why does lcd module need sla made in china

Laser, LCD, and DLP are three distinct methods of exposing a light-sensitive resin in layers to cause a cross-linking of liquid polymers, curing the liquid into a solid object. All of these are used within SLA printers, a term used to refer to the stereolithography process. There has been a disturbing trend to refer to LCD printers are “DLP” printer that started when lower price-point manufactures began to use the already-taken “DLP” term for marketing purposes and claiming it was ok because their LCD does light processing using digital signals. Doing so, however, is like calling a gasoline-engine car an electric vehicle – something that it is not – just to confuse consumers into thinking that they are getting something often seen as more desirable but at a lower price.

Laser, (originally L.A.S.E.R as an acronym for Light Amplification by Stimulated Emission of Radiation) uses galvanometer scanners to direct a light beam via vector and raster scanning. The process is fast for smaller object, but get progressively slower when it must draw out more objects. The advantage is a smooth surface finish and compatibility with resins high in polymer content for the strongest resulting parts. An example of desktop laser-based SLAs are the Peopoly Moai and the Formlabs Form-2 printer.

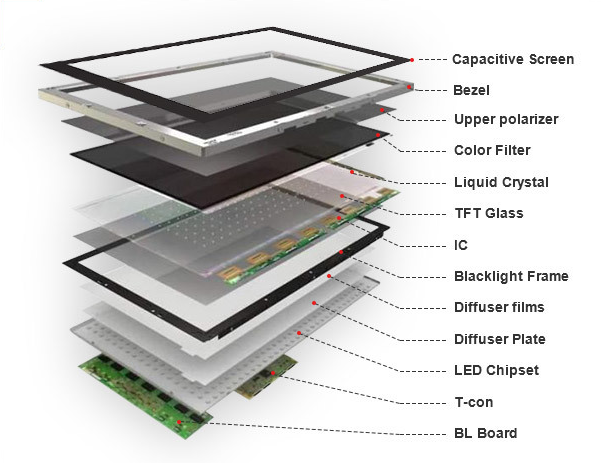

LCD is a variation of SLA that uses a Liquid Crystal Diode display, the same as in most laptops and mobile phones, as a mask. It is also known as MSLA, or masked SLA. A light source is placed on one side, and the resin on the other. Because the entire layer can be exposed at the same time, they are generally faster for printing more or larger objects. Example of LCD-based SLA printers are the Anycubic Photon, Wanhao Duplicator 7, and the EPAX-3D 1X. One reason why LCD still remains on the low end, because the fact that they can simply be manufactured for less cost, is that there is a limited amount of light that can pass through the LCD panel before it overheats and self-destructs. This limits the speed at which printing can take place. To help make up for this lower amount of light exposure, the resin makers increase the monomers and photo-sensitive initiators, with a resulting increase in potential for shrinkage and weaker parts. In reality though, due to advances in resin such as Siraya Labs Blu (the strongest LCD resin I have tested) and eSun Bioresin (the strongest solid-color LCD resin I have tested), some very strong parts can be made – just as strong, if not stronger, than PLA and ABS parts on FDM printers.

DLP uses a digital micro-mirror device in which light is reflected through a projector lens and onto a tank of resin. Because this matrix of mirrors can be well cooled, a lot more light can be directed than with LCD, thus making it the choice of larger, faster, and more expensive printers that can still make use of less sensitive and stronger resins normally reserved for laser. The downside being a higher price point, taller printer size, and sometimes lower resolution because DLP chips tend to max out at 1080P.

But you may ask – why is it not ok to refer to my LCD-based printer as “DLP” when the manufacturer says it has light processing and is digital? The answer is because the term DLP was already taken for a digital micro-mirror projector device, and there would be no distinction between the technologies, both of which are used in resin printers, if you used the same term for both.

However, I believe many careful partners have found that there is not only one kind of light curing 3D printer. At present, there are three common types on the market, mainly including SLA light curing 3D printer, DLP light curing 3D printer and LCD light curing 3D printer.

SLA technology is the first generation of light curing mainstream technology. It has a variety of translation names in China, such as three-dimensional lithography, three-dimensional printing, light modeling and so on. SLA forming technology is not only the first rapid prototyping technology to appear and commercialize in the world, but also one of the most deeply studied and widely used rapid prototyping technologies.

The basic principle of SLA molding technology is to use ultraviolet laser (355nm or 405nm) as the light source and use galvanometer system to control the laser spot scanning. The laser beam outlines the shape of the first layer of the object on the surface of liquid resin, then the manufacturing platform drops a certain distance (between 0.05-0.025mm), and then immerse the curing layer into liquid resin. After this, the solid printing is finally completed.

Digital light processing (DLP) appeared more than ten years after the emergence of SLA technology. This technology is also recognized as the second generation of light curing technology in the industry, and has a development history of more than 20 years. DLP technology was first developed by Texas Instruments. It is a rapid prototyping technology that solidifies photosensitive polymer liquid layer by layer through projector, so as to create 3D printed objects.

The consumables used in SLA and DLP are light curing resin, and the principles of the two molding technologies are very similar. Therefore, when studying 3D printing molding technology, the industry often likes to treat these two technologies as similar technologies, but they are still different in many aspects.

2. Molding speed. Because the working principle of DLP is to use the projector to solidify the photosensitive polymer liquid layer by layer, the printing speed is very fast; SLA uses a laser beam to draw objects on the surface of liquid resin, from point to line, and then from line to surface to form a solid model, because some work efficiency is much lower than the former.

3. Printing accuracy. Theoretically, there is no difference in the printing accuracy between the two, and they can reach the printing accuracy of micron level. However, since the light emitted by dlp3d printer is fan-shaped light, astigmatism will occur in the printing process, which is easy to cause the edge part to be blurred; The light emitted by SLA 3D printer is a straight line, so the latter has a slight advantage in the actual printing accuracy, but the gap is not obvious. Take the new generation DLP light curing 3D printer DP002 of chuangxiang 3D as an example. The printing accuracy is about 20-50 microns, so the forming surface is very smooth, and the step effect of FDM model can not be seen by the naked eye. Therefore, it is suitable for fields with high printing accuracy, such as dental dentures, jewelry, animation and so on. At present, the price is more than 50000 yuan.

As far as I know, the LCD light curing molding technology has only just appeared in 2013. The inventor is still a technology leader in China, but this is not the focus. The point is that this technology is open source, and the core parts are also very cheap.

Let"s talk about his forming principle first. In fact, compared with DLP molding technology, the simplest understanding is that the light source of DLP technology is replaced by LCD, and others are basically the same. The imaging principle of LCD liquid crystal panel uses optical projection to pass through the red, green and blue primary color filter to filter out infrared and ultraviolet rays (infrared and ultraviolet rays have a certain damaging effect on LCD), and then project the three primary colors through the three liquid crystal panels to synthesize projection imaging.

However, the molding technology needs to use high-power ultraviolet light irradiation and use a very small amount of ultraviolet light to cure and shape. The LCD itself is afraid of ultraviolet rays and will age rapidly after being irradiated. At the same time, the core component not only has to withstand the test of heat resistance and high-temperature heat dissipation, but also has to withstand several hours of high-intensity baking of tens of watts of 405 LED light beads, so its service life is very short. If it is often used, its core component LCD screen will be damaged in one to two months.

However, the prospect of this technology is still optimistic by the industry, and a team has invested a lot of human and material resources to conduct in-depth research on it, including the creality team of a well-known civil 3D printer company, and achieved considerable results. It is understood that in recent years, the company"s R & D team has carried out a lot of innovation and Optimization for the hard injury of short service life of LCD screen in LCD forming technology, successfully increased the service life of LCD screen to more than half a year (medium service intensity), and on this basis, launched the company"s first desktop LCD light curing 3D printer ld-001. Its subsidiary piocreat3d also launched LCD dental 3D printer dj89, which aroused strong repercussions in the industry!

It is understood that creality LCD 3D printer ld-001 and piocreat dj89 are not only no less than the high-end DLP light curing 3D printer in the market in terms of printing size and printing accuracy, but also the price is only about 1 / 15 of the latter. What"s more valuable is that based on the fact that the LCD 2K screen of the device is a lost part, creality also provides special LCD 2K screen parts for users to replace regularly. The cost is only about 300 yuan, which is very attractive!

Different businesses in varied industries are embracing the use of 3d printers to replicate a lot of their manufactured products using different materials. This has made the need for quality 3d printers soar and the market is booming. Different 3d printer brands have upgraded their systems and products to offer faster and more efficient options. With such 3d printers, work gets done faster without compromising on quality. There are different3d printer brandsout there with various features designed to help improve the user’s experience. Additionally, these3d printersalso come in different types with varied applications. Knowing more about them will help you determine which 3d printers work best for your specific needs. Some of the most common types of 3d printers include:

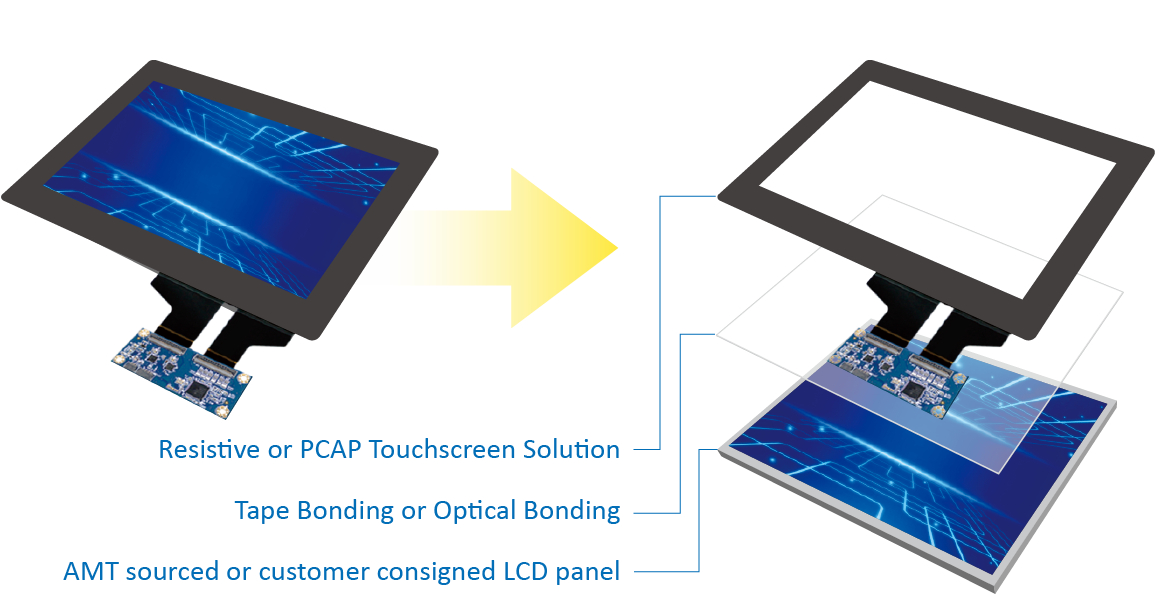

Low-cost LCD 3D printers have recently gained popularity, as they provide higher output for the same price as FDM 3D printers. These resin 3D printers use LCD panels with LED lights to cure the resin. LCD 3D printing works by flashing whole layers at once to cure the resin in the resin tank, but LCD printers don"t use mirrors. Instead, powerful LCD panels shine light at the model through LEDs, which the LCD panel blocks off in the areas not to be solidified.

The LCD screen only allows light to pass through areas that will be cured into the finished component, reducing the need for mirrors and galvanometers and simplifying the operation. An array of UV LCDs is used as a light source in LCD 3D printers. The light from the flat LCD panels shines directly on the build area in a parallel pattern. Pixel distortion is less of a problem with LCD printing since the light isn"t extended. This means that the LCD printer"s print quality is determined by the LCD density. The higher the number of pixels, the better the print quality.

Lcd 3d printers exhibit a faster printing process that allows users to have their end products with a better turnaround time. This makes these printers a great option to consider when looking forfast 3d printers.

Getting an LCD 3d printer can prove to be more expensive compared to investing in other printer options. This makes it a major drawback especially for those not working with a huge budget at their disposal.

This simply means that large models are more likely to have pixels at their edges. Regardless of the size of the print, the number of pixels on a DLP projector is the same. As a result, smaller and narrower prints on the same DLP printer may have higher precision than wider prints. It"s important to note that on more professional devices with higher-quality components, distortion is corrected. Furthermore, the problem of “zooming out” does not inherently mean that a DLP printer produces low print quality, but rather that its resolution is concentrated for smaller prints.

Speed in 3d printing is essential this is why these printers exhibit faster speeds compared to their counterparts. This makes them stand out and are more preferred.

Stereolithography is the oldest 3D printing technique, with 3D Systems commercializing it in the mid-1980s. SLA"s invention over 30 years ago marked the beginning of 3D printing, which has since grown to impact millions of people"s lives. SLA uses a laser beam to selectively solidify portions of a resin that has been deposited in a resin tank. The laser beam is guided to the exact region to be cured by mirrors called galvanometers, which are located at the bottom of the tank. This continues until the layer is fully cured then the construct platform rises one layer higher, and the process is repeated until the component is completed.

Normally, the laser is fixed, and moving mirrors (galvanometers) are used to focus the laser beam precisely where it is required. Since the printer targets light rather than directs a nozzle, which can be done much more specifically, the layer heights from such printers can be very thin. Many SLA printers will print at 25-micron layer heights (or .025mm or .001 inch).

The filament is extruded layer by layer and has a fixed thickness defined by the nozzle while printing with an FDM printer. Detail-oriented prints are difficult to achieve using this method. When working on this form of project, you"ll need a lot of post-processing to get it to the desired state. This is a challenge that none of the other 3D printers have.

The most important distinction between SLA and DLP is the process of resin curing. A projector is used in DLP, an LCD screen is used in LCD 3D printing, and a UV laser is used in SLA to trace the dimensions to be printed. Since DLP and LCD can construct whole layers at once, they are quicker than SLA, which involves manually tracing the dimensions of each layer with the laser. Another minor difference worth mentioning is that DLP 3D printers usually have shallower resin tanks, which store resin content during printing. This is beneficial if you want to save money because it eliminates the loss of costly unused resins.

When it comes to print quality comparison these printers may differ in one way or the other. Resin 3D printing is known for being one of the most detailed and accurate 3D printing technologies, and even low-cost LCD printers can produce complex geometries that Fused Deposition Modeling can"t match. To be frank, the print quality of an LCD 3D printer versus a DLP or SLA 3D printer is highly dependent on the 3D printer. With higher quality components and better resolutions and accuracy, an expensive SLA 3D printer will outperform a cheap DLP 3D printer.

Some resins can be used in both DLP and SLA printers, as well as DLP and LCD printers, so there is some crossover. However, although some 3D printer companies allow their machines to use some third-party resins, others only allow them to use their own branded resins. The best resins for you will eventually be determined by your goals for SLA, DLP, or LCD 3D printing. Basic resins, as well as castable, dental, engineering, and 3D, printed jewelry resins, are available for hobbyist 3D printer projects.

DLP and LCD printers are usually faster than SLA printers because SLA needs a laser to travel over each region of the component to be solidified, whereas DLP and LCD can cure entire layers instantly. Which is faster between DLP and LCD depends, once again, on the 3D printer you buy. More costly resin 3D printers will almost certainly print faster and with higher quality than a $300 LCD 3D printer, and a $2,500 DLP 3D printer will almost certainly print faster.

There are different 3d printer types for you to choose from depending on the specific requirements you have. Keep in mind that the best way to get quality is by working with a qualified 3d printer brand that will provide great industry options. Once you have your specific printer type in mind, discover the different 3d printers in the market that meet your exact needs. This will give you a leg up and allow you to find a printer that will meet your needs as desired.

A photosensitive suspension (photopolymer resin) is exposed by light (of certain wavelength) so it cures. The exposure pattern for each 3D slice is defined by a 2D photo mask (ultraviolet (UV) laser, UV light projector/DLP or LCD). After a layer is photocured, the Z axis moves up for the next layer of the 3D object. An FEP film clamped against the glass is used as the release layer.

So far, photocurable 3D printing has been difficult to be used in humans directly due to the low biocompatibility of photosensitive resin. Now, materials that can directly contact with human body through photocuring 3D printing are mainly inorganic materials. Bone materials with biological activities, such as hydroxyapatite and biological glass, are not photosensitive materials and need to be mixed with photosensitive resin. Therefore, the biological activity of products will be greatly affected after printing. Generally, after photocuring 3D printing, the material is dealt with sintering to remove the resin, leaving only the inorganic part, which is expected to be used as a substitute material for bones, teeth, etc. However, the volume shrinkage caused by the removal of organic matter needs to be compensated by software compensation technology, while the data calculation of special-shaped materials is very large, this software technical is not mature enough at present. At the same time, due to a large number of inorganic material filling, the resin is like paste and could not flow. Therefore, the photocurable 3D printing equipment for printing inorganic materials is unique. None of the printing devices described above can be implemented. More biomedical photocurable 3D printing materials are still in the academic research stage, involving scaffold printing, hydrogel printing and cell printing. Cui et al. [25] used PEG-DMA/chondrocyte mixture solution as bio-ink to print cartilage defect sites under ultraviolet light. The result showed the cell survival rate was relatively high. However, in the process of photocurable printing, several factors, such as the photopolymerization reaction, different wavelength, laser power, exposure time and photoinitiator, affect the cell activity inevitably [26], to some extent, limited the application of this print mode.

Some research groups prepared degradable biomedical support through photocurable 3D printing. It is known that polycaprolactone (PCLS), poly (lactic acid) (PLA), and medical polyurethane (PU), which is synthetic material, has been proved of good biodegradability and biocompatibility, and is widely used in the field of tissue engineering. Petrochenko et al. [27] used the photosensitive resin which was composed of polyurethane diacrylate (UDA) resin (Genomer 4215), two photosensitive diluents, 2-hydroxy-ethyl acrylate and glycol diacrylate to print support by SLA 3D printing technology, the printed sample was washed by 70% ethanol and 30% acetone solution repeatedly to remove the unpolymerized resin and diluent. Thus, the honeycomb scaffold with a porosity of up to 60% was obtained, mesenchymal stem cells (MSCs) were seeded on the surface of this honeycomb scaffold, it was found that the cells could be distributed on the porous scaffold evenly with a high adhesion rate, the pseudopodia of the cells were closely attached to the surface of the scaffold. With the regeneration of tissues or organs, the biodegradable scaffolds begin to degrade gradually, when the new tissue is fully grown, the scaffolds also completely degrade. Danilevicius et al. [28] successfully prepared tissue engineering scaffolds with three-dimensional porosity using PLA materials though SLA printing technology. They investigated the effects of porosity of scaffolds on physiological characteristics such as cell growth, adhesion and reproduction, the results showed that 3D printing technology can control arbitrary voids and porosity during the preparation of PLA tissue engineering scaffold model.

In the practical application, most of the photocuring 3D printing materials do not contact with the human body directly, such as in the field of dental restoration, dental orthodontic, dental surgery and so on. While, the application in biomedical field is mainly in the academic research stage [29,30]. Custom-made capacity and high precision of the photocuring 3D printing technique entitles this technique quite meet to fabricate the tissue engineering material. However, confined by the limited biocompatibility of photosensitive resin, it is difficult to employ the photocuring 3D printing technique in the biomedical field at present. It requires the innovation and mutual collaboration of both printing technique and material. For example, commonly, in the present, the hydrogel is printed by the injection printing for the low strength of the hydrogel. The printed hydrogel is of low precision and rough surface. Some tough hydrogels have been developed; however, it requires high intensity and short wavelength of light. Meanwhile, to print the hydrogel, the printing space of 3D printing machine should be kept constant temperature and humidity to prevent moisture volatilization. Brief summary, photocuring 3D printing has a promising future in biomaterials, but it still needs to overcome the difficulties in technology and materials.

You need to understand what type of value you need your prototyping supplier to provide. Let us assume you already have the drawings, schematics, etc. What is your need?

1. Just do it’ — most prototyping companies receive CAD drawings and a material spec, and produce some parts, without critical thinking. That’s what you can expect of most “rapid prototyping” companies because it goes straight from input into output. This is great if all you need is 1 or 2 components to play with, for a proof-of-concept.

2. ‘Review, provide suggestions, and then do’ — all designs, even if they were prepared by an experienced person, need to be reviewed and challenged (it is a ‘Design for Manufacturing” review). The prototyping process is part of the validation of the product design. If you expect this type of assistance, you need to assess the prototyping service provider’s engineering capability. This is important for the final prototype, especially for a full product that includes many parts.

3. ‘Review, suggest, do, but also check and test’ — In addition to the above, they translate your requirements into specifications and test plans, they organize those tests on the full product, and they provide their suggestions on how to get better performance/reliability. This is what you can expect from a full-blown R&D centre.

8.Design support services? Yes, they provide 2D to 3D CAD translation, development of an initial idea to a full CAD model capable of producing a rapid prototype component, and project management of the whole process, from concept to production.

Shape is an ISO 9001 certified facility which focuses on supporting hardware and IoT startups & SMEs with plastic and metal prototyping, small batch production, and more. Having said that, they have worked with very large companies such as Tesla, HP, and 3M. They have worked on AI & IoT & wearables, green tech, medical devices, and more.

1.Low - materials are mostly off the shelf and can include 3D custom prototype parts, cardboard paper, tape, glue, canned software, module electronics

IP rights are territorial, meaning an Australian trademark, patent or design only provides protection in Australia. To protect your IP rights in China, you need to register them in China. Registering IP rights in China as early as possible can save significant time and money later.

This printer does not appear to be receiving any updates of any kind from Monoprice or the manufacturer, Malyan. Also, the Wifi capabilities for this printer are sorely lacking. It can only use WPA security, which was cracked about a decade ago, so you don"t want it on your Wifi network anyway! It prints from the SD card just fine, though.

Configuring RTP-Based VoIP OperationsThis module describes how to configure an IP Service Level Agreements (SLAs) Real-Time Transport Protocol (RTP)-based Voice over IP (VoIP) Operation feature to set up and schedule a test call for using Voice gateway digital signal processors (DSPs) to gather network performance-related statistics for the call. Available statistical measurements for VoIP networks include jitter, frame loss, Mean Opinion Score for Conversational Quality (MOS-CQ), and Mean Opinion Score for Listening Quality (MOS-LQ).Finding Feature Information

Your software release may not support all the features documented in this module. For the latest caveats and feature information, see Bug Search Tool and the release notes for your platform and software release. To find information about the features documented in this module, and to see a list of the releases in which each feature is supported, see the feature information table.

Depending on the type of DSP, the statistics measured by the IP SLAs RTP-based VoIP operation will vary. For more information, see the “Statistics Measured by the IP SLAs RTP-Based VoIP Operation” section.

The IP SLAs RTP-based VoIP operation provides an enhanced capability to measure voice quality using DSP-based calculations to determine MOS scores. For customer scenarios where the destination gateway does not have DSP hardware, statistical information is gathered only from the DSP of the source gateway. In this case, the RTP data stream is looped back from the destination to the source gateway.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

These values are measured by sending RTP packets to IP SLAs Responder. The RTP data stream is then looped back from the destination to the source gateway.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

The source-to-destination value is measured by sending RTP packets to the IP SLAs Responder. No values are obtained from the DSP for this measurement.

These values are measured by sending RTP packets to IP SLAs Responder. The RTP data stream is then looped back from the destination to the source gateway.

Example:Router(config-ip-sla)# voip rtp 10.2.3.4 source-ip 10.5.6.7 source-voice-port 1/0:1 codec g711alaw duration 30 advantage-factor 5Enters IP SLAs VoIP RTP configuration mode and configures the IP

Example:Router(config-ip-sla-voip-rtp)# owner 10.16.1.1 cwb.cisco.com John Doe RTP 555-1212(Optional) Configures the SNMP owner of an IP SLAs operation.

Example:Router(config)# ip sla reaction-configuration 1 react frameLossDS action-type traponly threshold-type consecutive 3(Optional) Configures certain actions to occur based on events

verify-data command to the configuration of the operation (while configuring in IP SLA configuration mode) to enable data verification. When data verification is enabled, each operation response is checked for corruption. Use the

To view and interpret the results of an IP SLAs operation use the show ip sla statistics and show ip sla statistics aggregatedcommands. Checking the output for fields that correspond to criteria in your service level agreement will help you determine whether the service metrics are acceptable.

Use the show ip sla statistics command in privileged EXEC mode to display the current operational status and statistics for an IP SLAs operation. Use the show ip sla statistics aggregated command in privileged EXEC mode to display the aggregated hourly status and statistics for an IP SLAs operation.

The following table provides release information about the feature or features described in this module. This table lists only the software release that introduced support for a given feature in a given software release train. Unless noted otherwise, subsequent releases of that software release train also support that feature.

The Cisco IOS IP Service Level Agreements (SLAs) Internet Control Message Protocol (ICMP) jitter operation provides the capability to generate a stream of ICMP packets to gather network performance-related statistics. Available statistical measurements for the IP SLAs ICMP jitter operation include latency, round-trip time, jitter (interpacket delay variance), and packet loss between a Cisco device (source) and any other IP device (destination).

The Cisco IOS IP SLAs VoIP Call Setup Monitoring feature provides the ability to measure your network’s response time for setting up a VoIP call. Prior to configuring an IP SLAs VoIP call setup operation, you must enable the IP SLAs VoIP test-call application on the originating gateway (source). With the IP SLAs VoIP test-call application enabled, H.323 or Session Initiation Protocol (SIP) call messages can be sent to and received by the originating (source) and terminating (destination) gateways. The configuration for the IP SLAs VoIP call setup operation is essentially the same for both protocols.

The IP SLAs VoIP call setup operation can measure the total time from when an source gateway sends a call message, containing a call number, to when the sourcegateway receives a response from the destination gateway indicating that either the called number rang or the called party answered the call. As with all Cisco IOS IP SLAs operations, you can configure the VoIP call setup operation to repeat at specified time intervals, for a specified number of repetitions, and over a specified duration of time.

If a gatekeeper (GK) or directory gatekeeper (DGK) is involved in the H.323 call signaling, additional messages are sent and received between the source and destination gateways before the call message is actually sent. The additional time required for these messages is included in the IP SLAs VoIP call setup response time measurement. Likewise, if a proxy server or redirection server is involved in the SIP call signaling, any additional time required for messages to be sent and received prior to sending the call message, is included in the VoIP call setup response time measurement.

A plain old telephone service (POTS) IP phone can be set up at the terminating gateway to respond to an IP SLAs VoIP call setup test call. As an alternative to an actual IP phone, you can enable the IP SLAs VoIP Responder application in the destination gateway. The IP SLAs VoIP Responder application will respond to incoming call setup messages from the source gateway using H.323 or SIP.

That tells me that as a company they look at the majority of the SLA market as beneath them and don"t even want to consider them competitors. I get that they don"t want to compete in a race to the bottom and I appreciate that, but 4-7x the cost of similarly capable printers with little extra value to show for the extra cost is ridiculous.

Prusa is kidding themselves if they think they are competitive with the bottom of the professional printers as they offer nothing to minimize downtime when something does go wrong.

I think there is a place for a more expensive printer, but I think they need to realize that Epax is their real competitor right now and adjust accordingly. I think the SL1S should be about $800 to be competitive for what they offer at this time and then need to get a 10+" model out too in the $1200-1500 range. Get their support sorted out and then start offering a separate pro level support contract for faster support and replacements.

SLA 3D printers are used in various industries, from jewelry to dentistry to several companies, at affordable prices. We’ve compiled a list of the ten leading SLA 3D printers based on our research. Before that, let’s refresh what we know about SLA.

Stereolithography is also known as SLA. This method uses a UV laser and mirrors (galvanometers) to cure the photosensitive resin. It was one of the very first additive printing methods. SLA 3D printers were first invented in 1986 by Chuck Hull.

After SLA, many similar improvised processes emerged, such as DLP. However, SLA has not lost its significance over time. It’s used in the jewelry, automobile, and aerospace industries to make prototypes and functional parts.

There are hundreds of SLA 3D printers available in the market. If you want to buy one for your company, screening out each 3D printer that meets your requirements is time-consuming and exhausting, especially if you have no prior experience.

XYZPrinting is well-known for producing high-quality SLA 3D printers. The company began by manufacturing low-cost FDM 3D printers, but as demand for SLA printers grew, it expanded to include resin 3D printers.

Anycubic, a Chinese company, created the Proton S, the cheapest SLA 3D printer. It provides complex 3D prints. It’s a better version of the original Proton. The plastic resin is cured using a UV lamp.

Form 3 is a more sophisticated version of Form 2. Low Force Stereolithography is used, which is superior to SLA. The built-in volume of the printer is 145 x 145 x 185 mm. The layer resolution is set to 25 microns.

Uniz, a California-based company, created Slash Pro for professional use. For 3D printing, it is based on LCD technology. It has a build volume of 192 x 120 x 400 mm and can be used with any of the five resin types.

SLA 3D printers can produce high-quality prints, and their prices have dropped significantly in recent years. Both personal users and businesses can afford them.

This is why we compiled this list to show you the best SLA 3D printers on the market, but you must choose one, or you can also try our SelfCAD 3D Modeling and Printing software.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey