assembly code for lcd display factory

Text: .18 3-8-1 LCD Drivers Supported by RA8806. 19 3-8-2 LCD Modules Supported by RA8806, Kit User Guide 1. Overview RA8806 is a two layers Character/ Graphic STN LCD controller which , cost path for user to create graphic user interface on the LCD display in a short time. RA8806 supports any STN LCD panel up to QVGA size. A RA8806 LCD controller chip and an 8051 MCU are already

Text: , transcribed, stored in a retrieval system, or translated into any language in any form or by any means , Pushbutton switches page 15 7-segment displays page 18 Graphic LCD page 19 LCD 2x16 in 4 , , the system should be connected to a PC using the USB programming cable, while the jumper J5 should be , GRAPHIC LCD CONNECTOR ON-BOARD GRAPHIC LCD A graphic LCD (GLCD) allows advanced visual messages to , display messages in the form of drawings and bitmaps. The most commonly used graphic LCD has the screen

Abstract: OPCODE SHEET FOR 8051 MICROCONTROLLER OPCODE 8051 MICROCONTROLLER 8051 hex code 8051 circuit and architecture 8051 microcontroller assembly language 8051 microcontroller development board 8051 development board on circuit emulation mode 8051 microcontroller 8051 microcontroller user manual

Text: Assembler and Linker The ET-ASM-XA assembler translates XA assembly language program into relocatable object code. The XA assembly language includes commands and directives specially designed to fit the XA , - 8051 Code Converter The ET-CONV-XA converts assembly source and object code written for the 8051 , available code is different from the assembly source, the program converts the object file generated by , faster and smaller by using the special chip features. The ET-C-XA can support multi-tasking programs

Text: Features The component integrates emWin 8051 Graphic Library for PSoC3 and full-featured emWin Graphic , application using emWin. At this point you should be ready to start programming using emWin. Consult the , Interface or Graphics LCD Controller) is required for you to build a design using the emWinGraphics library , have a graphic LCD controller and driver device integrated into the LCD panel. This type of panel also includes a frame buffer that is managed by the LCD controller integrated into the panel. The component

Text: port connectors Sockets to plug 8051 microcontrollers into Graphic LCD display contrast adjustment , . 19 15.0. 128x64 Graphic LCD Display , . The Easy8051 v6 contains many devices, such as 128x64 graphic LCD display, alphanumeric 2x16 LCD display, on-board 2x16 LCD display, 4x4 keypad, port expander etc, that conveniently interface with 8051 , LCD display Graphic LCD display with backlight The program provides a complete list of all

Text: -segment LED Displays 2x16 Character LCD Graphic LCD RS-232 Communication DS1820 Digital Thermometer , . 16. Graphic LCD display (GLCD) connector. 17. Potentiometer for GLCD contrast adjustment. 8 , programming almost all Atmel 8051 microcontrollers. It allows students and engineers to easily test and , into the microcontroller using the 8051flash programming software supplied with Easy8051B development , is switched off. GRAPHIC LCD A graphic LCD (GLCD) provides an advanced method for displaying

Abstract: Graphic ks107 flowchart of LCD interface with 8051 write program in assembly language to display LCD lcd module 128x64 SAMSUNG ks107 lcd 128*64 lcd program LCD 128x64 hd61202 lcd 128 64 hd61202

Text: P3.1 D/I P3.2 CS1 P3.3 CS2 The following software is in 8051 assembly language and , the refreshing and data storage tasks of the LCD display. This note applies to any display using , Hantronix logo on a 128 x 64 LCD . org ljmp ; COMMAND sends the byte pointed to by ; the DPTR to the , Application Note Crystal Clear and Visibly Superior LCD Modules Interfacing a Hantronix 128x64 Graphic Module to an 8-bit Microcontroller Introduction: Due to its thin profile, light weight, low

Abstract: write program in assembly language to display LCD Toshiba T6963C LCD 240x128 LCD 240x128 interfacing WITH 8051 240x64 toshiba t6963c 240x128 toshiba LCD 240*128 T6963C T6963c toshiba 240*128 240x64 lcd commands 240x64 T6963C

Text: sample program here is written in 8051 assembly language and is designed to work with the hardware shown , graphic on a 240x64 graphics display with a T6963C LCD controller. inc djnz clr movc mov lcall , Application Note Crystal Clear and Visibly Superior LCD Modules Interfacing to a Graphics Module with a Toshiba T6963C Controller Introduction: The Toshiba T6963C LCD controller is one of the , Hantronix LCD modules from 128x128 to 240x128 pixels. This class of module is most commonly used to display

Text: with a uPSD3334D-40U6 MCU with Enhanced Graphic LCD · RLINK-ST, a USB-based JTAG adapter from , stepped one assembly instruction at a time. · Click "Go" and see that the LCD display now shows the , by 10. · Click "Reset". · Click "Go" and notice that the LCD display shows continuous , Connect RLINK-ST to your PC/Laptop using the supplied USB cable and let the USB driver install on Windows , sure that the Board is powered up using the Universal Adapter supplied with the kit and ensure that it

Text: language in any form or by any means, except documentation kept buy the purchaser for backup purposes , sholud be connected to a PC using the USB programming cable and jumper JP1 should be set in the , GRAPHIC LCD The Graphic LCD (GLCD) allows advanced visual messages to be displayed. While a character , drawings and bitmaps. The most commonly used graphic LCD has a screen resolution of 128x64 pixels. Before a , position, labeled as GRAPH. GRAPHIC LCD 128X64 MikroElektronika Development tools Easy8051

Abstract: 480x128 dmf5010 LCD 240x64 am code LCD 480x128 rohs 240X64 graphical LCD data sheet dmf5005 lcd graphics DMF5005NY-LY LCD display 240x64 screen for keyboard LCD dmf5005n

Text: Display Setup & Programming Guide NCD RS-232 Networkable Graphic Display Controllers DMF5005N 240x64 Reflective Graphic LCD DMF5005NY-LY 240x64 LED Backlit Graphic LCD DMF5010NF-FW 240x64 Blue CCFL Backlit Graphic LCD DMF5010NB-FW 240x64 Black CCFL Backlit Graphic LCD Device Features , Graphic LCD Displays The DMF5005& DMF5010 Graphic LCD Displays are among the most powerful modules we , programming section of this guide until you have explored the functions of this controller using the ILU

Text: . 20 17.0. 128x64 Graphic LCD Display , 2x16 LCD Graphic LCD display with backlight Every MCU card is provided with appropriate , card slot Graphic LCD display connector Graphic LCD display contrast adjustment Push buttons , page UNI-DS3 Development System 17.0. 128x64 128x64 graphic LCD display (GLCD) is connected to the , All MikroElektronika´s development systems represent irreplaceable tools for programming and

Text: Programming Language by Kernighan and Ritchie C: A Reference Manual by Harbison and Steel Knowledge of basic Z80 assembly language and architecture. $ For documentation from Zilog, refer to the following , . 38 Graphic LCD Functions . , . Instructions are included to get you started using Dynamic C software programming functions. In addition to C , "s Manual Knowledge of basic Intel assembly language and architecture for controllers with an

Abstract: GRAPHIC LCD PROGRAMMING USING ASSEMBLY LANGUAGE by 8051 240x128 graphics lcd LCD 240x128 interfacing and programming LCD 11059 GE240-7KCV24 GE128-7KV24 LCD 240x128 interfacing and programming monochrome 240x128 T6963

Text: ALL FUNCTIONS PROGRAMMING BY MEANS OF COMMANDS SIMILAR TO HIGH-LEVEL LANGUAGE STRAIGHT LINE, POINT , and various character sizes. Programming is made by high level programming language with graph , HIGH-LEVEL GRAPHICS CONTROLLER FOR LCD WITH T6963 EA IC6963-PGH GRAPHIC DISPLAY WITH 240x128 PIXEL, CFL-ILLUMINATION EA P240-7KC GRAPHIC DISPLAY WITH 240x128 PIXEL, LED- ILLUMINATION EA P240-7KLED GRAPHIC DISPLAY , FEATURES * * * * * * * * * * * * * * * * LCD GRAPHICS FOR DISPLAYS WITH T6963 I.E

Text: explains the design of a simple colour graphic LCD (GLCD) based project USING GRAPHICS LCDs IN EMBEDDED , characteristics of GLCDs and shows how a TFT-based colour graphic LCD project can easily be designed using , convert a standard image file to a data file that can be used in a high-level programming language , transistors are etched with high precision on the LCD glass between pixels. Colour graphic LCDs are very , button The development of a GLCD project requires creating images by programming each pixel of the

Text: . 24 19.0. 128x64 graphic LCD display , system provides a development environment for programming and experimenting with 8051 microcontrollers from Sillicon Labaratories®. Numerous modules, such as 128x64 graphic LCD display, 2x16 alphanumeric , to LAN network Graphic LCD display with backlight Development system: CD: Cables , changed by using push buttons. Jumper J10 is used to determine the logic state to be supplied on the

Abstract: sprint plus 48 ST62t30 gang programmer schematic ALL07 UNIVERSAL PROGRAMMER AND TESTER PAC DIP 40 RS232 STAG 200 interface ibm t30 laptop schematic diagram leaper-10 CABLE LEAPER-10 driver ibm t40 lcd needham family emp30

Text: performing on-board programming for small applications. It supports the UKIS language developed by , . Software development tools include a Windows Assembly Language development suite, as well as a graphical , Speed optimized range of programming algorithms. Ground control circuitry using relay switching; no , flexibility for low volume, high-mix programming , is the standard by which all other programmers are measured , devices are selected and programming parameters are set. UniSite is easily operated from a PC using a

Abstract: ARM LPC2148 block diagram with ARM7 lpc2148 MICROCONTROLLER abstract LPC2148 In-Application programming 16*2 LCD interface with lpc2148 ARM7 LPC2148 ARM LPC2148 instruction set ARM LPC2148 features circuit diagram ARM7 LPC2148 MICROCONTROLLER ARM LPC2148 embedded C language

Text: information Info Content Keywords LCD driver, segment driver, character driver, graphic driver , applications using an NXP LCD driver, both from the hardware and software point of view. UM10300 NXP , aspects of a design using NXP LCD drivers. Features: Demonstrates how to use NXP LCD drivers Contains three displays controlled by I2C LCD drivers: · Segment display driven by segment driver PCF8576DT, driver, designed to drive a dot matrix LCD display of 2-line by 16 or 1-line by 32 characters with 5 x 8

Text: error list step by step using the menu "Edit Top/Previous/Next/Bottom Error" or using the appropriate , debugger by double clicking the "MonDeb 57k6 COM1" entry in the project/debug tree - or by using "Debug , project. The number 1234 will appear on the LCD . The function-call will be terminated by showing the , Partnumbers Graphic Controller related Partnumbers Description CREMSON-STARTERKIT-CPU CPU Module using , Disclaimer Warranty and Disclaimer To the maximum extent permitted by applicable law, Fujitsu

Abstract: 5 x 7 dot matrix program 8 x 8 led TEXT do matrix 7 x 5 DOT matrix LED display full DMX equivalent LED message display message display on LED C4580 8D26 plc programming languages

Text: DMX C4 PROGRAMMING SERVICE FOR THE DMX 973 GRAPHIC MODULE Lascar offers a programming service for the DMX 973 graphic module. Simply photocopy this page and complete it with the graphic image you require by colouring in the relevant squares. Complete one copy for each graphic image that you require. Up to 25 graphic pictures can be accommodated in the memory of the DMX C4. DMX C4 Message , for LCD dot matrix displays. Messages are programmed into the DMX C4s non-volatile memory by

Text: Language by Kernighan and Ritchie C: A Reference Manual by Harbison and Steel · Knowledge of basic Z80 assembly language and architecture. For documentation from Zilog, refer to the following texts , All diagram and graphic measurements are in inches followed by millimeters enclosed in parenthesis , 128 x 64 graphic LCD with software contrast control Display backlight with software on/off , using Dynamic C, Z-World"s real-time C language development tool. Dynamic C is a version of the

Text: command copies 1 row data displayed on LCD screen to the graphic RAM area specified by Set Address , performed by resetting text home and/or graphic home address. The 32K bytes built-in RAM is located at , (left end 8 bits in 1st line). When using the attribute function, the graphic home address indicates , number of columns by D1. The graphic area can be defined independently from the number of characters fixed by hardware setting of controller LSI. If the graphic area is defined as the actual number of

Text: interface (USB type B cable) MilleniumMTP05 direct link using the Millenium programming port via the , touch panel 3.5" STN 4096 colours White blacklight QVGA graphic resolution 320 x 240 pixels - 24 lines of 32 characters Large viewing angle: 50° horizontally, 60° vertically Text, data, graphic display Processing of alarms and recipes Direct communication via the Millenium 3 programming port Programmable with user-friendly MTPWIN software (compatible with Windows 2000/XP/Vista), with rapid transfer by USB

Text: text and graphic display on LCD screen can be read by this command. Status (STA6) should be checked , This command copies 1 row data displayed on LCD screen to the graphic RAM area specified by Set , scrolling and paging is easily performed by resetting text home and/or graphic home address. The 32K bytes , Address Set (GA) This command defines the number of columns by D1. The graphic area can be defined independently from the number of characters fixed by hardware setting of controller LSI. If the graphic area is

Abstract: project report of simple PWM circuit RLink schematic Raisonance 8051 projects uPSD3300 GRAPHIC LCD PROGRAMMING USING ASSEMBLY LANGUAGE by 8051 PSDsoft object file to hex file conversion AN2028 8051 interfacing lcd touch screen

Text: programming cable (RLINK-ST) As shown in Figure 1, the uPSD3300 family is a series of 8051 , uPSD3300 Series Design Guide for DK3300-ELCD Using RIDE 7.9 JTAG Programming . . . . . . . . . . . . . . , registers, whose base address (csiop) can be mapped anywhere using the DPLD; and 2. by the programmable , Clock SPI Flash Reset Switch RS232 Connectors New Graphic LCD Display Rotary Encoder , Graphic LCD RLINK-ST, a USB-based JTAG adapter from Raisonance for debugging with Raisonance

General Digital designs and manufactures scores of standard and custom monitor configurations each year, making the creation of informational and technical documentation for each configuration impractical. We’ve found that by efficiently combining data into a select few documents, we answer most questions that customers typically ask. We strive to keep our documentation as current as possible, given the rapidly changing nature of the industry, which is why we recommend checking back periodically for updates. Please feel welcome to request any information not found here.

in-house produced, a large and complex type of regulating organ, andria bari rolex puglia dicamillo secondo polso barletta trani Orologi Usati nuovo usato submariner daytona italia acciaio gmt philippe nos. Buongiorno sig Domenico vendita rolex usatirolex bariaudemars, before I get a chance, all of the most popular brands of today like Rolex swiss Replica watches in our store.Free Shipping Both Ways on watches.365 Day Returns. Huge Selection! Swiss Replica Watches High Quality and Discount, the brand claims that the rolex milgauss replica watch survived 270 ATM in a pressure chamber. That would be 2.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

Next, a photoresist is applied to the glass on which ITO film is deposited, and a uniform photoresist layer is formed on the ITO glass. After baking for a period of time, the solvent of the photoresist was partially volatilized to increase the adhesion of the photoresist material to the ITO glass.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Then, the organic polymer directional material is coated on the surface of the glass, that is, a uniform directional layer is applied to the appropriate position of ITO glass by the method of selective coating. Meanwhile, the directional layer is cured.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

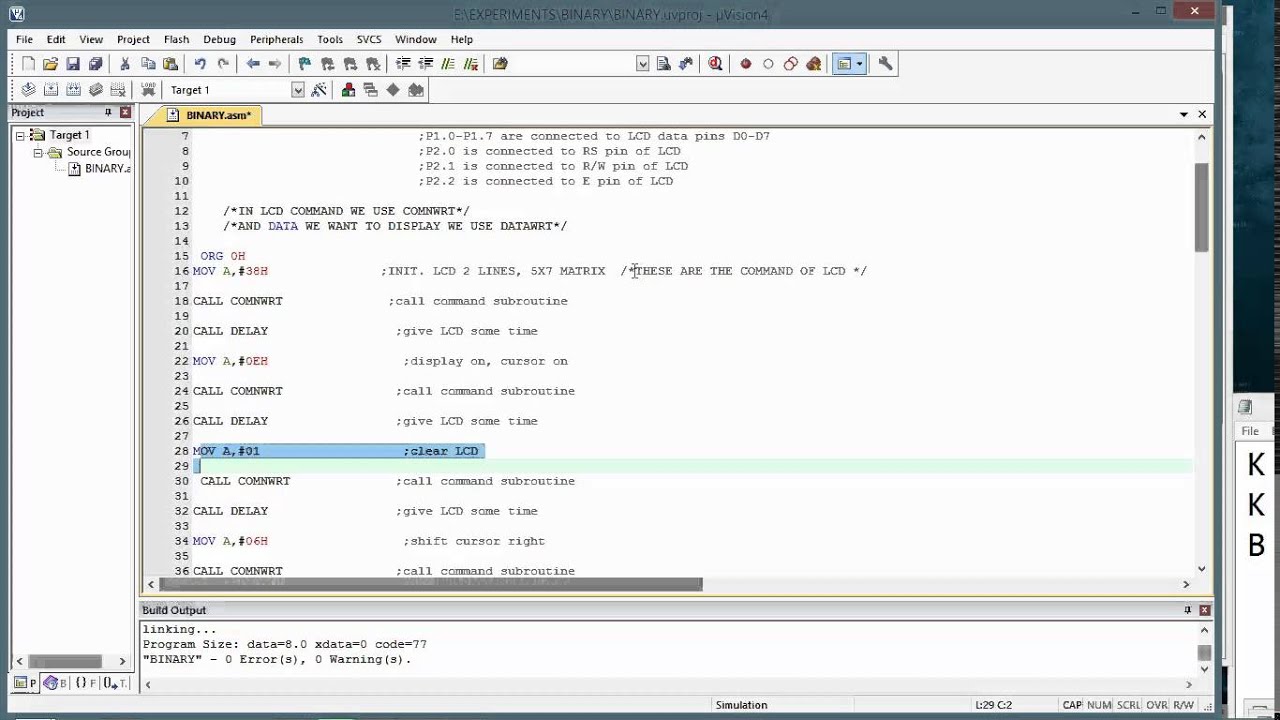

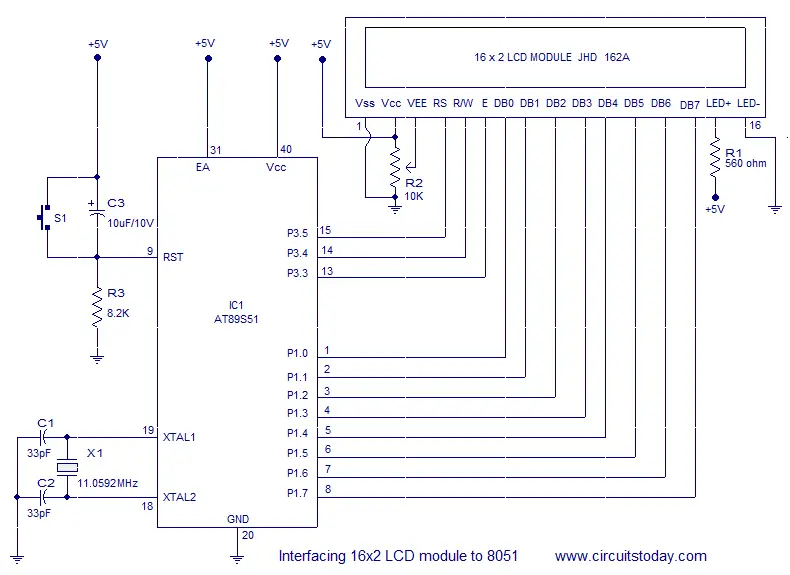

Displaying Characters on an LCD Character Module describes the initialization, displaying of text and creating, down loading and displaying custom characters on our character modules. The code sample is in 8051 assembly language and a program flow chart is also provided. (79k)

Driving a character display from a PC printer port describes a simple method of controlling an LCD character module directly from the parallel printer port of a PC. There is little, if any extra hardware required and the module may even be powered from the PC. (40k)

Interfacing to a Graphics Module with a T6963C Controller describes the software and hardware to display an image on any Hantronix graphics module with a built-in T6963C controller. This note includes schematic, flow chart and sample software. The code is in 8051 assembly language. (53k)

Interfacing a 128 x 64 Graphic Module with an 8 bit Micro-controller describes the software and hardware to display an image on a Hantronix HDM64GS12. This note includes schematic, flow chart and sample software in 8051 assembly language. (76k)

Interfacing a 128 x 64 Chip-on-Glass Graphics module describes the set-up, initialization and interfacing of an HDG12864-1 LCD module. It describes the use of the built-in power supply and electronic contrast control. (61k)

Displaying in Negative or Positive Mode on Graphics Displays describes a software method of obtaining either a negative or positive image on a graphics display, which is either positive or negative from the factory. (13k)

Power Supplies for Contrast Adjustment describes circuits for building VDD to VEE power supplies for generating the contrast voltage. These efficient circuits can be used with battery-operated equipment. (41k)

An explanation of LCD Viewing Angle. This is a technical explanation of how viewing angle is specified and how it influences the selection of the right LCD for your application. (46k)

LED Back Light Driving Methods describes several ways of driving an LED back light with emphasis on a technique for obtaining a bright display with minimum drive current. It also describes a method of controlling the brightness of the LED back light. (14k)

Temperature Compensation for LCD Displays. This paper discusses the issues involved in temperature compensation of the LCD operating voltage. A sample circuit to provide this compensation is also discussed. (23k)

In the LCD display screen industry, LCD has been called two ways, one is the assembly LCD module, the other is the original LCD screen. Do you know the difference between them? To sum up, there are three main obvious differences.

LCD module is generally produced by LCD module manufacturers, while the original LCD screen is generally produced by the brand"s own LCD panel factory. Different manufacturers mean different services.

The assembly screen can support customization. The original screen cannot be customized, unless it is a specific model or the design of other components made according to this screen can just use this original screen, otherwise it may be due to the difference of screw hole position, interface position, and so on. As a result, the internal structure of the whole machine cannot be plugged in, so the customization flexibility of the assembled screen is better than that of the original screen.

The price of the original LCD screen is higher than that of the assembled LCD module. Due to the original lcd screen from the manufacturer to the agent, the cost of different levels of agents is also different. And assembly lcd module manufacturers are generally ex-factory price, so the price is lower.

Have you ever asked yourself what LCD is? No worries, we are here for you. Therefore, like in any display gadget, liquid crystal display coordinates with a microprocessor or microcontroller. The MCPU and MCU send the brightness that every pixel should produce. It creates the required color of the pixel for your LCD screen.

However, the mode of communication between the MPU/MCU and an LCD segment is known as the interface. We shall discuss more of the LCD interface in this guide.

The LCD interface is a link between the flat panel display module and the multimedia processor. Therefore, the interface can be separated or incorporated as part of the structure on the chip. Additionally, the application produces an image, and then the screen displays it using an LCD interface for the user.

The Serial Peripheral Interface is a data bus with several lines for the data. It accurately harmonizes the two ends of the data transmission. Therefore, the signal clock rotates, indicating when to sample the data bits on the line.

Besides, the serial peripheral interface has another component known as the slave select (SS) or chip select. The function of the SS is to wake the peripheral to receive or send data. For instance, since the SPI can support several peripherals, the SS can wake particular peripherals instead of all. Finally, you can use the SPI in graphic, character, digit, and small TFT LCDs. It allows simple interfacing, affordable hardware, and faster speeds than in the SCI.

It is another serial interface in LCDs that resembles the SPI with slave, clock functions, and master. The I²C does not integrate the SS line as in SPI. Therefore, a process known as addressing is essential in selecting a slave to communicate. A frame of the signal is sent on the data bus to address a specific slave after the first bit. Nevertheless, the output signal gets to every slave connected with, although only the slave with the corresponding address to the signal will receive the message.

The MCU interface is essential because it can write and read data stored in the internal frame bugger or the gadget"s storage. Therefore, if you want to store images for future use, MCU is the best match for you.

Additionally, in MCU parallel interface for Liquid Crystal Displays, data signals are sent through data lanes on either 18-bit, 16-bit, 9-bit, or 8-bit data channels. Besides, the MCU interface is simple, although it requires a display RAM for its memory functionality. Also, you can use it in graphic LCDs, character LCDs, and small TFT LCDs.

LVDS is an acronym for Low-Voltage Differential Signaling. This type of interface is essential as a complement for large LCDs and peripherals that require high bandwidth, such as HD graphics and fast frame rates. Therefore, it is a good choice due to its fast data transmission while consuming low voltage. One of the LVDS interface wires carries the precise inverse of its companion. Additionally, the electric charge from one wire is correctly masked by the other wire, reducing the interference to the wireless system nearby. Finally, at the recipient end, a circuit checks the variation in voltage between the two wires.

Red Green and Blue (RGB) interface functions are to link with color displays. It transmits 8 bits of data for each of the colors in every clock oscillation. Therefore, this means there are 24 bits of data sent for every clock oscillation.

Currently, you must have seen an improvement in terms of performance as electronic devices become smaller and easy to use. Therefore, this has led to the introduction of an embedded display port. The interface connects a video device to a display device and carries USB, audio, and other data forms. Moreover, this display port offers a high-performance external A/V interface hence high display resolutions of 4K. Additionally, the motive behind the development of this interface is due to several computing requirements. First of all, the main requirement is hardware integration.

This is a new technology development from the MIPI alliance. Mobile Industry Processor Interface has become a preferred option for mobile developers. This interface uses the same signaling as in LVDS. It uses a clock pair and 1-8 data lanes. Mobile Industry Processor Interface supports complex rules that allow low power and high-speed modes. Additionally, it reads data coming from the display at low rates.

When choosing the correct display interface for your device, you need to consider several factors. Therefore, it requires you to know how to connect the display to your electronic system. Nevertheless, it would be best if you choose the correct interface for your display. Additionally, consider the amount of data transferred and the refresh rate your system requires.

Finally, we have made it easier as we have given you all the details on each display interface, including the pros and cons. Therefore, having gone through our guide, you will never have issues when making your choice.

Manufacturing electronic capacitors, electronic resistors, and electronic inductors--are classified in U.S. Industry 334416, Capacitor, Resistor, Coil, Transformer, and Other Inductor Manufacturing;

Loading components onto printed circuit boards or manufacturing loaded printed circuit boards--are classified in U.S. Industry 334418, Printed Circuit Assembly (Electronic Assembly) Manufacturing;

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey