can lcd displays be put on clothing factory

All these methods are age-old. Display your reports and dashboard on the LCD screen. This is an effective way to monitor shop floor production. Secondly production status will be visible to everyone who is working on the floor.

You also need data for the same. If you can provide these data on a digital display board, you don’t need to waste time in report making while you need.

You will say it is not possible to track the production of every minute. Checking hourly report or looking into it every half an hour is not possible.

With technology advancement it becomes possible. Now it becomes easier to display the production status of line real-time. Whatever reports you make in a spreadsheet can be displayed in the LCD screen. Just you need to take how many reports can be viewed in the LCD screen at a time.

You know the benefits of displaying real-time production and quality status to line supervisors and other staff members. I have mentioned it in another post – Use of display boards on sewing floor and its advantages.

If you have the technology to capture real-time production then, I suggest you add display board (digital) in the sewing floor. Our clients are using an LCD screen to display real-time data on the floor.

I have seen factories to use the LCD screen to display the production status of the sewing lines. Each sewing line has one display board at the end of the line. They display reports based on their need. See example on a few display boards.

This is a very simple one. They display line output quantity only. Other things like target production report are entered into the system. The balance quantity to be produced by the line in balance time and line efficiency at this moment is calculated by the system. See the following screen.

Efficiency data can be shown in speedometer or in digits. If you have multiple sewing line in one floor and you like to display data in one display board you can do that. See the screen no 2, the factory is displaying efficiency data for 3 lines.

Displaying the production quantity of critical operations of a line will help to see a balancing of the line. If there are pick and valley in the bar chart, you know that there is a balancing issue in the line. See graphs on screen 2.

You are checking stitched pieces at the end-of-line. You prepare quality reports on defects founds and frequency of defects. You do analysis stitching quality in the form of DHU (defects per 100 units) of checked pieces. If you don"t share quality performance of the line your reports have no use.

Like production reports, you can display other data and analysis on the LCD screen. One factory displays only operator hourly report on the screen. That helps them to monitor each and every sewing operator in the line. If anybody is producing below the target can be found easily.

You might ask how to make a report on the Excel sheet. And how to get real-time data if you don’t have real-time data tracking technology in your company.

Prepare report templates and punch data on an Excel sheet and make dashboard in a separate sheet. Then connect dashboard and reports to the LCD screen.

Consider displaying data on screens and place the screen on the shop floor. Make good reports using graph and charts. As data can"t be visible from a distance but a chart can be.

A new kind of fabric can turn into a working keyboard, light up like a display, or even help send texts all while being bent, folded, and even washed like any other piece of clothing.

Researchers from China"s Fudan University built the material to withstand all the abuse we put other articles of clothing through while still serving as a useful piece of tech, according to The Independent. The tech, assuming it takes off and weaves its way into our clothing, could make for some useful new wearable gadgets — or, at the very least, lead to some great new hypebeast-style shirts with changing, billboard-like displays.

Most attempts to develop electronic textiles result in an unsurprisingly-fragile piece of cloth, but this new fabric display still worked, mostly, even after 100 washing and drying cycles, according to research published last week in the journal Nature.

That"s an important step toward building electronic clothing that actually makes it out of the lab and onto people"s bodies — a leap that has often proved insurmountable to other electronic textiles that remained in the proof-of-concept stage.

It"s not all fun and games, either. In the paper, the authors suggest that using a speech-to-text display that shows a message on their shirt could help people communicate in a new language or even help people with physical or cognitive impairments express their needs.

And in a purely aesthetic sense, the tech might open up a whole new world of clothing design as artists integrate electronic displays into outfits — hopefully even causing a revival of those cool light-up sneakers I never got to wear as a kid.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The breakthrough has been made by researchers from the Holland’s Holst Centre, Belgium headquartered imec, and CMST, imec’s associated lab at Ghent University.

Wearable devices such as healthcare monitors and activity trackers are quite common, but to date they haven’t been integrated into clothing. Doing so will make wearable devices less obtrusive and more comfortable, encouraging people to use them more regularly and increase the quality of data collected. A key step towards realising wearable devices in clothing is creating displays that can be integrated into textiles to allow interaction with the wearer.

“Wearable devices allow people to monitor their fitness and health so they can live full and active lives for longer. But to maximise the benefits wearables can offer, they need to be able to provide feedback on what users are doing as well as measuring it. By combining imec’s patented stretch technology with our expertise in active-matrix backplanes and integrating electronics into fabrics, we’ve taken a giant step towards that possibility,” said Edsger Smits, senior research scientist at Holst Centre.

The display is said to be very thin and mechanically stretchable. A fine-grain version of meander interconnect technology was developed by the CMST lab at Ghent University and Holst Centre to link standard (rigid) LEDs into a flexible and stretchable display.

The LED displays are fabricated on a polyimide substrate and encapsulated in rubber, allowing the displays to be laminated in to textiles that can be washed. Furthermore, the technology uses fabrication steps that are known to the manufacturing industry.

Following an initial demonstration at the Society for Information Display’s Display Week in San Jose, USA earlier this year, Holst Centre presented the next generation of the display at the International Meeting on Information Display (IMID) in Daegu, Korea where smaller LEDs are now mounted on an amorphous indium-gallium-zinc oxide (a-IGZO) TFT backplane that employs a two-transistor and one capacitor (2T-1C) pixel engine to drive the LEDs. These second-generation displays are claimed to offer higher pitch and increased, average brightness. The presentation featured a 32x32 pixel demonstrator with a resolution of 13 pixels per inch (ppi) and average brightness above 200 candelas per square meter (cd/m2).

The world’s first stretchable and conformable thin-film transistor (TFT) driven LED display laminated into textiles developed by Holst Centre, imec and CSMT.

Researchers from Holst Centre (set up by TNO and imec), imec and CMST, imec"s associated lab at Ghent University, have demonstrated the world"s first stretchable and conformable thin-film transistor (TFT) driven LED display laminated into textiles. This paves the way to wearable displays in clothing providing users with feedback.

Wearable devices such as healthcare monitors and activity trackers are now a part of everyday life for many people. Today"s wearables are separate devices that users must remember to wear. The next step forward will be to integrate these devices into our clothing. Doing so will make wearable devices less obtrusive and more comfortable, encouraging people to use them more regularly and, hence, increasing the quality of data collected. A key step towards realizing wearable devices in clothing is creating displays that can be integrated into textiles to allow interaction with the wearer.

"Wearable devices allow people to monitor their fitness and health so they can live full and active lives for longer. But to maximize the benefits wearables can offer, they need to be able to provide feedback on what users are doing as well as measuring it. By combining imec"s patented stretch technology with our expertise in active-matrix backplanes and integrating electronics into fabrics, we"ve taken a giant step towards that possibility," says Edsger Smits, Senior research scientist at Holst Centre.

The conformable display is very thin and mechanically stretchable. A fine-grain version of the proven meander interconnect technology was developed by the CMST lab at Ghent University and Holst Centre to link standard (rigid) LEDs into a flexible and stretchable display. The LED displays are fabricated on a polyimide substrate and encapsulated in rubber, allowing the displays to be laminated in to textiles that can be washed. Importantly, the technology uses fabrication steps that are known to the manufacturing industry, enabling rapid industrialization.

Following an initial demonstration at the Society for Information Display"s Display Week in San Jose, USA earlier this year, Holst Centre has presented the next generation of the display at the International Meeting on Information Display (IMID) in Daegu, Korea, 18-21 August 2015. Smaller LEDs are now mounted on an amorphous indium-gallium-zinc oxide (a-IGZO) TFT backplane that employs a two-transistor and one capacitor (2T-1C) pixel engine to drive the LEDs. These second-generation displays offer higher pitch and increased, average brightness. The presentation will feature a 32x32 pixel demonstrator with a resolution of 13 pixels per inch (ppi) and average brightness above 200 candelas per square meter (cd/m2). Work is ongoing to further industrialize this technology.

With the promotion of the "Made in China 2025" strategic policy, the process of popularizing intelligent manufacturing in China has been gradually implemented. More and more intelligent manufacturing demonstration bases have been generated, which has also brought models to many domestic manufacturing enterprises. In the context of intelligent manufacturing, according to public data, the market scale of China"s intelligent hardware is expected to reach 1076.7 billion yuan in 2020. Relying on various basic technical support and application scenario expansion, intelligent hardware has become important product in industrial manufacturing consumption.

The introduction of intelligent hardware equipment in manufacturing and production, and the creation of a unique intelligent production system for enterprises, can increase the efficiency of workers by about 30%. Among them, as one of the major industries in manufacturing, the garment industry is gradually integrating "intelligence" into every link of enterprise order, supply chain, production, sales, and service, building a flexible supply chain, using the concept of supply-side structural reform and the means of intelligent manufacturing to realize the transformation and upgrading of China"s garment industry.

In clothing manufacturing, it has realized the expansion of application scenarios, such as intelligent typesetting, typesetting, and revision system, intelligent cutting system, intelligent sewing system, intelligent hanging system, intelligent ironing system, and intelligent distribution system. Among them, take the clothing hanging system as an example, it is a production unit or system developed on the basis of automatic equipment and computer technology projects such as numerical control machinery, robot, automatic warehouse, and automatic conveying.

Problems such as unclear production schedule of traditional garment manufacturing, unstable efficiency caused by unbalanced production line, long overtime time of workers, poor quality rate, unclear order production schedule, and difficulty to confirm production delivery date have been effectively solved in intelligent clothing manufacturing.

As an important core of intelligent clothing manufacturing, touch display equipment is widely used in cutting machine tools, fabric detection, production line boards, sewing workbench, and many other scenes. For example, in the production process of sewing workbench, the touch display equipment is installed, and the corresponding production information will be displayed on the flat panel display screen on the worker"s seat, to ensure that one person, one garment, one single flow, real-time information transmission, to ensure that the workers accurately define the product requirements and avoid the waste of raw materials.

In the transformation of the clothing manufacturing line, what are the requirements for touch display equipment users? Take an application case of Touch Think intelligence as an example, let"s take a look.

·In the transformation of the production line, the user chooses the Touch Think 10.1-inch 4th-GEN industrial Android all-in-one tablet PC, mostly in the use scenarios of the embedded cabinet, sewing workbench, etc.

·The thickness of the front panel is 10mm, round arc frame design offering a good touching experience for users. Ultra-thin ultra-narrow frame, small size with a large vision angle, beautiful and safe, not easy to scratch.

·All the hardware parts of the whole tablet PC are made by one-piece die casting, which has a strong sense of industrial science and technology. Fully meet the users" demand and offer perfect cost performance.

·Front panel is designed with industrial-grade IP65 dust-proof and water-proof, satisfy the indoor application, the built-in waterproof strip, which can meet the requirements of multiple dust use scenarios in a clothing manufacturing workshop.

·Capacitive touch screen mode is suitably used in such environments, ten-point touch technology with fast response, and optimizes the operation interface, easy to use.

·Default with Android 6.0 operating system, also supports other versions, and the SDK software development kit can be provided to meet the needs of users" APP and easy for connection of mobile terminals.

·The CPU configuration adopts Allwinner A64 Cortex-A53 quad-core 64-bit, main frequency is up to 1.5GHz, the mainboard is industrial grade quality and with good anti-vibration.

·All Touch Think industrial tablet PCs have past 48-hour aging test, they have stable performance and supports the automatic reset function, which can guarantee the production line to run without fault for 7 * 24h.

·Support a variety of installation methods, such as embedded, desktop, VESA 75, VESA 100, wall-mounted, and other types, to meet the needs of a variety of production line scenarios.

·It supports Ethernet / WiFi, 3G / 4G network connection, and has rich interface functions. DC port adopts an anti-falling design, which is more durable in the workshop environment.

Through the use of touch display equipment in each clothing manufacturing scene, the data of the whole production process from cutting machine to delivery can be grasped in real-time. At the same time, it can return to MES production management system and manage the real-time production progress, production balance, product quality, flow direction of semi-finished products, factory efficiency, worker efficiency, IE operation data, IE data analysis, etc. through data analysis, it not only shortens the auxiliary processing time of clothing manufacturing, greatly improves production efficiency, reduces the defective rate and raw material waste, but also reduces the area of semi-finished products, ensures the quality of products, and reap the dividends of intelligent clothing manufacturing.

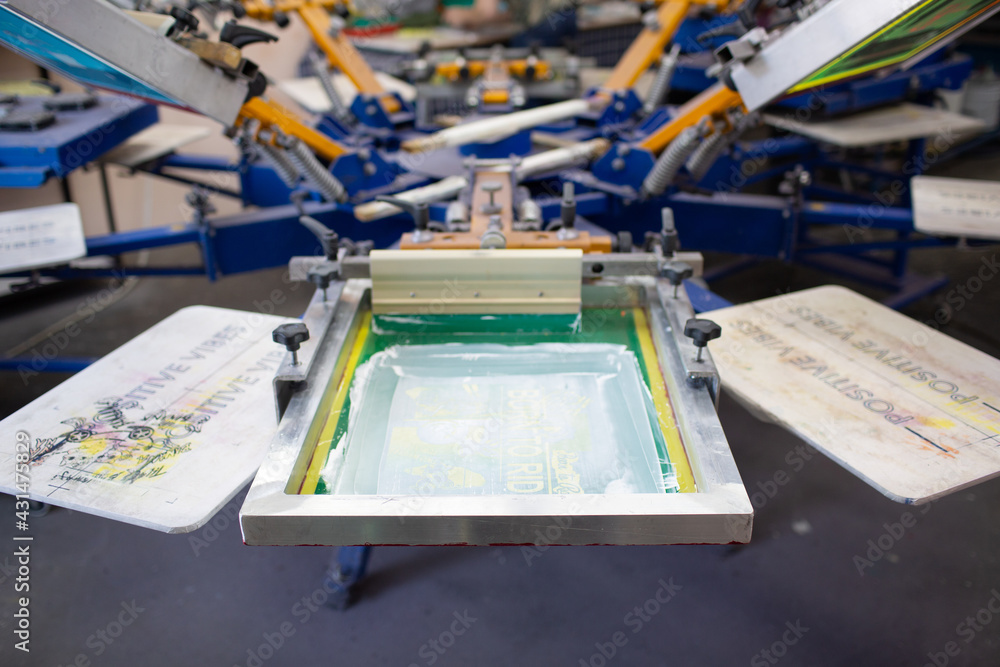

There are different methods of screen printing, but they all involve the same basic technique. The form of printing we"ll talk about below uses a special light-reactive emulsion to create a custom stencil; this tends to be the most popular type of commercial printing, as it can be used to make intricate stencils.

Here, we"ll talk you through the screen printing process step by step. We’ve also put together a video of the process taking place in our workshop, so you can see how we create our top-quality custom screen-printed clothing.

To start, the printer takes the design they want to create on the finished product, and prints it out onto a transparent acetate film. This will be used to create the stencil.

the printer will choose a mesh screen to suit the complexity of the design, and the texture of the fabric being printed. The mesh screen is then coated with a layer of light-reactive emulsion, which will harden when developed under bright light.

The acetate sheet featuring the design is then laid onto the emulsion-coated screen, and the whole thing is exposed to a very bright light. The light hardens the emulsion, so the parts of the screen which are covered by the design remain in liquid form.

If the final design is going to include more than one colour, then a separate screen must be used to apply each layer of ink. To create multi-coloured products, the printer must use his skill to design each stencil, and line them up perfectly to ensure the final design is seamless.

After the screen has been exposed for a set time, the areas of the screen not covered by the design will have turned hard. Any unhardened emulsion is then carefully rinsed away. This leaves a clear imprint of the design on the screen for the ink to pass through.

The screen is then dried, and the printer will make any necessary touch-ups or corrections to make the imprint as accurate as possible to the original design. The stencil is now ready to be used.

STEP 5: THE ITEM IS PREPARED FOR PRINT The screen is then placed on the printing press. The item or garment being printed is laid down flat onto the printing board, underneath the screen.

There are a number of different presses, including manual and automatic styles, but most modern commercial printers will use an automatic rotary carousel printer, as this allows several different screens to work at once. For multicoloured prints, this sort of printer can also be used to apply the separate colour layers in quick succession.

Step 6: The ink is pressed through the screen onto the item The screen is lowered down onto the printing board. Ink is added to the top end of the screen, and a squeegee is used to pull the ink along the full length of the screen. This presses the ink through the open areas of the stencil, imprinting the design on the product underneath.

If the printer is creating multiple items, then the screen is raised and a new garment is placed onto the printing board. The process is then repeated.

Once all the items have been printed and the stencil has served its purpose, the emulsion is removed using a special washing fluid so the mesh can be reused to create new stencils.

Step 7: The product is dried, checked and finished The printed product then passes through a dryer, which "cures" the ink and creates a smooth, colourfast finish. The final product will be checked and washed thoroughly to remove any residue, before being passed on to its new owner.

If you’re new here or recently joined a team where you’re responsible for sourcing shirts, hats or any type of apparel for your agency or organization, you’ve come to the right place. The team at the Embroidery Factory are considered the experts in the field of contract and wholesale embroidery and screen printing with over a 100 years of experience combined.

So are you wondering how to navigate this world? When to place an order for screen printed shirts vs. embroidery? We’re here to help. Below is a quick reference guide that may help but if you run into any questions or if we can help you with an upcoming order, don’t hesitate to give us a shout at orders@embroideritl.com. Prefer to speak to a human? We don’t blame you. Here’s our number, 570.654.7640.

What is screen printing?Screen printing is a printing technique where a mesh is used to transfer ink using a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One color is printed at a time, so several screens can be used to produce a multicoloured image or design.

What is wholesale screen printing?Since the 1960’s, sports teams and corporations across the United States have created partnerships with screen printers to brand their clothing, uniforms and in modern times, even masks. If you’re a franchisor and are looking to control your image throughout several hundred franchisees or are a pharmacy or hospital that has a standard uniform that you abide by, then screen printing is an affordable option to keep costs down while still managing brand standards at a corporate level.

What is contract screen printing?Contract screen printing is a term that’s often used in the agency world. In our world, this means that we work with a third party, Whether it’s an ad agency or a promotional firm to complete a project on the behalf of one of their clients. The majority of agencies in today’s society simply do not have the capability to produce large orders in-house so they use a third-party recourse to facilitate the client’s request. We’re the silent partner or factory who does the work but we never interact with the client themselves. In this instance, the agency contact is our client.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One colour is printed at a time, so several screens can be used to produce a multi-coloured image or design.

Traditionally, silk was used in the process. Currently, synthetic threads are commonly used in the screen printing process. The most popular mesh in general use is made of polyester. There are special-use mesh materials of nylon and stainless steel available to the screen-printer. There are also different types of mesh size which will determine the outcome and look of the finished design on the material.

The technique is used not only for garment printing but for printing on many other substances, including decals, clock and watch faces, balloons, and many other products. Advanced uses include laying down conductors and resistors in multi-layer circuits using thin ceramic layers as the substrate.

The poster shop at Heart Mountain War Relocation Center was operated by Japanese-American internees who used the silkscreen method to print information for the entire center (January 1943)

Early in the 1910s, several printers experimenting with photo-reactive chemicals used the well-known actinic light–activated cross linking or hardening traits of potassium, sodium or ammonium chromate and dichromate chemicals with glues and gelatin compounds. Roy Beck, Charles Peter and Edward Owens studied and experimented with chromic acid salt sensitized emulsions for photo-reactive stencils. This trio of developers would prove to revolutionize the commercial screen printing industry by introducing photo-imaged stencils to the industry, though the acceptance of this method would take many years. Commercial screen printing now uses sensitizers far safer and less toxic than bichromates. Currently,

A group of artists who later formed the National Serigraph Society, including WPA artists Max Arthur Cohn, Anthony Velonis and Hyman Warsager, coined the word "serigraphy" in the 1930s to differentiate the artistic application of screen printing from the industrial use of the process.

Historians of the New York WPA poster shop give sole credit to Anthony Velonis for establishing Silkscreen methods used there, a reputation bolstered by the publication of his 1937 booklet Technical Problems of the Artist: Technique of the Silkscreen Process. Guido Lengweiler has corrected this misunderstanding in his book, A History of Screen Printing, published in English in 2016. Outgrowths of these WPA poster shops, at least two New York City studios in wartime started decorating ceramic tiles with fire-on underglaze applied by silkscreen starting as early as 1939: Esteban Soriano and Harold Ambellan"s Designed Tiles.

The Printers" National Environmental Assistance Center says, "Screenprinting is arguably the most versatile of all printing processes. Since rudimentary screenprinting materials are so affordable and readily available, it has been used frequently in underground settings and subcultures, and the non-professional look of such DIY culture screenprints have become a significant cultural aesthetic seen on movie posters, record album covers, flyers, shirts, commercial fonts in advertising, in artwork and elsewhere.

Credit is given to the artist Andy Warhol for popularising screen printing as an artistic technique. Warhol"s silk screens include his 1962 Marilyn Diptych, which is a portrait of the actress Marilyn Monroe printed in bold colours. Warhol was supported in his production by master screen printer Michel Caza, a founding member of Fespa.

Sister Mary Corita Kent gained international fame for her vibrant serigraphs during the 1960s and 1970s. Her works were rainbow coloured, contained words that were both political, and fostered peace and love and caring.

American entrepreneur, artist and inventor Michael Vasilantone started to use, develop, and sell a rotatable multicolour garment screen printing machine in 1960. Vasilantone later filed for a patentbowling garments, but was soon directed to the new fad of printing on T-shirts. The Vasilantone patent was licensed by multiple manufacturers and the resulting production and boom in printed T-shirts made this garment screen printing machine popular. Screen printing on garments currently

Graphic screen-printing is widely used today to create mass- or large-batch produced graphics, such as posters or display stands. Full colour prints can be created by printing in CMYK (cyan, magenta, yellow and black).

Screen printing lends itself well to printing on canvas. Andy Warhol, Arthur Okamura, Robert Rauschenberg, Roy Lichtenstein, Harry Gottlieb and many other artists have used screen printing as an expression of creativity and artistic vision.

Another variation, digital hybrid screen printing, is a union between analog screen printing and traditional digital direct-to-garment printing, two of the most common textile embellishment technologies in use today. Essentially, digital hybrid screen printing is an automatic screen-printing press with a CMYK digital enhancement located on one of the screen print stations. Digital hybrid screen printing is capable of variable data options, creating endless customizations, with the added ability of screen print specific techniques.

Screen printers use a silkscreen, a squeegee, and hinge clamps to screen print their designs. The ink is forced through the mesh using the rubber squeegee, the hinge clamps keep the screen in place for easy registration

A screen is made of a piece of mesh stretched over a frame. The mesh could be made of a synthetic polymer, such as nylon, and a finer and smaller aperture for the mesh would be utilized for a design that requires a higher and more delicate degree of detail. For the mesh to be effective, it must be mounted on a frame and it must be under tension. The frame which holds the mesh could be made of diverse materials, such as wood or aluminum, depending on the sophistication of the machine or the artisan procedure. The tension of the mesh may be checked by using a tensiometer; a common unit for the measurement of the tension of the mesh is Newton per centimeter (N/cm).

A stencil is formed by blocking off parts of the screen in the negative image of the design to be printed; that is, the open spaces are where the ink will appear on the substrate.

Before printing occurs, the frame and screen must undergo the pre-press process, in which an emulsion is "scooped" across the mesh. Once this emulsion has dried, it is selectively exposed to ultra-violet light, through a film printed with the required design. This hardens the emulsion in the exposed areas but leaves the unexposed parts soft. They are then washed away using a water spray, leaving behind a clean area in the mesh with the identical shape as the desired image, which will allow passage of ink. It is a positive process.

In fabric printing, the surface supporting the fabric to be printed (commonly referred to as a pallet) is coated with a wide "pallet tape". This serves to protect the "pallet" from any unwanted ink leaking through the screen and potentially staining the "pallet" or transferring unwanted ink onto the next substrate.

Next, the screen and frame are lined with a tape to prevent ink from reaching the edge of the screen and the frame. The type of tape used in for this purpose often depends upon the ink that is to be printed onto the substrate. More aggressive tapes are generally used for UV and water-based inks due to the inks" lower viscosities and greater tendency to creep underneath tape.

The last process in the "pre-press" is blocking out any unwanted "pin-holes" in the emulsion. If these holes are left in the emulsion, the ink will continue through and leave unwanted marks. To block out these holes, materials such as tapes, speciality emulsions and "block-out pens" may be used effectively.

The screen is placed atop a substrate. Ink is placed on top of the screen, and a floodbar is used to push the ink through the holes in the mesh. The operator begins with the fill bar at the rear of the screen and behind a reservoir of ink. The operator lifts the screen to prevent contact with the substrate and then using a slight amount of downward force pulls the fill bar to the front of the screen. This effectively fills the mesh openings with ink and moves the ink reservoir to the front of the screen. The operator then uses a squeegee (rubber blade) to move the mesh down to the substrate and pushes the squeegee to the rear of the screen. The ink that is in the mesh opening is pumped or squeezed by capillary action to the substrate in a controlled and prescribed amount, i.e. the wet ink deposit is proportional to the thickness of the mesh and or stencil. As the squeegee moves toward the rear of the screen the tension of the mesh pulls the mesh up away from the substrate (called snap-off) leaving the ink upon the substrate surface.

Textile items printed with multi-coloured designs often use a wet on wet technique, or colours dried while on the press, while graphic items are allowed to dry between colours that are then printed with another screen and often in a different colour after the product is re-aligned on the press.

Most screens are ready for re-coating at this stage, but sometimes screens will have to undergo a further step in the reclaiming process called dehazing. This additional step removes haze or "ghost images" left behind in the screen once the emulsion has been removed. Ghost images tend to faintly outline the open areas of previous stencils, hence the name. They are the result of ink residue trapped in the mesh, often in the knuckles of the mesh (the points where threads cross).

The original image is created on a transparent overlay, and the image may be drawn or painted directly on the overlay, photocopied, or printed with a computer printer, but making so that the areas to be inked are not transparent. Any material that blocks ultra violet light can be used as the film, even card stock. A black-and-white positive may also be used (projected onto the screen). However, unlike traditional plate-making, these screens are normally exposed by using film positives.

A screen must then be selected. There are several different mesh counts that can be used depending on the detail of the design being printed. Once a screen is selected, the screen must be coated with a photosensitive emulsion and dried. Once dry, it is then possible to burn/expose the print.

The screen is washed off thoroughly. The areas of emulsion that were not exposed to light dissolve and wash away, leaving a negative stencil of the image on the mesh.

A caviar bead is a glue that is printed in the shape of the design, to which small plastic beads are then applied – works well with solid block areas creating an interesting tactile surface.

Discharge inks use zinc formaldehyde sulfoxylate (the zinc analogue of Rongalite) to remove, or discharge, the dye back off the fabric. Cons of using discharge inks are that the process only works properly on dark fabrics that have a content of 100% cotton. Fabrics with under-dyes and fabric blends will discharge their dye to different degrees. The fumes resulting from the application and curing are pungent and strong ventilation and a face mask are commonly needed to relieve exposure. Pros to this process is that discharge is especially effective for distressed prints and under-basing on dark garments that are to be printed with additional layers of plastisol. It adds variety to the design and gives it that natural soft feel.

Expanding ink, or puff, is an additive to plastisol inks which raises the print off the garment, creating a 3D feel and look to the design. Mostly used when printing on apparel.

Foil is much like flock, starting with an adhesive glue or plastisol ink base layer. Foil is finished by applying a thin sheet of reflective/mirror like material on top of the screened base, then heat pressed to set. The foil substrate does not adhere to non-screened areas of the design, and the balance of the foil sheet is discarded.

Four-colour process is when the artwork is created and then separated into four colours (CMYK) which combine to create the full spectrum of colours needed for photographic prints. This means a large number of colours can be simulated using only 4 screens, reducing costs, time, and set-up. This processes utilises halftones. The inks are required to blend and are more translucent, meaning a compromise with vibrancy of colour.

Glitter or shimmer ink is when metallic flakes become an additive in the ink base to create this sparkle effect. Usually available in gold or silver but can be mixed to make most colours.

Metallic ink is similar to glitter, but smaller particles suspended in the ink. A glue is printed onto the fabric, then nano-scale fibers applied on it. This is often purchased already made.

Plastisol is the most common ink used in commercial garment decoration. Good colour opacity onto dark garments and clear graphic detail with, as the name suggests, a more plasticized texture. This print can be made softer with special additives or heavier by adding extra layers of ink. Plastisol inks require heat (approx. 150 °C (300 °F) for many inks) to cure the print, except in the case of low cure inks.

PVC and phthalate free is relatively new breed of ink and printing with the benefits of plastisol but without the two main toxic components. It also has a soft texture and is being produced by most major suppliers.

Suede ink is a milky coloured additive that is added to plastisol. With suede additive you can make any colour of plastisol have a suede feel. It is actually a puff blowing agent that does not bubble as much as regular puff ink. The directions vary from manufacturer to manufacturer, but generally up to 50% suede can be added to normal plastisol.

these penetrate the fabric more than the plastisol inks and create a much softer feel. Ideal for printing darker inks onto lighter coloured garments. Also useful for larger area prints where texture is important. Some inks require heat or an added catalyst to make the print permanent.

As opposed to a thicker "Plastisol Alternative" this (ink) arrives as a concentrate which is mixed into a printing paste (thickener) to allow Screen Printing, this process is best used on light garments and as the dye is in the fibers themselves is often used for dish cloths, napkins and the like. This is similar to traditional textile printing.

High density is a process which uses a type of varnish against a lower mesh count with many coats of emulsion or a thicker grade of emulsion (e.g., Capillex). After the varnish passes through to the substrate, an embossed-appearing, "raised" area of varnish is created. When cured at the end of the process, the varnish yields a Braille effect, hence the term "high density".

Screen printing is more versatile than traditional printing techniques. The surface does not have to be printed under pressure, unlike etching or lithography, and it does not have to be planar. Different inks can be used to work with a variety of materials, such as textiles, ceramics,

In screen printing on wafer-based solar photovoltaic (PV) cells, the mesh and buses of silver are printed on the front; furthermore, the buses of silver are printed on the back. Subsequently, aluminum paste is dispensed over the whole surface of the back for passivation and surface reflection. One of the parameters that can vary and can be controlled in screen printing is the thickness of the print. This makes it useful for some of the techniques of printing solar cells, electronics etc.

Solar wafers are becoming thinner and larger, so careful printing is required to maintain a lower breakage rate, though high throughput at the printing stage improves the throughput of the whole cell production line.

To print multiple copies of the screen design on garments in an efficient manner, amateur and professional printers usually use a screen printing press, which is a colloquial term as most screen printing machines are vastly different from Offset Printing Presses. Many companies offer simple to sophisticated printing presses. These presses come in one of three types, Manual (also referred to as Handbench), Semi-Automatic, and Fully Automatic. Most printing companies will use one or more semi-automatic or fully automatic machines with manual machines for small runs and sampling.

Whilst Manual Screen Printing can be done with Carousels, Handbenches (both of which are often referred to colloquially as presses) or even on to tables. Semi and Fully-Automatic machines are broken into two main categories; Flatbed Printers

These machines are much faster and use either pneumatic pressure generated by air compressors or use electric motors to draw the squeegees, rotate and raise or lower pallets removing much of the manual labour from the task - resulting in significant reductions in operator fatigue as well as more consistent results.

In electronic design automation, the silk screen is part of the layer stack of the printed circuit board (PCB), and the top and bottom sides are described in individual Gerber files like any other layers (such as the copper and solder-stop layers).service print overlays include tSilk/bSilk aka PLC/PLSTSK/BSK (EAGLE), F.SilkS/B.SilkS (KiCad), PosiTop/PosiBot (TARGET), silkTop/silkBottom (Fritzing), SST/SSB (OrCAD), ST.PHO/SB.PHO (PADS), SEVS/SERS (WEdirekt)GTO/GBO (Gerber and many others

The letters "C" and "S" in EAGLE"s old Gerber filename extensions .PLC/.PLS for the top and bottom silk screens have their origin in times when printed circuit boards were typically equipped with components populated on one side of the board only, the so called "component side" (top) versus the opposite "solder side" (bottom) where these components were soldered (at least in the case of through-hole components). Each silk screen layer is often a combination of the corresponding Place and Names layers (and the Dimension layer), thus the "PL" in the filename extension.

"History"s Influence on Screen Printing"s Future | ScreenWeb". screenweb.com. 2006-05-04. Archived from the original on 2013-01-21. Retrieved 2012-11-15.

Pop impressions: Europe/USA (PDF). New York, N.Y.: The Museum of Modern Art, Department of Prints and Illustrated Books. 1999. pp. 1–2. Archived (PDF) from the original on 2022-10-09.

Kiddell, Peter (2015-06-26). "Understanding ceramic and glass decorating - Techniques". FESPA. Archived from the original on 2015-07-07. Retrieved 2015-07-01.

"Preparing the Manufacturing Data: Gerber Files for Photoplotters with Variable Aperture Wheels". EAGLE - Easily Applicable Graphics Layout Editor - Manual - Version 3.55 and later (PDF) (2 ed.). Delray Beach, Florida, USA: CadSoft Computer, Inc. 1999. p. 88–90 [89]. Archived (PDF) from the original on 2022-08-30. Retrieved 2022-08-30.

"Gerber Output Options" (PDF). 1.3. Altium Limited. 2011-07-27 [2008-03-26, 2005-12-05]. Archived (PDF) from the original on 2022-08-29. Retrieved 2022-08-29.

Biegeleisen, Jacob I. Biegeleisen (1972). Screen Printing: A Contemporary Guide to the Technique of Screen Printing for Artists, Designers, and Craftsmen. New York: Watson-Guptill Publications. ISBN 0823046656.

Chieffo, Clifford T. (1979). Silk-Screen as a Fine Art : A Handbook of Contemporary Silk-Screen Printing. New York: Van Nostrand Reinhold. ISBN 0442215614.

Cut and Sew Sublimation Printing Cut and sew sublimation is a high-fashion garment printing process, yielding beautiful full-color designs — and the only limitation is your budget. Cut and sew sublimation printing is done on unassembled pieces of fabric. Cut and sew sublimation avoids many of the limitations (creasing, blurring) of blank apparel sublimation. Cut and sew sublimation has a longer turn-around time. Blank Garment Sublimation Printing Blank apparel sublimation is an economic garment printing […]

Stylus Apparel offers both contract screen printing services and commercial screen printing services. When printing garments, screen printing should be your first choice and consideration. Not only does screen printing allow for the creation of high quality custom apparel, it also produces durable, wearable results. Stylus’s screen printed garments will last through many washes — as long as the garment itself lasts! We offer a large number of blank stock garments and accessories, along with […]

Custom woven clothing labels are a great finishing choice, especially for clothing lines and especially for completely customized Cut and Sew pieces. A woven fabric label created specifically for a piece of clothing or a brand helps show the quality and detail of the piece — as well as the dedication of the piece’s designers and manufacturers. Woven clothing labels simply give a professional quality to any custom-made apparel. If you’re a clothing line, including […]

Stylus Apparel offers both contract embroidery services and commercial embroidery services. We create custom embroidered hats and caps, polo shirts, t-shirts, and much more — all embroidered with your custom design or logo! Our embroidery services are among the best in the custom garment and apparel industry. We are well known for Tackle Twill and Applique, 3D Puff Embroidery, Embroidered Patches, and distress services. Stylus Apparel’s Embroidery Services Embroidery is most often used on caps, hats, […]

Stylus Apparel is a leader in contract cut and sew garment manufacturing services. Stylus offers apparel development, sampling, and production services for your clothing line or label, providing creative design and development from concept to production to distribution. With more than 30 years of experience in cut and sew garment manufacturing, Stylus Apparel is absolutely committed to creating quality cut and sew apparel. Our state-of-the-art cut and sew contracting facility has the capacity for large […]

Since 2003, Stylus Apparel has provided factory direct apparel solutions to a number of distinguished clientele. We work with clothing lines and brands — both the young start-up brand and the well-established private label. We are contract garment manufacturers with the ability to create a large number of garments on demand. We work with corporate customers to deliver the highest quality apparel merchandise and employee workwear. We offer our customers apparel customization services from design to distribution, keeping every step in between under one roof and in one place.

Some parts of our website are accessible only via registering for Stylus Apparel. We cordially invite you to register to view all parts of our website: you will be able to request garment manufacturing quotes or contact us.

Costing: To provide proper costing a finished sample is required from the brand which allows us to determine fabric costs, construction details and embellishments (e.g. embroidery/screen print/sublimation and tag labels, etc.).

Production: Once a pre production samples are approved production can begin. Production lead times differ based on the complexity of the order and will be provided on a case by case basis.

LMI offers screen printing which is the process of plastisol inks through a screen. We screen print onto apparel such as t-shirts, sweatshirts, shorts, jackets, and caps containing cotton, polyester or cotton/polyester blended fabric.

Screen printed inks are often used for most printing found in large retail stores and offer the look, feel and durability you expect. Screen printing can be single or multi-color. We also offer metallic colors and foil prints. Choose from ink formulas, standard or glitter. Send us your designs or we have in-house designers that can put your idea to reality.

We specialize in Direct-to-Garment or custom digital T-shirt printing to allow you to easily personalize your apparel with a design that’s uniquely your own. Direct-to-Garment Printing uses a high-tech inkjet printer to print digital designs and images directly onto a garment. The result? A full-color, high-resolution design that lasts longer.

LMI offers High quality custom embroidery using state of the art embroidery machines. We have a variety of colors to choose from. We stock a large selection of thread colors and we also match pantone colors. We will take your logo or artwork and program it into an embroidery computer file, using the latest software. LMI will digitize your files as needed.

During sublimation the ink becomes a gas, absorbing into the fibers, becoming part of the fabric. This is totally different from screen printing, where the ink is deposited on the surface of the fabric, suffocating the technical fabric’s characteristic ability to breath. Sublimation, on the other hand, allows the garment to maintain its technical characteristics, continuing to breath and wick moisture away from the body. The fabric, which absorbs the dye completely, remains soft. Your design is permanently infused into the fiber of the fabric and does not crack, peel, or wear off.

Once you’ve done your research and narrowed the selection down to 3-4 fashion factories, it’s time to start asking questions. The point of this is to gain as much information about each factory and their set-ups as you can, so approach this as if you were interviewing a potential partner for your company.

Your relationship with your manufacturer is one of the most important relationships your company will have. As such, they need to be responsible, trustworthy and reliable. They will need to produce a well-made product, that’s also competitively priced and delivered when you require it.

Your approach should be friendly with an attitude that says “I am a brilliant company and I’d love to work with you.” Flatter them. However, try not to get too excited until you’ve asked some pertinent questions.

The initial contact with any potential factories should be to determine what kind of manufacturing they do and whether they’re a good fit for your particular needs.

This is an important question to ask, even if you think you know. It is worth reaffirming and letting them describe in their own words what they are best suited for and proud to make.

Often factories will try to give a very broad answer, and your mission will be to narrow this as much as possible. The fear of losing potential business makes many a factory think of themselves as a “Jack of All Trades.” But we all know the old adage: A Jack of all trades is master of none. Make sure you have a good understanding of the main focus of their work.

Ask alternative questions that will identify what their “forte” is. Ask them perhaps to single out things that they do NOT do too. Ideally, you want to know what is it that they are best at manufacturing and people know and recommend them for.

One of your first questions to a potential business partner is whether they’re taking on new customers. Sometimes “No” means that they’re too busy at this particular time, but they may be open to a future relationship.

Some garment factories offer pattern cutting and grading services. Others also offer to make your Spec Packs (also referred to as a Tech Pack). In addition to this, they may also produce samples, source fabrics, and trims as well as packaging.

As a smaller company, it often makes sense to source these things through the manufacturer, as they should be in contact with suppliers and may have better buying power. These price reductions should be passed on to you, meaning you’ll get better prices.

Before you move to production – be it for an existing product or an initial idea – most brands will have to sample the product in order to approve the make and agree on the price.

The process of sample development and sampling is a laborious one, and costly! Most factories will tell you that the time and effort they spend on sampling is rarely realised and properly expensed. Often, especially with smaller brands and startups, samples either don’t make it to production at all or the orders are small and don’t fully justify the effort and time spent on sample development.

As a result, most factories charge extra for the samples. Some charge a one-off development fee, others charge double the production cost of the product and more and more factories are starting to charge both – a one-off fee and double production cost.

Be clear on how they work, how they charge, how long they take to turn around samples, how they deal with revisions and reiterations of a sample before you start.

You’re basically asking them what is the minimum amount of product they will produce for you in a single order. This doesn’t just relate to the number of pieces, however, as you need to ascertain whether this is per style, size, and/or colour.

In light of the poor conditions and use of child labour in some fashion factories, it’s important to check whether the factory is fully compliant. Ask to see a client list as this will give you an idea of the type of clients the factory is employed by.

Does the factory comply with the following:Compliance with laws: Factory must be compliant with local laws. Ask for a copy of their No Objection Certificates (NOC) provided by the Labour Department, Fire Department and other necessary certificates from various Government offices.

While this is important to ask, bear in mind that smaller factories do not have audits and certain regulations in place. Mostly because these cost money and they cannot afford them. Asking questions that will give you an idea of how they operate or better still – visiting the factory in person is the best way to know who you are or will be working with.

Enquire about the technology level of the prospective supplier by asking about their machines. If your garments or products require any special treatments such as washing or dying or specialist sewing machines. do they have washing machines or dyeing facilities? Perhaps embroidery or printing has to be added to your products after stitching, so inquire about the relevant machines needed for those specifications.

A good designer or growing brand will also think ahead in anticipation of receiving larger orders in the not too distant future. Will the factory be able to scale up from 400 pieces to 4,000 if your order book warrants it?

It is important to think ahead. And even if the factory you’re talking to is small, finding out what their plans and ambitions are is important. Many brands started working with small factories and together they grew and became large and successful businesses in their own rights.

Some factories may be reluctant to tell you who they currently work with, but they should still be able to provide you with a few names that you can call for references. If they refuse to divulge any information of this kind, then it is probably better that you move on and look for alternatives.

When working with new clients, most fashion factories would ask for full payment in advance at the time of placing the order, others will ask for 50/50 – in other words, half paid upon placing the order and the remaining half paid prior to shipment. Usually, these harder payment terms are in place for new clients only and get relaxed as time passes and more orders follow.

Always ask how the factory works with first-time clients and then when repeat orders are placed. Do try to negotiate at this point, but be respectful if they are unwilling to compromise. Usually, their rules are in place for a reason.

It should be important to you that the fashion factories you work with have some quality control systems in place. Ask to see some items that they have made in the first instance. Secondly, enquire whether they have employees or external resources to check the product at key stages in its production.

Again, be mindful of the fact that many small to medium size fashion factories do not have any formal procedures in place but they should be willing to work to your guidelines and encourage you to clearly define what your acceptance criteria are and will work towards meeting it.

In conclusion, there are many more questions you could ask fashion factories, but these are the most important ones. The first time you work with a factory will be the most challenging. If your relationship develops and you understand each other’s methods, then things will get easier over time.

Try to foster a friendly but professional relationship with the factory, as if things go well and your business progresses you will find yourself spending a lot of time there.

And a final word of advice: After any conversations conducted by telephone, make sure you document the details of the call in an email and send it to all parties involved. People forget what they say when they want to work with someone (this goes for both parties) or change their minds – and either scenario can have disastrous implications later on.

If you are not sure if the factory you are working with is the right one for you and your product, then this article will help you: find the right manufacturer for your product.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey