lcd displays design services factory

A turnkey LCD solution is a project built so that the end customer is sold a completed LCD product, ready for use. It is our specialty to take on the responsibility for designing and developing a product that is ready to be used upon completion. We have a team of experts ready to take on any challenging turnkey LCD need you have. AGDisplays offers in-house assembly, testing and quality measures, packaging and drop ship capabilities. We are able to accommodate small and large volume production quantities.

LCD turnkey projects involve kitting LCD peripherals and components or just selling commercial off the shelf LCD products that are applicable across all industries.

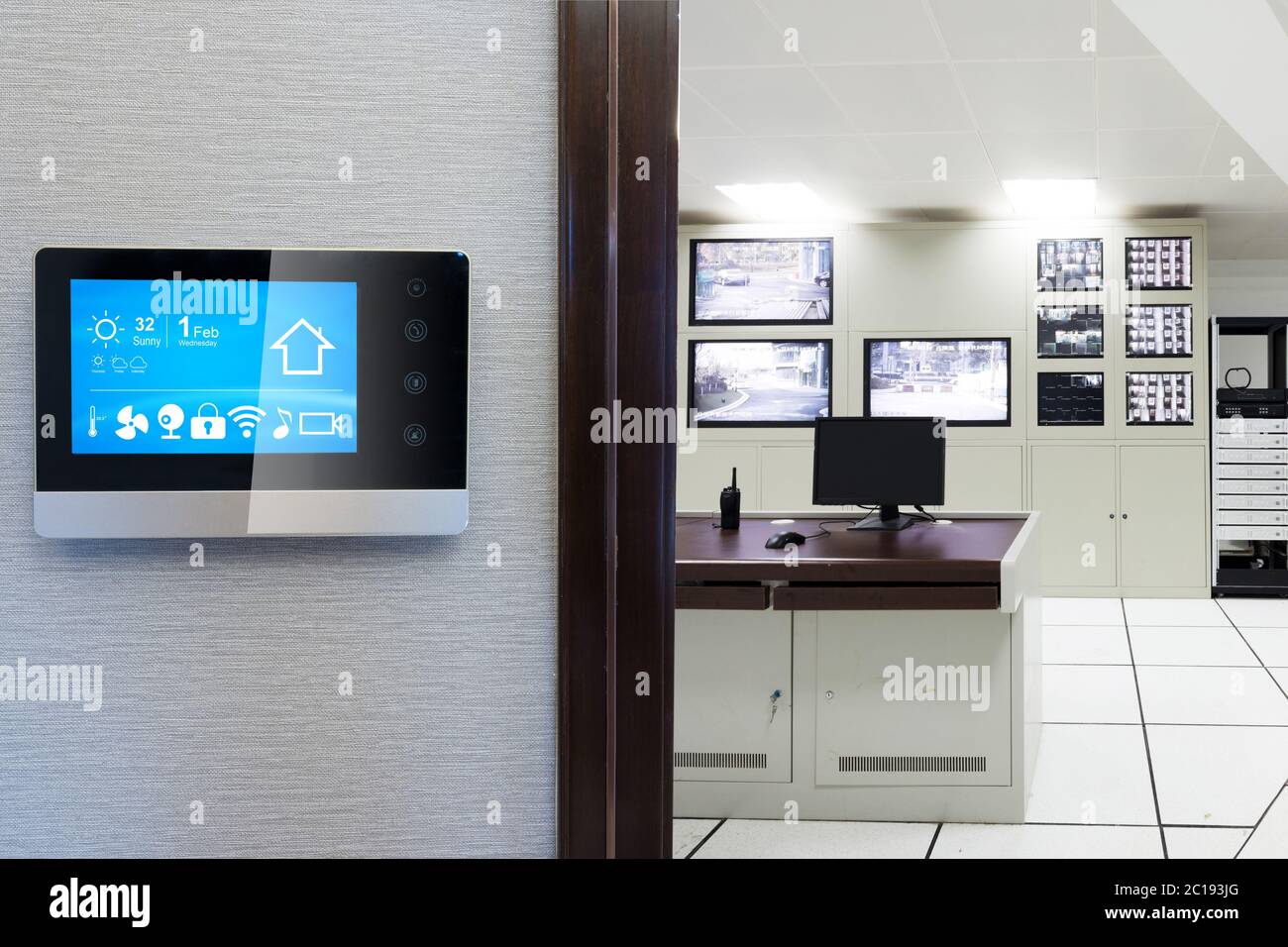

A closed frame monitor is described as a monitor with a front bezel that is fully enclosed, just as most consumer grade LCDs are. Many industrial grade monitors are sold with a closed frame. A few examples include multi media kiosks and point of sale terminals. These LCDs are closed in basic enclosures. Most LCDs purchased in this format are not designed to be removed from the enclosures. In fact, they are built with the enclosure as a layer of protection for the LCD, as well as for the practical purposes of the enclosed LCD.

Open frame LCDs are sold as a solution to the need for the absence of the aforementioned enclosure. An open frame LCD is sold as just a raw LCD, capable of having a wide range of sizes, resolutions, and other attributes. The LCD still is secured with a metal chassis cover to protect internal components. The biggest benefit of the open frame LCD is the flexibility to build the LCD into an existing project design. Without the enclosure, an integrator is about to customize design enclosures to match their specific application without working around the LCD.

These panels are typically more expensive, as they are often industrial/higher grade LCDs. Higher grade panels have the benefit of increased durability and performance. Another benefit to the open frame LCDs is the ability to and flexibility to insert additional components inside the chassis. Moreover, internal components are easily replaceable if they fail; upgrades are easily installed.

Both open and closed frames are used in project designs and applications across the industries; applications range from retail digital signage, to manufacturing applications to handheld industrial devices.

Handheld tablets are seen every day with almost everyone owning a tablet or a smartphone. It is becoming more common to see workers in a professional environment using handheld tablets in their line of work, from doctors using tablets as medical databases to manufacturing businesses using tablets on their production floors to keep business running smoothly. By offering a grip into the computing world, tablets have become a reliable, efficient, and cost-effective way to bring connectivity into the hands of employees. The difference between the tablet you have in your hand and the project manager on the floor of a manufacturing warehouse is the industrial components that make an LCD/tablet built for durability versus built for the mass consumer.

Standard tablets offer very limited protection against the elements, and may be unusable in certain predicaments like a rain or dust storm. Because of these limitations, AGDisplays has introduced a portfolio of ruggedized tablets available for use in non-standard situations. These tablets offer all of the specifications of high-end consumer tablets, but with the addition of features that not only protect the device, but extend its lifespan, and expand its capabilities as well. Some of these features, like military grade components, shock and drop testing, and ingress ratings let a ruggedized tablet far exceed the capabilities of a normal “off the shelf” device. AGDisplays tablets are IP rated, MIL-STD compliant and allow for a range of integrated connectivity options.

AGDisplays’ line of industrial tablets that are designed to work in a demanding and rough environment. With high resiliency and strong performance levels, our tablets are made to withstand constant environmental exposure. Whether your application calls for indoor or outdoor use, our tablet offerings are sure to bring you real-time access to your critical data.

All in One LCD displays from AGDisplays can include industrial panels with rack mounting options; included in the LCD panel are robust processing systems, operating system options and memory options. These offerings are design to meet long term demand of high performance PC applications. Many of our all in ones come equipped with touchscreen functionality for ease of access.

VESA mounting (Video Electronics Standards Association) is a set of standards created for mounting flat panel monitors, TVs and other displays to stands and wall mounts. The VESA standard defines the dimensions of a display’s four-hole mounting attachment interface, as well as the screws used to fit the holes. Also defined in this standard are the positions of the holes. VESA MIS-D, 100/75, C compliant displays are equipped with either a 100 x 100 mm or 75 x 75 mm square hole pattern. This is the most common interface for monitors weighing under 30 lbs (14 kg). VESA MIS-E, C compliant displays are equipped with a 200 x 100 mm rectangular hole pattern. Mid-size displays sometimes use this interface; typical displays in this class weigh less than 50 lbs (23 kg). VESA MIS-F, C compliant displays have varied hole patterns that are spaced in 200 mm increments.

Depending on the technology, touch screens are capable of detecting touches made by a finger or hand, or other passive objects such as a stylus or a pen. A touch screen typically has three components: a touch sensor, a controller, and a software driver. There are multiple touch technologies on the market, each vary in characteristics and features: resistive, surface capacitive, projected capacitive, surface acoustic wave, and infrared. Without touchscreen technology, user speed and accuracy may be insufficient and confusing. AGDisplays designs compatible solutions for existing LCD designs or we also provide a new unit that is touch compatible. Touchscreen types include resistive, surface capacitive, projected capacitive, surface acoustic wave, and infrared.

The industry is flooded with manufacturers of varying capabilities, resources, commitment to quality and pre/post sales support. Some of these manufacturers will produce average quality displays without the needed enhancements that your customers expect today.

E3 Displays is all about making the manufacturing of your perfect display simple. We’ll guide you through an easy process to help you built your product so you never have to worry about low quality, inferior technology, unnecessary enhancements, and post sales continued support. Let’s make your business thrive.

Transform your design into an innovative product with our electronics manufacturing services. Scale your product with the help of a reliable manufacturing partner.

In addition to custom LCD displays, we provide custom PCB assemblies and turnkey solutions for products that feature a Displaytech LCD. As a display manufacturer, our engineering and production staff are experienced in handling the design and manufacturing of printed circuit board assemblies for front panels, rack mount equipment, handheld devices and many other products.

Since its establishment in 2008, GSD Co., Ltd., has been manufacturing and providing customized display solutions like a professional resized LCD and high brightness LCD all over the world for Casino/arcade Gaming, Transportation, Public information, Advertising, ATM, Outdoor KIOSK, Medical display, Marine display and so on.

We are now achieving new custom display solutions with unique design and supreme image quality to meet your various needs. With extensive experiences in LCD displays. GSD also provides P-Cap touch solutions with various glass design support and high quality optical bonding services.

Whatever you require to us, we will offer you the custom displays which are reliable and stable even in extreme environments as we have diverse experience on display industry. We promise you to supply innovative products focusing on continuous improvement of product design, manufacturing quality and technical services.

Every BoldVu® display is engineered to deliver the highest performance in the intended application and end-use environment. We’re so confident in our displays that we offer the industry’s only guarantee on performance for display brightness, contrast, and color saturation in the outdoor space – a guarantee that’s good for 10 years.

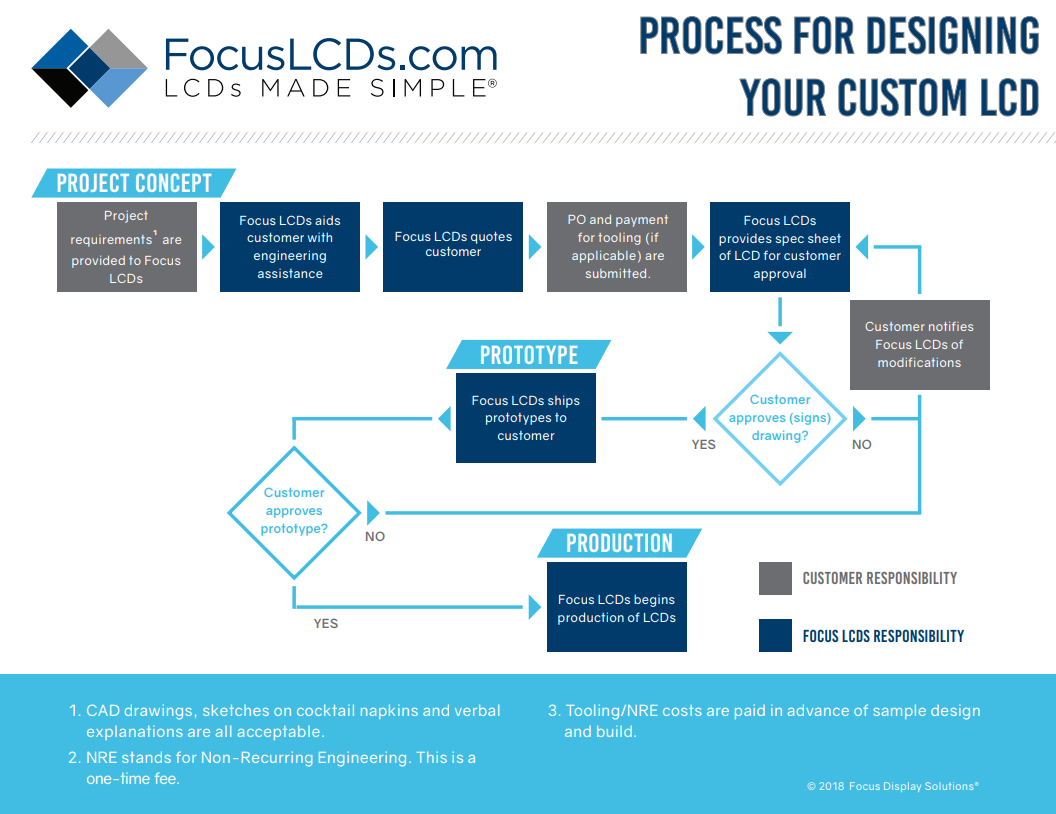

Since 2001 we’ve provided product development, engineering design services, and turn-key solutions for all industries. Work with our engineers to develop the ideal display for your unique application.

Our US-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Adjust length, position, and pinout of your cables or add additional connectors. Get a cable solution designed to make your connections streamlined and secure.

Enhance your user experience with capacitive or resistive touchscreen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

We have complete control over our display products" design, manufacturing, and quality control processes. Our USA based Engineers will work with you on a prototype to validate and test your design.

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

Our custom display, touch and cover lens solutions are used in a variety of end-user applications. For example, our touchscreens are used in many vehicle infotainment systems and dashboard controls. We also provide custom touch displays for popular marine applications such as watercraft navigation screens and fish finders. For consumer electronics, we manufacture custom touchscreen display solutions and smartphone screen protectors. Whether your application will be used in the great outdoors, a construction site, or a hospital operating room, we can build a custom, all-in-one solution for your needs.

Our strength as a custom display company comes from the extensive technical expertise of our engineering team. The approach our engineers take is always based on experience and data-driven decisions that help you find the right solution for your application. In addition, our extensive manufacturing capabilities enable us to deliver quick design cycles, cost-effective solutions, and high-quality products that will meet your specifications even in the harshest conditions. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a full service provider of LCD modules, PDI specializes in small format (typically 15” and less) character display, graphic display, color display, and custom display formats. Our Customers leverage PDI’s decades of LCD display experience, technical expertise, and manufacturing capabilities to obtain the most competitively priced, highest quality LCD module solution. These solutions span the spectrum from off the shelf standard products to completely custom display based solutions. PDI’s mission is to actively engage our customers early in the design phase. We will utilize our years of LCD experience and our understanding of the compete LCD module system to provide a smooth transition from design concept to prototypes, through pilot run and into high volume production.

Alternatively, if a 100% identical cross match design of an existing display is needed, our team will evaluate your current solution, offer any recommendations for design improvement and then quote accordingly, typically saving up to 20%. Once PDI develops a 100% compatible drop-in replacement display, this LCD module is then fully tested and qualified in the product application prior to shipping. This process insures a plug and play solution.

PDI produces its LCD displays utilizing the latest or most practical technology trends including Chip on Glass (COG), Chip on Board (COB), Tape Automated Bonding (TAB) and Chip on Flex (COF). PDI can integrate touch panels into any of our display systems. In addition to a full portfolio of standard and custom LCD modules, PDI offers manufacturing services to build your display into the next higher sub-assembly or final assembly to give customers the competitive cost advantages afforded to those utilizing off-shore based manufacturing. Often this practice includes integrating the display design and existing peripheral components such as PCB’s, switches, overlays and custom cables which eliminates interconnects, improves the overall system reliability and most importantly, reduces cost.

Customers that need a new supplier for an existing production display. This occurs for a variety of reasons including cost pressures, lead time concerns, quality issues, stocking needs, or lack of responsiveness from current LCD supplier.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

As a full service provider of LCD modules, PDI specializes in small format (typically 15” and less) character display, graphic display, color display, and custom display formats. Our Customers leverage PDI’s decades of LCD display experience, technical expertise, and manufacturing capabilities to obtain the most competitively priced, highest quality LCD module solution. These solutions span the spectrum from off the shelf standard products to completely custom display based solutions. PDI’s mission is to actively engage our customers early in the design phase. We will utilize our years of LCD experience and our understanding of the compete LCD module system to provide a smooth transition from design concept to prototypes, through pilot run and into high volume production.

Alternatively, if a 100% identical cross match design of an existing display is needed, our team will evaluate your current solution, offer any recommendations for design improvement and then quote accordingly, typically saving up to 20%. Once PDI develops a 100% compatible drop-in replacement display, this LCD module is then fully tested and qualified in the product application prior to shipping. This process insures a plug and play solution.

PDI produces its LCD displays utilizing the latest or most practical technology trends including Chip on Glass (COG), Chip on Board (COB), Tape Automated Bonding (TAB) and Chip on Flex (COF). PDI can integrate touch panels into any of our display systems. In addition to a full portfolio of standard and custom LCD modules, PDI offers manufacturing services to build your display into the next higher sub-assembly or final assembly to give customers the competitive cost advantages afforded to those utilizing off-shore based manufacturing. Often this practice includes integrating the display design and existing peripheral components such as PCB’s, switches, overlays and custom cables which eliminates interconnects, improves the overall system reliability and most importantly, reduces cost.

Customers that need a new supplier for an existing production display. This occurs for a variety of reasons including cost pressures, lead time concerns, quality issues, stocking needs, or lack of responsiveness from current LCD supplier.

Take your product design to the next levelwith our range of LCD, OLED and ePaper monochrome LCD displays, with or without touch. All our displays are customisable to suit your application requirements and can be paired with an embedded system for a fully integrated module.

With over 35 years expertise in LED technology, we offer products and services from LED Displays and LED components,including Infrared, Ultra-Violet and RGB LEDs,to customised solutionssuch as LED looms with connectors and custom LED PCBA.

"Anders was able to satisfy our ISO 13485 medical compliance requirements right at the start of design, which was a fantastic addition from a company that goes above and beyond when they deliver their products."

Discover how we approach and simplify your display product fulfilment from the feasibility study all the way through the mass productionand beyond,addressing any technical challenges and supporting your project on the way to make sure you have a truly outstanding solution fit for purpose, on time, on budget and exceeding all design goals.

When you partern with Anders for your display and embedded system, you are in good hands! Our vision is to deliver exceptional products, solutions and services exceeding your expectations through a design led consultative approach.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

Lincoln Technology Solutions is a Design Services and LCD Integration Company, focused on creating solutions with unrivaled optical performance. We have in-house engineering expertise in all disciplines with prototype manufacturing in NC, USA. We pride ourselves in offering the flexibility, agility, and creativity that you cannot find with other companies that offer similar services. All of our solutions focus on solving our customer’s challenges with a cost-effective, manufacturable product.

In addition, we also offer turnkey production of our LCD solutions through our wholly owned ISO 9001 Certified LCD factory in Shenzhen, China and our PCB and subassembly assembly partner in Thailand. We will create the LCD’s you need so you can provide the solutions that your customers demand.

“Here at LTS we strive to ensure that everyone’s work makes a difference in order to provide our customers with the best engineering services possible. Within our growing team, we are able to allow all employees to have hands-on impact with designing, make critical decisions and give each individual a sense of ownership and pride with the work they are able to contribute.

David previously worked for various large-scale corporations, and throughout his career at these different businesses, he realized that he wanted to branch out to be able to bring his own creativeness and innovation to the LCD and PCB industry. The ability to make a difference and build the best displays in the world is what keeps him motivated, along with spending time with his family, playing ice hockey, and enjoying a relaxing day on the lake.

Jesse’s drive comes from being able to work with highly motivated individuals, who are all working toward the common goal of producing world class displays. He also believes that LTS is a great company because we are an agile organization with the ability to react quickly and exceed customer expectations. When he is not busy here at our Cary office, Jesse enjoys spending time with his family, travelling, and being outdoors as much as possible.

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

We develop, design, manufacture, and sell displays where it is necessary for the interface that deliver a lot of information at an instant and deliver it to the global market. We create interactive spaces that go beyond the expected, elevate everyday lives, and move people"s hearts. From bases in major cities in Asia, Europe, and North America, we build strong customer relationships by developing products that respond to market needs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey