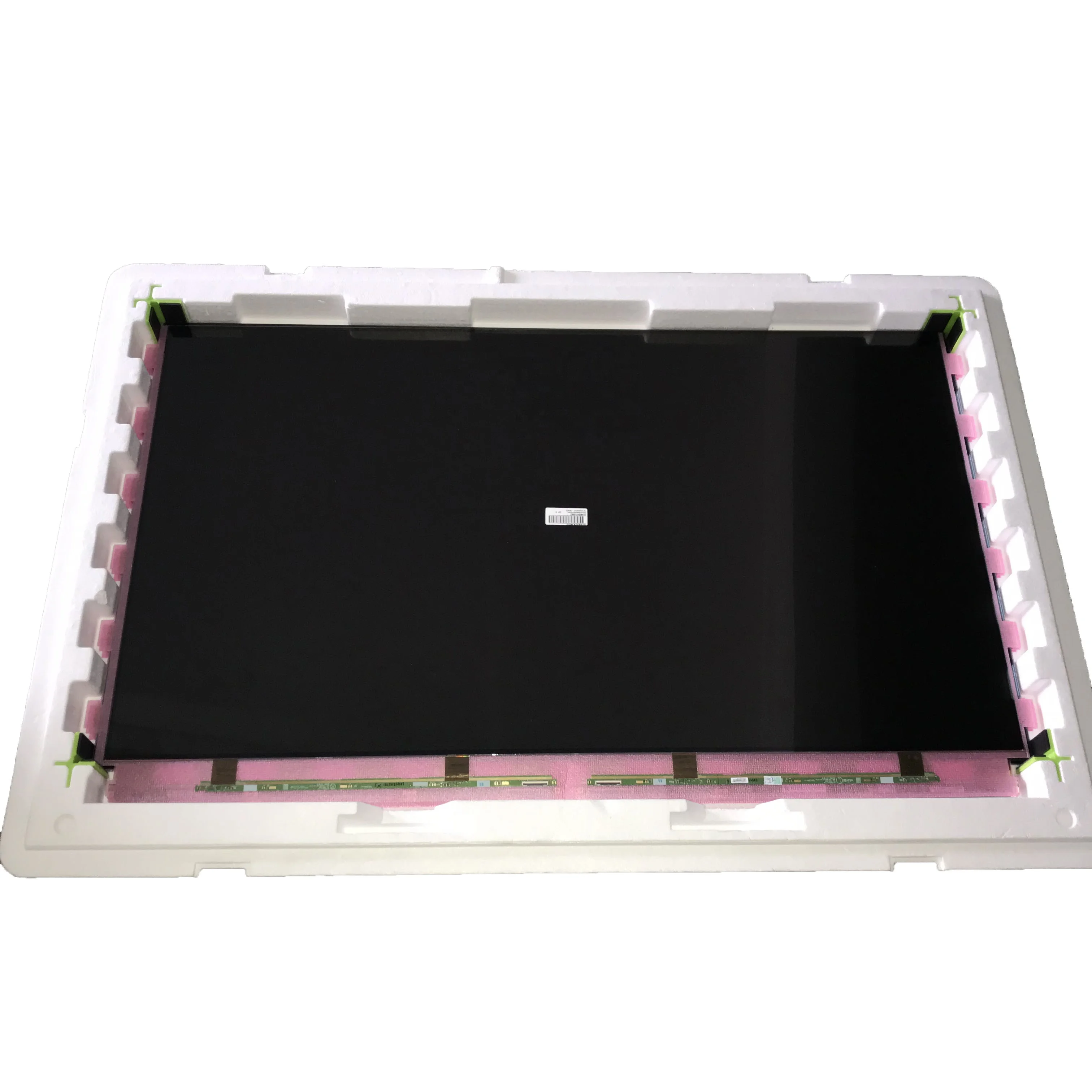

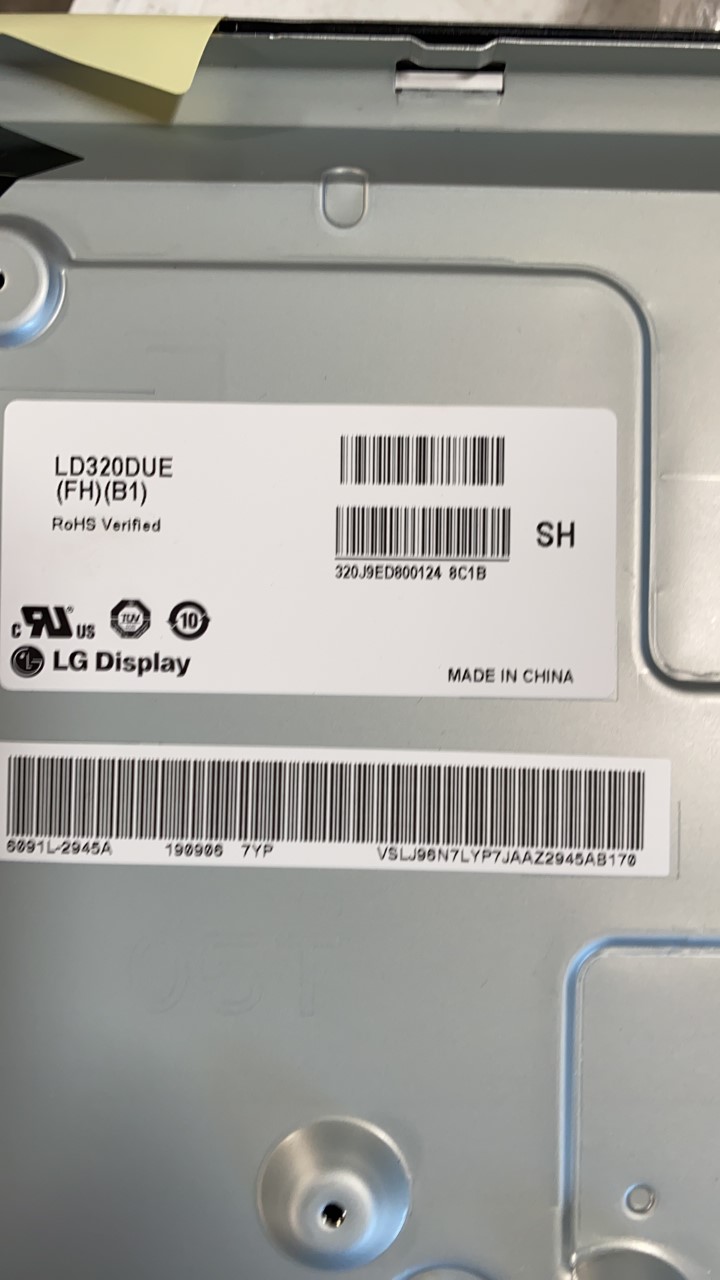

lg lcd panel made in china

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAscensionAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia-HercegovinaBotswanaBrazilBritish Indian Ocean TerritoryBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Dem Rep ofCook IslandsCosta RicaCroatiaCubaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEast TimorEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IsHondurasHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory CoastJamaicaJapan 曰本JordanKazakhstanKenyaKirgizstanKiribatiKosovoKuwaitLaosLatviaLebanonLeeward IslesLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedonia, FYRMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Fed States ofMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinePanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaST MartinSaint HelenaSaint Kitts and NevisSaint LuciaSaint Vincent and GrenadinesSamoaSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth GeorgiaSpainSri LankaSudanSurinameSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUS Minor Outlying IsUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayUzbekistanVanuatuVenezuelaVietnamVirgin Islands, BritishVirgin Islands, USWallis and FutunaYemenZambiaZimbabwe

LG Display and Samsung Display are struggling to find their ways out of the deterioration of their performance even after withdrawing from production of liquid crystal display (LCD) panels. The high-priced organic light emitting diode (OLED) panel sector regarded as a future growth engine is not growing fast due to the economic downturn. Even in the OLED panel sector, Chinese display makers are within striking distance of Korean display makers, experts say.

On Aug. 30, Display Supply Chain Consultants (DSCC), a market research company, predicted that LCD TV panel prices hit an all-time low in August and that an L-shaped recession will continue in the fourth quarter. According to DSCC, the average price of a 65-inch ultra-high-definition (UHD) panel in August was only US$109, a 62 percent drop from the highest price of US$288 recorded in July in 2021. The average price of a 75-inch UHD panel was only US$218, which was only about half of the highest price of US$410 in July last year. DSCC predicted that the average panel price in the third quarter will fall by 15.7 percent. As Chinese companies’ price war and the effect of stagnation in consumption overlapped, the more LCD panels display makers produce, the more loss they suffer.

As panel prices fell, manufacturers responded by lowering facility utilization rates. DSCC said that the LCD factory utilization rate descended from 87 percent in April to 83 percent in May, 73 percent in June, and 70 percent in July.

Now that the LCD panel business has become no longer lucrative, Korean display makers have shut down their LCD business or shrunk their sizes. In the LCD sector, China has outpaced Korea since 2018. China’s LCD market share reached 50.9 percent in 2021, while that of Korea dropped to 14.4 percent, lower than Taiwan’s 31.6 percent.

Samsung Display already announced its withdrawal from the LCD business in June. Only 10 years have passed since the company was spun off from Samsung Electronics in 2012. LG Display has decided to halt domestic LCD TV panel production until 2023 and reorganize its business structure centering on OLED panels. Its Chinese LCD production line will be gradually converted to produce LCD panels for IT or commercial products. TrendForce predicted that LG Display will stop operating its P7 Plant in the first quarter of next year.

Korean display makers’ waning LCD business led to a situation in which Korea even lost first place in the display industry. Korea with a display market share of 33.2 percent was already overtaken by China with 41.5 percent) in 2021 according to market researcher Omdia and the Korea Display Industry Association. Korea’s market share has never rebounded in for five years since 2017 amid the Korean government’s neglect. Seventeen years have passed since 2004 when Korea overtook Japan to rise to the top of the world in the LCD industry. Korea’s LCD exports amounted to more than US$30 billion in 2014, but fell to US$21.4 billion last year.

A bigger problem is that Korean display makers may lose its leadership in the OLED panel sector although it is still standing at the top spot. While Korea’s OLED market share fell from 98.1 percent in 2016 to 82.8 percent last year, that of China rose from 1.1 percent to 16.6 percent. Considering that the high-end TV market is highly likely to shrink for the time being due to a full-fledged global consumption contraction, some analysts say that the technology gap between Korea and China can be sharply narrowed through this looming TV market slump. According to industry sources, the Chinese government is now focusing on giving subsidies to the development of OLED panel technology rather LCD technology. On the other hand, in Korea, displays were also wiped out from national strategic technology industry items under the Restriction of Special Taxation Act which can receive tax benefits for R&D activities on displays.

Seoul, Korea (Sept. 1, 2014) – LG Display, the world’s leading innovator of display technologies, announced today that it held an opening ceremony of its first overseas LCD panel fabrication plant in Guangzhou, China, expanding its presence by adding to its existing module assembly plant in the city.

With plans to mass produce 40-plus-inch large-size LCD panels for TVs in the 8.5th generation plant, LG Display will further enhance its competitiveness in China, the world’s largest LCD TV market, thereby strengthening its leading position in the global market.

The new 8.5th generation (2,200mm x 2,500mm) LCD panel plant will be operated by LG Display China (LG Display China Co., Ltd, LGDCA), a joint venture between LG Display, the Guangzhou Development District (GDD), and Skyworth, one of the leading Chinese TV manufacturers and strategic partner to LG Display. LG Display contributed 70 percent of the $4 billion investment in the plant on the 330,000㎡ site, while GDD and Skyworth contributed 20 percent and 10 percent, respectively.

“By operating our first overseas LCD panel plant in China which has now became the world’s biggest TV market, we are going to further strengthen our position in the country,” said Dr. Sang Beom Han, CEO and President of LG Display, at the ceremony attended by top executives from LG group, representatives of major Chinese TV manufacturers and government officials from China and Korea. “Based on our success in China, LG Display will continue to lead the global display market,” he added.

The LG Display China facility will mainly focus on producing 42-inch, 49-inch and 55-inch Ultra HD and Full HD panels, aiming to advance its leadership in the Chinese premium TV market. The company will produce 60,000 sheets per month based on input glass sheets in the initial stage of operation and achieve full capacity of 120,000 sheets per month by the end of 2016.

The Guangzhou panel plant will enable LG Display to solidify its competitiveness in China as well as the global market by saving costs, improving on-time local delivery, and providing fast technical support to Chinese customers.

LG Display is confident that the Guangzhou plant will improve production efficiency. The company believes that maximizing production efficiency, combined with differentiated strategies such as making high-end, high value-added products and developing niche markets, will maintain its global leadership. The company is expecting improved cost advantages in terms of logistics and lower tariffs by locating in Guangzhou, close to major Chinese TV makers, including Skyworth, Konka, and TCL, operating in Guangdong Province.

The Guangzhou panel plant also has achieved a landmark by being recognized by the Chinese government as the country’s first ‘Green Plant’ after it passed a stringent certification process as part of the “Green China Policy.”

In being recognized as China’s first “Green Plant,” the new LG Display facility had to pass China’s Certification System as well as seven international certifications, including Environmental Management (ISO14001) and Safety and Health Management (OHSAS18001). This reflects LG Display’s commitment to creating an environmental-friendly production strategy, which was highlighted by applying the international standard system from the initial stage of the Guangzhou panel plant’s construction.

Until now, LG Display’s overseas production operations have focused on the manufacturing of modules in Nanjing, Guangzhou and Yentai in China as well Wroclaw, Poland and Reynosa, Mexico to better serve worldwide customers. The addition of the LCD panel plant in China will further bolster the LG Display’s local production base.

It appears too soon to say that Samsung Display and LG Display, the nation’s top display makers, will exit from the less lucrative LCD market amid a cutthroat competition with Chinese rivals with cheaper pricing.

Until a few years ago, the two firms had hinted at retiring from the old-school LCD business to focus on more advanced technologies such as upgraded LCDs or OLEDs to widen the gap with Chinese runner-ups.

But experts here say there has been a sign of change in the attitudes more recently, pointing out that their full shutdown of LCD operations ultimately would hinge on elevating profitability of their high-end push.

In 2020 alone, Samsung Display posted a deficit of more than 1 trillion won ($841.5 million) in its LCD business. But it has no other option but to continue production to meet the demand from its parent Samsung Electronics, the world’s largest TV maker.

The firm last year sold its LCD production facility in China to its Chinese rival TCL China Star Optoelectronics Technology, a key supplier to Samsung TVs. But the LCD line in Suzhou, China recently cut its panel supply almost in half, with Samsung’s display unit highly likely to be tasked with filling the void.

“(Samsung Electronics) have few choices but to contract with Samsung Display to make up for its LCD TV set capacity,” said Yi Choong-hoon, chief analyst at UBI Research.

This put Samsung Display‘s full exit plan in disarray. After the sell-off of the Chinese facility, the firm is also scaling down its LCD plant in Asan, South Chungcheong Province, to convert part of the facilities to its quantum-dot OLED lines to supply to set makers including Japanese firm Sony.

LG Display’s LCD business -- with production lines in Paju, Gyeonggi Province and Guangzhou, China -- is poised to generate 2.5 trillion won in operating profit for 2021, up fourfold from the previous year, according to Kim Jung-hwan, an analyst at Korea Investment & Securities, on Thursday.

This comes in sharp contrast with OLED TV earnings estimate. According to Kim, LG Display‘s OLED TV operations will post 152 billion won in operating loss, as its fourth-quarter forecast to generate 62 billion won income was dwarfed by 214 billion won losses for the previous three quarters. Since inception, LG’s OLED panel business has been in the red due to heavy spending.

Now, the question is whether the company is ready to be fully dedicated to next-generational OLED panels for premium TVs featuring self-lit pixels. Yi of UBI Research says it is too premature.

“A bigger penetration of OLED TVs to consumers is a prerequisitie for a conversion of (LG Display’s) existing LCD TV lines to OLED TV lines,” he said.

Analysts also said LG Display has already streamlined its LCD TV lines under a series of restructuring of LCD TV lines, including a conversion to lines for IT devices including mobile phones.

“(LG Display‘s) LCD TV fabs with low profit margin have completed a retreat in the first half of 2021,” said Kim Sun-woo of Meritz Securities. “LG is now capable of maintaining LCD capacity with a decent profit margin.”

This comes against the backdrop of industry projections that LCD TV panel prices continue to fall steadily over the course of the first quarter, and Chinese rivals are forecast to ramp up dominance in LCD market,

According to US-based market intelligence firm Display Supply Chain Consultants, Chinese firms’ LCD market share on a capacity basis are forecast to rise to 71 percent by 2025, from 53 percent in 2020, far outpacing Korea, Japan and Taiwan, as of June 2020.

Another estimate, released earlier this week, showed the price for LCD TV panels regardless of size -- ranging from 32- to 65-inch -- is projected to fall until March, giving up almost entire gains from July 2020 to July 2021 that is partly attributable to announced exits of Korean LCD panel makers.

The quarter-on-quarter price declines in the first quarter of 2022 to range between 10 percent and 23 percent and average 15 percent, with mid-sized panels taking the largest dip.

“Although the declines are slowing down in the first quarter, they are still severe for panel makers,” noted Robert O‘Brien, co-founder and principal analyst at DSCC.

SEOUL, Korea (Aug. 30, 2019) – LG Display announced today the opening of its 8.5th generation (2,200mm x 2,500mm) OLED panel production plant in Guangzhou, China, ushering in an era of producing 10 million large-size OLED panels a year.

LG Display’s new Guangzhou OLED panel plant started mass-production from this month and will mainly manufacture large-size high-resolution OLED products including 55-inch, 65-inch and 77-inch panels. The initial monthly capacity will be 60,000 sheets, which will be further expanded to 90,000 sheets by 2021.

The company expects to produce over 10 million OLED panels a year by 2022 when this monthly capacity of 90,000 sheets is combined with the 70,000 sheets currently manufactured at its OLED panel plant in Paju, Korea, as well as an additional 45,000 sheets to be produced at its 10.5th generation (2,940mm x 3,370mm) plant in Paju from 2022.

The new 8.5th generation OLED panel plant is operated by LG Display High-Tech China (LG Display High-Tech China Co., Ltd, LGDCO), a joint venture established between LG Display and Guangzhou Development District (GDD). LG Display holds a 70 percent stake with KRW 2.6 trillion in capital.

“Based on our vast experience and capability in OLED production, LG Display will make every effort to ensure the success of LG Display High-Tech China,” said Dr. Sang Beom Han, CEO and Vice Chairman of LG Display, at the opening ceremony attended by Korean and Chinese officials, top executives from LG group, and representatives from customer and partner companies. He added, “With our dual OLED panel production sites in Korea and China, the company will further accelerate the OLED trend in the global premium TV market by providing large-size OLED panels to the world.”

The new 8.5th generation OLED panel plant is built on 74,000 m² of land -- the equivalent of around 10 football fields. With nine levels above ground, the total floor area amounts to 427,000 m². The total area of the LG Display Guangzhou Cluster, which includes LCD panel and module plants, partner company complexes and additional facilities, amounts to 1.3 million m².

As many companies are not able to mass-produce large-size OLED panels due to technical limitations, LG Display, the pioneer and only manufacturer of large-size OLED panels in the world, plans to further widen the gap with its competitors and strengthen its leading position starting from the operation of its Guangzhou OLED plant. Given that LG Display’s customers, including LG Electronics, Sony, Philips, Hisense, Skyworth, Changhong, and Konka, operate TV production plants in China, the company will further boost its competitiveness by providing technology and products in a timely manner.

In addition, as LG Display has been running an 8.5th generation LCD panel plant in Guangzhou, excellent conditions optimized for 8.5th generation display production have already been established in this region in terms of infrastructure, tariffs, and labor and distribution costs.

The sharp increase in OLED TV demand is driven by a growing number of global TV brands manufacturing OLED TVs. The total number of those brands is now 15 worldwide and will reach 16 in 2020 when the largest TV maker in the U.S., Vizio, joins the trend. Accordingly, LG Display’s large-size OLED panel sales are on a significant and constant rise. The company saw an increase in OLED TV panel sales to 2.9 million units in 2018 and yet another increase to 3.8 million units is anticipated in 2019. LG Display expects its large-size OLED panel business to turn to profitability on an annual basis for the first time this year due to these increasing sales.

In order to meet the rapid growth in demand for OLED panels in the premium TV market, LG Display has decided to implement a two-track OLED production strategy by manufacturing large-size OLED panels in both Korea and China. LG Display’s large-size OLED panel production capacity will further increase once the 10.5th generation OLED panel production line at its P10 plant in Paju, Korea goes into operation in 2022. To this end, the company recently announced an additional investment of KRW 3 trillion into this 10.5th generation OLED production line. Through this increased production capacity, LG Display can improve productivity and profitability via economies of scale, thereby advancing the OLED era.

NEW YORK -- State-backed Chinese manufacturer BOE Technology Group is expected to outstrip South Korea"s LG Display as the top maker of flat-panel displays this year, marking China"s growing dominance in the field.

The Beijing-based and Shenzhen-listed supplier of television screens to companies including Sony, Samsung Electronics and Hisense will reach a 17.7% share in flat-panel-display production capacity to beat LG Display for the first time, market research provider IHS Markit said in a Tuesday report.

Guangzhou qiangfeng electronics co., LTD was formally established in 2010, the registered capital of one million yuan, is a company with powerful strength and abundant resources LCD,is Innolux Corporation (Taiwan) company special authorization of professional distributors,mainly manages the brand have: Innolux,AUO, LG, BOE, HKC, SHARP, PANDA etc., can be in Hong Kong, and overseas countries for LCD SKD product distribution services,the company to "focus on quality, service" business philosophy, hope to expand the market at the same time providing customers with value of products and services,to create core values for display field.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success.

LG Display (Korean: LG 디스플레이) is one of the world"s largest manufacturers and supplier of thin-film transistor liquid crystal display (TFT-LCD) panels, OLEDs and flexible displays. LG Display is headquartered in Seoul, South Korea, and currently operates nine fabrication facilities and seven back-end assembly facilities in Korea, China, Poland and Mexico.

LG Display was originally formed as a joint venture by the Korean electronics company LG Electronics and the Dutch company Philips in 1999 to manufacture active matrix liquid crystal displays (LCDs) and was formerly known as LG.Philips LCD, but Philips sold off all its shares in late 2008.joint venture, called LG.Philips Displays, dedicated to manufacturing cathode ray tubes, deflection yokes, and related materials such as glass and phosphors.

On 12 December 2008, LG.Philips LCD announced its plan to change its corporate name to LG Display upon receiving approval at the company"s annual general meeting of shareholders on 29 February. The company claimed the name change reflects the company"s business scope expansion and business model diversification, the change in corporate governance following the reduction of Philips" equity stake, and LG"s commitment to enhanced responsible management.

LG Display became an independent company in July 2004 when it was concurrently listed on the New York Stock Exchange (NYSE: LPL) and the South Korean Stock Exchange (KRX: 034220).

They are one of the main licensed manufacturers of the more color-accurate IPS panels used by Dell, NEC, ASUS, Apple (including iMacs, iPads, iPhones, iPod Touches) and others, which were developed by Hitachi.

In December 2010, the EU fined LG Display €215 million for its part in an LCD price fixing scheme.Chimei Innolux, AU Optronics, Chunghwa Picture Tubes Ltd., and HannStar Display Corp.

This followed the 2008 case in the US, when LG Display Co., Chunghwa Picture Tubes and Sharp Corp., agreed to plead guilty and pay $585 million in criminal finesliquid crystal display panels.

LG Display would pay $400 million, the second-highest criminal fine that the US Justice Department antitrust division had ever imposed. Chunghwa would pay $65 million for conspiring with LG Display and other unnamed companies and Sharp would pay $120 million, according to the department.

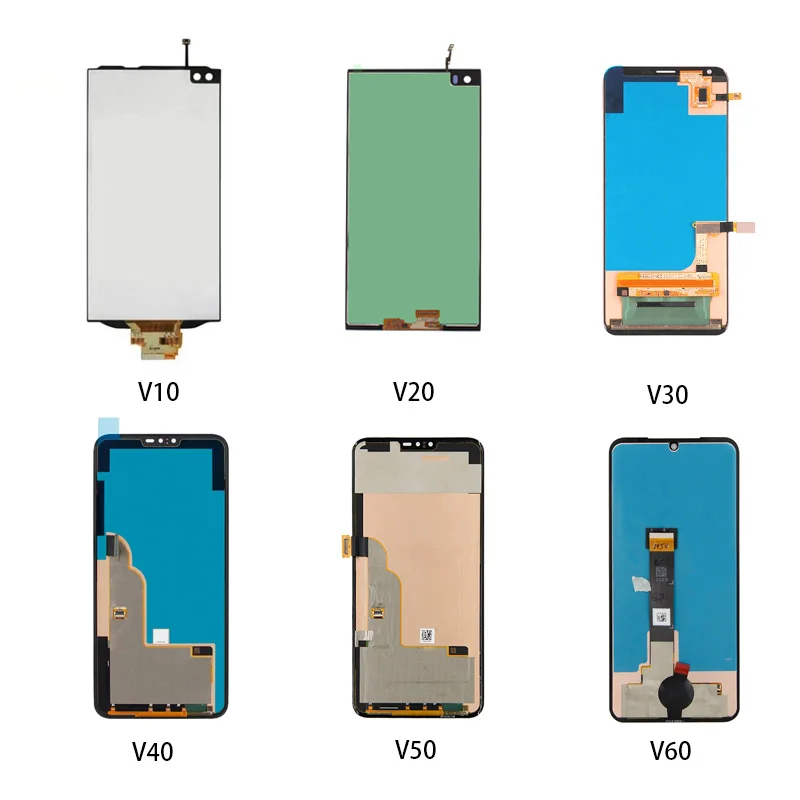

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Guangzhou qiangfeng electronics co., LTD was formally established in 2010, the registered capital of one million yuan, is a company with powerful strength and abundant resources LCD,is Innolux Corporation (Taiwan) company special authorization of professional distributors,mainly manages the brand have: Innolux,AUO, LG, BOE, HKC, SHARP, PANDA etc., can be in Hong Kong, and overseas countries for LCD SKD product distribution services,the company to "focus on quality, service" business philosophy, hope to expand the market at the same time providing customers with value of products and services,to create core values for display field.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success.

"DSCC sources in China have learned that BOE plans to commercialize the 95" 8K White OLED TV panel shown at Display Week. I must admit, I heard this at the exhibit during Display Week but did not believe it, but our sources in China confirm BOE’s intent," reads Bob O"Brien"s report.

BOE"s monster panel boasts an ultra-thin bezel and a resolution of up to 7680×4320 pixels, together with a contrast ratio of 1,000,000:1 and a DCI-P3 99% wide color gamut. The display is understood to be equipped with an HDR algorithm that allows for deeper black levels, and a peak brightness of 800 nits.

Price wars in the LCD TV market have forced LG and Samsung to concentrate on premium OLED panels. Samsung Display is expected to cease production of its LCD panels in June, while LG has already slashed its LCD production.

With any luck, BOE"s rumoured entry into the OLED market will make it cheaper to buy an ultra-large TV. Currently, an 88-inch 8K LG Z29 OLED TV will set you back £25,000 (around $30,000 / AU$43,000), so a more affordable OLED solution would be most welcome.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey