flexible lcd display arduino free sample

To get started, open up Example1_Text under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example1_Text. Upon opening this example, you"ll notice that our void loop() is empty. This is because we only need to draw the image to our OLED one time in order for it to stay there. We first initialize our screen with CS connected to pin 10 and RES connected to pin 9, with the line SSD1320 flexibleOLED(10, 9);. Then in our setup loop we use flexibleOLED.begin(160, 32); to begin a display that is 160x32 pixels. We then use the following lines to first clear the display, set the font, the location where we"d like to type, and the text we"d like to type. The final line tells the display to show what we"ve just written to the display buffer.

This will write the text to the display when our microcontroller runs the setup loop and leave it there, the output should look something like the below image.

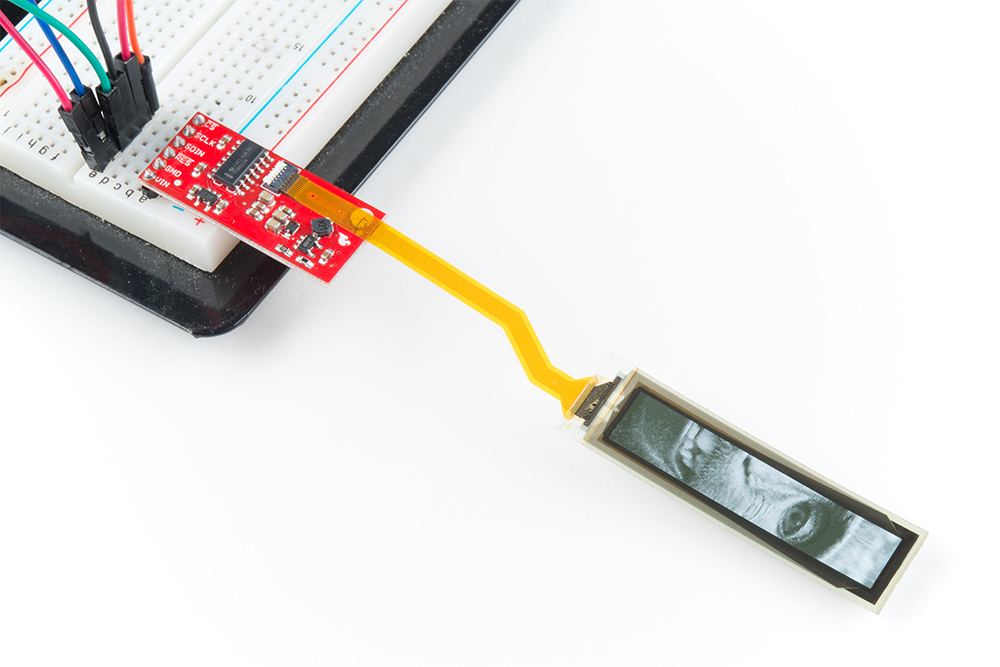

To get started, open up Example2_Graphics under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example2_Graphics. This example will draw a grayscale image from pre-converted image data, in this case, an image of a macaque. In order to convert your own images to a format readable by the OLED, check out this neat Python script for converting Bitmaps to arrays for the grayscale OLED. First you"ll need a *.bmp file that is 160 pixels wide and 32 pixels tall. Once you have your *.bmp, generating an image array is as simple as running the python script from the command line like below. (Make sure you put in the proper file paths)

Then, in our sketch, we"ll need to make sure we include the file containing this array, so make sure to put an #include "TestImage.h" at the top of your sketch. Also make sure you comment out any other image files that may be included. If you haven"t gone ahead and replaced the macaque with your own image, the output should look like the below image, otherwise, it should obviously look like whatever image you"ve chosen to display on your OLED.

To get started, open up Example3_Lines under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example3_Lines. This example draws a few shapes on the display. Once again, it simply writes the image to the display and leaves it there. Play around with the parameters that draw each rectangle and circle to determine how this affects their positioning and size. The stock example code should look something like the below image.

In this example, we"ll feed bitmaps directly into the screen using a serial terminal like Tera Term. If you"re not too familiar with using a terminal, check out our overview of serial terminal basics and download Tera Term. This is useful because we don"t have to convert our bitmaps into a prog_mem or anything. To get started we"ll first have to make sure our microcontroller can properly parse the serial input into pixel data. Go ahead and open up Example4_BMP_Eater under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example4_BMP_Eater. Once you have this open and uploaded, check out the getBitmap() function, which checks the structure of what we"re sending over serial and then writes it to the screen. Now that our microcontroller is ready for data, it"s time to open up Tera Term and start sending data. A new instance of Tera Term should prompt you to enter the COM port. Be sure to enter the port that your microcontroller is on.

Once we"ve done this, we"ll need to change the baud rate of our terminal to match the microcontroller"s baud of 57600. Do this by going to Setup > Serial Port... and select 57600 from the drop-down menu. Now that we"ve opened a connection to the OLED we can start sending images to it. To do this, all we need to do is go to File > Send File... and select the bitmap we want to send to our screen. Go to Documents > Arduino > Libraries > SparkFun_Flexible_Grayscale_OLED_Breakout > Examples > Example4_BMP_Eater. This folder should contain a few bitmaps. If you got fancy and created your own bitmap in the second example, you can load that up as well. Select your file, make sure you"re sending it in a binary format (the image below shows the binary box checked).

To get started, open up Example5_AllTheText under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example5_AllTheText. This example displays all of the text capabilities of the OLED. Take a look at the text example functions below to see how each one writes the corresponding text.

This next example will play us a nice little game of fake pong. To get started, open up Example6_Pong under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example6_Pong. The meat and potatoes of this pong example is contained in the shapeExample() function, shown below.

Most of this function is simply math to move the paddles and ball around the screen and check for collisions. The actual drawing of the objects is executed in the last few lines of the function, right before the flexibleOLED.display(): function. The shapeExample() function is called repeatedly in our void loop() to progress the positions of the Pong pieces. The OLED should look something like the below GIF with this code uploaded.

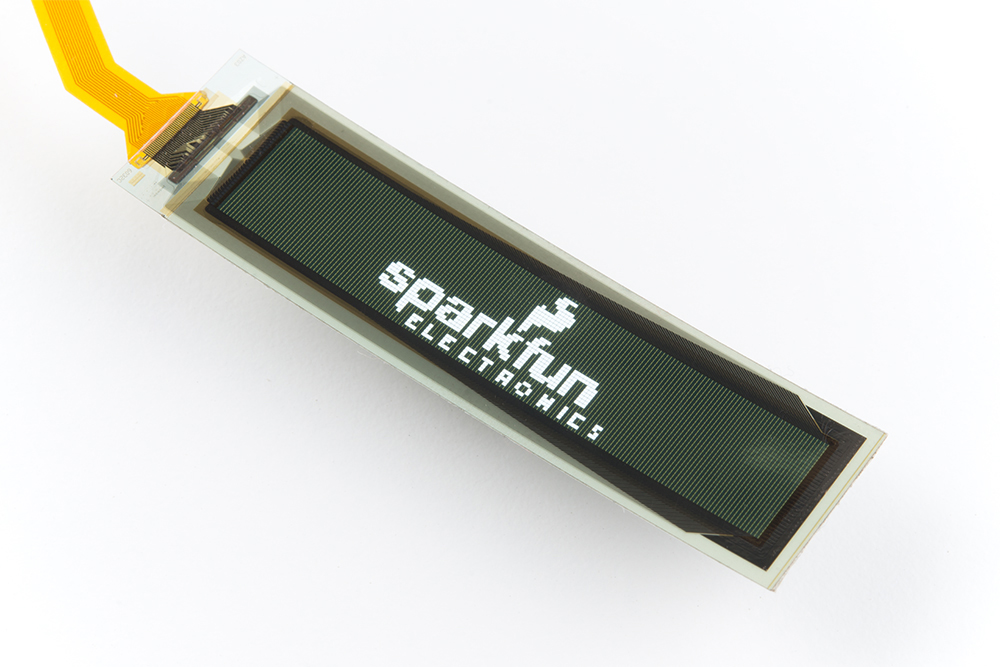

To get started, open up Example7_Logo under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example7_Logo. This example simply shows us how to display what was already in the OLED"s buffer. All we have to do is initialize the screen without clearing the buffer, give the flexibleOLED.display() command, and the OLED will show the SparkFun logo. It"ll look similar to the image below.

To get started, open up Example8_NoiseDrawing under File > Examples > SparkFun Flexible Grayscale OLED Breakout > Example8_NoiseDrawing. This example writes noise directly to the display and also to the buffer. However, the buffer is incapable of grayscale so we will only get black and white noise when calling the writeToBuffer() function. We can see upon closer inspection that each of these functions writes noise from the A0 and A1 pins, so make sure these aren"t connected to anything. The output will look something like the below image. Notice how the noise from the buffer is only in black and white.

Stop breadboarding and soldering – start making immediately! Adafruit’s Circuit Playground is jam-packed with LEDs, sensors, buttons, alligator clip pads and more. Build projects with Circuit Playground in a few minutes with the drag-and-drop MakeCode programming site, learn computer science using the CS Discoveries class on code.org, jump into CircuitPython to learn Python and hardware together, TinyGO, or even use the Arduino IDE. Circuit Playground Express is the newest and best Circuit Playground board, with support for CircuitPython, MakeCode, and Arduino. It has a powerful processor, 10 NeoPixels, mini speaker, InfraRed receive and transmit, two buttons, a switch, 14 alligator clip pads, and lots of sensors: capacitive touch, IR proximity, temperature, light, motion and sound. A whole wide world of electronics and coding is waiting for you, and it fits in the palm of your hand.

There are a number of options for displaying text or graphics in your project. LEDs and LCDs are the traditional choices but in recent years another type of display has been getting a lot of attention – the OLED.

OLED’s are used in display applications large and small, from giant television screens to tiny smartwatch displays. They are bright, easy to see in a variety of lighting conditions and they consume very little current.

Kodak was also the first company to release a commercial device using OLEDs. Its EasyShare LS633 camera was released in March 2003 and used an OLED display screen.

OLEDs have a very wide field of view, approaching 170 degrees. This allows users to enjoy the video display without needing to sit directly in front of it.

Early OLED displays had lifespan problems. This has been improved, however blue OLEDs still have a shorter life expectancy than their traditional LED equivalents.

Currently, OLEDs are more expensive to manufacture. This will likely change as more factories produce them. Eventually, they will rival or beat LCDs in value, but right now they are more expensive.

Transparent OLEDs can be made up to 85% as transparent as their substrate (the material they are printed on) is. This will improve and has a lot of potential for heads-up displays.

Foldable OLEDs are perhaps the most intriguing of them all. These OLEDs have already been used in curved video displays and will find a lot of use in the design of phones with bendable screens.

But the real exciting aspect of foldable OLEDs is that they can be printed onto cloth. This creates the possibility of a new generation of wearable electronics. Imagine a t-shirt that is also a video display.

So now that we know a bit about OLEDs how do we get one connected to an Arduino and start displaying wonderful things? There are actually a couple of ways.

OLED displays typically come with either an SPI or an I2C interface. Some even have both interfaces, one of the ones we will look at today works like that.

To display data on an OLED you will first load it into the OLED buffer and then give it a command to write to the display. There are several libraries available for the Arduino that will simplify this, I’ll be showing you one from Adafruit that is very versatile.

As the OLED display is really a matrix of OLEDs you’ll need to address them individually to control them. The Adafruit library simplifies this, as do the other OLED libraries.

We will start by working with a couple of very common I2C OLED displays. These displays are based on the SSD1306 OLED driver chip so they can use the same software libraries.

One of my displays is 128×32. It is a very simple I2C display with no provision for changing its I2C address. Mine came configured for I2C address 0x3C, which is probably the most common OLED address.

The second display is 128×64, twice as many lines as the first one. It is actually a bicolor display, the top 16 pixels are yellow and the bottom 32 are blue. This type of display is often used as an indicator for devices like FM radios and MP3 players.

The larger display has the same connections as its smaller counterpart, it also has provisions for changing its I2C address. The address change involves moving a surface-mount resistor from one set of solder pads to another. Not quite as simple as using a jumper wire or solder bridge!

As long as you keep your OLED and Arduino reasonably close you should just be able to connect them directly without any other components. If you experience errors try adding pull-up resistors, I didn’t find that to be necessary myself.

The power and ground connections to the display are pretty obvious. Most of these displays have an onboard regulator to supply power to the OLEDs and to the “charge pump” used to drive them.

TheSCLconnection goes to Arduino pinA4. TheSCLconnection goes toA5. If your Arduino Uno has a separate set of SDA and SCK connections (usually located near theAREFpin) you can use those instead, they are actually the same connection.

Adafruit SSD1306– The library for the SSD1306 monochrome OLED display. It was originally designed for an Adafruit-specific display but has been enhanced to work with any display based upon the SSD1306 driver chip.

Both Adafruit libraries are available at GitHub, but it is much easier to install them using the Library Manager in the Arduino IDE. You can do that as follows:

One thing to note is that you should check your I2C address and adjust the sketch to match. The 64 line sketch has a different I2C address, I had to change it to run on my display.

For fun, I connected two 32 Line displays up to the Arduino, by running them in parallel on the I2C bus. Normally you would never connect two I2C devices with the same address onto one I2C bus but in this case, it actually works.

It works because displays only receive data, they don’t return any to the host Arduino. Both displays have the same address so they simply respond to the data for that address.

The Waveshare 1.5 inch display module is a monochrome 128 x 128 OLED display that can use either an I2C or SPI interface. Connections can be made to the module using an included cable that mates with a connector on the module itself. There are also holes for header pins to make the same connections if you prefer.

I used the supplied cable to hook up the OLED display to my Arduino, you can also solder header pins to the module and plug it into a breadboard if you prefer. Either way the connections are the same, as follows:

You can’t use the Adafruit demos with this display, even when wired in SPI mode. The Waveshare 1.5 inch OLED display uses the SSD1327 driver, which is a different beast than the SSD1306 driver used in the I2C displays we looked at previously.

Without adding extra memory to your Arduino you can’t really do any animation on the display as there won’t be enough memory to hold the display buffer – remember, this is a 128 x 128 display. But as I don’t really want to add extra RAM to my Arduino Uno I restricted myself to the ”internal memory” sketch.

You’ll need to locate your Arduino sketchbook folder, the one that holds the Arduino sketches from the Arduino IDE on your computer. Locate and open that folder, it’s probably calledArduino.

If your Arduino libraries folder does not already have aFontsfolder just copy the whole folder in. If there is already aFontsfolder then copy just the contents of the WaveshareFontsfolder into the existing folder.

Open theINT_RAMfolder in the WaveshareArduinofolder. You’ll see another folder calledOLED_Show. Copy this entire folder to yourArduinofolder on your local computer.

Open theOLED_Showfolder. You’ll see a number of files, including a sketch calledOLED_Show.ino. This is the demo sketch, you can open it with your Arduino IDE.

When you compile and upload the sketch you may get a message warning you about low memory on the Arduino. Just accept the message, the sketch leaves very little free memory as it uses most of it to load the display buffer.

The demo displays a fake “clock” along with a number of graphic symbols and some text. It will give you an idea of what kind of characters you can display and how they will look.

If you want to see some animated demos using this display you are probably better off running the code included for the Raspberry Pi, as this won’t have the memory limitations the Arduino code does.

The previous examples will help you get your OLED display setup and ensure that it is working. They can also be used as starting points for your own sketch to control the OLED display.

But they can also be a bit overwhelming. Because they contain a lot of graphics and animation coding to show off the display the demo scripts are also rather complex. And that makes it a bit more difficult for a beginner to figure out how to control their display.

In order to make it easier for you to get started with OLED displays, I’ve created a very simple project that you can build that uses simple code to display text.

Since both the AM2320 and OLED display are I2C devices the wiring of our OLED temperature and humidity meter couldn’t be easier. Here is the hookup diagram.

In order to run this sketch, you’ll need to install more libraries to work with the AM2320 (I will assume you installed the two Adafruit libraries we discussed earlier as you need those too). Again these will be installed from the Library Manager in your Arduino IDE, using the same procedure you followed when installing the OLED libraries earlier.

Now onto the sketch. It starts by loading all of the libraries we just spoke of, along with theArduino Wire Libraryto communicate via I2C. Note that the Graphics library has been included but isn’t really being used in this sketch, you can omit the include statement for it if you wish.

We then setup an object calleddisplay that represents our OLED display. Note that the original Adafruit OLED tha the library was written for used a Reset pin that still needs to be defined, even if it isn’t used.

Now we work with the OLED display. Keep in mind that when you work with an OLED you are first setting up your data in a display buffer, after which you issue a command to display the buffer contents.

Next, we set the display color. As we are using a monochrome display we always useWHITE. It doesn’t matter what color your display actually is (mine is yellow and blue but I still useWHITEfor both). Color values don’t really come into play until you work with RGB OLEDs.

We then move the cursor down and print the word “Humidity:” followed by some spaces – the spaces are a crude attempt at lining up the display! We then print the actual humidity value from the float, followed by a space and a percentage symbol.

The project worked perfectly the first time I tried it. You’ll notice some gibberish on the display when it is first fired up, this will clear in two seconds when the first readings are displayed.

The cost of OLEDs is continually falling and it won’t be too long before they rival LCDs in price. They don’t need a backlight and they are visible in all types of lighting environments.

I’m planning to start experimenting with RGB OLED displays next, so if you enjoyed this article and video keep your eyes open for an article about color OLEDs soon.

OLED displays are bright, lightweight and easy to read in almost any lighting environment. In this article, you"ll learn how OLEDs differ from regular LEDs and LCDs and how to use them with an Arduino.

Crystalfontz has a wide variety of LCD display products. Including ePaper, OLED, TFT and accessories. Watch our LCD videos below to see our display solutions in action.

Not sure how the difference between transflective and transmissive affects sunlight readability? Here is a video that takes you from pitch black to full sunlight, showing how the transflective CFAF480640A-035T compares to a transmissive TFT display module.

In this video, we"re demonstrating driving a 800x480 5" TFT with an Seeeduino (Arduino UNO Clone with 3.3v / 5v switch) and the help of our CFA10100 EVE accelerated board.

Awesome little transparent OLED display. Its a 128x56 pixels and 1.51 inch diagonal. Super-bright, monochrome (light blue). We powered it up with a Seeeduino for this demonstration.

This is a quick video showing our new 1.3 inch TFT LCD. This is a small, full-color TFT. It"s controlled via 4-wire SPI. It has a ST7789H2 controller. This display runs off a single 3.3v supply which controls the logic and backlight.

Ever wonder what will happen if you submerge an OLED display in water? Well we tried it, we also tried coating the components with various sealants to see if we can help protect them in high humidity, or high-water level scenarios.

This is a 2.4" IPS TFT designed for embedded systems. This wide viewing angle IPS display can be used in any orientation--landscape or portrait. The backlight is 850 nits (cd/m2) so it can be used in most lighting conditions.

This is a Capacitive Touch 2.4" IPS TFT designed for embedded systems. This wide viewing angle IPS display can be used in any orientation--landscape or portrait. The backlight is 730 nits (cd/m2) so it can be used in most lighting conditions.

Check out this small, low power transflective LCD display. Available in many options including with and without a backlight, breakout board, or a complete development kit.

– Arduino is an open-source platform used for building electronics projects. Arduino consists of both a physical programmable microcontroller and a piece of software, or IDE (Integrated Development Environment) that runs on your computer, used to write and upload computer code to the physical board.

– The Arduino platform unlike most previous programmable circuit boards, the Arduino does not need a separate programmer to load new code onto the board — you can simply use a USB cable. Additionally, the Arduino IDE uses a simplified version of C++, making it easier to learn to program.

– The open sources and extensible language: Arduino IDE is based on open source tool. The programming language used can be extended through the C++ library.

– The open source and expandable hardware: Arduino is based on Atmel’s ATMEGA 8-bit microcontrollers and its SAM3X8E and SAMD21 32-bit microcontrollers. Development boards and modules are planned to be released under the premise of following the “Creative Commons License Agreement”, so experienced circuit designers can make their own modules and carry out corresponding expansions and improvements. Even users who are relatively inexperienced can make a trial version of the basic Uno development board, which is easy to understand the principle of its operation and save costs.

– The Arduino hardware and software were designed for artists, designers, hobbyists, hackers, newbies, and anyone interested in creating interactive objects or environments. Arduino can interact with buttons, LEDs, motors, speakers, GPS units, cameras, the internet, and even your smart-phone or your TV.

Arduino Leonardo: Arduino’s first development board to use one microcontroller with built-in USB. It is cheaper and simpler. The code libraries allow the board to emulate a computer keyboard, mouse, and more.

LCD means liquid crystal display. Basically, any displays can be used with Arduino, including alphanumeric character LCD display, monochrome graphic LCD display, color TFT LCD display, IPS LCD display. It can also be used for non LCD displays like: PMOLED display, AMOLED display, E-ink (E-paper) displays. Orient Display developed easy interface (SPI, I2C) displays which can be easily used with Arduino.

LCD displays were first used for watches and calculators. Now, LCD display technology dominants the display world, it can be found in wearables, smart homes, mobile phones, TVs, laptops, monitors, kiosks, aircraft cockpit, digital cameras, lab instrument, power grid etc.

LCD itself can emit light itself. It has to utilize outside light sources. LCD display module normally includes LCD glass (or LCD panel), LCD driving circuitry ( can be COG, COB or TAB) and a backlight.

A LCD display 16*2 is actually a basic and simple to use LCD module. It includes LCD glass, COB (Chip on PCB Board) LCD control board, backlight, zebra to connect LCD glass and control board and a bezel to hold everything together. 16×2 LCD display can display 16 characters per line and there are two lines. Each character has 5×7 dot matrix pixels and the cursor underneath. All 16×2 LCD display originally used standard Hitachi HD44780 driver. Of course the legendary HD44780 controller had EOL long time ago. All the 16×2 LCD displays use HD44780 compatible LCD controllers. Some of them are drop replacement, some of them need to modify the initialization code a little.

Pin5 (Read/Write/Control Pin): This pin toggles the display among the read or writes operation, and it is connected to a microcontroller unit pin to get either 0 or 1 (0 = Write Operation, and 1 = Read Operation).

Pins 7-14 (Data Pins): These pins are used to send data to the display. These pins are connected in two-wire modes like 4-bit mode and 8-bit mode. In 4-wire mode, only four pins are connected to the microcontroller unit like 0 to 3, whereas in 8-wire mode, 8-pins are connected to microcontroller unit like 0 to 7.

A 16×2 LCD has two registers like data register and command register. The RS (register select) is mainly used to change from one register to another. When the register set is ‘0’, then it is known as command register. Similarly, when the register set is ‘1’, then it is known as data register.

Command Register: The main function of the command register is to store the instructions of command which are given to the display. So that predefined tasks can be performed such as clearing the display, initializing, set the cursor place, and display control. Here commands processing can occur within the register.

Data Register: The main function of the data register is to store the information which is to be exhibited on the LCD screen. Here, the ASCII value of the character is the information which is to be exhibited on the screen of LCD. Whenever we send the information to LCD, it transmits to the data register, and then the process will be starting there. When register set =1, then the data register will be selected.

All of the code below uses the LiquidCrystal library that comes pre-installed with the Arduino IDE. A library is a set of functions that can be easily added to a program in an abbreviated format. In order to use a library, it needs be included in the program. Line 1 in the code below does this with the command #include

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now let’s just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

The LiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and number of columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program.

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°).

The detailed LCD tutorial can be found in the article. ARDUINO LCD SET UP AND PROGRAMMING GUIDE or to check https://github.com/arduino-libraries/LiquidCrystal

This LED strip is made by WS2812B LEDs wired in series. These LEDs have an IC built right into the LED. This allows a communication via a one-wire interface. This means that you can control lots of LEDs using just one digital pin of your Arduino.

This kind of strips are very flexible and can be cut to any length you want. As you can see, the strip is divided into segments, and each segment contains one RGB LED.

These strips come with connectors at each end. I’ve decided to cut the connectors, and solder header pins. It’s more handy if you want to connect the strip to an Arduino or to a breadboard.

In this example, the WS2812B LED strip will be powered using the 5V Arduino pin. In my case, I’m controlling 14 LEDs. If you want to control many LEDs, you’ll need to use an external power source.

After installing the needed library, upload the following code to your Arduino board (this is an example sketch provided in the library examples folder). Go to File > Examples > FastLED > ColorPalette or copy the code below.

This post is an introduction to the addressable RGB LED strip with the Arduino. We’ve just experimented with the library example. You should modify the example to only display the effects you want. We hope you’ve found this guide useful.

LiquidCrystal fork for displays based on HD44780. Uses the IOAbstraction library to work with i2c, PCF8574, MCP23017, Shift registers, Arduino pins and ports interchangably.

The most powerful and popular available library for using 7/14/16 segment display, supporting daisy chaining so you can control mass amounts from your Arduino!

A simple library to display numbers, text and animation on 4 and 6 digit 7-segment TM1637 based display modules. Offers non-blocking animations and scrolling!

Monochrome LCD, OLED and eInk Library. Display controller: SSD1305, SSD1306, SSD1309, SSD1312, SSD1316, SSD1318, SSD1320, SSD1322, SSD1325, SSD1327, SSD1329, SSD1606, SSD1607, SH1106, SH1107, SH1108, SH1122, T6963, RA8835, LC7981, PCD8544, PCF8812, HX1230, UC1601, UC1604, UC1608, UC1610, UC1611, UC1617, UC1638, UC1701, ST7511, ST7528, ST7565, ST7567, ST7571, ST7586, ST7588, ST75160, ST75256, ST75320, NT7534, ST7920, IST3020, IST3088, IST7920, LD7032, KS0108, KS0713, HD44102, T7932, SED1520, SBN1661, IL3820, MAX7219, GP1287, GP1247, GU800. Interfaces: I2C, SPI, Parallel.

True color TFT and OLED library, Up to 18 Bit color depth. Supported display controller: ST7735, ILI9163, ILI9325, ILI9341, ILI9486,LD50T6160, PCF8833, SEPS225, SSD1331, SSD1351, HX8352C.

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode,light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row and line in the display is controlled sequentially, one by one,thin-film transistor (TFT) backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

An OLED display works without a backlight because it emits its own visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight. OLED displays are made in the same way as LCDs, but after TFT (for active matrix displays), addressable grid (for passive matrix displays) or indium-tin oxide (ITO) segment (for segment displays) formation, the display is coated with hole injection, transport and blocking layers, as well with electroluminescent material after the first 2 layers, after which ITO or metal may be applied again as a cathode and later the entire stack of materials is encapsulated. The TFT layer, addressable grid or ITO segments serve as or are connected to the anode, which may be made of ITO or metal.transparent displays being used in smartphones with optical fingerprint scanners and flexible displays being used in foldable smartphones.

Research into polymer electroluminescence culminated in 1990, with J. H. Burroughes et al. at the Cavendish Laboratory at Cambridge University, UK, reporting a high-efficiency green light-emitting polymer-based device using 100nm thick films of poly(p-phenylene vinylene).plastic electronics and OLED research and device production grew rapidly.et al. at Yamagata University, Japan in 1995, achieved the commercialization of OLED-backlit displays and lighting.

In 1999, Kodak and Sanyo had entered into a partnership to jointly research, develop, and produce OLED displays. They announced the world"s first 2.4-inch active-matrix, full-color OLED display in September the same year.

Manufacturing of small molecule OLEDs was started in 1997 by Pioneer Corporation, followed by TDK in 2001 and Samsung-NEC Mobile Display (SNMD), which later became one of the world"s largest OLED display manufacturers - Samsung Display, in 2002.

The Sony XEL-1, released in 2007, was the first OLED television.Universal Display Corporation, one of the OLED materials companies, holds a number of patents concerning the commercialization of OLEDs that are used by major OLED manufacturers around the world.

Polymer light-emitting diodes (PLED, P-OLED), also light-emitting polymers (LEP), involve an electroluminescent conductive polymer that emits light when connected to an external voltage. They are used as a thin film for full-spectrum colour displays. Polymer OLEDs are quite efficient and require a relatively small amount of power for the amount of light produced.

Typical polymers used in PLED displays include derivatives of poly(p-phenylene vinylene) and polyfluorene. Substitution of side chains onto the polymer backbone may determine the colour of emitted lightring opening metathesis polymerization.

The bottom-emission organic light-emitting diode (BE-OLED) is the architecture that was used in the early-stage AMOLED displays. It had a transparent anode fabricated on a glass substrate, and a shiny reflective cathode. Light is emitted from the transparent anode direction. To reflect all the light towards the anode direction, a relatively thick metal cathode such as aluminum is used. For the anode, high-transparency indium tin oxide (ITO) was a typical choice to emit as much light as possible.thin film transistor (TFT) substrate, and the area from which light can be extracted is limited and the light emission efficiency is reduced.

In "white + color filter method," red, green, and blue emissions are obtained from the same white-light LEDs using different color filters.uneven degradation rate of blue pixels vs. red and green pixels. Disadvantages of this method are low color purity and contrast. Also, the filters absorb most of the light waves emitted, requiring the background white light to be relatively strong to compensate for the drop in brightness, and thus the power consumption for such displays can be higher.

Transparent OLEDs use transparent or semi-transparent contacts on both sides of the device to create displays that can be made to be both top and bottom emitting (transparent). TOLEDs can greatly improve contrast, making it much easier to view displays in bright sunlight.Head-up displays, smart windows or augmented reality applications.

In contrast to a conventional OLED, in which the anode is placed on the substrate, an Inverted OLED uses a bottom cathode that can be connected to the drain end of an n-channel TFT especially for the low cost amorphous silicon TFT backplane useful in the manufacturing of AMOLED displays.

The most commonly used patterning method for organic light-emitting displays is shadow masking during film deposition,photochemical machining, reminiscent of old CRT shadow masks, are used in this process. The dot density of the mask will determine the pixel density of the finished display.−5Pa. An oxygen meter ensures that no oxygen enters the chamber as it could damage (through oxidation) the electroluminescent material, which is in powder form. The mask is aligned with the mother substrate before every use, and it is placed just below the substrate. The substrate and mask assembly are placed at the top of the deposition chamber.virtual reality headsets.

Although the shadow-mask patterning method is a mature technology used from the first OLED manufacturing, it causes many issues like dark spot formation due to mask-substrate contact or misalignment of the pattern due to the deformation of shadow mask. Such defect formation can be regarded as trivial when the display size is small, however it causes serious issues when a large display is manufactured, which brings significant production yield loss. To circumvent such issues, white emission devices with 4-sub-pixel color filters (white, red, green and blue) have been used for large televisions. In spite of the light absorption by the color filter, state-of-the-art OLED televisions can reproduce color very well, such as 100% NTSC, and consume little power at the same time. This is done by using an emission spectrum with high human-eye sensitivity, special color filters with a low spectrum overlap, and performance tuning with color statistics into consideration.

Transfer-printing is an emerging technology to assemble large numbers of parallel OLED and AMOLED devices efficiently. It takes advantage of standard metal deposition, photolithography, and etching to create alignment marks commonly on glass or other device substrates. Thin polymer adhesive layers are applied to enhance resistance to particles and surface defects. Microscale ICs are transfer-printed onto the adhesive surface and then baked to fully cure adhesive layers. An additional photosensitive polymer layer is applied to the substrate to account for the topography caused by the printed ICs, reintroducing a flat surface. Photolithography and etching removes some polymer layers to uncover conductive pads on the ICs. Afterwards, the anode layer is applied to the device backplane to form the bottom electrode. OLED layers are applied to the anode layer with conventional vapor deposition, and covered with a conductive metal electrode layer. As of 2011mm × 400mm. This size limit needs to expand for transfer-printing to become a common process for the fabrication of large OLED/AMOLED displays.

Experimental OLED displays using conventional photolithography techniques instead of FMMs have been demonstrated, allowing for large substrate sizes (as it eliminates the need for a mask that needs to be as large as the substrate) and good yield control.

For a high resolution display like a TV, a thin-film transistor (TFT) backplane is necessary to drive the pixels correctly. As of 2019, low-temperature polycrystalline silicon (LTPS)– TFT is widely used for commercial AMOLED displays. LTPS-TFT has variation of the performance in a display, so various compensation circuits have been reported.excimer laser used for LTPS, the AMOLED size was limited. To cope with the hurdle related to the panel size, amorphous-silicon/microcrystalline-silicon backplanes have been reported with large display prototype demonstrations.indium gallium zinc oxide (IGZO) backplane can also be used.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing,plasma displays. However, fabrication of the OLED substrate as of 2018 is costlier than that for TFT LCDs.registration — lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks.nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1ms for their fastest color transition, and are capable of refresh frequencies as high as 240Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,μs (0.01ms), which could theoretically accommodate refresh frequencies approaching 100kHz (100,000Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

The biggest technical problem for OLEDs is the limited lifetime of the organic materials. One 2008 technical report on an OLED TV panel found that after 1,000hours, the blue luminance degraded by 12%, the red by 7% and the green by 8%.hours to half original brightness (five years at eight hours per day) when used for flat-panel displays. This is lower than the typical lifetime of LCD, LED or PDP technology; each rated for about 25,000–40,000hours to half brightness, depending on manufacturer and model. One major challenge for OLED displays is the formation of dark spots due to the ingress of oxygen and moisture, which degrades the organic material over time whether or not the display is powered.

However, some manufacturers" displays aim to increase the lifespan of OLED displays, pushing their expected life past that of LCD displays by improving light outcoupling, thus achieving the same brightness at a lower drive current.cd/m2 of luminance for over 198,000hours for green OLEDs and 62,000hours for blue OLEDs.hours for red, 1,450,000hours for yellow and 400,000hours for green at an initial luminance of 1,000cd/m2.

Degradation occurs three orders of magnitude faster when exposed to moisture than when exposed to oxygen. Encapsulation can be performed by applying an epoxy adhesive with dessicant,Atomic Layer Deposition (ALD). The encapsulation process is carried out under a nitrogen environment, using UV-curable LOCA glue and the electroluminescent and electrode material deposition processes are carried out under a high vacuum. The encapsulation and material deposition processes are carried out by a single machine, after the Thin-film transistors have been applied. The transistors are applied in a process that is the same for LCDs. The electroluminescent materials can also be applied using inkjet printing.

The OLED material used to produce blue light degrades much more rapidly than the materials used to produce other colors; in other words, blue light output will decrease relative to the other colors of light. This variation in the differential color output will change the color balance of the display, and is much more noticeable than a uniform decrease in overall luminance.

Improvements to the efficiency and lifetime of blue OLEDs is vital to the success of OLEDs as replacements for LCD technology. Considerable research has been invested in developing blue OLEDs with high external quantum efficiency, as well as a deeper blue color.

Blue TADF emitters are expected to market by 2020WOLED displays with phosphorescent color filters, as well as blue OLED displays with ink-printed QD color filters.

Water can instantly damage the organic materials of the displays. Therefore, improved sealing processes are important for practical manufacturing. Water damage especially may limit the longevity of more flexible displays.

As an emissive display technology, OLEDs rely completely upon converting electricity to light, unlike most LCDs which are to some extent reflective. E-paper leads the way in efficiency with ~ 33% ambient light reflectivity, enabling the display to be used without any internal light source. The metallic cathode in an OLED acts as a mirror, with reflectance approaching 80%, leading to poor readability in bright ambient light such as outdoors. However, with the proper application of a circular polarizer and antireflective coatings, the diffuse reflectance can be reduced to less than 0.1%. With 10,000 fc incident illumination (typical test condition for simulating outdoor illumination), that yields an approximate photopic contrast of 5:1. Advances in OLED technologies, however, enable OLEDs to become actually better than LCDs in bright sunlight. The AMOLED display in the Galaxy S5, for example, was found to outperform all LCD displays on the market in terms of power usage, brightness and reflectance.

While an OLED will consume around 40% of the power of an LCD displaying an image that is primarily black, for the majority of images it will consume 60–80% of the power of an LCD. However, an OLED can use more than 300% power to display an image with a white background, such as a document or web site.

OLEDs use pulse width modulation to show colour/brightness gradations, so even if the display is at 100% brightness, any pixel that"s, for example, 50% grey will be off for 50% of the time, making for a subtle strobe effect. The alternative way to decrease brightness would be to decrease the constant power to the OLEDs, which would result in no screen flicker, but a noticeable change in colour balance, getting worse as brightness decreases.

Almost all OLED manufacturers rely on material deposition equipment that is only made by a handful of companies,Canon Tokki, a unit of Canon Inc. Canon Tokki is reported to have a near-monopoly of the giant OLED-manufacturing vacuum machines, notable for their 100-metre (330 ft) size.Apple has relied solely on Canon Tokki in its bid to introduce its own OLED displays for the iPhones released in 2017.

OLED technology is used in commercial applications such as displays for mobile phones and portable digital media players, car radios and digital cameras among others, as well as lighting.Philips Lighting has made OLED lighting samples under the brand name "Lumiblade" available onlineNovaled AG based in Dresden, Germany, introduced a line of OLED desk lamps called "Victory" in September, 2011.

Nokia introduced OLED mobile phones including the N85 and the N86 8MP, both of which feature an AMOLED display. OLEDs have also been used in most Motorola and Samsung color cell phones, as well as some HTC, LG and Sony Ericsson models.ZEN V, the iriver clix, the Zune HD and the Sony Walkman X Series.

The Google and HTC Nexus One smartphone includes an AMOLED screen, as does HTC"s own Desire and Legend phones. However, due to supply shortages of the Samsung-produced displays, certain HTC models will use Sony"s SLCD displays in the future,Nexus S smartphone will use "Super Clear LCD" instead in some countries.

OLED displays were used in watches made by Fossil (JR-9465) and Diesel (DZ-7086). Other manufacturers of OLED panels include Anwell Technologies Limited (Hong Kong),AU Optronics (Taiwan),Chimei Innolux Corporation (Taiwan),LG (Korea),

The use of OLEDs may be subject to patents held by Universal Display Corporation, Eastman Kodak, DuPont, General Electric, Royal Philips Electronics, numerous universities and others.

Flexible OLED displays have been used by manufacturers to create curved displays such as the Galaxy S7 Edge but they were not in devices that can be flexed by the users.

On 31 October 2018, Royole, a Chinese electronics company, unveiled the world"s first foldable screen phone featuring a flexible OLED display.Samsung announced the Samsung Galaxy Fold with a foldable OLED display from Samsung Display, its majority-owned subsidiary.MWC 2019 on 25 February 2019, Huawei announced the Huawei Mate X featuring a foldable OLED display from BOE.

The 2010s also saw the wide adoption of tracking gate-line in pixel (TGP), which moves the driving circuitry from the borders of the display to in between the display"s pixels, allowing for narrow bezels.

Textiles incorporating OLEDs are an innovation in the fashion world and pose for a way to integrate lighting to bring inert objects to a whole new level of fashion. The hope is to combine the comfort and low cost properties of textile with the OLEDs properties of illumination and low energy consumption. Although this scenario of illuminated clothing is highly plausible, challenges are still a road block. Some issues include: the lifetime of the OLED, rigidness of flexible foil substrates, and the lack of research in making more fabric like photonic textiles.

The number of automakers using OLEDs is still rare and limited to the high-end of the market. For example, the 2010 Lexus RX features an OLED display instead of a thin film transistor (TFT-LCD) display.

A Japanese manufacturer Pioneer Electronic Corporation produced the first car stereos with a monochrome OLED display, which was also the world"s first OLED product.Yazaki,Hyundai Sonata and Kia Soul EV use a 3.5-inch white PMOLED display.

By 2004, Samsung Display, a subsidiary of South Korea"s largest conglomerate and a former Samsung-NEC joint venture, was the world"s largest OLED manufacturer, producing 40% of the OLED displays made in the world,AMOLED market.million out of the total $475million revenues in the global OLED market in 2006.

In October 2008, Samsung showcased the world"s thinnest OLED display, also the first to be "flappable" and bendable.mm (thinner than paper), yet a Samsung staff member said that it is "technically possible to make the panel thinner".cd/m2. The colour reproduction range is 100% of the NTSC standard.

At the Consumer Electronics Show (CES) in January 2010, Samsung demonstrated a laptop computer with a large, transparent OLED display featuring up to 40% transparency

Samsung"s 2010 AMOLED smartphones used their Super AMOLED trademark, with the Samsung Wave S8500 and Samsung i9000 Galaxy S being launched in June 2010. In January 2011, Samsung announced their Super AMOLED Plus displays, which offer several advances over the older Super AMOLED displays: real stripe matrix (50% more sub pixels), thinner form factor, brighter image and an 18% reduction in energy consumption.

In May 2007, Sony publicly unveiled a video of a 2.5-inch (6.4 cm) flexible OLED screen which is only 0.3 millimeters thick.mm thick 3.5 inches (8.9 cm) display with a resolution of 320×200 pixels and a 0.3mm thick 11-inch (28 cm) display with 960×540 pixels resolution, one-tenth the thickness of the XEL-1.

In July 2008, a Japanese government body said it would fund a joint project of leading firms, which is to develop a key technology to produce large, energy-saving organic displays. The project involves one laboratory and 10 companies including Sony Corp. NEDO said the project was aimed at developing a core technology to mass-produce 40inch or larger OLED displays in the late 2010s.

In October 2008, Sony published results of research it carried out with the Max Planck Institute over the possibility of mass-market bending displays, which could replace rigid LCDs and plasma screens. Eventually, bendable, see-through displays could be stacked to produce 3D images with much greater contrast ratios and viewing angles than existing products.

In January 2015, LG Display signed a long-term agreement with Universal Display Corporation for the supply of OLED materials and the right to use their patented OLED emitters.

On 6 January 2011, Los Angeles-based technology company Recom Group introduced the first small screen consumer application of the OLED at the Consumer Electronics Show in Las Vegas. This was a 2.8" (7cm) OLED display being used as a wearable video name tag.cm) OLED displays on a standard broadcaster"s mic flag. The video mic flag allowed video content and advertising to be shown on a broadcasters standard mic flag.

On 6 January 2016, Dell announced the Ultrasharp UP3017Q OLED monitor at the Consumer Electronics Show in Las Vegas.Hz refresh rate, 0.1 millisecond response time, and a contrast ratio of 400,000:1. The monitor was set to sell at a price of $4,999 and release in March, 2016, just a few months later. As the end of March rolled around, the monitor was not released to the market and Dell did not speak on reasons for the delay. Reports suggested that Dell canceled the monitor as the company was unhappy with the image quality of the OLED panel, especially the amount of color drift that it displayed when you viewed the monitor from the sides.Hz refresh rate and a contrast ratio of 1,000,000:1. As of June, 2017, the monitor is no longer available to purchase from Dell"s website.

Apple began using OLED panels in its watches in 2015 and in its laptops in 2016 with the introduction of an OLED touchbar to the MacBook Pro.iPhone X with their own optimized OLED display licensed from Universal Display Corporation.iPhone XS and iPhone XS Max, and iPhone 11 Pro and iPhone 11 Pro Max.

A third model of Nintendo"s Switch, a hybrid gaming system, features an OLED panel in replacement of its current LCD panel. Announced in the summer of 2021, it was released on 8 October 2021.

On 18 October 2018, Samsung showed of their research roadmap at their 2018 Samsung OLED Forum. This included Fingerprint on Display (FoD), Under Panel Sensor (UPS), Haptic on Display (HoD) and Sound on Display (SoD).

Various venders are also researching cameras under OLEDs (Under Display Cameras). According to IHS Markit Huawei has partnered with BOE, Oppo with China Star Optoelectronics Technology (CSOT), Xiaomi with Visionox.

In 2020, researchers at the Queensland University of Technology (QUT) proposed using human hair which is a source of carbon and nitrogen to create OLED displays.

Hari Singh Nalwa (Ed.), Handbook of Luminescence, Display Materials and Devices, Volume 1–3. American Scientific Publishers, Los Angeles (2003). ISBN 1-58883-010-1. Volume 1: Organic Light-Emitting Diodes

Chang, Yi-Lu; Lu, Zheng-Hong (2013). "White Organic Light-Emitting Diodes for Solid-State Lighting". Journal of Display Technology. PP (99): 1. Bibcode:2013JDisT...9..459C. doi:10.1109/JDT.2013.2248698. S2CID 19503009.

Flat-panel electronic displays: a triumph of physics, chemistry and engineering, Philosophical Transactions of the Royal Society, Volume 368, Issue 1914

D. Ammermann, A. Böhler, W. Kowalsky, Multilayer Organic Light Emitting Diodes for Flat Panel Displays Archived 2009-02-26 at the Wayback Machine, Institut für Hochfrequenztechnik, TU Braunschweig, 1995.

Ishibashi, Tadashi; Yamada, Jiro; Hirano, Takashi; Iwase, Yuichi; Sato, Yukio; Nakagawa, Ryo; Sekiya, Mitsunobu; Sasaoka, Tatsuya; Urabe, Tetsuo (25 May 2006). "Active Matrix Organic light Emitting Diode Display Based on "Super Top Emission" Technology". Japanese Journal of Applied Physics. 45 (5B): 4392–4395. Bibcode:2006JaJAP..45.4392I. doi:10.1143/JJAP.45.4392. ISSN 0021-4922. S2CID 121307571.

US 5986401, Mark E. Thompson, Stephen R. Forrest, Paul Burrows, "High contrast transparent organic light emitting device display", published 1999-11-16

Bower, C. A.; Menard, E.; Bonafede, S.; Hamer, J. W.; Cok, R. S. (2011). "Transfer-Printed Microscale Integrated Circuits for High Performance Display Backplanes". IEEE Transactions on Components, Packaging and Manufacturing Technology. 1 (12): 1916–1922. doi:10.1109/TCPMT.2011.2128324. S2CID 22414052.

Sasaoka, Tatsuya; Sekiya, Mitsunobu; Yumoto, Akira; Yamada, Jiro; Hirano, Takashi; Iwase, Yuichi; Yamada, Takao; Ishibashi, Tadashi; Mori, Takao; Asano, Mitsuru; Tamura, Shinichiro; Urabe, Tetsuo (2001). "24.4L: Late-News Paper: A 13.0-inch AM-OLED Display with Top Emitting Structure and Adaptive Current Mode Programmed Pixel Circuit (TAC)". SID Symposium Digest of Technical Papers. 32: 384. doi:10.1889/1.1831876. S2CID 59976823.

Tsujimura, T.; Kobayashi, Y.; Murayama, K.; Tanaka, A.; Morooka, M.; Fukumoto, E.; Fujimoto, H.; Sekine, J.; Kanoh, K.; Takeda, K.; Miwa, K.; Asano, M.; Ikeda, N.; Kohara, S.; Ono, S.; Chung, C. T.; Chen, R. M.; Chung, J. W.; Huang, C. W.; Guo, H. R.; Yang, C. C.; Hsu, C. C.; Huang, H. J.; Riess, W.; Riel, H.; Karg, S.; Beierlein, T.; Gundlach, D.; Alvarado, S.; et al. (2003). "4.1: A 20-inch OLED Display Driven by Super-Amorphous-Silicon Technology". SID Symposium Digest of Technical Papers. 34: 6. doi:10.1889/1.1832193. S2CID 135831267.

Gustafsson, G.; Cao, Y.; Treacy, G. M.; Klavetter, F.; Colaneri, N.; Heeger, A. J. (1992). "Flexible light-emitting diodes made from soluble conducting polymers". Nature. 357 (6378): 477–479. Bibcode:1992Natur.357..477G. doi:10.1038/357477a0. S2CID 4366944.

"Comparison of OLED and LCD". Fraunhofer IAP: OLED Research. 18 November 2008. Archived from the original on 4 February 2010. Retrieved 25 January 2010.

"Display maker Royole shows off "world"s first" flexible smartphone R". Theinquirer.net. 1 November 2018. Archived from the original on 1 November 2018. Retrieved 27 November 2019.link)

Sam Byford (8 October 2013). "Samsung"s Galaxy Round is the first phone with a curved display". Theverge.com. Vox Media, Inc. Archived from the original on 9 November 2013. Retrieved 10 November 2013.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey