arduino oscilloscope tft lcd free sample

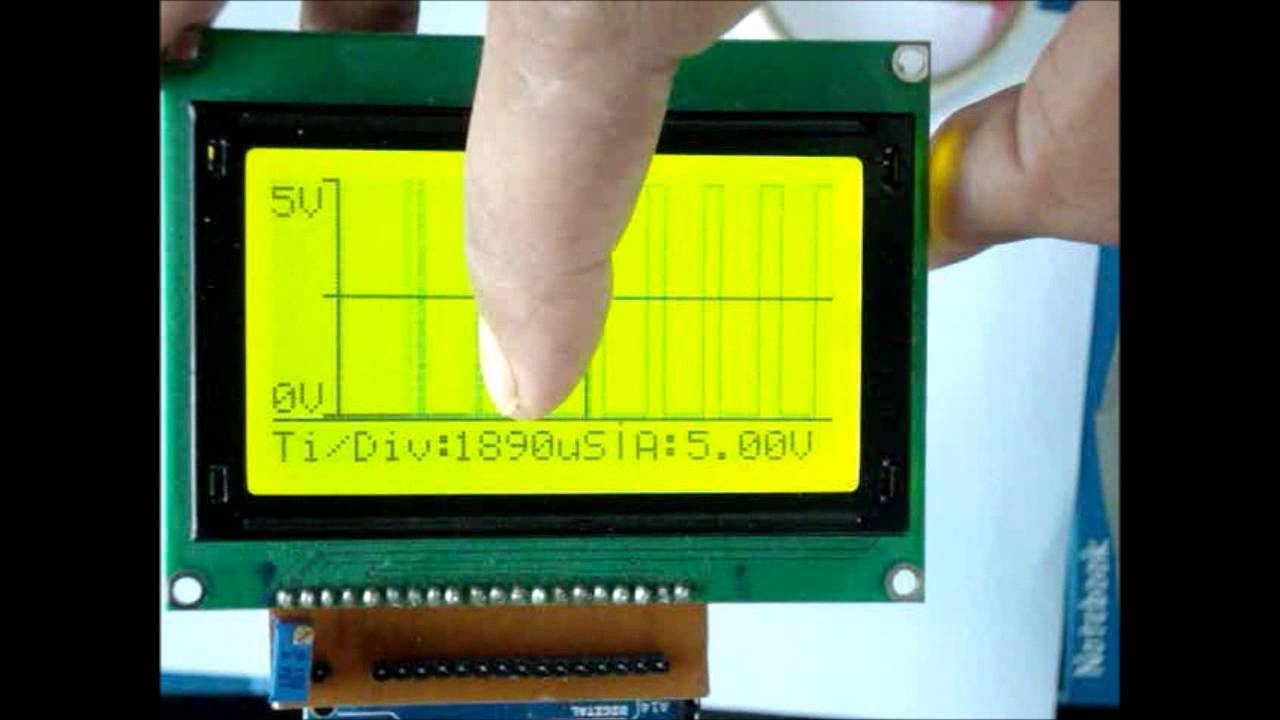

The 320x240 2.4 inch TFT LCD shield with touch panel has only A5, TXD and RXD free if you leave the SD card interface. Assuming that the A5 is an analog input, the remaining TXD and RXD are internally connected for downloading programs from USB, so I don"t want to use them as much as possible. For the time being, you can check the operation using only A5, but that alone is boring. I want to make the best use of software that assumes 2CH.

Some Arduino UNO compatible machines that use the QFP package for the CPU have A6 and A7 through holes. So use them to assign A6 for CH1 A/D input and A7 for CH2 A/D. Thus, it can be a 2-channel oscilloscope. Furthermore, if you make a UNO-like board with Arduino Nano or Pro Mini using a shield board and do not wire the SD card terminal, you can use D10-D13, so you can use it for judgment such as DC/AC selection.

I wanted to use the screen almost fully for the waveform, so if I set it to 10 horizontal scales and 8 vertical scales, it will be 300x240 with 30 dots/scale, and 20 dots left in the horizontal direction. The 20 dot width on the right side has a button area that connects to the off-screen icon. The LCD shield I got has an icon outside the display screen, and the detection range of the touch sensor has expanded to that extent. Maybe it"s for old smartphones, but it may be hard to get now. You can operate it by touching this button area, icon, or character display position.

There are so many variations of the 320x240 2.4 inch TFT LCD shield, you may have to adjust the controller ID and pinout of the touch sensors. The controller of My TFT LCD shield wasn"t popular ILI9341.

const int sw_lv[] ={878,839,796,728,580,478,420,370,318,242}; // 09/04/2017 with adapter powering arduino //{918, 876, 810, 710, 500, 378, 312, 248, 180, 100}; //{889, 800, 700, 611, 514, 419, 338, 231, 132, 70}; //5/11/2016 2050 //these values are probably based on voltage divider || refer to notes, for voltage breakdown.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

On Instructables with all easy and quick steps: http://www.instructables.com/id/How-to-Use-24-TFT-LCD-Shield-With-Arduino-Mega/Easy to learn how to do this h...

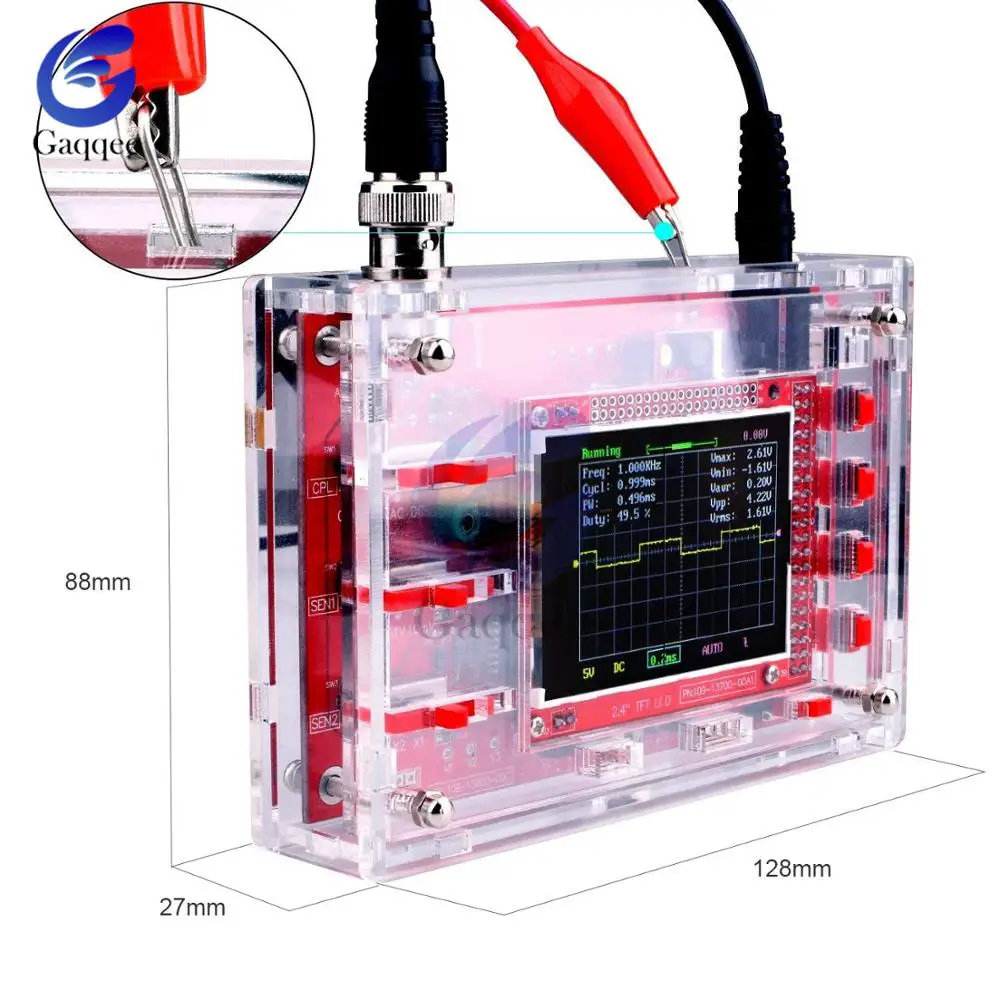

Today I’ll talk about a really good project you can do with your Arduino! This is the best way you can have a cheap oscilloscope around, I didn’t write this code, I’ve found it on the internet a while back ago and I’ve decided to share this awesome project. Let’s start…

I like to know how is the board connected and connected to which pin for the KL25Z and the LCD display for the LCD to work as i myself got the adafruit TFT LCD

Hi motoo-San is it possible to achieve this oscilloscope by using one kl25z board or I need more than one kl25z board to achieve for the LCD display and the oscilloscope. Is it possible to do with only the adafruit TFT screen.

Hi Moto-san, does that mean that the input signal will be probe for my oscilloscope and the kl25z will be able to power up my Adafruit LCD Dsiplay.Does that mean that the KL25Z is my power source to power up my adafruit LCD. Is it possible to achieve the oscilloscope if i do not connect my adafruit LCD to my KL25z. Can i connect my adafruit LCD display and my kl25z seperately

Hi Moto-san , May i know what is the highest frequency and voltage can this oscilloscope withstand as i am trying to hook up. Afraid that my frequency and voltage will be too high and damage the board.

Hi Moto-san, I have trided the oscilloscope and is able to work, after that i try to connect the function generator that you provide to LCD it is able to work but after some time the TFT adafruit is unable to work for the touch screen is unable to work. is there anything to do to rework LCD touch screen

An oscilloscope is a laboratory instrument commonly used to display and analyze the waveform of electronic signals. In effect, the device draws a graph of the instantaneous signal voltage as a function of time.Oscilloscopes are used in the sciences, medicine, engineering, and telecommunications industry. Oscilloscopes are very essential and best friend for students, maker, hobbyist and electronics enthusiast. While a digital multimeter can help you measure steady state and RMS (Root-Mean-Squ...

Graphical display terminals using large screen cathode ray tubes (CRT) soon evolved. These displays were essentially “up-sized oscilloscopes” whose X-Y beam deflection was driven by a computer.

The answer proved to be YES! What resulted, I call the Arduino Graphics Interface, or AGI for short. With AGI, you can transform a leftover analog oscilloscope into a high resolution computer graphics display and gain valuable insights into computer graphics, digital-to-analog conversion (ADC), and advanced Direct Memory Access (DMA) hardware and software techniques. It’s easy to add a real time clock (RTC) module and interactive controls to turn the AGI platform into a “CRT CLOCK” (Figure 2) or other high resolution computer graphics display device.

In this article, we’ll focus on the overall concepts, circuit design, and hardware fabrication. In Part 2, we’ll integrate the hardware to XYscope: the software control and plotting library that enables an Arduino Due CPU + analog oscilloscope to become a high resolution XY graphics display. Let’s get started!

You can see that a pair of digital-to-analog converters (DACs) inside of the ATMEL SAM 32-bit CPU (the heart of an Arduino Due) is used to drive the X and Y axes of an analog oscilloscope. Rather than use the normal oscilloscope Amplitude vs. Time display mode, we run the scope in X-Y mode. That is, the internal oscilloscope time base that usually drives the X axis is not used, but rather all XY information for deflecting the CRT beam comes directly from the Arduino through the AGI circuits.

To create graphical images with AGI, the programmer need only build a list of 12-bit X-Y integers that make up the individual points we want to show. One after the other, the DACs of the Due receive and convert each XY integer coordinate pair into small X-Y voltages that drive the CRT beam about the oscilloscope screen. The block diagram shows that we also provide a blanking pulse (a.k.a., Z axis blanking) as a third signal to the scope.

The AGI uses an analog oscilloscope for its graphics output display. You’ll have to dust off your old analog oscilloscope or perhaps buy a vintage unit off eBay. The Oscilloscope Requirements sidebar details the features you need to look for when evaluating possible scope candidates for use with this project. Since we use an oscilloscope as the display screen, the size and display color is fixed by the cathode ray tube inside the scope.

At first, I labored over the multitude of CPU boards available, but it soon became apparent only one board would “Due.” (I know, it’s a terrible pun.) Even though the Beagle Bone and Raspberry Pi families have faster CPUs and more memory, only the Arduino Due CPU includes a pair of DMA-driven on-chip DACs.

While programmed I/O using an Arduino analogWrite() command is a common way to output data to the DACs, the AGI uses DMA techniques. We’ll discuss this further in Part 2, but for now, suffice it to say that we connect the DMA hardware inside the Due to a COUNTER-TIMER which automatically sends the X-Y data array out through the DACs to the oscilloscope screen at very high speeds.

For the AGI project, the Due provides two DAC outputs; each of which translates a 12-bit unsigned integer into one of 4,096 different analog voltage levels. As measured at the processor DAC pins, the CPU outputs a voltage of 0.5V when converting the integer value 0, and outputs 2.75V when converting the integer value 4095. Dividing this 2.25 volt peak-to-peak voltage range by 4096 means that each step or bit change at the DAC input results in a 550 μV change at the DAC output. These signals are buffered by the AGI circuits before they are sent on to the oscilloscope for display.

Using an oscilloscope to monitor the DAC outputs, Figure 4 shows that a full-scale change in output of the DAC from 0 to 4095 in one step takes slightly over 300 ns. Similarly, the step going from 4095 back to 0 is seen to be about 300 ns as well.

Next, note that the X and Y conversions follow each other in time, with the DAC0 signal (the X axis value) changing first, followed one DMA_CLK cycle later by the DAC1 signal (Y axis). Analog sample and hold circuits are used to time-synchronize the X and Y signals to one another before they are sent out to the oscilloscope as the X-Drive (TP8) and Y-Drive (TP9) signals for display.

Given the DAC rise and fall times, it’s possible to determine the highest DMA_CLK frequency we can use. My tests show reliable high quality graphics plotting can be achieved at DMA_CLK frequencies up to 800 kHz. Above 800 kHz, the DAC rise and fall time delays begin to distort the graphics display, appearing as incorrectly plotted points on the oscilloscope screen whenever adjacent members in the XY list are far away from one another.

With the DMA_CLK frequency set to 800 kHz, it’s possible to send about 10,000 points to the screen within the 20 ms target refresh interval. When more than 10K points are present in the display list, the software driver will automatically extend the refresh interval as needed so all points can be displayed. Depending on the phosphor decay characteristics of your oscilloscope screen and your personal POV sensitivity, you will probably notice the onset of image flicker when plotting more than about 12,000 points.

POWER SUPPLY — Any wall wart that can supply 12-15 VDC at .5 amps can be used to power the AGI circuitry. As shown in Figure 5, onboard linear regulators provide clean low-noise regulated +9.75V and +5.0V outputs to power both the AGI analog circuits (9.75V) as well as the logic and Arduino Due CPU (5.0V).

X-Y BUFFER AMPS — In Figure 6, you can see that the DAC0 (X axis) and DAC1 (Y axis) signals from the Due are received and buffered by high frequency op-amp U4. Potentiometers are provided at this stage so that signal gain (amplitude) and offset (screen position) for X and Y can be independently set. The gain pot on each output will vary the amplitude within a 1.0V to 4.0V P-P range. The centering pot varies the signal offset so that it can reside anywhere within a .2V to 4.75V window. Final display adjustment will be a combination of these AGI pots, as well as the oscilloscope gain and centering controls; my scope works well with AGI outputs adjusted to 1.5V P-P centered about +2.5 VDC.

SAMPLE AND HOLD CIRCUITS — As seen in Figure 4, the DAC0 and DAC1 outputs are not simultaneously output by the Due CPU; the X value is converted first, followed by the Y value one DMA_CLK cycle later. Analog switch U5a-b, hold capacitors C9 and C13, and buffer amps U3a-b make up the pair of Sample and Hold (S/H) circuits that align and synchronize the X-Y point pair voltages, so they change together when they’re sent to the oscilloscope for display. The X and Y buffer amps are followed by transmission gates U5a-b and output op-amps U7a-b which work together to form two independent S/H circuits.

DATA CLOCK TIMING — COUNTER_TIMER_0 of the Due is programmed to be the DMA_CLK. This signal drives the internal DMA operations, but as shown in Figure 7, also comes to the outside world through CPU pin D2. This signal is fed to U6a and U8b to create all the needed AGI timing signals. Flip-flop U6a divides the DMA_CLK by 2 to create a signal that represents a point pair transfer completed signal or POINT_CLK. The POINT_CLK_NOT signal is then combined to generate the S/H_PULSE and the SHOW_POINT signals. As depicted in the timing traces of Figure 4, the S/H_PULSE signal is used to “grab and hold” the X-Y voltage pair. Then, the SHOW_POINT pulse is sent to the Z axis of the oscilloscope (a.k.a., “Z-Drive”) to unblank each point after it has settled down and is ready to be illuminated.

You can’t go wrong purchasing an authentic Arduino Due board for this project from www.arduino.cc (about $50 each). However, since the Due design is open source, Due-compatible boards are also available from several other places. Once you have the Due in hand, the AGI interface circuit must be built. I prototyped the AGI circuit using a solderless breadboard (Figure 8) and later built a more robust point-to-point soldered-wire version.

Since I wanted to keep things simple and easy to build, I opted to use only through-hole components for this project. I made the AGI PCB a little larger than a standard Arduino board so that the Due could be easily mounted on top of the AGI circuit board using 4-40 spacers.

Just like any other Arduino project, the AGI system can be programmed using the Arduino Integrated Development Environment (IDE). In Part 2, we’ll focus on the software by looking at CRT_SCOPE: a test and checkout program that you can use to get your build up and running. We’ll also use this program as a vehicle to demonstrate how easy it is to use XYscope: the Arduino AGI software support library.

You can get ready for Part 2 by downloading and installing the Arduino IDE, Due board definition files, Due timer library, and the AGI library. If this is your first Arduino Due project, I suggest you start out with some basic “hello world” and “blinking LED” test programs to get the IDE set up, compiling, and properly connected to your Due. Check out the References for links to the IDE and a few others that you might find interesting.

Overall plot quality is influenced by the quality and performance of the oscilloscope and CRT used. This project works well only with analog oscilloscopes; digital scopes will only produce poor looking output.

Hi guys, welcome to today’s tutorial. Today, we will look on how to use the 1.8″ ST7735 colored TFT display with Arduino. The past few tutorials have been focused on how to use the Nokia 5110 LCD display extensively but there will be a time when we will need to use a colored display or something bigger with additional features, that’s where the 1.8″ ST7735 TFT display comes in.

The ST7735 TFT display is a 1.8″ display with a resolution of 128×160 pixels and can display a wide range of colors ( full 18-bit color, 262,144 shades!). The display uses the SPI protocol for communication and has its own pixel-addressable frame buffer which means it can be used with all kinds of microcontroller and you only need 4 i/o pins. To complement the display, it also comes with an SD card slot on which colored bitmaps can be loaded and easily displayed on the screen.

The schematics for this project is fairly easy as the only thing we will be connecting to the Arduino is the display. Connect the display to the Arduino as shown in the schematics below.

Due to variation in display pin out from different manufacturers and for clarity, the pin connection between the Arduino and the TFT display is mapped out below:

We will use two libraries from Adafruit to help us easily communicate with the LCD. The libraries include the Adafruit GFX library which can be downloaded here and the Adafruit ST7735 Library which can be downloaded here.

We will use two example sketches to demonstrate the use of the ST7735 TFT display. The first example is the lightweight TFT Display text example sketch from the Adafruit TFT examples. It can be accessed by going to examples -> TFT -> Arduino -> TFTDisplaytext. This example displays the analog value of pin A0 on the display. It is one of the easiest examples that can be used to demonstrate the ability of this display.

The second example is the graphics test example from the more capable and heavier Adafruit ST7735 Arduino library. I will explain this particular example as it features the use of the display for diverse purposes including the display of text and “animated” graphics. With the Adafruit ST7735 library installed, this example can be accessed by going to examples -> Adafruit ST7735 library -> graphics test.

The first thing, as usual, is to include the libraries to be used after which we declare the pins on the Arduino to which our LCD pins are connected to. We also make a slight change to the code setting reset pin as pin 8 and DC pin as pin 9 to match our schematics.

Next, we create an object of the library with the pins to which the LCD is connected on the Arduino as parameters. There are two options for this, feel free to choose the most preferred.

The complete code for this is available under the libraries example on the Arduino IDE. Don’t forget to change the DC and the RESET pin configuration in the code to match the schematics.

Uploading the code to the Arduino board brings a flash of different shapes and text with different colors on the display. I captured one and its shown in the image below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey