time to print out each individual model using this type of printing technique.

As SLA 3D printers use a different technique while printing it cannot entirely be compared to the printing techniques of DLP or LCD 3D printers. If you"re looking to print models with speed, it would be better to purchase LCD 3D printers for speed and accuracy purposes as SLA 3D printers print extremely slowly.

LCD 3D Printers: In comparison to other 3D printing techniques, LCD 3D printers are created as an affordable alternative to their 3D printing counterparts. These 3D printers use an LCD panel for printing purposes which can easily be replaced. Moreover, LCD printers can be made to be small, so most LCD 3D printers are desktop-sized which makes them easy to store.

DLP 3D Printers:DLP 3D printers are also more expensive than LCD 3D printers as it requires the use of Digital Micromirror Device (DMD) which tends to be costly as well.

SLA 3D Printers:In terms of cost, SLA 3D printers tend to be more costly than their counterparts: DLP and LCD 3D printers. This is because SLA 3D printers include machines and lasers which tend to be more expensive.

Depending on the brand and type of SLA 3D printer you choose to purchase, the price could range from $3,500 for a basic SLA 3D printer to several hundred thousand dollars for an industrial SLA 3D printer.

While DLP 3D printers print the fastest, these produce models with low resolution and are also more costly than LCD 3D printers. 3D prints can also be easily distorted due to the use of a projector lens.

Though SLA 3D printers prints out resin 3D prints with accuracy and precision through the use of a laser, it prints very slowly, as it can only print one 3D model at a time. In comparison, both DLP and LCD 3D printers are capable of printing out an entire plate of 3D models in one go.SLA 3D printers also tend to be

Even though LCD 3D printers don’t print as fast as DLP 3D printers, it prints with accuracy and precision through the use of an LCD screen and UV lights, producing 3D models with extremely high resolution. LCD 3D printers, especially

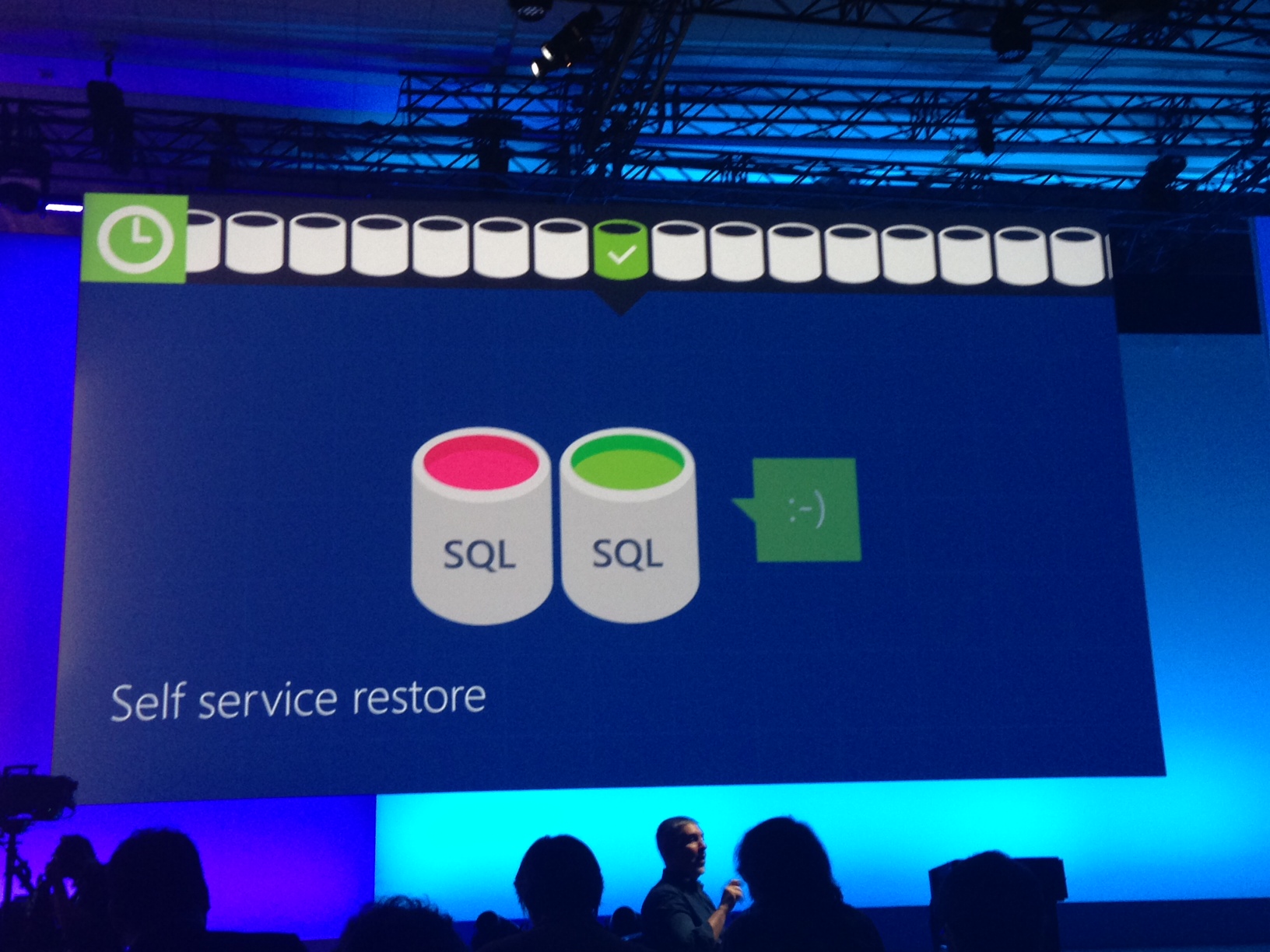

Determining the right amount of time to commit to for SLAs is a balancing act. As much as we might want to promise instant responses, it’s not a practical promise to make to customers. If we over-promise on response times and don’t deliver, customers will be disappointed and there might be serious contractual consequences such as fines, usage credits, or early contract termination.

On the other hand, SLAs should help the customer feel assured that they will get timely responses if and when they need assistance. Set the goal post too far away and customers will be disappointed with slow responses. Instead, find a balance between over-promising but still meeting the needs of customers - often by personalizing SLA policies by customer segment. Here are six things to think about when designing your SLA team policies.

SLAs are promises you make to your customers. If you’re a smaller company that doesn’t offer contracts or legally binding SLAs, your SLAs might be similar to the internal goals your customer support team sets for response and resolution times.

However, if you’ve outlined your SLAs in your terms of service or in a legal contract, there are serious repercussions for breaches. Your customer support team"s goals shouldn’t be to meet the bare minimum level of service. In this case, you’d want to set your internal team benchmarks more ambitiously than simply avoiding SLA breaches.

Plus, setting your external SLAs the same as your internal goals don’t give you much room for error. Ideally, you should aim to resolve inquiries well within SLAs. SLAs should be the longest acceptable time for a customer to wait, but they shouldn’t be your measurement for quality.

The best practice is to set your customer support team response and resolution goals well below your SLAs so that you’re consistently working to exceed customer expectations.

When determining your SLA policy, it’s important to consider if all customers fall into the same bucket, or if some customers require unique policies. Understanding your customers’ needs based on their plan type or contract requirements and setting up different SLAs can help provide more personalized experiences.

Tiering customers by plan type:High-value customers might get priority over a lower or free pricing plan. While it doesn’t always make sense to set an SLA for free users, setting SLAs for enterprise customers is expected and often required in contract negotiations.

Personalizing SLAs for VIP customers: High-value contracts will often require personalized SLA conditions. With multiple SLA policies, you can set a unique deadline for each customer and for each situation you might encounter.

While every customer concern is important, not all of them are equally urgent. By categorizing common support problems by priority and setting separate SLAs for each type of question, your team can better prioritize the needs of your customers. For example, an outage SLA time might be a lot shorter than a request to update a billing address. Using multiple SLA policies allows your team to get as granular as you’d like to serve each type of customer uniquely.

When setting SLA policies, take customer feedback into account. If customers complain about slow responses or leave negative customer satisfaction responses, it’s time to revisit your SLAs to ensure you’re meeting the needs of all your customers.

Understanding why customers need specific response times is important too. Critical software or products like banking apps or point-of-sale systems might require faster SLAs because any wait time will seem unbearable. Other products, like e-commerce or entertainment apps, might not require as quick of responses - meaning that you can dedicate resources to other priorities.

It might be tempting to optimize SLA policies based on agent availability - but this is the wrong approach to take. Instead, base your SLA policies on the customer experience as a first priority and then staff your team to meet those requirements. If you can’t meet your customer’s expectations and are experiencing SLA breaches, you’ll need to hire more agents to handle incoming inquiries.

Operational Level Agreements are critical to consistently meeting SLAs when there are internal dependencies to resolve an inquiry. As mentioned above, OLAs are agreements between internal teams that help prevent bottlenecks. When an SLA isn’t met, customers don’t care who’s fault it is - engineering, support, or system administrators - they only care that their agreement wasn’t honored. OLAs help teams work together to meet their commitments to the customer.

If you don’t offer support 24 hours a day, 7 days a week, it’s possible to set SLAs that only take into account your operating hours. For example, if you have a 24 hour Response Time SLA, but only have agents working during the weekdays, customers who send in an email Friday afternoon shouldn’t expect a response until Monday. Setting your SLAs to Business Hours instead of Calendar Hours will only keep the timer running while agents are scheduled to be working.

However, while using business hours might make your reporting look better, customers are still waiting over the entire weekend (or night) for a response. They might not care that you don’t have agents working - they only know that they aren’t getting help. If you choose to only report on business hour SLAs, it’s still important to keep in mind the customer experience for customers that live in different time zones or are trying to contact you after-hours.

The two main types of SLA systems are desktop (prototyping) and industrial printers. Industrial SLA machines can produce more accurate components than their desktop counterparts (and maintain better accuracy over larger builds), and often make use of higher-cost materials. While desktop SLA can achieve tolerances between 150 and 300 microns, industrial printers are capable of tolerances as low as 30 microns for nearly any build size.

One of the limitations of most industrial machines is that they produce parts using a top-down approach resulting in the need for large resin tanks (over 100L). This makes swapping between materials difficult and can increase lead time on parts. This also makes these machines more expensive to maintain.

Compared to desktop printers, industrial machines are designed for repeatability and reliability. They can often produce the same part over and over again and do not need the high level of user interaction that desktop machines typically require.

Overall, SLA’s unique ability to batch produce intricate, customized parts makes it a popular method of manufacturing small parts, low-run production.

So, if you just want to display a list of SLA"s where you want to show an association to a catalog item, you can create a M2M tableto make that association. This would only be for display purposes and you would have to manually edit the list for each catalog item.

If you wanted to display SLA"s automatically then you would have to create a relationship and would need to ensure that part of your SLA definition matches your catalog item, which could be as simple as adding a field to the SLA form as a reference to sc_cat_item.

Afghanistan, Africa, Albania, American Samoa, Andorra, Anguilla, Antigua and Barbuda, Argentina, Armenia, Aruba, Azerbaijan Republic, Bahamas, Bahrain, Bangladesh, Barbados, Belize, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, British Virgin Islands, Brunei Darussalam, Cambodia, Cayman Islands, China, Colombia, Cook Islands, Costa Rica, Dominica, Dominican Republic, Ecuador, El Salvador, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Georgia, Gibraltar, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guernsey, Guyana, Haiti, Honduras, India, Indonesia, Iraq, Jamaica, Jersey, Jordan, Kazakhstan, Kiribati, Kuwait, Kyrgyzstan, Laos, Lebanon, Liechtenstein, Macau, Macedonia, Maldives, Marshall Islands, Martinique, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Nauru, Nepal, Netherlands Antilles, New Caledonia, Nicaragua, Niue, Oman, Pakistan, Palau, Panama, Papua New Guinea, Paraguay, Peru, Qatar, Russian Federation, Saint Kitts-Nevis, Saint Lucia, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, San Marino, Serbia, Solomon Islands, Sri Lanka, Suriname, Svalbard and Jan Mayen, Tajikistan, Tonga, Trinidad and Tobago, Turkmenistan, Turks and Caicos Islands, Tuvalu, Ukraine, United Arab Emirates, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Virgin Islands (U.S.), Wallis and Futuna, Western Samoa, Yemen

Service Level Agreements (SLAs) are a crucial part of Service Level Management, and therefore one of the key components of IT service management. They are the basis for building and delivering IT services, and play a key role in ensuring that both the client and the service provider are on the same page and that the service delivery is at par with or exceeds customer expectations.

In this article, we’ll cover every aspect of SLAs: what they are, their components, and advantages and disadvantages, as well as some of the commonly asked questions about SLAs.

SLAs are essentially a contract between a service provider and a client. They detail the nature of services that will be provided and their quality and performance metrics. They were used by telecom operators and internet service providers, and are now employed by companies and organizations in many industries.

SLAs can be between more than two parties and different departments or units in an organization. Though their main goal is to align the services provided with those required by the client, they can be legally binding. In fact, they also contain measures to be initiated in case the service provider could not deliver the services or meet the specified quality requirements.

For example, most cloud service providers often 99.99% (often referred to as four nines) or even 99.999% uptime for their services in their SLAs. And if they fail to deliver on it, they’ll give service credits (points that can be redeemed for cloud services).

From a client’s perspective, an SLA guarantees that the requested services will be delivered; it assures the client that they will fit their requirements. The SLA dictates the standards for every service provided and how these standards will be measured.

From a service provider perspective, the SLA ensures clear communication between them and the client. It removes (to a large extent) ambiguity between client expectations and what the service provider understood. It reduces the possibility of a dispute over services delivered, and if a conflict does occur, the SLA offers remedial mechanisms.

The document also dictates the deliverables from the client’s end as well. It dictates the elements or resources, such as different documents, access credentials, information, and other resources the service provider may need to deliver the services.

Another benefit is that the SLA standardizes the processes for the service provider. Every client may have different requirements, but with carefully documented SLAs, they can align client requirements with the organization’s operations. An SLA helps service providers organize resources efficiently.

As you can imagine, the exact components of a service level agreement may vary between service providers, industries, and the clients" specific requirements. And there are many guidelines on how to build an SLA.

Besides these components, customers or service providers may add additional elements, such as the goals of the parties involved (for a general good faith interpretation of the SLA) or situations in which the SLA doesn’t apply or is wholly voided.

For example, in the case of cloud service, 99.99% availability may seem good for a layperson, but this translates to 3.65 days of unavailability in a year.

By defining the service levels, the SLA brings the service provider on the same page on what good quality service means. These service-level metrics could be MTTR, MMTF, FCR, and other KPIs that may translate to availability, reliability, security, and other factors.

This dictates how the processes will be monitored and reported to see how far the service provider meets the defined service levels. The SLA may define the tools, format, or even third-party services used to monitor the service levels. It may also determine how often the reports may be reviewed.

The SLA will specify how long it is valid and how often it may be renewed. It may also determine how the SLA may be terminated before the end of the service date, the conditions for the same, and how both parties will respond to it. It may specify a notice period from all parties.

These service level agreements are more for clear communication and understanding and less about ramifications in case the requirements are unmet. Theinternal SLAs will indeed contain service level targets and dictate monitoring and reporting.

A customer-based SLA is between an individual customer or a group of customers and a service provider. These SLAs are designed around all the services rendered to the group of customers.

A service-based SLA revolves around a specific service. They are not unique to a customer or a group of customers but are typical for all the customers who avail of the particular service.

A corporate-level SLA applies to organizations and the customers who avail of specific services. A service-level SLA may apply to organizations and customers benefitting from particular services.

Multilevel service level SLAs are used in large organizations that may offer many different services to customers and standardize the SLAs for other customers.

A SaaS company offering different services may have an individual plan, a team plan that supports ten users, and an enterprise plan that supports more than 100 users. A corporate-level SLA may have conditions that prohibit users from selling the services to other users or copying the UI of the solution. For users on different plans, separate SLAs may dictate conditions for availability.

SMART means Specific, Measurable, Attainable, Relevant, and Time-bound. So, ensure the SLA has concrete goals, not vague or subjective statements. If the service provider has met the objectives of the SLA, it should be possible to measure performance. You want to ensure that the SLAs help your business grow.

Don’t overcomplicate SLAs unnecessarily. Use plain language and avoid jargon. Simple SLAs are understood and referred to; complicated SLAs create confusion and are left behind.

Don’t make a watermelon out of your SLAs — all green on the outside and red on the inside. Service providers and clients often use metrics that sound great on the technical side but don’t align with the business goals. All the metrics are ideal, but the client experience is abysmal.

For example, imagine a service provider hosting a website for a client. The SLA mention 99.99% availability, and the provider have exceeded it for a given month. But the website is super slow, and the client is losing customers.

You’ll also have to be careful with service credits in the SLAs. They must incentivize the provider to meet the service requirements and highlight its essential aspects. The threshold should be set considering the provider’s capabilities and client requirements. Nobody wants a situation where the service provider considers missing targets and charges a premium to cover the service credits.

Don’t build a service level agreement and keep it the same throughout the relationship with the client. Review and renew the SLAs whenever the requirements or services are changed besides the periodic renewals.

Different services have different specifications, and customers have different requirements. You need other metrics for various services. While you can keep a general SLA template, you must tailor it for individual requirements. You don’t want to use the same SLA for cloud services and IT support.

You’ll also need separate SLAs for separate groups of customers, if not individual customers. Small organizations may not be able to afford or even need the service levels that large organizations will need.

If your business offers multiple services or serves various types of customers, developing multi-level service agreements may be a good idea. With this, you can standardize these to a large extent and customize them as needed.

While SLAs continue to help organizations deliver IT services aligned with their customers" needs, they have a couple of drawbacks. Here are two of them that showcase how SLAs require a reasonable faith interpretation to work, which sometimes makes them less effective.

For example, consider an app that meets all the availability criteria, but the time it goes down is during peak usage hours. Or an e-commerce platform that can handle peak loads and meets all the requirements in the SLA, but customers keep abandoning their cart right before checkout.

For this reason, experts have suggested focusing on XLAs or Experience Level Agreements, not as an alternative but to augment the SLAs. They bring the “voice of the customer” into service management.

"XLAs do not replace SLAs. XLAs work hand in hand, they augment SLAs. [...] Whatever you learn is most important to people and impacting their overall sentiment is going to be in your XLA.

hearing the service experience. We can still keep our blessed SLAs and track service levels. [...] But we"re going to supplement them. We"re going to start listening to number one, what the customers actually care about, what they value, and then you can start measuring that because that"s what"s important to them."

From a client perspective, the SLA"s goal is to guarantee service delivery at targeted service levels. And they define the service levels and penalties to reflect this. The penalties are often monetary, so the service provider will be incentivized to prevent loss. This is how the mechanism works, but it can have unintended consequences.

Or consider a situation where a client wants uninterrupted service delivery during peak hours. For this, the client sets a very high service level and huge penalties if the provider fails to meet them. If the service is interrupted, there’s no way the service provider can mitigate their loss. So if the service does fail, the provider has no incentive to get it back up.

Of course, some SLAs include service credit buyback opportunities, in which the provider can reclaim the credits by exceeding or maintaining the service levels. But this strategy undermines the service credit mechanism; clients can afford not to meet the service level requirements.

Most cloud service providers showcase the SLAsfor theircloud services —like Azure or AWS. These SLAs are reasonably simple and easy to understand but are at the same time very specific. And they all have different SLAs for different services.

They usually dictate the availability criteria, the scope of services, the parties involved, and the service credit if the SLA requirements are not met. Since many users with similar needs define their business model, they are standard for almost all users availing of the same plan for the same service.

SLAs between SaaS providers and customers (often referred to as subscription service agreements) are similar to cloud service SLAs in that they apply to the entire customer base, or at least all customers on the same plan.

A Service Level Agreement or an SLA is a document that dictates the nature of services delivered by service providers and clients. The document dictates the type of services, service levels, and how the service will be provided. They can be between an organization and external customers or between different departments in an organization.

Three different types of SLAs are Customer-based SLAs, Service-based SLAs, and Multi-level SLAs. Customer-based SLAs are defined around a customer or catering to the requirements of a specific group of customers. Service-based SLAs are for all customers receiving a particular service.

Multi-level SLAs usually have multiple levels or parts, each referring to a provider"s customers, a specific customer group, and customers receiving certain services. Each level may have different SLAs, and a particular customer may get a combination of SLAs from all the levels.

One of the most common challenge is to make SLAs aligned with customer needs and provider capabilities. It is crucial and challenging to design an SLA that motivates the service provider to deliver quality services and prioritize the essential service delivery aspects.

The four aspects of an SLA are service delivery, service level metrics, service monitoring, reporting, and remedies and penalties if service levels are not met.

Sadly I have a sneaking suspicion that it"ll be a bit of both: SLAs triggered in-month but not necessarily ended, and "legacy" SLAs carried forward month(s) to the point at which they end. It"s a really good question, the answer to which I suspect will be hidden within the contracts.

Pickup later allows you to provide a direct online to offline experience for your customers. For items that can be picked up in store within a specific SLA regardless of store availability, pickup later allows you to use your stores as an omnichannel asset and differentiator. Unlike other local inventory ads features, pickup later doesn"t require full inventory information.

Pickup later for local inventory ads gives you full flexibility for granular SLA information at the store level for each product. Additionally, pickup later for local inventory ads is compatible with all of the other local inventory ads products: you can advertise pickup later alongside in-stock inventory in a way that maximizes the value of your stores as omnichannel assets.

In Sugar Serve 11.0 and higher, the Cases module contains ten fields that are used to track first response Service Level Agreement (SLA) and case resolution statistics, primarily for use in reporting. Sugar Serve includes many stock reports that use the data in these fields to highlight trends in case processing. This article describes these ten fields as well as two other related fields, including the information they hold and how they work together to provide insight into case processing in your organization.

Eight fields available on the Cases module for Serve users track information on the case"s first response SLA, in both calendar hours and business hours. The table below contains a description of each of these fields, in addition to the Follow Up Date field, which is also available in Sugar Enterprise and, if on version 12.0 or higher, Sugar Sell:

The calculated date and time by which the first response must be sent to meet the SLA. This field is set based on the value of the Follow Up Date field at the time the First Response Sent field is set to "true".

Two fields available on the Cases module for Serve users track information on the case"s resolution, in both calendar hours and business hours. The table below contains a description of each of these fields, in addition to the Resolved Date field, which is also available in Sugar Enterprise and, if on version 12.0 or higher, Sugar Sell.:

The Case Follow-Up Date Management V2 SugarBPM template must be configured to work in your instance. You may also wish to change the criteria that cause the First Response Sent and First Response SLA Met fields to be set to suit your organization"s processes. For example, you might alter the status changes that cause the First Response Sent field to be set to "Yes".

A case is created with a status of "New", which triggers a Case Follow-Up Date Management V2 process that sets the Follow Up Date field based on the appropriate SLA.

When the case"s status is updated from "New" to anything else, the process sets the First Response Sent field to "Yes". After saving, Sugar calculates values for the following fields according to their descriptions in the Case SLA Fields section above:

Each time the case"s status changes to Pending Input to indicate it is awaiting the customer"s response, 16 business hours are added to the Follow Up Date field"s value. If the customer does not reply by the follow-up date, it is extended by another 16 business hours. The next time the customer misses the follow-up date, the SugarBPM process automatically closes the case.

One of the most valuable ways to use these fields is to run reports on the data to analyze trends in the SLA and case resolution data captured by these fields. Sugar Serve includes several stock reports that report on these fields, such as the First Response SLA Success Rate and the Average Time to First Response by Agent reports. It is also possible to create custom reports on the fields if you wish to capture different information than that shown by the stock reports; refer to the Reports documentation for more details on creating these.

In addition to trends, these fields can also provide customer service representatives with valuable information on their case processing. When reviewing an individual case, the agent can see how quickly they responded to the case relative to the SLA and how efficiently they were able to close the case. They can also use stock reports such as the My SLA Success Rate report to see their aggregated SLA or case resolution performance. This is useful for agents to track their performance and for supervisors to understand their business more deeply.

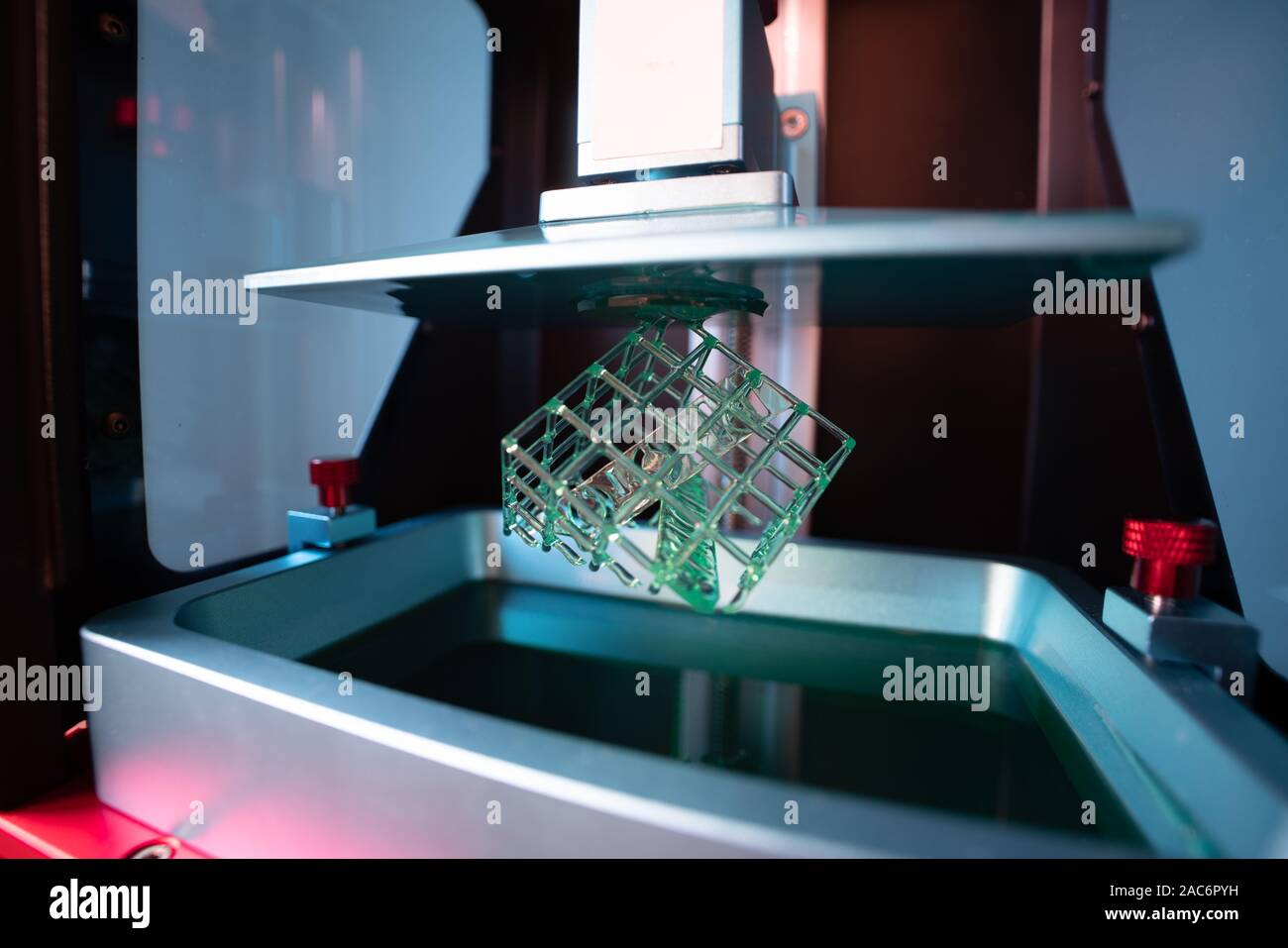

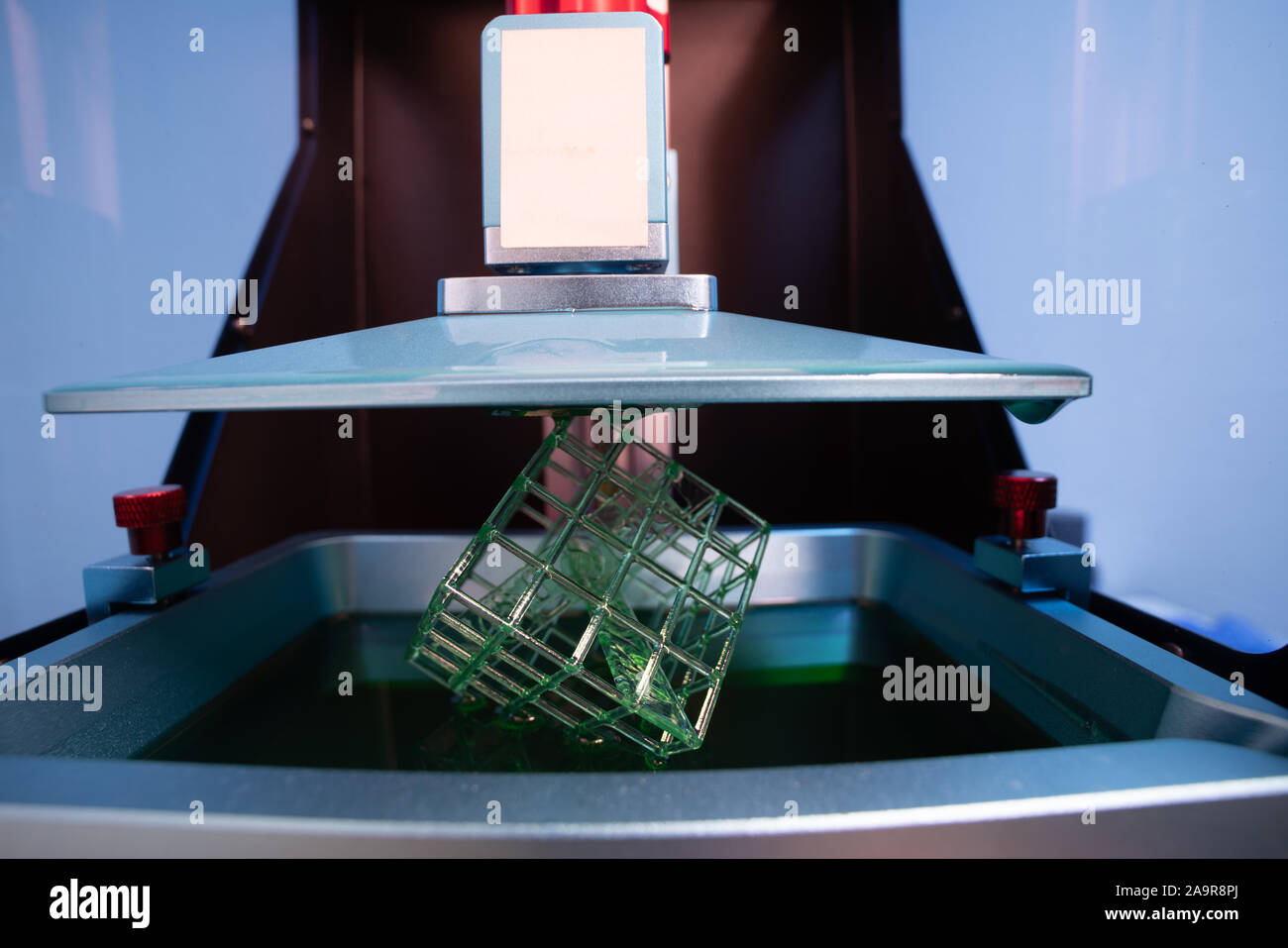

In today’s dev diary, we’ll explore the world of pixels and subpixels. In addition, we’ll shed some light on how we managed to tame UV light, and most importantly, how we managed to make the Original Prusa SL1S the fastest desktop MSLA 3D printer.

We launched the Original Prusa SL1 in May 2019 – a robust masked SLA 3D printer with a heavy aluminum frame, high-quality components, RGB exposure display, and a 64-bit motherboard. The exposure times were around 6-7 seconds, the movement of the platform and tilt mechanism took about five to seven seconds. Over the two years, we focused on making the SL1 better and better, mainly through firmware releases and accessories such as the display calibration adaptor. And we wanted to make it faster. A lot faster. A monochrome LCD was the way to go.

However, we quickly learned that simply swapping the RGB display with a monochrome counterpart was only the beginning of a more complex case. The printer worked, sure. However, all models suddenly lacked details and appeared blurry compared to the prints from the stock SL1. So we started investigating the cause of this effect. The new screen has pretty much the same resolution – so why the sudden change in quality?

This illustration shows the original light reflector from the SL1. It consists of a UV LED panel at the bottom and a reflective rectangular funnel. The LEDs cast UV light rays, which bounce off the reflective surface under various angles. These rays then pass through the mask displayed on the LCD: dark areas (pixels turned off) block the UV light, bright areas (pixels turned on) allow UV light to pass through. This is the general principle of how a masked SLA 3D printer works. That’s nothing unusual. To see where it gets really interesting, we have to look closely. Very closely.

There’s a simple reason why an RGB display is called RGB: every pixel consists of three subpixels – Red, Green and Blue. Only the blue subpixel can transmit a substantial amount of UV light, which is still a mere one percent! It’s enough to cure the resin, though. Red transmits a completely negligible amount, while green blocks the UV light nearly perfectly. For simplicity, imagine that the blue subpixel is a narrow gap. The UV light bounces around the reflector thanks to the reflective walls, which means it passes through the gap under various angles – this is why the actual area exposed to UV light is slightly larger than the blue pixel itself.

The light, which passes through the larger pixel, exposes an area even larger than the pixel itself. One pixel on the monochrome display is larger than a subpixel in an RGB display. This is why our first combination of a monochrome LCD and reflector caused a loss of details! And there’s another thing: in the areas where light from two pixels overlaps, the model becomes distorted due to overexposure. Not an easy issue to solve. Yet, the benefits of using a monochrome display easily outweigh the negative aspects – we simply had to figure out how to cast light through it.

Our goal wasn’t only to decrease the time required for curing one layer. We wanted to increase the print quality even further while taking advantage of our custom-made tilt mechanism for faster and more reliable printing. This was one of the reasons why we didn’t want to use an off-the-shelf solution.

We already had the new monochrome display inserted into the SL1 frame. It was a rather easy job because the SL1 was built with upgradeability in mind like all of our machines. Then, we needed to find a light source that would produce a collimated beam of light – this means that the light rays don’t spread into sides; they remain parallel. The other important aspect is the homogeneity of the light source. If there is a difference in the strength of the light across the print area, some parts of the print may be over- or underexposed, an unwanted effect in both cases.

We turned a plano-convex lens into a Fresnel lens, which was made either by casting a UV-resistant optical resin into an SLA print or by pressing an inversion matrix into molten Plexiglass. However, achieving the required level of quality proved to be nearly impossible. Finally, we ended up with a lens array which gave us a required level of quality in terms of light collimation and homogeneity. However, it wasn’t a typical “eureka moment,” we still had a ton of work ahead of us.

It’s hard to tell what gave us the idea of making the SL1S not just as fast as possible but, simply, the fastest. I believe it was about four months before the launch. We had everything laid out on the table: a monochrome LCD with a roughly 5% efficiency/light transmission (compared to the 1 % of the RGB screen), brand new lenses, and a new LED array was in the works. We were reaching considerable increases in speed (also thanks to improved tilt mechanism speed), even the print quality went up. I guess it was one of the “what if…” moments. What if we massively increased the power of the UV LEDs? Two times? Four times?

Before I tell you the rest of the story, let me take a slight detour here – let’s talk about the tilt mechanism and print times. When you browse through various SLA 3D printers, the commonly published information is the exposure time per single layer, which can be anything from two to eight seconds. However, this is just a part of the real experience. The printer also has to move the platform upwards after a layer is cured to allow the resin to flow back under the platform and spread evenly. Then, the platform is lowered back into the resin tank and the print continues. This process takes some time – several seconds at a minimum. So the total print time is not just exposure per single layer multiplied by a number of layers, but rather exposure per one layer plus the entire up&down motion multiplied by the number of layers. In a vast majority of cases, our tilt mechanism is considerably faster. So don’t judge a 3D printer merely by comparing the exposure times.

Back to the UV LED array! First of all, the new UV LEDs we use are the cream of the crop. The manufacturer we chose tests every single LED manufactured, then separates them into so-called “bins” based on how good the parameters of the LED are, so we went straight for the top.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey