led vs tft display brands

Confused about LED vs. LCD vs. TFT? Here"s everything you need to know. Creating or upgrading a device display or screen can involve a lot of different things, but it often comes down to one major question - what kind of display should you get?

So, there are 3 common displays LED, LCD and TFT available in the market. All terms refer to the flat-panel display, or screen, of a computer monitor or television set. In this article, we are going to differentiate between them. It will help you to choose a better one.

LCD stands for liquid crystal display. Works by adjusting the amount of light blocked. Usually has a backlight but might not (clocks, calculators, Nintendo Gameboy). The green-black ones can be very cheap and are a mature technology. Response time can be slow. An LCD display uses the light balancing qualities of crystals. Today LCDs are used in a great number of products and applications. Your TV, computer screen, calculator, cell phone and the dreaded alarm clock are all made of an LCD flat panel. Color LCDs produce the color based on two techniques: Passive matrix and active matrix. Passive matrix is the cheapest technology of the two. The other technology is called an active matrix or TFT. Active matrix displays produce really sharp and clear images.

This is a type of LCD with a thin film transistor attached to each pixel. All computer LCD screens are TFT since the early 2000s; older ones had slower response times and poorer color. Cost is now very good; power consumption is fairly good but dominated by the backlight. Has to be manufactured out of glass. The TFT layer is embedded in the screen itself, it reduces crosstalk between pixels. Crosstalk happens when a signal sends to a pixel also affects the pixel next to it. This makes the TFT technology the technology offering the best resolution and image quality. It also makes it a bit more expensive. Today TFTs have become the standard when producing LCD screens.

LED stands for a light emitting diode. As the name suggests, emits light rather than blocking it like LCD. Used for red/green/blue/white indicator lights everywhere. Some manufacturers advertise "LED" displays that are TFT screens with a white LED backlight, which is just confusing. Ones that are real LED screens are usually OLED.

Some devices actually have backlights made from Red, Green and Blue LEDs, normally referred to as RGB LED, which tend to have better color reproduction than any other display.

LED screen is just like saying that it is a plastic screen. You still have the WHOLE screen illuminated all the time and LED is "good" only for being more eco-friendly and probably more bright at max setting if you ever need this.

An LCD panel is, in fact, 2 layers of glass with some volume of Liquid Crystal in between. These two form the panel itself. The 2 layers are usually called Color Filter Glass (above) and TFT glass (below).

A standard TFT has a whole "lamp" behind it, illuminating the whole screen all the time. This way, you cannot have a true black, as it is still illuminated and stay grayish.

TFTs are a type of active matrix display that controls individual pixel updates several times per second on the screen to update the image relative to the content source.

TFT displays use more electricity than regular LCD screens, so they not only cost more in the first place, but they are also more expensive to operate.

LCDs use fluorescent lights while LEDs use those light emitting diodes. The fluorescent lights in an LCD are always behind the screen. On an LED, the light emitting diodes can be placed either behind the screen or around its edges.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

"Thin film transistor" and "light emitting diode" are two terms used to describe different parts of a liquid crystal display screen. It is possible for a LCD to use both TFT and LED technology at the same time. TFT technology handles how the pixels are displayed on the screen whereas LED refers to how the screen lights up. Most consumer LCD displays use TFT technology; however, some higher-end screens use Organic Light-Emitting Diode technology instead. LED are an improvement over fluorescent back-lighting technology.

TFTs are a type of active matrix display that controls individual pixel updates several times per second on the screen to update the image relative to the content source. These displays are built from a thin layer of transistors located on the back of the screen that handles screen animation. The display receives information from a computer or video source and updates the screen contents row-by-row so many times per second that it looks like the entire screen is updating content in real-time as opposed to being a collection of frames. A more advanced type of TFT technology called In-Plane-Switching improves the screen viewing angles.

Unless a LCD screen is called a Organic Light-Emitting Diode Display, it uses TFT technology. OLEDs improve upon TFT technology by illuminating the screen itself and making a backlight unnecessary to view screen content. OLEDs feature a more vibrant picture, a wider viewing radius, thinner screen, faster refresh rate and less power consumption than LCDs. OLED technology beats TFT technology for display quality, but is more expensive and requires a glass-covered screen.

A display that carries the LED tag in its name is still a LCD screen; the LED name is used because it"s shorter than the more descriptive names like LED-LCD or LED-backlit-LCD. LEDs are used as a static, one-color light source in power indicators and flashlights. LED screens use a non-colored LED light source to illuminate the screen; this provides a more dynamic brightness range than traditional fluorescent backlighting. LED screens are able to make black appear darker and the brightest colors appear brighter.

If a LCD screen doesn"t use LED backlighting or OLED technology, it uses a fluorescent lamp to illuminate screen content. Fluorescent lights aren"t as dynamic in brightness range as LEDs, but they are cheaper to manufacture and can still display a high-quality image. In addition to having inferior picture quality, fluorescent lights have a shorter lifespan, take up more space and use more power to operate than LED lights. TVs and monitors that use fluorescent back-lights are actually using the same technology that"s used to create fluorescent room lighting.

LCD: liquid crystal display. Works by adjusting the amount of light blocked. Usually has a backlight but might not (clocks, calculators, Nintendo Gameboy). The green-black ones can be very cheap and are a mature technology. Response time can be slow.

TFT: is a type of LCD with a thin film transistor attached to each pixel. All computer LCD screens are TFT since early 2000s; older ones had slower response times and poorer colour. Cost is now very good; power consumption is fairly good but dominated by the backlight. Has to be manufactured out of glass.

LED: light emitting diode. As the name suggests, emits light rather than blocking it like LCD. Used for red/green/blue/white indicator lights everywhere.

Some manufacturers advertise "LED" displays that are TFT screens with a white LED backlight, which is just confusing. Ones that are real LED screens are usually OLED.

OLED: organic LED (rather than silicon or germanium based like regular LEDs). Comparatively recent technology, so cost still quite variable and not available in really large sizes. In theory can be printed on plastic, resulting in lighter flexible displays with good brightness, good power consumption and good response time.

Then there are the technical terms to deal with, such as LED TV, LCD TV, QLED TV, UHD TV, OLED TV, and more. You might feel like you need to be a tech pro just to watch your favourite TV show in the evening or enjoy a game with your friend.

First, an important thing to understand is that the LED (Light Emitting Diode) monitor is an improvised version of the LCD (Liquid Crystal Display). This is why all LED monitor is LCD in nature, but not all LCDs are LED monitors.

LCD technology revolutionized monitors by using cold cathode fluorescent lamps for backlighting to create the picture displayed on the screen. A cold cathode fluorescent lamp (CCFL) is a tiny fluorescent bulb. In the context of this article, LCDs refer to this traditional type of CCFL LCD TVs.

LED monitors took the old technology a step further by replacing the fluorescent bulbs with LED backlight technology. And OLED (organic light-emitting diode) technology improves it even further by eliminating the need for backlighting.

The quality of direct-view LED screens is measured by pixel pitch. The pixel pitch is the distance between two adjacent LEDs on the display. The smaller the pixel pitch, the better the quality of the image.

Since LEDs replace fluorescent bulbs with light-emitting diodes, LED TVs are more energy-efficient than LCDs. A 32-inch LED TV screen consumes 10 watts less power than the same size LCD screen. The difference in power consumption increases as the size of the display increases.

Light-emitting diodes are considerably smaller than fluorescent lamps used in LCD monitors. Fluorescent lamps have a considerable thickness, but the thickness of diodes is next to none. Moreover, countless diodes are assembled in the same plane, so the thickness of the array isn’t increased no matter how many diodes are present.

Edge-lit LEDs have a slight drawback in viewing angle compared to LCDs, because of the position of the light source. However, direct-view LEDs offer a better angle for viewing than LCDs as the light source is evenly spread on the screen.

Since LED displays use full-array LED backlighting rather than one big backlight, LED TVs offer significantly better contrast than LCDs. LCD backlighting technology only shows white and black, but LED backlighting can emit the entire RGB spectrum, thereby providing a deeper RGB contrast.

If you wonder which display will last longer, this debate is also won by LED displays. LED televisions have a longer lifespan of 100,000 hours on average, compared to 50,000 hours provided by LCD televisions.

An LED display provides the option to dim the backlight, along with other eye comfort features. Not only that, it provides a wider viewing angle without harming image quality. Therefore, an LED display is far better for your eyes than an LCD.

In an LED display, a lot of smaller diodes are used and if a diode is damaged, it can be replaced. In an LCD, you will need to replace the entire bulb in case of damage. Therefore, an LED display is easier and cheaper to maintain than an LCD.

Since LEDs are a better and newer technology, the price of an LED display is higher than an LCD. However, this is only when we are considering the purchase cost.

The picture quality of an LED display is far better than an LCD. Due to modular light-emitting diodes, an LED screen produces better control over the contrast, rendering a clear picture. Also, LED provides RGB contrast, which can show truer blacks and truer whites.

Not to forget, they provide a shorter response time as well. Both of these factors result inLED displays having a better picture quality compared to LCD displays.

Since LED displays are considerably thinner than LCDs, they weigh considerably less. On average, an LED screen weighs about half of an LCD screen of the same size.

As you might have noticed by now, LED wins the battle with LCD without any doubt. This is because LED displays have an advantage in all the factors that matter when considering a purchase, except price.

Even when you consider the price, you will find that while LED technology is costlier, it provides better value for money in the long run. This is because of the longer lifespan and easier maintenance of LED screens.

They are more attractive too. With the increasing shortage of space in new residential complexes, what better solution than an ultra-thin LED display giving a cinematic experience in the comfort of your home.

LED screens are the first choice among the public today, across generations. All are opting to switch to LED from LCD to make their lives more enjoyable and better.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

Relies on backlighting to provide brightness rather than producing its own light, hence, they need built-in light emitting diodes (LEDs) in their backlighting structure

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

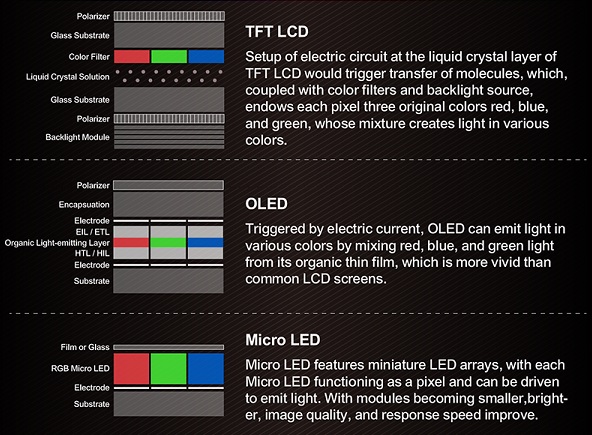

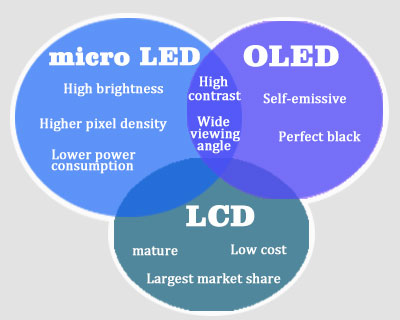

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Have you ever wonder where TFT derive from? Why is TFT referred to as LCD? The phenomenon started in early days, when bulky CRT displays were thing of the past and LCD was its replacement, but as time progresses, there were still room for improvement, which leads to the birth of TFT’s.

TFT is a variant of an LCD which uses thin film transistor technology to improve an image quality, while an LCD is class of displays that uses modulating properties of liquid crystals to form what we call an LCD (liquid crystals display) which in fact does not emits light directly.

Even though LCDs were very energy efficient, light weight and thin in nature, LCD were falling behind to the CRT display, which then leads to a change in LCD manufacturing, where performance became a big problem.

For example, having a 2001 Mustang vs a 2014 Mustang, the dimensions and engine of the 2014 has been redesign for performance reasons, not mentioning user friendly, so does the LCD to TFT.

As the birth of TFT, the elements are deposited directly on the glass substrate which in fact the main reason for the switch was because TFTs are easier to produce, better performance in terms of adjusting the pixels within the display to get better quality.

As TFT’s become very popular throughout the century due to its elaborate low charge associate and outstanding response time, LCDs became a thing of the past, and TFT became the predominant technology with their wider viewing angles and better quality this technology will be around for a long time.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

MicroLED shows promise as a display technology, potentially offering power savings and a reduced screen thickness when put beside current-generation display panels. Apple has recognized the potential, and has invested heavily into developing the technology over the last few years, with a view to using it in the company"s future products.

To understand fully how MicroLED can benefit Apple, it is worth understanding how the commonly-used display technologies work in the first place, before examining how different MicroLED really is in a comparison.

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

Displays that use collections of LEDs as individual pixels do exist, but it isn"t usually found in consumer products. LED screens are commonly used for billboards, in attractions, and as a large-scale display for events.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

As the name implies, OLED uses an organic compound film that is put between two electrodes, which are used to provide charge. Instead of the charge changing how light passes through, the current instead causes the emissive electroluminescent layer to emit light, without the need for a rear light source.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

OLED also can be produced on plastic substrates instead of glass, allowing it to be used to create flexible displays. While this is currently embodied in curved and other non-flat screens in some devices, it has the potential to be employed in foldable smartphones or rolled up for storage, an area Apple is also allegedly examining.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

OLED panels are also affected by the presence of water, both in production and in use. Small amounts of water contacting the organic substrate can cause immediate damage to the display, rendering parts of the screen useless.

So far, Apple"s usage of OLED consists of the premium iPhone X and the Apple Watch. As the cost of production drops down, it is plausible for Apple to use OLED in more future products, providing a better screen for customers to use.

Thought to be the next big thing in display technology, MicroLED basically takes the idea of using LEDs for pixels in a large stadium-style screen and miniaturizes it all.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED doesn"t use an organic compound to produce light, making it less susceptible to failure compared to OLED. Just like OLED, it can be applied onto a flexible material, allowing it to be used for curved displays or non-stationary components, like a watch strap, and can result in an extremely thin display panel.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

While MicroLED is an attractive proposition for Apple, it is not the only technology under development by the company"s engineers. Apple has previously filed patent applications for a technology described as "Quantum Dot LED and OLED Integration for High Efficiency Displays."

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

The technology in theory can create an even thinner display than OLED, along with a more streamlined manufacturing process. True QD displays are also capable of high pixel densities of up to 1,000ppi, multiple times the density required to be called a Retina-quality display, and based on Apple"s hybrid invention, will also boast the response times of OLED technology.

As is usually the case, Apple does produce a considerable number of patent applications every week that are filed with the US Patent and Trademark Office, and not everything it files will be fully commercialized.

The QD patent application certainly shows Apple is thinking about display technology in multiple ways, and how it can be applied to future devices, but short of getting firm supply chain information or an official announcement from Apple directly, it is difficult to confirm which direction it will be heading.

Apple has been interested in using the technology for some time now, with the first notable sign being its acquisition of LuxVue in May 2014, alongside assorted related patents. A MicroLED specialist, LuxVue was rumored to have been the display producer for the ill-fated Google Glass headset, but was also the holder of assorted patents in the LED display field, including MicroLED.

At the time, the acquisition was thought to be an attempt by Apple to bring part of its display technology development in-house, with suggestions the MicroLED technology would be used in another rumored-at-the-time device, the Apple Watch. A more recent report suggests Apple is working with TSMC to make small panels for a future premium Apple Watch, potentially starting mass production by the end of the year.

Apple has also reportedly set up a secret facility just 15 minutes away from Apple Park, believed to be used for developing MicroLED. The 62,000 square-foot facility is thought to house around 300 engineers on a project named "T159," relating directly to the technology"s development.

The facility is also claimed to be sufficient in size to perform small scale manufacturing of display panels, allowing the company to keep development and testing in-house without involving third-parties. Considering Apple"s previous history in developing technologies before issuing information to manufacturing partners, it is possible that Apple is trying to work out the kinks in production before suppliers even attempt to make MicroLED panels.

The rumored small screen production may be for the Apple Watch now, but it may also benefit another often-rumored device, namely the VR or AR headset. This type of hardware relies on light components to keep the weight off the user"s head and neck, as well as displays with a high refresh rate and as close to perfect color reproduction as possible.

Apple is also apparently planning to use the technology in larger displays, said to be bigger in size than those in the MacBook Pro lines. This could be an iMac or iMac Pro, or even an external display, but ultimately there"s no real indication of Apple"s plans at this point, regardless of the scale of the screen.

Reports from last year also suggest Apple"s investment in MicroLED was a cause for concern for Samsung, LG, and other South Korean suppliers who provide display panels for the company"s products. Owning the process for MicroLED manufacturing could allow Apple to migrate away from its existing display suppliers in the coming years, reducing revenues and profits.

Aside from Apple"s development, there has been little in the way of announcements from other firms for products using the technology that could be bought by consumers in the coming months. The exception is Samsung, Apple"s main rival in the mobile marketplace and a major supplier of display panels, but its usage of MicroLED is not aimed at producing smaller screens.

At CES 2018, Samsung introduced The Wall, a 148-inch TV claimed to be the "world"s first consumer modular MicroLED" television. According to the South Korean electronics giant, The Wall"s modularity meant consumers would be able to customize their television"s size and shape to suit their needs.

The impending use of the technology in a high-priced consumer product could be considered proof that MicroLED display technology is maturing enough for use in devices. If the reports claiming Apple is getting close to mass producing panels is true, the inclusion of MicroLED in the Apple Watch could end up being the first mainstream usage of the technology.

.png)

At Display Technology we understand that each market sector has different requirements, therefore we pick our suppliers based on what our customers want. But, there is a common process and thought strategy used, when picking each supplier.

We aim to offer TFT LCD displays of the best quality for the price, and where we can secure a continuity of supply. The quality of products reflects on our business, and so we do not want to be linked to inferior quality stock. We also understand that there is a certain amount of development time, approvals and cost if a product changes.

With every development we look at the impact and consult with our clients the best route forward in order to meet requirements. When we choose a partner, unlike some TFT display suppliers, we do not just add on without understanding how the range fits within our business model. It is also important that we can add value to a suppliers range for an improved solution for the end customer.

We know all our TFT monitors will require support from other components within our range, including touch screens, interface cards or backlight controllers. Therefore we endeavour to fully test new panels for compatibility prior to releasing onto the market.

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

12°° displays (top view, TV) are best built into a table-top unit. All displays can be read vertically from the front.Reflective, transflective, transmissive

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

However, the lighting also determines the optical impression made by the display, and the display mode; blue or yellow-green – does not always have an influence. Below you can see the EAP162-3N display with different types of lighting by way of example:Lighting

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

Text displays require what is known as a dot matrix, an area consisting of 5x7=35 dots, in order to display all of the letters in the alphabet as well as various special characters. Graphics displays have a similar structure to text displays. In this case, however, there are no spaces between the lines and characters.Display drivers and controllers

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Pure display drivers work in a similar way to a shift register. They generally have a serial input. They require an external pulse, and in multiplex operation with high frequency they require new display data continuously in order to achieve a refresh frequency that is as high as possible (MSM5219, UPD7225, HD44100, LC7942, etc.). An example of a genuine controller is theHD44780 for dot-matrix displays: Once it has received the ASCII code, the controller manages its character set, memory and multiplexing entirely on its own. The following controllers are widely used for graphics displays: HD61202/3, HD61830, SED1520, SED1330, T6963.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

For all the new technologies that have come our way in recent times, it’s worth taking a minute to consider an old battle going on between two display types. Two display types that can be found across monitors, TVs, mobile phones, cameras and pretty much any other device that has a screen.

In one corner is LED (light-emitting diode). It’s the most common type of display on the market, however, it might be unfamiliar because there’s slight labelling confusion with LCD (liquid crystal display).

For display purposes the two are the same, and if you see a TV or smartphone that states it has an ‘LED’ screen, it’s an LCD. The LED part just refers to the lighting source, not the display itself.

In a nutshell, LED LCD screens use a backlight to illuminate their pixels, while OLED’s pixels produce their own light. You might hear OLED’s pixels called ‘self-emissive’, while LCD tech is ‘transmissive’.

The light of an OLED display can be controlled on a pixel-by-pixel basis. This sort of dexterity isn’t possible with an LED LCD – but there are drawbacks to this approach, which we’ll come to later.

In cheaper TVs and LCD-screen phones, LED LCD displays tend to use ‘edge lighting’, where LEDs sit to the side of the display, not behind it. The light from these LEDs is fired through a matrix that feeds it through the red, green and blue pixels and into our eyes.

LED LCD screens can go brighter than OLED. That’s a big deal in the TV world, but even more so for smartphones, which are often used outdoors and in bright sunlight.

Brightness is generally measured as ‘nits’ – roughly the light of a candle per square metre. Brightness is important when viewing content in ambient light or sunlight, but also for high dynamic range video. This applies more to TVs, but phones boast credible video performance, and so it matters in that market too. The higher the level of brightness, the greater the visual impact.

Being able to see unwanted backlighting affects a display’s contrast, which is the difference between its brightest highlights and its darkest shadows.

You’ll often see a contrast ratio quoted in a product’s specification, particularly when it comes to TVs and monitors. This tells you how much brighter a display’s whites are compared to its blacks. A decent LCD screen might have a contrast ratio of 1,000:1, which means the whites are a thousand times brighter than the blacks.

Contrast on an OLED display is far higher. When an OLED screen goes black, its pixels produce no light whatsoever. That means an infinite contrast ratio, although how great it looks will depend on how bright the screen can go. In general, OLED screens are best suited for use in darker rooms, and this is certainly the case where TVs are concerned.

OLED panels enjoy excellent viewing angles, primarily because the technology is so thin, and the pixels are so close to the surface. You can walk around an OLED TV or spread out in different spots in your living room, and you won’t lose out on contrast. For phones, viewing angles are extra important because you don’t tend to hold your hand perfectly parallel to your face.

Viewing angles are generally worse in LCDs, but this varies hugely depending on the display technology used. And there are lots of different kinds of LCD panel.

Perhaps the most basic is twisted nematic (TN). This is the type used in budget computer monitors, cheaper laptops, and very low-cost phones, and it offers poor angled viewing. If you’ve ever noticed that your computer screen looks all shadowy from a certain angle, it’s more than likely it uses a twisted nematic panel.

IPS is used in most smartphones and tablets, plenty of computer monitors and lots of TVs. It’s important to note that IPS and LED LCD aren’t mutually exclusive; it’s just another bit of jargon to tack on. Beware of the marketing blurb and head straight to the spec sheet.

OLED’s colours have fewer issues with pop and vibrancy, but early OLED TVs and phones had problems reining in colours and keeping them realistic. These days, the situation is better, Panasonic’s flagship OLEDs are used in the grading of Hollywood films.

Where OLED struggles is in colour volume. That is, bright scenes may challenge an OLED panel’s ability to maintain levels of colour saturation. It’s a weakness that LCD-favouring manufacturers enjoy pointing out.

Both have been the subject of further advancements in recent years. For LCD there’s Quantum Dot and Mini LED. The former uses a quantum-dot screen with blue LEDs rather than white LEDs and ‘nanocrystals’ of various sizes to convert light into different colours by altering its wavelength. Several TV manufacturers have jumped onboard Quantum Dot technology, but the most popular has been Samsung’s QLED branded TVs.

Mini LED is another derivation of LED LCD panels, employing smaller-sized LEDs that can emit more light than standard versions, increasing brightness output of the TV. And as they are smaller, more can be fitted into a screen, leading to greater control over brightness and contrast. This type of TV is becoming more popular, though in the UK and Europe it’s still relatively expensive. You can read more about Mini LED and its advantages in our explainer.

OLED, meanwhile, hasn’t stood still either. LG is the biggest manufacturer of large-sized OLED panels and has produced panels branded as evo OLED that are brighter than older versions. It uses a different material for its blue OLED material layer within the panel (deuterium), which can last for longer and can have more electrical current passed through it, increasing the brightness of the screen, and elevating the colour volume (range of colours it can display).

Another development is the eagerly anticipated QD-OLED. This display technology merges Quantum Dot backlights with an OLED panel, increasing the brightness, colour accuracy and volume, while retaining OLED’s perfect blacks, infinite contrast and potentially even wider viewing angles, so viewers can spread out anywhere in a room and see pretty much the same image. Samsung and Sonyare the two companies launching QD-OLED TVs in 2022.

And for smartphones there’s been a move towards AMOLED (Active-Matrix Organic Light Emitting Diode) screens for Android screens, while Apple has moved towards OLED for its smartphones and tried Mini LED with its iPad Pro. Technologies are consistently evolving with Superand Dynamic AMOLED versions available, more performance is being eked out.

While LED LCD has been around for much longer and is cheaper to make, manufacturers are beginning to move away from it, at least in the sense of the ‘standard’ LCD LED displays, opting to explore the likes of Mini LED and Quantum Dot variations.

OLED has gained momentum and become cheaper, with prices dipping well below the £1000 price point. OLED is much better than LED LCD at handling darkness and lighting precision, and offers much wider viewing angles, which is great for when large groups of people are watching TV. Refresh rates and motion processing are also better with OLED though there is the spectre of image retention.

If you’re dealing with a limited budget, whether you’re buying a phone, a monitor, a laptop or a TV, you’ll almost certainly end up with an LCD-based screen. OLED, meanwhile, incurs more of a premium but is getting cheaper, appearing in handheld gaming devices, laptops, some of the best smartphones as well as TVs

Which is better? Even if you eliminate money from the equation, it really comes down to personal taste. Neither OLED nor LCD LED is perfect. Some extol OLED’s skill in handling darkness, and its lighting precision. Others prefer LCD’s ability to go brighter and maintain colours at bright levels.

How do you decide? Stop reading this and go to a shop to check it out for yourself. While a shop floor isn’t the best environment in which to evaluate ultimate picture quality, it will at least provide an opportunity for you to realise your priorities. Whether you choose to side with LCD or OLED, you can take comfort in the fact that both technologies have matured considerably, making this is a safe time to invest.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey