lcd display issues manufacturer

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

Point defect is a kind of defect that some point on your screen don’t display correctly. There are mainly three situations: the point keeps displaying black or whitewhen the screen is working or the point can only display a single color.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

You may notice there are some screens have uneven display, which means some white area appears in dark picture or vice versa. We call this ‘mura’, a word originated from Japanese.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Typically, the default blame starts with the supplier. However, it could be an issue with your assembly process, the design integration between the product and the display, or even a problem with a non-display component that fails (that affects the display).

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

The likelihood of damage, or the display being non-functional from the supplier’s end, is fairly low, as it is standard to test 300%, or three times throughout the process. Additionally, the final packaging itself is subject to drop testing during the initial development phase prior to mass production to ensure a damage-free trip despite your carrier’s best efforts to drop the packaging. That means the defect is likely latent or occurred during installation into the end-product.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

Five simple words that can equate to significant LCD display challenges for you. Here’s how you can successfully address and resolve these 5 LCD display challenges:

Proactively address this challenge with the LCD display provider and within your company. Internally, assure suppliers’ lead-times are accurate in your MRP. Additionally, maintain a 2-4-week buffer stock or more depending on lead-times and component scarcity.

The LCD display supplier can also carry a buffer stock for your application. Reactively, the LCD display supplier should offer expedited options. Effective display provider can pressure the upstream supply chain, adjust production schedules, ship partial quantities and accelerate shipments. Applying these solutions eliminates most delivery problems and handles unplanned customer demand (a good thing!).

Find a display provider that is prepared for and addresses obsolescence when it rears its ugly head. Display providers who are manufacturing more customized systems are more likely to work with your needs than high-volume suppliers. Understand what would cause an LCD display to become obsolete. Your ideal design partner(s) will design for obsolescence mitigation. Then, by giving a long end-of-life (EOL) notice period, the LCD display provider can react by creating safety stock, sourcing alternates and re-engineering your display around a readily available replacement. Additionally, they should plan development of a compatible replacement so your product development doesn"t need to change. Obsolescence management safeguards your product line and down the road - your bottom line.

Quality issues generally arise in a few ways. First, the LCD display"s failure to meet the performance specification as intended. This involves defining what"s required to satisfy the product"s intent and customers" needs. Next, there are the optical and mechanical aspects of LCD display manufacturing. This includes meeting dimensional tolerances and maximum defect limitations.

A supplier that manufactures to your specific needs will minimize quality issues due to their ability to bring flexibility and expertise by modifying the LCD display for your specific product, and then actively supporting ongoing product improvements.

Defining “performance” begins with the application. Who is the target market or end user and how will they interact with the LCD display? In what environment will it be used? How is it being sold or demonstrated to customers? What data does the LCD display need to convey? Must it be readable by the visually impaired?

When performance is fully understood, we can define the idealdisplay type, size, pixel density, contrast, temperature range, brightness, color gamut response time, etc. Over-specifying any of these factors adds unnecessary cost, while under-specifying will detract from the end product"s usability. Ensure performance is optimized in order for your application to be successful. It is key to find an LCD display provider who is willing to adjust and customize these particular variables and explain them to you in terms of the end user experience.

Determining the right price to pay depends on three factors. What does the display need to do? What does the display NOT need to do? And lastly, what quantity is needed? In most cases the ideal option is a custom or semi-custom display perfectly designed for its application. Despite what many think, this is often the most cost-effective solution.

Another cost challenge is system-level manufacturability. This is where display integration improvements can reduce product complexity, improve manufacturing time, and reduce system level manufacturing defects. For the most seamless LCD display integration, there are additional components such as buttons, LEDs, PCB boards, and connectors that are more efficiently integrated on the display rather than a separately assembled component. Clearly in this case, the LCD display cost will go up, but when done right, the system level cost is reduced to result in a net gain.

Lastly, you need to know system-level costs. If you’re giving up customer valued performance or functions, you"re trading market share and profitability for display savings and the net result may be decreased profit. The opposite also holds true; adding performance that is not necessary (these are attributes that the customer does not value) simply adds additional product costs.

Choosing the right supplier, based on your volume and quality needs is essential. Then implement the optimal LCD display solution with the optimal features and performance.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

The main reasons are insufficient design and imperfect control of the production process. Well-known manufacturers have many years of LCD screen experience, rich design experience and proper management capabilities, and have developed weird development and production methods from them.

Under the condition of high temperature and low voltage driving LCD screen, for this kind of products, it is necessary to have extremely high professional ability to select the raw materials of backlight and strictly control the manufacturing process. The raw materials include PI/sealant/liquid crystal materials and important factors such as ion pollution control in the manufacturing process, which can meet the use requirements of a wide temperature environment.

Cross-shadowing or ghosting: The main reason is that the driving waveform is incomplete due to the weak driving capability of the IC. The professional ability of ITO design and the power consumption control of LCD can effectively reduce the power consumption between IC and LCD and achieve good display effect.

Wide temperature, extreme temperature, wide temperature LCD, low operating temperature -40°c, good material combination and strict process control, can withstand the operating requirements of extreme environments.

LED screen products display high contrast, but the original supplier can’t control it? Before mass production, the boundary samples displayed in production are imported into production. Before the first batch of products are mass-produced, they will focus on control to avoid production disputes and delay customer delivery and quality.

Surprisingly cost issue is the least common. The pain of changing LCD suppliers is high, such that all the problems mentioned above end up costing more than a regular cost delta between competitive suppliers.

An LCD’s cost is an obvious challenge as it’s usually the most expensive component. The challenge is that cost is also difficult to quantify and properly understand. Determining the right price to pay depends on three main factors.

The ideal option in most cases is a custom or semi-custom display designed for its application. This is often the most cost-effective solution, despite what many think.

System-level manufacturability is another cost challenge where display integration improvements can reduce product complexity, improve manufacturing time, and reduce system-level manufacturing defects. For the most seamless LCD integration, additional components such as buttons, LEDs, PCB boards, and connectors are more efficiently integrated on display than a separately assembled component. Clearly, in this case, the LCD cost will go up, but when done right, the system-level cost is reduced to result in a net gain.

Lastly, you need to know system-level costs. You are trading market share and profitability for display savings, and the net result may be decreased profit if you are giving up customer valued performance or functions. The opposite also holds; adding performance that is not necessary (these are attributes that the customer does not value) adds additional product costs.

Unlike older cathode ray tube (CRT) displays that scan an electron beam over a phosphor screen to create light, LCD displays are composed of a fixed grid of tricolor pixels that change transparency based on a range of voltage levels provided by the monitor"s controller. Without a voltage the pixel is opaque and blocks the screen"s backlight from transferring through it, and when a full voltage is applied then the pixel allows full transmittance of the backlight. When this is done over the entire pixel grid in patterns, then you see those patterns on the screen.

At a very basic level, the way pixels work is a voltage change alters the pixel to allow more or less light through. When there is no voltage, no light is let through (darker), and when the voltage is at its maximum level then 100 percent of the light is allowed to pass through (brighter). By supplying intermediate voltages the computer adjusts the pixel"s transmittance levels for its three color components, to display various combined colors and intensities.

This pixel-based setup for LCD monitors provides many advantages over CRT displays, but does have potential drawbacks arising from the fact that the image is dependent on millions of independent electrical components as opposed to a single scanning beam, so if faults occur in these components then the display output can be affected. The resulting problems include stuck or dead pixels, as well as a residual image effect.

One of the more common problems with LCD displays is the potential for stuck or broken pixels, where the pixel either does not receive a voltage and remains black, or does not respond to voltage changes and stays at a set luminance level. Sometimes this can happen for individual pixels, suggesting a problem with the pixel itself, or it can happen to groups of pixels, suggesting the possibility of problems with the display"s controller or a defect in a portion of the pixel grid.

When stuck or broken pixels occur, there are a couple of things you can try in order to fix the problem. One is to apply a small amount of pressure to the pixel when turning the display on or off, which can sometimes help stimulate the electronics to work properly. Unfortunately, Apple"s glass-covered glossy displays prevent this from working on modern Mac systems.

The alternative to using pressure is to exercise the pixel"s electronics by using a program that displays quick-changing patterns on the screen and thereby rapidly switches the pixels on and off. Three such programs that will work on the Mac are the following:

LCD monitors can also be affected by another problem called "transient persistence" that is reminiscent of CRT burn-in. Classic burn-in would happen because the phosphor coating on the screen would get depleted by the persistent bombardment of electrons from the CRT, resulting in the inability of those sections of the display to convert the electron beam to visible light. This meant that if you kept a specific pattern showing on the screen then over time it could become a permanent residual image on the display that would show even when the display was turned off. This was a reason why screensavers were developed--to keep the wear on the screen"s phosphor coating as even as possible.

The physical burn-in of displays is no longer an issue now that LCD displays have taken over, but while transient image persistence is not a physical burn of the device, it is an alteration of the pixel response to voltage changes (usually temporary) that prevents pixels from getting as bright as others on the screen.

Similar to CRT burn-in, LCD image persistence generally happens after you have displayed a pattern of intense colors on screen; however, unlike CRT burn-in, LCD persistence can sometimes set in after only a few hours of displaying the image, as opposed to the weeks or even months that it can take for burn to set in on a CRT monitor. Additionally, unlike CRT burn-in, image persistence can often be reversed.

What happens with LCD monitors is the affected pixels have lost their ability to respond to the full range of voltages that the display gives them, resulting in a limited range of colors that can be output. This can happen if the pixel is acting like a capacitor and is retaining a residual charge, or if it is not able to reach the level of luminance that is desired when given a specific voltage. Either way, the pixel is not able to reach its full range of possible intensities.

Unlike stuck or dead pixels that may benefit from having the monitor turned on and off rapidly to produce rapid voltage changes, image persistence will benefit from a lengthy stretching of the pixel"s range. Therefore, instead of using tools like JScreenFix to run random patterns over the affected screen area, you might instead place a pure white window (such as an empty TextEdit window, or what you get using the "White" option in the LCD Repair tool listed above) over the affected area for a few hours or even a few days if necessary. Doing this will force those pixels to be fully on, and over time their intensities may increase to be the same as the surrounding pixels.

Likewise, try turning off the pixels fully by shutting down the display for a long period of time or placing a pure black texture over the affected area (see the LCD Repair tool listed above for this option as well). This will turn the pixels completely off and allow residual voltage in them to drain slowly over time.

So far we have discussed pixel-based problems with LCD displays, but the system"s backlight can also suffer some common problems that include the backlight randomly blinking off, not turning on, or only illuminating part of the screen.

When the display fully cuts out and does not show any light, one possibility could be that your computer is not properly communicating with the display, or the display"s controllers or power supply are not working properly. If this occurs, try connecting the display to another system. But if power LEDs and other indicator lights turn off when the backlight goes out, then it may be your display"s power supply is failing.

If only the backlight is malfunctioning, then the LCD panel itself should still be working just fine and should be rendering the text and images of your computer"s output. To test for this, use a bright flashlight and shine it on your screen at an angle in an area where you expect images and text to be (such as the Dock or menu bar). On Apple"s laptop systems, you can shine the flashlight through the Apple logo on the back to illuminate the screen on the front and better detect text and images that way.

If shining an alternative light source on the display causes graphical content to show up, then either the backlight or some component involved in controlling it (such as the power inverter for it) have failed and will likely need to be replaced, especially if you cannot rectify the problem by restarting the system, resetting PRAM and SMC, or otherwise toggling different hardware and software settings on your system.

How do I know if my monitor is really showing true 4K video?Make sure that that the signal you are sending is 4K resolution (3840x2160). You can test this by pressing the monitor’s Menu button. The monitor’s Menu screen will display the incoming video resolution and timing in the top-right corner of the screen.

Certain touch panels are susceptible to issues due to grease/dust/water and therefore may need added care. If this is a constant problem, please contact us for further assistance.

My monitor is displaying a message saying “Sync Out of Range”If you are seeing this on your monitor, it means you are sending a video resolution to your monitor that is higher than your monitor’s native resolution.

Convenience without sacrificing functionality is a major focus of the latest technological innovations. Wearable gadgets are part of the leading change — easy to carry and high-tech at the same time. Recent data show the rising popularity of wearable devices, which set a record of 310 million units shipped in 2017 alone and resulted in $30.5 billion revenue. Many factors have made this possible, from LCD module manufacturer to software engineers and application designers.

Since these gadgets are made to be worn, the space available for display has always been a vital design issue. The most basic ones involve the use of a LED indicator that flash to convey messages to the user. Segmented elements allow display of digits and letters. An active matrix display makes it possible to create an image by turning pixels on and off.

Fortunately, there are several options for design engineers. If you’re willing to sacrifice resolution for low power usage, bistable displays might work. If you want clear and beautiful images, LCD and OLED panels are the better choice. LCD module manufacturers are capable of producing panels that can show full-color images with extremely high resolution. A wearable gadget display must also be able to:

Wearable devices can be vulnerable to dirt, dust, water, heat, and other elements. If your device is going to be exposed a lot, optical bonding is an excellent way to protect the surface. It stops dangerous elements from reaching the LCD through a combination of lamination and bonding agents.

The sun can be a major problem for wearable gadget displays. Too much exposure to heat can threaten to melt the crystals in the display. UV rays can also have a negative effect on the device’s durability and lifetime. Ventilation, infrared protective films, and UV protective films offer great protection.

Ultimately, wearable displays should satisfy the goals of your project. Searching for the right LCD or OLED displays for your devices? Our team offers a variety of solutions. We can assist you from the design level throughout the manufacturing process and beyond.

Troubleshooting CRTs versus LCDs begins with similar steps, but diverges due to the differing natures of the two display types. The first troubleshooting steps are similar for either display type: power down the system and display and then power them back up; make sure the power cable is connected and that the outlet has power; verify that the signal cable is connected firmly to both video adapter and display and that there are no bent pins; verify that the video adapter is configured properly for the display; try the problem display on a known-good system, or try a known-good display on the problem system; and so on. Once you"ve tried the "obvious" troubleshooting steps, if the problem persists, the next step you take depends on the type of display. The following sections cover basic troubleshooting for CRTs and LCDs.

CRTs seldom fail outright without obvious signs, such as a loud snap or a strong odor of burning electrical components. Most CRT problems are really problems with the power, video adapter, cable, or hardware/software settings. To eliminate the CRT as a possible cause, connect the suspect CRT to a known-good system, or connect a known-good display to the suspect system. It is worth noting, that older CRTs eventually wear out, and starts dimming. Common signs of a weak CRT are a dim picture, dysfunctional brightness and/or color controls, image smearing at high brightness, and in color CRTs, a tint towards a single color (Red Green Blue)

CRTs contain multiple filaments, which can be broken, or gas may have leaked into the vacuum inside the CRT. CRTs damaged this way are unrepairable without specialist equipment. With the display open. check if all three filaments are glowing bright orange. Excessive redness or purple arcing signifies gas has leaked in. There may also be an internal short inside the CRT, which is also unfixable without specialist equipment.

If you have ACPI or APM power management enabled, it may be causing the problem. Some systems simply refuse to wake up once power management puts them to sleep. We have seen such systems survive a hardware reset without restoring power to the CRT. To verify this problem, turn off power to the system and CRT and then turn them back on. If the CRT then displays an image, check the power management settings in your BIOS and operating system and disable them if necessary.

The horizontal and/or vertical deflection system has failed. The CRT tube itself is fine, but the circuitry driving the tube has failed. Replace the display.

There are two likely causes. First, you may be driving the CRT beyond its design limits. Some CRTs display a usable image at resolutions and/or refresh rates higher than they are designed to use, but under such abuse the expected life of the CRT is shortened dramatically, perhaps to minutes. To correct this problem, change video settings to values that are within the CRT"s design specifications. Second, the power receptacle may be supplying voltage lower than the CRT requires. To correct this problem, connect the CRT to a different circuit or to a UPS or power conditioner that supplies standard voltage regardless of input voltage.

The video card settings are likely outside the range supported by the CRT, particularly if you have just installed the CRT or have just changed video settings. To verify this, restart the system in Safe Mode (press F8 during boot to display the Windows boot menu and choose Safe Mode). If the system displays a VGA image properly, change your display settings to something supported by the CRT.

Most modern CRTs can display signals at many different scan frequencies, but this doesn"t mean that the CRT will necessarily automatically display different signals full-screen and properly aligned. Use the CRT controls to adjust the size and alignment of the image.

The CRT may need to be degaussed. A CRT that sits in one position for months or years can be affected even by the earth"s very weak magnetic field, causing distortion and other display problems. Exposing a CRT to a strong magnetic field, such as unshielded speakers, can cause more extreme image problems. Many modern CRTs degauss themselves automatically each time you cycle the power, but some have a manual degauss button that you must remember to use. If your CRT has a manual degauss button, use it every month or two. The degaussing circuitry in some CRTs has limited power. We have seen CRTs that were accidentally exposed to strong magnetic fields, resulting in a badly distorted image. Built-in degaussing did little or nothing. In that case, you can sometimes fix the problem by using a separate degaussing coil, available at RadioShack and similar stores for a few dollars. We have, however, seen CRTs that were so badly "magnet burned" that even a standalone degaussing coil could not completely eliminate the problem. The moral is to keep magnets away from your CRT, including those in speakers that are not video-shielded.

An incorrect yoke may have been attached to the CRT. Unless you have a lot of spare time on your hands, this is usually not worth fixing. Replace the display.

If your LCD displays no image at all and you are certain that it is receiving power and video signal, first adjust the brightness and contrast settings to higher values. If that doesn"t work, turn off the system and LCD, disconnect the LCD signal cable from the computer, and turn on the LCD by itself. It should display some sort of initialization screen, if only perhaps a "No video signal" message. If nothing lights up and no message is displayed, contact technical support for your LCD manufacturer. If your LCD supports multiple inputs, you may need to press a button to cycle through the inputs and set it to the correct one.

Unlike CRTs, where increasing the refresh rate always reduces flicker, LCDs have an optimal refresh rate that may be lower than the highest refresh rate supported. For example, a 17" LCD operating in analog mode may support 60 Hz and 75 Hz refresh. Although it sounds counterintuitive to anyone whose experience has been with CRTs, reducing the refresh rate from 75 Hz to 60 Hz may improve image stability. Check the manual to determine the optimum refresh rate for your LCD, and set your video adapter to use that rate.

First, try setting the optimal refresh rate as described above. If that doesn"t solve the problem and you are using an analog interface, there are several possible causes, most of which are due to poor synchronization between the video adapter clock and the display clock, or to phase problems. If your LCD has an auto-adjust, auto-setup, or auto-synchronize option, try using that first. If not, try adjusting the phase and/or clock settings manually until you have a usable image. If you are using an extension or longer than standard video cable, try connecting the standard video cable that was supplied with the display. Long analog video cables exacerbate sync problems. Also, if you are using a KVM switch, particularly a manual model, try instead connecting the LCD directly to the video adapter. Many LCDs are difficult or impossible to synchronize if you use a KVM switch. If you are unable to achieve proper synchronization, try connecting the LCD to a different computer. If you are unable to achieve synchronization on the second computer, the LCD may be defective. Finally, note that some models of video adapter simply don"t function well with some models of LCD.

If the screen is displaying a full, stable image, but that image is of poor quality, first verify that the display is not connected through a KVM switch or using an extension cable. If so, connect the display directly to the video adapter using the standard cable. If that is already the case, adjust the brightness, contrast, and focus controls. If you are unable to get a proper image using these controls, the problem is most likely a clock or phase mismatch, which you can cure by taking the steps described in the preceding item.

Your video card is supplying a video signal at a bandwidth that is above or below the ability of your LCD to display. Reset your video parameters to be within the range supported by the LCD. If necessary, temporarily connect a different display or start Windows in Safe Mode and choose standard VGA in order to change video settings.

This occurs when you run an LCD at other than its native resolution. For example, if you have a 19" LCD with native 1280x1024 resolution but have your display adapter set to 1024x768, your LCD attempts to display those 1024x768 pixels at full screen size, which physically corresponds to 1280x1024 pixels. The pixel extrapolation needed to fill the screen with the smaller image results in artifacts such as blocky or poorly rendered text, jaggy lines, and so on. Either set your video adapter to display the native resolution of the LCD, or set your LCD to display the lower-resolution image without stretching the display (a feature sometimes referred to as display expansion), so that pixels are displayed 1:1, which results in the lower resolution using less than the entire screen.

This is a characteristic of LCDs, particularly older and inexpensive models, caused by defective pixels. Manufacturers set a threshold number below which they consider a display acceptable. That number varies with the manufacturer, the model, and the size of the display, but is typically in the range of 5 to 10 pixels. (Better LCDs nowadays usually have zero dead pixels.) Nothing can be done to fix defective pixels. Manufacturers will not replace LCDs under warranty unless the number of defective pixels exceeds the threshold number.

Some people claim that leaving the unit powered off for a day or two will "erase" a persistent after-image. Others suggest leaving a neutral gray screen (like the one used for phase adjustment) up on the screen to "equalize" the display. I dunno. FWIW, I"ve seen this problem on older Samsung panels but never on the Sony or NEC/LaCie panels I use.

Again, this is a characteristic of LCDs, particularly older and inexpensive models. The after-image occurs when the display has had the same image in one place for a long time. The after-image may persist even after you turn the display off.

Transistor-based pixels in an LCD respond more slowly than the phosphors in a CRT. The least-expensive LCDs exhibit this problem even with slow image movement, as when you drag a window. Better LCDs handle moderately fast image movement without ghosting, but exhibit the problem on fast-motion video. The best LCDs handle even fast-motion video and 3D gaming very well. The only solution to this problem is to upgrade to an LCD with faster response time.

Use the brightness control to increase image brightness. If you have set brightness to maximum and the image is still too dim, contact the display manufacturer. The CCRTs used to backlight the screen have a finite lifetime and may begin to dim as they near the end of their life.

If one or more horizontal and/or vertical lines appear on the display, first power-reset the computer and display. If the lines persist, run the auto-setup function of your display. If that does not solve the problem, power the system and display down, remove the video cable, and verify that the video plugs and jacks on both computer and display ends do not have broken or bent pins. Even if all appears correct, try a different video cable. If the problem persists, contact the display manufacturer.

SShock, 31 May 2022They already use OLED on most "budget" devices like Galaxy A50 series. I can safely ... moreThis news is not related to mobile division it is related to Samsung Display TV panels. They ll no longer manufacture LCD TV panels they ll procure from others like TCL

AlienKiss, 01 Jun 2022I"m all for OLED displays, BUT I just want to warn you guys to make sure that you don... morethat"s right. but Samsung Display is not the same which produces TVs so maybe they will buy lcd panel from different brand

gyess it upto you what you want to be blinded by. :)Blue light is not affected by display type itself, you"ll get blu elight from OLED or LCD displays. It"s just color temperature above 3000K spectrum that"s considered "blue light". You can tune both OLED and LCD displays to display warmer color spectrum and you solve that. PWM was also an issue with LCD displays because it can be used for backlight LEDs.

I"m all for OLED displays, BUT I just want to warn you guys to make sure that you don"t fall asleep while watching YT or using VLC or any app that won"t turn off the phone display. You"ll wake up in the morning with screen burn-ins on the display.

Anonymous, 31 May 2022This is so true. I hear so much about how crappy LCD are but then I look at stuff like the iPa... moreThey already use OLED on most "budget" devices like Galaxy A50 series. I can safely assume they make OLED displays in such high volume they can afford to put lowest end OLED displays even on Galaxy A00 models now. I mean, we had OLED displays 12 years ago, I had Samsung Wave and Galaxy S2, both sporting SuperAMOLED (which is type of OLED). S2 was a flagship at the time, but Wave wasn"t and it still had SuperAMOLED and it even predates S2 by 1 year. Not the "Plus" version of panel, but frankly I think Wave"s display was better and more vibrant where S2 felt muted and dull for some reason even though it was released later and as a better version. So, I don"t know. It"s also possible they"ll outsource LCD panels from other manufacturer to fill in the gap on lowest end models. But in the end I think they"ll make more profit if they focus entirely on OLED and sell it within their own corporation (Samsung Display to Samsung Mobile) instead of buying it from someone else.

SShock, 31 May 2022People also greatly over-exaggerate the blacks or the lack of it. iPhone XR, the one everyone ... moreThis is so true. I hear so much about how crappy LCD are but then I look at stuff like the iPad and the Tab s8 and I"m just like "these look great why are ppl hating on LCD so much?" I understand also that OLED is better and it is obvious when you put them side by side but on its own, a high quality LCD panel still looks great.

G, 31 May 2022Good to see people discussing about the two different display technologies despite them being ... morePeople also greatly over-exaggerate the blacks or the lack of it. iPhone XR, the one everyone whined over its LCD display so much has blacks so deep you can"t really distinguish the black display from the black frame around the display or the notch itself. You really need to look super hard and at an angle to see slight difference. That"s with automatic brightness which is usually at around 1/3. Only when I really maxed out the brightness I could more clearly see the difference, but is almost entirely unrealistic situation anyways. I"m well aware OLED will always be better at that because it can actually turn off pixels where image is suppose to be black, but still, the way people frame it, one has a feeling like black color doesn"t even exist and it"s just a shade of dark grey that sticks out like a sore thumb. Which is very far from reality. Quality LCD displays can still get really good blacks. Usually bigger issue with LCD is that it"s just thicker component which requires more surrounding space to be used. Garbage LCD display on a 150€ Realme or Nokia is not the same as LCD display found in basically any iPhone that still used it and were constantly relentlessly mocked for still being LCD.

Dandy238, 30 May 2022I do not understand so much hatred for the LCD displays, they are great as they are, most comp... moreGood to see people discussing about the two different display technologies despite them being really apples and oranges though serving the same purpose and applications.

Your point about black not being black enough (contrast) on LCDs has actually been worked around by a local dimming backlight unit. Costs are still high and the backlight requires driving so it will not be a mainstream structure compared to the traditional diffusion side lighting.

Samsung just exited LCDs because the playing field is now just about price wars between everyone else. Like the Japanese, better to focus more on profitable unique displays.

After months of price cuts, manufacturers of large-size liquid-crystal displays (LCDs) are under pressure to reduce panel prices further, following a major build-up of inventory. A recent report from US business analyst iSuppli revealed that the second quarter of 2010 saw the manufacture of 52 million large (ten inches and above) LCD television panel shipments, but the sale of only 38.7 million LCD television sets. The resulting imbalance between supply and demand is having a strong impact on the sector.

“This gap is higher than anything seen in 2009. Over-supply persisted in the first two months of the third quarter as buyers cut orders in July and August,” says iSuppli analyst Sweta Dash. “LCD television brands are expected to lower prices more aggressively to reduce their inventory levels, thus putting mounting pressure on panel suppliers to reduce prices further.”

Dash points out that manufacturers of monitor and notebook panels have been reducing supply to mitigate excessive inventory levels, and that panel prices are now stabilizing as a result. In contrast, high depreciation costs at relatively new LCD television panel fabrication plants mean suppliers have been less willing to reduce production.

However, Dash predicts that the potentially strong sales of LCD television sets in China could reduce inventory levels and help to steady panel prices by the end of the fourth quarter of 2010.

At the same time, rapidly rising sales of smart phones and tablet PCs are predicted to see the global market for small- and medium-size thin-film transistor (TFT) LCDs expanding at its fastest pace for three years. According to analyst Vinita Jakhanwal, also from iSuppli, global shipments of TFT LCD panels are set to rise by 28.1% in 2010, from 1.8 billion to 2.3 billion units.

“Sales of smart phones and tablets are booming thanks to the iPhone, iPad and other competing products,” explains Jakhanwal. “Smart phone manufacturers are now adopting TFT LCDs that use in-plane switching technology, which supports a wider viewing angle and better picture quality than a conventional LCD.” But the fast-paced market expansion probably won"t last, predicts Jakhanwal. “Growth in TFT LCD shipments will slow in 2011 and beyond as the expansion of smart phone and tablet markets cools to more normal levels.”

The adoption of touch-screen technology in the mobile phone industry is fuelling the demand for active-matrix organic light-emitting diode (AMOLED) displays, reports US market research firm DisplaySearch. AMOLED displays have been the only technology in the mobile phone display market to increase revenues every quarter this year, as both unit shipments and average prices have risen. “With an average worldwide market penetration of mobile phones at 70%, manufacturers are eager to introduce new features such as touch-screens to ensure continued growth this year,” says Calvin Hsieh, research director at DisplaySearch. “The success that AMOLED displays are finding in high-end smart phones reflects these trends.”

AMOLED technology rose in popularity after its integration into mobile phones manufactured by Samsung and HTC. In the first quarter of 2010, the average screen size for an AMOLED display exceeded three inches, which is larger than that of competing TFT LCDs. Taiwan-based display manufacturers AUO and Chimei Innolux are scheduled to start mass-producing AMOLED displays in 2011. Hsieh believes AMOLED technology will now see increased year-on-year growth, although TFT LCDs will still ship more units.

US-based quantum-dot and materials developer Nanosys has opened a new facility in Gyeonggi-do, Korea, to support its recent expansion into the Asian market. Led by former LG Electronics vice president Jong-Uk Bu, Nanosys Korea will develop "architected materials" for Asian electronics manufacturers, including high-performance LED backlights for displays and silicon composite anode materials for use in lithium–ion batteries. Earlier this year, Nanosys unveiled QuantumRail, quantum-dot-based LED backlighting units that improve LED backlit display colour gamut and efficiency. Nanosys says that its quantum dot LED technology makes it possible to deliver saturated red, green and blue colours that exceed the NTSC 1953 guidelines for displays. This latest announcement follows collaborations with Korea-based electronics manufacturers LG Innotek and Samsung Electronics to develop display products based on quantum-dot crystals.

Established in 2007, Raystar has built its reputation by offering advanced products in PMOLED display and modules as well as in FSTN / STN LCD Display Module, COG LCD, TFT LCD Display.

Every valued customer of Raystar plays a key role in our current success. We promise to keep growing as your most trustworthy partner for display solutions in the decades ahead.

To find the app that causes issues, uninstall recently downloaded apps one by one. After you remove the app that causes the problem, you can reinstall the other apps you removed.

Dell Technologies recommends ensuring that the device drivers and BIOS are up to date using the SupportAssist application for optimal video performance and to help resolve common video-related issues.

It is essential to verify if the problem is inherent with the monitor, video card (GPU) or video settings on your computer. A straightforward way to identify this is to connect the computer to a known-good external monitor or TV and ensure that the display cable (S-video, VGA, DVI, HDMI, DisplayPort, USB-C, or Thunderbolt 3) is firmly connected to the video port on the computer and the monitor.

If the issue persists on the other monitor it may be due to the video card (GPU) or video settings and not the monitor, go to the step Verify display or video issue in Windows Safe Mode. Else go to the next step.

Performance issues may occur if there is any type of damage that is caused to the display cables or the LCD screen. LCD screen may show that symptoms like LCD screen stops working, work intermittently, color mismatch, flickering, display horizontal or vertical lines if there is damage to the display cables or the LCD screen.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry image, horizontal or vertical lines, color fade, it is a good practice to isolate the monitor by running a diagnostic test on the Dell monitor.

NOTE: Self-test feature check (SFTC) helps check if the Dell monitor is working normally as a stand-alone device. To check for screen abnormalities such as flickering, distortion, clarity issues, fuzzy or blurry image, horizontal or vertical lines, color fade, and so on, run the integrated self-test (BIST) or integrated diagnostic (BID) test.

Dell monitors can be reset to factory default settings using the on-screen display (OSD) menu. This can be accessed using the buttons or joystick that is available on the Dell monitor. For step-by-step instructions to reset a Dell monitor to factory default settings, see the User Guide of your Dell monitor at the Dell Manuals website.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of your Dell monitor. Changing the display settings can help resolve several types of video issues.

The announcement is similarly noteworthy for the components slated to be manufactured at this new facility. Although Foxconn is best known to many in the U.S. for its role in assembling Apple iPhones in China, the new Foxconn fab isn’t targeted to service the lucrative smartphone market. In a move that pivots its attention from small-screen portable devices, the Foxconn facility in Wisconsin will produce LCD displays for large-screen televisions.

The market for LCD display panels is notoriously volatile, prone to upswings and downswings as consumer tastes and market demands shift. Panel suppliers must calibrate their manufacturing capacity accordingly, carefully calculating production and inventory targets to preserve their razor-thin profit margins. In this context, a $10B investment in a new LCD panel fab can be perceived as a major gamble.

But a brand new fab is precisely what’s required to sustain production capacity when transitioning from sub-40-inch displays to displays that are 50 inches and larger – sometimes much larger. You can’t simply upgrade an existing fab to accommodate significantly larger glass panels. Across the entire production line, from the manufacturing tools to the conveyers and beyond, new infrastructure and equipment will be needed.

And yet Foxconn has correctly predicted that a new large-screen LCD display fab is a sound investment to meet growing consumer demand for larger TVs. Experts estimate that global demand for large-sized TVs is growing at an annual rate of more than 20%. Market research firm IHS Markit specifically notes that 65-inch and 75-inch LCD TVs are the fastest growing segments in the LCD TV market, and the 60-inch and above LCD TV market in North America is expected to grow from 4.2 million units in 2015 to 9.5 million units in 2021. Indeed, North America is the biggest market for large-screen LCD displays of 55-inches and above, perhaps a telling reason why Foxconn has expanded its manufacturing operations here.

Bulky, plastic bezels have given way to sleeker designs that maximize screen space and conserve living room space, and the evolution to 4K video and onward to 8K is enabling shorter viewer-to-TV viewing distances. Where previously a standard HD, large-screen TV required a wide viewing berth to compensate for image pixilation, the newest generation of ultra-HD, large screen LCD TVs enable comfortable, closer-range viewing regardless of room size. Factoring in the additional benefits of new quantum dot color enhancement technology, one could make the argument that there’s never been a better time to upgrade our LCD TVs.

When you view the same image on both the notebook or All-in-One display and an external display panel (monitor, projector, or television), the image shown on the computer display might shrink to a lower resolution, with black borders around the edges of the reduced display.

This issue can occur when the native display resolution of the computer and the resolution of the external monitor are not the same. When the graphic control detects two displays, it usually defaults to the lower resolution for both devices.

To resolve this issue, disconnect the external monitor to verify that the resolution on the computer display changes back to the desired settings. Reconnect the external monitor, and then adjust the resolution settings for each device using one of the following methods:

To use Windows to control the graphic display, connect both displays, right-click the desktop, select Screen Resolution, and then change the resolution for each display. On some models, you can select an advanced option to either Duplicate the same image on both displays or Extend the desktop image across both displays.

Certain computer models that feature a high-performance chip or secondary graphics processing unit (GPU) have an advanced graphics maintenance function. Names of advanced graphics options may vary. To use an advanced graphics maintenance function (if available) to control the graphics display, right-click on the desktop and select one of the following options:

For most customers, visiting a professional repair provider with certified technicians who use genuine Apple parts is the safest and most reliable way to get a repair. These providers include Apple and Apple Authorized Service Providers, and Independent Repair Providers, who have access to genuine Apple parts.* Repairs performed by untrained individuals using nongenuine parts might affect the safety of the device or functionality of the display. Apple displays are designed to fit precisely within the device. Additionally, repairs that don"t properly replace screws or cowlings might leave behind loose parts that could damage the battery, cause overheating, or result in injury.

Depending on your location, you can get your iPhone display replaced—in or out of warranty—by visiting an Apple Store or Apple Authorized Service Provider, or by shipping your iPhone to an Apple Repair Center. Genuine Apple parts are also available for out-of-warranty repairs from Independent Repair Providers or through Self Service Repair.*

The iPhone display is engineered together with iOS software for optimal performance and quality. A nongenuine display might cause compatibility or performance issues. For example, an issue might arise after an iOS software update that contains display updates.

Apple has determined that some iPhone X displays may experience touch issues due to a component that might fail on the display module. An affected device may exhibit the following:

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

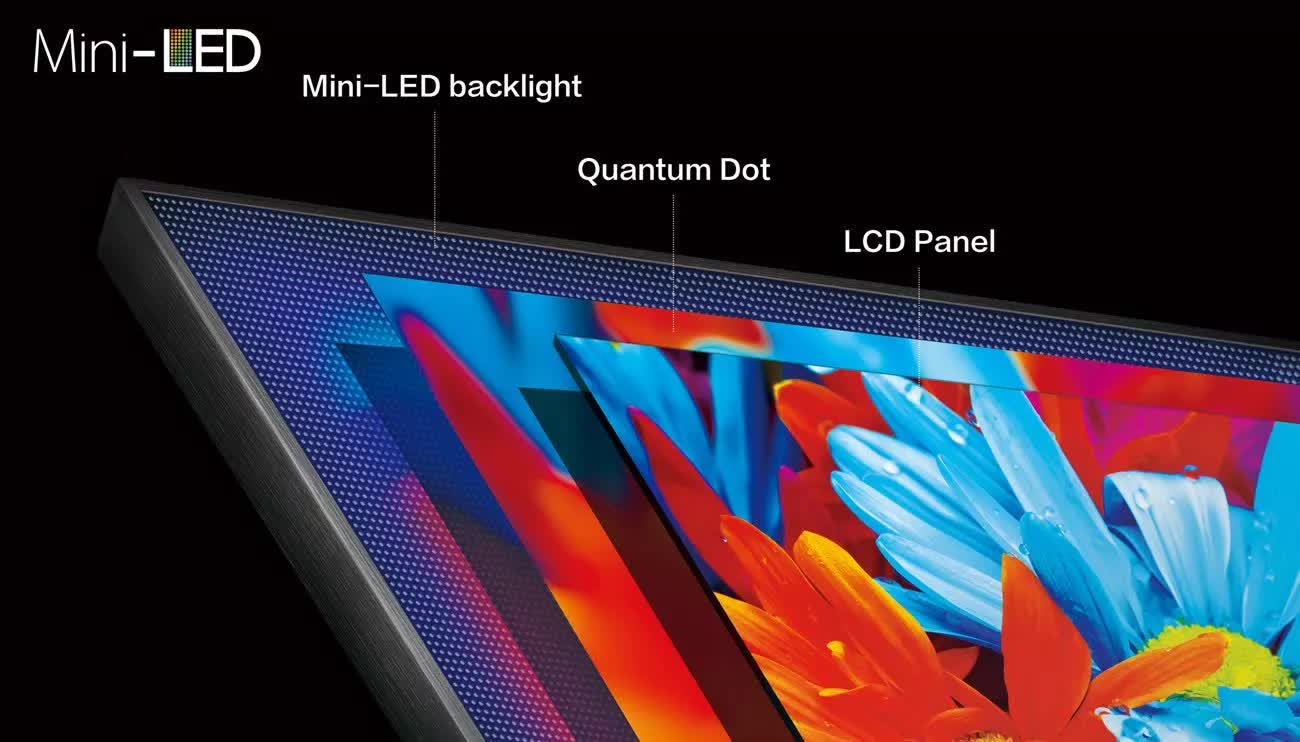

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating i

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey